Abstract

Nuclear fusion energy is considered as a clean and safe energy source. As the fuel of deuterium–tritium (D–T) fusion reactor, T must be produced by the reaction between neutron and lithium (Li) in the breeders. The blanket of fusion reactor will work in a high-temperature and radioactive environment. The long-term contact between T breeders and structural materials in such a harsh environment will result in corrosion and microstructure modification of material surfaces, and then affect the mechanical properties and thermal conductivity of materials. To protect the structural materials from corrosion, coatings are applied to their surface. In addition, the coating also plays a role in preventing T permeation. The compatibility of T breeder materials with structural materials and coatings in the breeding blanket has always been a concern. In this paper, the up-to-date data on liquid and solid blanket of fusion reactors, the interaction behavior of T breeders with candidate structural materials, including reduced activation ferritic/martensitic steel, oxide dispersion-strengthened steel, silicon carbide and vanadium alloy, and coatings are reviewed. The corrosion mechanism is also expounded. Furthermore, the corrosion behavior between different types of materials is compared comprehensively. At the end, the research and development prospects on this topic are suggested.

Similar content being viewed by others

References

http://www.iter.org. Accessed 10 June 2021.

Chan VS, Costley AE, Wan BN, Garofalo AM, Leuer JA. Evaluation of CFETR as a Fusion Nuclear Science Facility using multiple system codes. Nucl Fusion. 2015;55: 023017.

http://cnmfrdg.ustc.edu.cn. Accessed 10 June 2021.

Tanabe T. Tritium issues to be solved for establishment of a fusion reactor. Fusion Eng Des. 2012;87:722.

Richardson IA, Leachman J. Thermodynamic properties status of deuterium and tritium. In: AIP conference proceedings, Spokane, 2012.

Johnson CE, Noda K, Roux N. Ceramic breeder materials: status and needs. J Nucl Mater. 1998;258–263:140.

Giancarli LM, Bravo X, Cho S, Ferrari M, Hayashi T, Kim BY, Leal-Pereira A, Martins JP, Merola M, Pascal R, Schneiderova I, Sheng Q, Sircar A, Strebkov Y, van der Laan J, Ying A. Overview of recent ITER TBM Program activities. Fusion Eng Des. 2020;158:111674.

Utili M, Bassini S, Boccaccini L, Bühler L, Cismondi F, Del Nevo A, Eboli M, DiFonzo F, Hernandez T, Wulf S, Kordač M, Martelli D, De les Valls EM, Melichar T, Mistrangelo C, Tarantino M, Tincani A, Vála L. Status of Pb–16Li technologies for European DEMO fusion reactor. Fusion Eng Des. 2019;146:2676.

Wan Y, Li J, Liu Y, Wang X, Chan V, Chen C, Duan X, Fu P, Gao X, Feng K, Liu S, Song Y, Weng P, Wan B, Wan F, Wang H, Wu S, Ye M, Yang Q, Zheng G, Zhuang G, Li Q. Overview of the present progress and activities on the CFETR. Nucl Fusion. 2017;57: 102009.

Jiang K, Ding W, Zhang X, Li J, Ma X, Huang K, Luo Y, Liu S. Development of neutronic-thermal hydraulic-mechanic-coupled platform for WCCB blanket design for CFETR. Fusion Eng Des. 2018;137:312.

Konishi S, Enoeda M, Nakamichi M, Hoshino T, Ying A, Sharafat S, Smolentsev S. Functional materials for breeding blankets—status and developments. Nucl Fusion. 2017;57: 092014.

Wang S, Cao Q, Wu X, Wang X, Zhang G, Feng K. Updated conceptual design of helium cooling ceramic blanket for HCCB-DEMO. Fusion Eng Des. 2016;112:148.

Liu S, Cheng X, Ma X, Chen L, Jiang K, Li X, Bao H, Wang J, Wang W, Peng C, Lu P, Li M, Huang K. Progress on design and related R&D activities for the water-cooled breeder blanket for CFETR. Theor Appl Mech Lett. 2019;9:161.

Giancarli LM, Abdou M, Campbell DJ, Chuyanov VA, Ahn MY, Enoeda M, Pan C, Poitevin Y, Rajendra Kumar E, Ricapito I, Strebkov Y, Suzuki S, Wong PC, Zmitko M. Overview of the ITER TBM Program. Fusion Eng Des. 2012;87:395.

Zhan Q, Zhao W, Yang H, Hatano Y, Yuan X, Nozaki T, Zhu X. Formation of α-alumina scales in the Fe–Al(Cr) diffusion coating on China low activation martensitic steel. J Nucl Mater. 2015;464:135.

Zhang GK, Chen CA, Luo DL, Wang XL. An advance process of aluminum rich coating as tritium permeation barrier on 321 steel workpiece. Fusion Eng Des. 2012;87:1370.

Chikada T, Suzuki A, Adelhelm C, Terai T, Muroga T. Surface behaviour in deuterium permeation through erbium oxide coatings. Nucl Fusion. 2011;51: 063023.

Serra E, Glasbrenner H, Perujo A. Hot-dip aluminium deposit as a permeation barrier for MANET steel. Fusion Eng Des. 1998;41:149.

Vertkov AV, Evtikhin VA, Lyublinski IE, Syichev AA, Demina EV, Prusakova MD. Mechanical properties of low activation Cr-Mn austenitic steels changes in liquid lithium. J Nucl Mater. 1993;203:158.

Borgstedt HU, Röhrig HD. Recent results on corrosion behaviour of MANET structural steel in flowing Pb–17Li eutectic. J Nucl Mater. 1991;179–181:596.

Broc M, Flament T, Fauvet P, Sannier J. Corrosion of austenitic and martensitic stainless steels in flowing 17Li-83Pb alloy. J Nucl Mater. 1988;155–157:710.

Chopra OK, Smith DL. Compatibility of ferrous alloys in a forced circulation Pb–17Li system. J Nucl Mater. 1986;141–143:566.

Coen V, Fenici P. Compatibility of structural materials with liquid breeders—a review of recent work carried out at JRC. Ispra Nucl Eng Des Fusion. 1984;1:215.

Ruedl E, Sasaki T. Effect of lithium on grain-boundary precipitation in a Cr-Mn austfnitic steel. J Nucl Mater. 1983;116:112.

Ruedl E, Coen V, Sasaki T, Kolbe H. Intergranular lithium penetration of low-Ni, Cr-Mn austenitic stainless steels. J Nucl Mater. 1982;110:28.

Coen V, Kolbe H, Orecchia L, Sasaki T. Compatibility in Li and in Li containing traces of LiH of low Ni, Cr-Mn austenitic stainless steels. J Nucl Mater. 1979;85–86:271.

Tavassoli A-AF, Diegele E, Lindau R, Luzginova N, Tanigawa H. Current status and recent research achievements in ferritic/martensitic steels. J Nucl Mater. 2014;455:269.

Chopra OK, Smith DL. Effects of lithium environment on the fatigue properties of ferritic and austenitic steels. J Nucl Mater. 1981;103:651.

Lyublinskia IE, Evtikhina VA, Pankratova VY, Krasinb VP. Numerical and experimental determination of metallic solubilities in liquid lithium, lithium-containing nonmetallic impurities, lead and lead-lithium eutectic. J Nucl Mater. 1995;224:288.

Kondo M, Takahashi M, Tanaka T, Tsisar V, Muroga TM. Compatibility of reduced activation ferritic martensitic steel JLF-1 with liquid metals Li and Pb–17Li. Fusion Eng Des. 2012;87:1777.

Malang S, Mattas R. Comparison of lithium and the eutectic lead-lithium alloy, two candidate liquid metal breeder materials for self-cooled blankets. Fusion Eng Des. 1995;27:399.

Hubberstey P. Pb–17Li and lithium: a thermodynamic rationalisation of their radically different chemistry. J Nucl Mater. 1997;247:208.

Flamenta T, Tortorellib P, Coenc V, Borgstedtd HU. Compatibility of materials in fusion first wall and blanket structures cooled by liquid metals. J Nucl Mater. 1992;191–194:132.

Pulham RJ, Hubberstey P. Comparison of chemical reactions in liquid lithium with those in liquid sodium. J Nucl Mater. 1983;115:239.

Natesan K. Influence of nonmetallic elements on the compatibility of structural materials with liquid alkali metals. J Nucl Mater. 1983;115:251.

Barker MG, Frankham SA. The effects of carbon and nitrogen on the corrosion resistance of type 316 stainless steel to liquid lithium. J Nucl Mater. 1982;107:218.

Xu Q, Kondo M, Nagasaka T, Muroga T, Nagura M, Suzuki A. Corrosion characteristics of low activation ferritic steel, JLF-1, in liquid lithium in static and thermal convection conditions. Fusion Eng Des. 2008;83:1477.

Kondo M, Muroga T, Nagasaka T, Xu Q, Tsisar V, Oshima T. Mass transfer of RAFM steel in Li by simple immersion, impeller induced flow and thermal convection. J Nucl Mater. 2011;417:1200.

Splı́chal K, Zmı́tko M. Corrosion behaviour of EUROFER in Pb–17Li at 500 °C. J Nucl Mater. 2004;329–333:1384.

Glasbrenner H, Konys J, Voß Z. Corrosion behaviour of low activation steels in flowing Pb–17Li. J Nucl Mater. 2000;281:225.

Konys J, Krauss W, Novotny J, Steiner H, Voss Z, Wedemeyer O. Compatibility behavior of EUROFER steel in flowing Pb–17Li. J Nucl Mater. 2009;386–388:678.

Konys J, Krauss W, Voss Z, Wedemeyer O. Corrosion behavior of EUROFER steel in flowing eutectic Pb–17Li alloy. J Nucl Mater. 2004;329–333:1379.

Li Y, Abe H, Nagasaka T, Muroga T, Kondo M. Corrosion behavior of 9Cr-ODS steel in stagnant liquid lithium and lead–lithium at 873K. J Nucl Mater. 2013;443:200.

Li YF, Kondo M, Nagasaka T, Muroga T, Tsisar V. Influence of exposure to Pb–Li on microstructure and mechanical properties of 9Cr-ODS and CLAM steels. Fusion Sci Technol. 2011;60:359.

Jiang H, Lu W, Wang W, Chen Z, Chu D, Han J, Huang Y, Wu Y. Experimental study on corrosion-erosion behavior of ITER blanket structure materials in flowing Pb–17Li. Fusion Eng Des. 2020;156: 111596.

Krauss W, Wulf S-E, Konys J. Long-term corrosion behavior of ODS-Eurofer in flowing Pb–15.7Li at 550 °C. Nucl Mater Energy. 2016;9:512.

Sandim HRZ, Renzetti RA, Padilha AF, Raabe D, Klimenkov M, Lindau R, Möslang A. Annealing behavior of ferritic–martensitic 9%Cr–ODS–Eurofer steel. Mater Sci Eng A. 2010;527:3602.

Bassini S, Cuzzola V, Antonelli A, Utili M. Long-term corrosion behavior of EUROFER RAFM steel in static liquid Pb–16Li at 550 °C. Fusion Eng Des. 2020;160: 111829.

Atchutuni SS, Agravat HS, Chauhan JP, Kumar R. Corrosion behavior of IN-RAFM steel with stagnant lead-lithium at 550 °C up to 9000 h. Fusion Eng Des. 2018;135:102.

Konys J, Krauss W. Corrosion and precipitation effects in a forced-convection Pb–15.7Li loop. J Nucl Mater. 2013;442:S576.

Konys J, Krauss W, Steiner H, Novotny J, Skrypnik A. Flow rate dependent corrosion behavior of Eurofer steel in Pb–15.7Li. J Nucl Mater. 2011;417:1191.

Giancarli L, Chuyanov V, Abdou M, Akiba M, Hong BG, Lässer R, Pan C, Strebkov Y. Test blanket modules in ITER: an overview on proposed designs and required DEMO-relevant materials. J Nucl Mater. 2007;367–370:1271.

Pint BA, Moser JL, Tortorelli PF. Liquid metal compatibility issues for test blanket modules. Fusion Eng Des. 2006;81:901.

Pint BA, Moser JL, Tortorelli PF. Investigation of Pb–Li compatibility issues for the dual coolant blanket concept. J Nucl Mater. 2007;367–370:1150.

Park C, Nozawa T, Kasada R, Tosti S, Konishi S, Tanigawa H. The effect of wall flow velocity on compatibility of high-purity SiC materials with liquid Pb–Li alloy by rotating disc testing for 3000 h up to 900 °C. Fusion Eng Des. 2018;136:623.

Ling X, Huang Q, Gao S, Zhu Z, Chen Y, Song Y, Liu S, Wu Y, Zhao S. Compatibility of SiC with static liquid LiPb at 800°C. Fusion Eng Des. 2011;86:2655.

Park C, Noborio K, Kasada R, Yamamoto Y, Konishi S. Compatibility of SiCf/SiC composite exposed to liquid Pb–Li flow. J Nucl Mater. 2011;417:1218.

Nagasaka T, Muroga T, Li M, Hoelzer DT, Zinkle SJ, Grossbeck ML, Matsui H. Tensile property of low activation vanadium alloy after liquid lithium exposure. Fusion Eng Des. 2006;81:307.

Muroga T, Tanaka T, Kondo M, Nagasaka T, Xu Q. Characterization of liquid lithium blanket with RAFM and V-alloy for TBM and DEMO. Fusion Sci Technol. 2009;56:897.

Pint BA, Unocic KA. Pb–Li compatibility issues for DEMO. J Nucl Mater. 2013;442:S572.

Tanabe T. Tritium fuel cycle in ITER and DEMO: issues in handling large amount of fuel. J Nucl Mater. 2013;438:S19.

Sawada A, Suzuki A, Terai T. Lithium compatibility of insulator coatings fabricated by RF sputtering method. Fusion Eng Des. 2006;81:579.

Matsunaga M, Horikoshi S, Mochizuki J, Fujita H, Hishinuma Y, Isobe K, Hayashi T, Terai T, Oya Y, Chikada T. Lithium-lead corrosion behavior of erbium oxide, yttrium oxide and zirconium oxide coatings fabricated by metal organic decomposition. J Nucl Mater. 2018;511:537.

Miura S, Nakamura K, Akahoshi E, Kano S, Yagi J, Hishinuma Y, Tanaka T, Chikada T. Lithium-lead corrosion behavior of zirconium oxide coating after heavy-ion irradiation. Fusion Eng Des. 2021;170: 112536.

Nagura M, Suzuki A, Muroga T, Terai T. LiErO2 formation on Er2O3 in static and natural convection lithium. Fusion Eng Des. 2009;84:1384.

Chikada T, Suzuki A, Terai T, Muroga T, Koch F. Compatibility of erbium oxide coating with liquid lithium–lead alloy and corrosion protection effect of iron layer. Fusion Eng Des. 2013;88:640.

Chikada T, Suzuki A, Koch F, Maier H, Terai T, Muroga T. Fabrication and deuterium permeation properties of erbia-metal multilayer coatings. J Nucl Mater. 2013;442:S592.

Horikoshi S, Matsunaga M, Mochizuki J, Fujita H, Hishinuma Y, Oya Y, Chikada T. Microstructure change and deuterium permeation behavior of ceramic-metal multi-layer coatings after immersion in liquid lithium-lead alloy. Nucl Mater Energy. 2018;16:66.

Horikoshi S, Mochizuki J, Oya Y, Chikada T. Deuterium permeation and retention behaviors in erbium oxide-iron multilayer coatings. Fusion Eng Des. 2017;124:1086.

Kleykamp H. Chemical interactions in the EXOTIC-7 experiment. J Nucl Mater. 1999;273:171.

Hofmann P, Dienst W. Chemical compatibility between lithium-based oxide ceramics and stainless steels. J Nucl Mater. 1986;141–143:289.

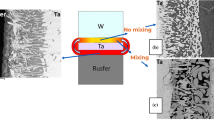

Mukai K, Sanchez F, Knitter R. Chemical compatibility study between ceramic breeder and EUROFER97 steel for HCPB-DEMO blanket. J Nucl Mater. 2017;488:196.

Hernández T, Gázquez MC, Sánchez FJ, Malo M. Corrosion mechanisms of Eurofer produced by lithium ceramics under fusion relevant conditions. Nucl Mater Energy. 2018;15:110.

Hernández T, Fernández P. Corrosion susceptibility comparison of EUROFER steel in contact two lithium silicate breeders. Fusion Eng Des. 2014;89:1436.

Hernández T, Fernández P, Vila R. Corrosion susceptibility of EUROFER97 in lithium ceramics breeders. J Nucl Mater. 2014;446:117.

Hernández T, Fernández P. Effect of the environment on the corrosion of EUROFER97 by solid lithium breeders. J Nucl Mater. 2014;447:160.

Mukai K, Sanchez F, Hoshino T, Knitter R. Corrosion characteristics of reduced activation ferritic–martensitic steel EUROFER by Li2TiO3 with excess Li. Nucl Mater Energy. 2018;15:190.

Cho S, Park Y-H, Chun Y-B, Min K-M, Ahn M-Y, Park SC, Lee Y. Chemical compatibility between ARAA alloy and lithium meta-titanate breeder material. Fusion Eng Des. 2017;124:1052.

Aktaa J, Walter M, Gaisina E, Kolb MHH, Knitter R. Assessment of the chemical compatibility between EUROFER and ceramic breeder with respect to fatigue lifetime. Fusion Eng Des. 2020;157: 111732.

Wang L, Ye X, Feng Y, Luo X, Hong Z, Yan J, Gong B, Liao H, Wang X, Zhu C, Yang J, Gong M. Hydrogen isotope permeability of reduced activation ferritic/martensitic steel CLF-1 corroded by Li4SiO4. Fusion Eng Des. 2020;153: 111490.

Wang M, Xiang M, Zhang Y, Zhou Z. Study on the chemical compatibility study between Li2TiO3 pebbles and 14Cr-ODS steel. J Fusion Energy. 2018;37:247.

Sonak S, Jain U, Haldar R, Kumar S. Chemical compatibility study of lithium titanate with Indian reduced activation ferritic martensitic steel. Fusion Eng Des. 2015;100:507.

Kleykamp H. Chemical reactivity of SiC fibre-reinforced SiC with beryllium and lithium ceramic breeder materials. J Nucl Mater. 2000;283–287:1385.

Nogami S, Hasegawa A, Murayama T, Otake N, Satou M, Abe K. Compatibility between SiC and Li ceramics for solid breeding blanket system. J Nucl Mater. 2009;386–388:628.

La Barbera A, Riccardi B, Donato A, Nannetti CA, Moreschi LF. Stability of SiC/SiC fibre composites exposed to Li4SiO4 and Li2TiO3 in fusion relevant conditions. J Nucl Mater. 2001;294:223.

Hernández T, Sánchez FJ, Moroño A, León-Gutiérrez E, Panizo-Laiz M, Monclus MA, González-Arrabal R. Corrosion behavior of diverse sputtered coatings for the helium cooled pebbles bed (HCPB) breeder concept. Nucl Mater Energy. 2020;25: 100795.

Hernández T, Sánchez FJ, Di Fonzo F, Vanazzi M, Panizo M, González-Arrabal R. Corrosion protective action of different coatings for the helium cooled pebble bed breeder concept. J Nucl Mater. 2019;516:160.

Zhang W, Zhu C, Yang J, Chen Q, Wang L, Feng Y, Feng K, Liao J, Yang Y, Liu N, Yang J. Chemical compatibility between the α-Al2O3 tritium permeation barrier and Li4SiO4 tritium breeder. Surf Coat Technol. 2021;410:126960.

Chikada T, Kolb MHH, Fujita H, Nakamura K, Kimura K, Rasinski M, Hishinuma Y, Mukai K, Knitter R. Compatibility of tritium permeation barrier coatings with ceramic breeder pebbles. Corros Sci. 2021;182:109288.

Chikada T, Kimura K, Mochizuki J, Horikoshi S, Matsunaga M, Fujita H, Okitsu K, Tanaka T, Hishinuma Y, Sakamoto Y, Someya Y, Nakamura H. Surface oxidation effect on deuterium permeation in reduced activation ferritic/martensitic steel F82H for DEMO application. Fusion Eng Des. 2019;146:450.

Acknowledgements

This study was financially supported by the Youth Innovation Promotion Association of Chinese Academy of Sciences (2018484).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no interest conflict.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, C., Ji, BL., Gu, SX. et al. Recent research progress on the compatibility of tritium breeders with structural materials and coatings in fusion reactors. Tungsten 4, 170–183 (2022). https://doi.org/10.1007/s42864-022-00160-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42864-022-00160-7