Abstract

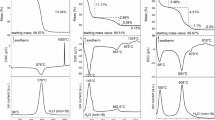

In the production of alumina (Al2O3) from clays by acid leaching, thermal activation by calcination is applied widely as a pre-treatment to improve the dissolution of aluminum. Previous studies have focused only on the thermal behavior of high-purity kaolinite and pyrophyllite, individually. However, thermal activation of complex clay ores containing several silicate minerals and their effect on aluminum extraction have not been studied. The purpose of the present study was to characterize the thermal behavior of a clay ore containing mainly pyrophyllite (Al2Si4O10(OH)2), kaolinite (Al2Si2O5(OH)4), muscovite (KAl2(AlSi3O10)(OH)2), quartz (SiO2), and kyanite (Al2SiO5) from the Pütürge clay deposits (Malatya, Turkey) for possible use in alumina (Al2O3) production by acid leaching. The ore and its calcination products obtained at various temperatures were characterized with respect to their mineral paragenesis, crystal structure, surface morphology, and thermal, calorimetric, and aluminum dissolution properties in order to understand the changes that occurred. Aluminum recovery in the leach solution increased in direct proportion to the dehydroxylation degree (Dtg) of the ore as the calcination temperature increased to 900°C. A maximum aluminum extraction of 90.57% was achieved by leaching of the product from calcination at 900°C. Aluminum extraction decreased sharply above that temperature, even though Dtg increased a little. By increasing the calcination temperature; the structures of pyrophyllite, kaolinite, and muscovite were destroyed by dehydroxylation, resulting in the exfoliation of the mineral layers, thus, a mixture of dehydroxylated phases formed. Depending mainly on the temperature range at which each of the dehydroxylated phases is durable, aluminum could be leached to some extent. The sharp decrease in the extraction of aluminum, iron, and potassium at higher temperatures was attributed to compaction of previously exfoliated layers of the minerals through re-crystallization to form mullite-like structures which seemed insensitive to acid attack during the leaching.

Similar content being viewed by others

References

Adekitan, O. A., & Ayininuola, G. M. (2017). Optimizing the thermal treatment of Abeokuta kaolin (south-west Nigeria) for production of natural pozzolan. African Journal of Science, Technology, Innovation and Development, 9, 361–365.

Al-Ajeel, A. W. A., & Al-Sindy, S. I. (2006). Alumina recovery from Iraqi kaolinitic clay by hydrochloric acid route. Iraqi Bulletin of Geology and Mining, 2, 67–76.

Altıokka, M. R., & Hoşgün, H. L. (2003). Investigation of the dissolution kinetics of kaolin in HCl solution. Hydrometallurgy, 68, 77–81.

Altıokka, M. R., Akalın, H., Melek, N., & Akyalçın, S. (2010). Investigation of the dissolution kinetics of meta–kaolin in H2SO4 solution. Industrial & Engineering Chemistry Research, 49, 12379–12382.

Al-Zahrani, A. A., & Abdul-Majid, M. H. (2009). Extraction of alumina from local clays by hydrochloric acid process. Journal of King Abdulaziz University: Engineering Sciences, 20, 29–41.

Aydoğmuş, R. (2019). Activation of enriched Malatya-Pütürge pyrophyllite ore for alumina production. Master of Science Thesis, İnönü University, Turkey.

Aydoğmuş, R., & Erdemoğlu, M. (2019). Acidic leaching of thermally activated pyrophyllite concentrate for alumina production. 7thInternational Congress of Mining Machinery and Technologies, İzmir, Turkey.

Barry, T. S., Uysal, T., Birinci, M., & Erdemoğlu, M. (2019). Thermal and mechanical activation in acid leaching processes of non-bauxite ores available for alumina production – A review. Mining Metallurgy & Exploration, 36, 557–569.Corrected as "Barry T.S" in the reference.

Bazin, C., El-Ouassiti, K., & Ouellet, V. (2007). Sequential leaching for the recovery of alumina from a Canadian clay. Hydrometallurgy, 88, 196–201.

Birinci, M., Uysal, T., Erdemoğlu, M., Porgalı, E., & Barry, T.S. (2017). Acidic leaching of thermally activated pyrophyllite ore from Pütürge (Malatya-Turkey) deposit. 17th Balkan Mineral Processing Congress, Antalya, Turkey.

Blasy, M. (2014). Characterization of a metasomatic muscovite after pegmatitic potash feldspar with a soapstone appearence, Eastern Desert, Egypt. International Journal of Science & Engineering Research, 5, 94–96.

Bozkaya, Ö., Yalçın, H., Başıbüyük, Z., & Bozkaya, G. (2007). Metamorphic-hosted pyrophyllite and dickite occurrences from the hydrous Al-Silicate deposits of the Malatya-Pütürge Region. Central Eastern Anatolia, Turkey. Clays and Clay Minerals, 55, 423–442.

Bragg, W., & Gibbs, R. E. (1925). The structure of α and β quartz. Proceedings of the Royal Society of London A, 109(751), 405–427.

Brigatti, M. F., Frigieri, P., & Poppi, L. (1998). Crystal chemistry of Mg-, Fe-bearing muscovites-2M1. American Mineralogist, 83, 775–785.

D'Eliaa, A., Pinto, D., Eramo, G., Giannossa, L. C., Ventruti, G., & Laviano, R. (2018). Effects of processing on the mineralogy and solubility of carbonate-rich clays for alkaline activation purpose: mechanical, thermal activation in red/ox atmosphere and their combination. Applied Clay Science, 152, 9–21.

Erdemoğlu, M., Birinci, M., Uysal, T., Porgalı, E., & Barry, T. S. (2018). Acid leaching performance of mechanically activated pyrophyllite ore for Al2O3 extraction. Journal of Materials Science, 53, 13801–13812.

Fitzgerald, J. J., Hamza, A. I., Ara, S. F., & Bronnimann, C. E. (1996). Solid-State 27Al and 29Si NMR and 1H CRAMPS studies of the thermal transformations of the 2:1 phyllosilicate pyrophyllite. The Journal of Physical Chemistry, 100, 17351–17360.

Gonzáles-Miranda, F. M., Garzon, E., Reca, J., Pérez-Villarejo, L., Martínez-Martínez, S., & Sánchez-Soto, P. J. (2018). Thermal behaviour of sericite clays as precursors of mullite materials. Journal of Thermal Analysis and Calorimetry, 132, 967–977.

Gridi-Bennadji, F., Beneu, B., Laval, J. P., & Blanchart, P. (2008). Structural transformations of muscovite at high temperature by X-ray and neutron diffraction. Applied Clay Science, 38, 259–267.

Guggenheim, S., Chang, Y. H., & Koster van Groos, A. F. (1987). Muscovite dehydroxylation: High-temperature studies. American Mineralogist, 72, 537–550.

Gupta, C.K., & Mukherjee, T.K. (1990). Hydrometallurgy in Extraction Processes. Boca Raton, Florida, USA, CRC Press Inc, Vol. 1, 225 pp.

Habashi, F. (1999). Textbook of Hydrometallurgy. Second Edition, Metallurgie Extractive, Quebec, Canada, 739 p.

Hansen, T. (2018). Quartz inversion. https://digitalfire.com/4sight/glossary/glossary_quartz_inversion.html.

Hulbert, S. F., & Huff, D. E. (1970). Kinetics of alumina removal from a calcined kaolin with nitric, sulphuric and hydrochloric acids. Clay Minerals, 8, 337–345.

Ilić, B., Radonjanin, V., Malešev, M., Zdujić, M., & Mitrović, A. (2016). Effects of mechanical and thermal activation on pozzolanic activity of kaolin containing mica. Applied Clay Science, 123, 173–181.

Kakali, G., Perraki, T., Tsivilis, S., & Badogiannis, E. (2001). Thermal treatment of kaolin: the effect of mineralogy on the pozzolanic activity. Applied Clay Science, 20, 73–80.

Kyriakogona, K., Giannopoulou, I., & Panias, D. (2017). Extraction of aluminum from kaolin: a comparative study of hydrometallurgical processes. Proceedings of the 3rd World Congress on Mechanical, Chemical, and Material Engineering, Rome, Italy, 133, 1–6.

Li, G., Zeng, J. H., Luo, M., Liu, M., Jiang, T., & Qiu, G. (2014). Thermal transformation of pyrophyllite and alkali dissolution behavior of silicon. Applied Clay Science, 99, 282–288.

Lima, P. E. A., Angélica, R. S., & Neves, R. F. (2014). Dissolution kinetics of metakaolin in sulfuric acid: Comparison between heterogeneous and homogeneous reaction methods. Applied Clay Science, 88–89, 159–162.

Lundell, G. E. F., & Knowles, H. B. (1929). Use of 8-hydroxyquinoline in separations of aluminum. Journal of Research of the National Bureau of Standards, 5, 91–96.

Mackenzie, K. J. D., Brown, I. W. M., Meinhold, R. H., & Browden, M. E. (1985). Thermal reactions of pyrophyllite studied by high-resolution solid-state 27Al and 29Si nuclear magnetic resonance spectroscopy. Journal of the American Ceramic Society, 68, 266–272.

Mariani, E., Brodie, K. H., & Rutter, E. H. (2006). Experimental deformation of muscovite shear zones at high temperatures under hydrothermal conditions and the strength of phyllosilicate-bearing faults in nature. Journal of Structural Geology, 28, 1569–1587.

Mikuni, A., Wei, C., Komatsu, R., & Ikeda, K. (2005). Thermal alteration of pyrophyllites and elution properties of the calcined pyrophyllite in alkali solution. Journal of the Society of Inorganic Materials, Japan, 12, 191–199.

Numluk, P., & Chaisena, A. (2012). Sulfuric acid and ammonium sulfate leaching of alumina from Lampang clay. E-Journal of Chemistry, 9, 1364–1372.

Olaremu, A. G. (2015). Sequential leaching for the production of alumina from a Nigerian clay. International Journal of Engineering Technology, Management and Applied Sciences, 3, 103–109.

Öner, F., & Taş, A. (2013). Geochemistry, mineralogy and genesis of pyrophyllite deposits in the Pötürge Region (Malatya, Eastern Turkey). Geochemistry International, 51, 140–154.

Pérez-Maqueda, L. A., Pérez-Rodriguez, J. L., Scheiffele, G. W., Justo, A., & Sánchez-Soto, P. J. (1993). Thermal analysis of ground kaolinite and pyrophyllite. Journal of Thermal Analysis, 39, 1055–1067.

Rahier, H., Wullaert, B., & Van Mele, B. (2000). Influence of the degree of dehydroxylation of kaolinite on the properties of aluminosilicate glasses. Journal of Thermal Analysis and Calorimetry, 62, 417–427.

Sánchez-Soto, P. J., & Pérez-Rodriguez, J. L. (1989a). Thermal-analysis of pyrophyllite transformations. Thermochimica Acta, 138, 267–276.

Sánchez-Soto, P. J., & Pérez-Rodriguez, J. L. (1989b). SEM study of pyrophyllite high-temperature transformations. Journal of Materials Science, 24, 3774–3778.

Sánchez-Soto, P. J., & Pérez-Rodriguez, J. L. (1998). General properties of pyrophyllite. Part II. Deposits, applications and use as ceramic raw material. The Journal of the Spanish Ceramic and Glass Society, 37, 359–368.

Sánchez-Soto, P. J., Sobrados, I., Sanz, J., & Pérez-Rodríguez, J. L. (1993). 29-Si and 27-Al magic angle spinning nuclear magnetic resonance study of the thermal transformations of pyrophyllite. Journal of the American Ceramic Society, 76, 3024–3028.

Schomburg, J. (1985). Thermal investigation of pyrophyllites. Thermochimica Acta, 93, 521–524.

Schomburg, J., & Zwahr, H. (1997). Thermal differential diagnosis of mica mineral group. Journal of Thermal Analysis, 48, 135–139.

Uygun, A., & Solakoğlu, E. (2002). Geology and origin of pyrophyllite deposits in Malatya Pütürge Massive (In Turkish). Bulletin of the Mineral Research and Exploration, 123–124, 13–19.

Wardle, R., & Brindley, G. W. (1972). The crystal structures of pyrophyllite, 1Tc, and of its dehydroxylate. American Mineralogist, 57, 732–750.

Wu, J. J., Chen, H., Zhao, S., & Li, B. (2012). The impact of heat treatment on pyrophyllite structure and acid-soluble properties. Advanced Materials Research, 366, 326–329.

Zhang, Z., & Wang, L. (1998). X-ray powder diffraction analysis on characteristics of heating phase transformation of pyrophyllite. Journal of the Chinese Ceramic Society, 26, 618–629.

Acknowledgments

The authors thank the Scientific and Technological Research Council of Turkey (TÜBİTAK) for financially supporting this study via Project No 214M432, İnönü University Scientific Research Project Unit for supporting the study through Project No 2015/44G, Çimsa Cement Inc. (Enis Solakoğlu, Tuğhan Delibaş, and Melike Sucu), and İçel Mining Inc. (İbrahim Altuntaş and Nihat Akkaya), for providing pyrophyllite ore samples from Pütürge (Malatya, Turkey). The support of Prof. Dr. Ömer Bozkaya (Department of Geological Engineering, Pamukkale University, Turkey) is also acknowledged gratefully.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Erdemoğlu, M., Birinci, M. & Uysal, T. Thermal Behavior of Pyrophyllite Ore during Calcination for Thermal Activation for Aluminum Extraction by Acid Leaching. Clays Clay Miner. 68, 89–99 (2020). https://doi.org/10.1007/s42860-019-00061-w

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42860-019-00061-w