Abstract

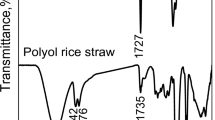

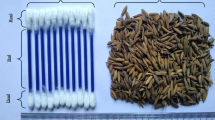

Plastic consumption has continued to grow over the years. Meanwhile, conventional petroleum-based plastics are associated with challenges like environmental unsustainability. As a result, bio-based polymer composites have received much attention in past decades. Polymer matrices can not only be easily be reinforced with agricultural fibers to reduce price, but also improve mechanical and thermal properties. The aim of this study was to investigate the effect of magnesium hydroxide modification on properties of K85 and K98 rice husk varieties in Uganda for their use as reinforcement in polymer composites. Raw rice husks underwent pre-treatment in 4% Mg(OH)2 concentration for 1 h at room temperature. Water absorption, thermogravimetric analysis (TGA), energetic density (ED), and fuel value index (FVI) of rice husks were investigated. Raw husks exhibited higher water absorption capabilities (9.1–11.2%) than modified rice husks (5.6–5.89%). TGA confirmed that alkali modification of rice husks provides a higher resistance to thermal degradation than that of raw husks. Mean reactivity to char residues ratio reduced from 4.3 × 10−4 to 3 × 10−4 °C/min upon modification of K85 rice husks while modification of K98 rice husks led to increasing mean reactivity to char residues ratio by 11.4%. ED sharply reduced upon alkali modification of both K85 and K98 rice husks. FVI of rice husks greatly depended on the amount of ash in the rice husks. As such, K85 husks had higher FVI than K98 husks as the former had lower ash compositions (21.2%). The results suggest that alkali-modified rice husks can be successfully used as reinforcement in polymer composites.

Similar content being viewed by others

Availability of Data and Materials

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Abdul Azam FA, RajendranRoyan NR, Yuhana NY, Mohd Radzuan NA, Ahmad S, Sulong AB (2020) Fabrication of porous recycled HDPE biocomposites foam: effect of rice husk filler contents and surface treatments on the mechanical properties. Polymers 12(2):475. https://doi.org/10.3390/polym12020475

Adeosun SO, Aworinde AK, Diwe IV, & Olaleye SA (2016) Mechanical and microstructural characteristics of rice husk reinforced polylactide nano composite. West Indian J Eng 39(1):63–71. https://ir.unilag.edu.ng/handle/123456789/7013

Anggono J, Budiarto BILY, Sugondo S, & Purwaningsih H (2020) The strength of polylactic acid composites reinforced with sugarcane bagasse and rice husk. In Materials Science Forum (Vol. 1000, pp. 193–199). Trans Tech Publications Ltd. https://doi.org/10.4028/www.scientific.net/MSF.1000.193

Aridi NAM, Sapuan SM, Zainudin ES, AL-Oqla FM (2016) Mechanical and morphological properties of injection-molded rice husk polypropylene composites. Int J Polym Anal Charact 21(4):305–313. https://doi.org/10.1080/1023666X.2016.1148316

Arjmandi R, Hassan A, Majeed K, & Zakaria Z (2015) Rice husk filled polymer composites. Int J Polym Sci 1-32. https://doi.org/10.1155/2015/501471

Běhálek L, Borůvka M, Brdlík P, Habr J, Lenfeld P, Kroisová D, ... & Novák J (2020) Thermal properties and non-isothermal crystallization kinetics of biocomposites based on poly (lactic acid), rice husks and cellulose fibres. J Therm Anal Calorimetry 142(2):629-649. https://doi.org/10.1007/s10973-020-09894-3

Behera S, Arora R, Nandhagopal N, Kumar S (2014) Importance of chemical pretreatment for bioconversion of lignocellulosic biomass. Renew Sustain Energy Rev 36:91–106. https://doi.org/10.1016/j.rser.2014.04.047

Bledzki AK, Mamun AA, Bonnia NN, Ahmad S (2012) Basic properties of grain by-products and their viability in polypropylene composites. Ind Crops Prod 37(1):427–434. https://doi.org/10.1016/j.indcrop.2011.05.010

Chen H, Liu J, Chang X, Chen D, Xue Y, Liu P, Han S (2017) A review on the pretreatment of lignocellulose for high-value chemicals. Fuel Process Technol 160:196–206. https://doi.org/10.1016/j.fuproc.2016.12.007

Chougan M, Ghaffar SH, Al-Kheetan MJ, Gecevicius M (2020) Wheat straw pre-treatments using eco-friendly strategies for enhancing the tensile properties of bio-based polylactic acid composites. Ind Crops Prod 155:112836. https://doi.org/10.1016/j.indcrop.2020.112836

Dahiya S, Katakojwala R, Ramakrishna S, Mohan SV (2020) Biobased products and life cycle assessment in the context of circular economy and sustainability. Mater Circular Econ 2(1):1–28. https://doi.org/10.1007/s42824-020-00007-x

Doan TTL, Brodowsky HM, & Mäder E (2016) Polyolefine composites reinforced by rice husk and saw dust. Compos Renew Sustain Mater. London: InTech, 1–24. https://doi.org/10.5772/65264

Farrokh NT, Suopajärvi H, Sulasalmi P, Fabritius T (2019) A thermogravimetric analysis of lignin char combustion. Energy Procedia 158:1241–1248. https://doi.org/10.1016/j.egypro.2019.01.413

Ferreira MVF, Neves ACC, de Oliveira CG, Lopes FPD, Margem FM, Vieira CMF, Monteiro SN (2017) Thermogravimetric characterization of polyester matrix composites reinforced with eucalyptus fibers. J Market Res 6(4):396–400. https://doi.org/10.1016/j.jmrt.2017.09.002

Hamdan MM, Siregar JP, Rejab MRM, Bachtiar D, Jamiluddin J, Tezara C (2019) Effect of maleated anhydride on mechanical properties of rice husk filler reinforced PLA matrix polymer composite. Int J Precision Eng Manufact-Green Technol 6(1):113–124. https://doi.org/10.1007/s40684-019-00017-4

Hegyesi N, Zhang Y, Kohári A, Polyák P, Sui X, Pukánszky B (2019) Enzymatic degradation of PLA/cellulose nanocrystal composites. Ind Crops Prod 141:111799. https://doi.org/10.1016/j.indcrop.2019.111799

Hidalgo-Salazar MA, Salinas E (2019) Mechanical, thermal, viscoelastic performance and product application of PP-rice husk Colombian biocomposites. Compos B Eng 176:107135. https://doi.org/10.1016/j.compositesb.2019.107135

Huerta-Cardoso O, Durazo-Cardenas I, Longhurst P, Simms NJ, Encinas-Oropesa A (2020) Fabrication of agave tequilana bagasse/PLA composite and preliminary mechanical properties assessment. Ind Crops Prod 152:112523. https://doi.org/10.1016/j.indcrop.2020.112523

Ismail H, Nizam JM, Khalil HA (2001) The effect of a compatibilizer on the mechanical properties and mass swell of white rice husk ash filled natural rubber/linear low density polyethylene blends. Polym Testing 20(2):125–133. https://doi.org/10.1016/S0142-9418(00)00013-1

KassimShaari NZ, Taha AR, Hanipah SH (2020) Composite from high density polyethylene (HDPE) reinforced with rice husks (Oryza sativa): preparation and mechanical property. Malays J Chem Eng Technol (MJCET) 3(2):25–29. https://doi.org/10.24191/mjcet.v3i2.10941

Lubwama M, Yiga VA (2018) Characteristics of briquettes developed from rice and coffee husks for domestic cooking applications in Uganda. Renew Energy 118:43–55. https://doi.org/10.1016/j.renene.2017.11.003

Marquez-Reynoso MI, Ramírez-Marcial N, Cortina-Villar S, Ochoa-Gaona S (2017) Purpose, preferences and fuel value index of trees used for firewood in El Ocote Biosphere Reserve, Chiapas, Mexico. Biomass Bioenerg 100:1–9. https://doi.org/10.1016/j.biombioe.2017.03.006

Massuque J, De Assis MR, & Trugilho PF (2020) Characterization of Miombo species used by rural communities as fuelwood in Northern Mozambique. Energy Sources A Recov Utiliz Environm Effects 1-10. https://doi.org/10.1080/15567036.2020.1815910

Masuelli M (Ed.) (2013) Fiber reinforced polymers: the technology applied for concrete repair. BoD–Books on Demand. Chapter 2:41–54. https://doi.org/10.5772/3162

Menya E, Olupot PW, Storz H, Lubwama M, Kiros Y (2018) Characterization and alkaline pretreatment of rice husk varieties in Uganda for potential utilization as precursors in the production of activated carbon and other value-added products. Waste Manage 81:104–116. https://doi.org/10.1016/j.wasman.2018.09.050

Mierzwa-Hersztek M, Gondek K, Jewiarz M, Dziedzic K (2019) Assessment of energy parameters of biomass and biochars, leachability of heavy metals and phytotoxicity of their ashes. J Mater Cycles Waste Manage 21(4):786–800. https://doi.org/10.1007/s10163-019-00832-6

Monte LS, Escócio VA, de Sousa AMF, Furtado CRG, Leite MCAM, Visconte LLY, Pacheco EBAV (2018) Study of time reaction on alkaline pretreatment applied to rice husk on biomass component extraction. Biomass Convers Biorefinery 8(1):189–197. https://doi.org/10.1007/s13399-017-0271-9

Musinguzi TL, Yiga VA, Lubwama M (2019) Production of bio-composite polymers with rice and coffee husks as reinforcing fillers using a low-cost compression molding machine. J Eng Agric Environ 5(1):61–72. https://doi.org/10.37017/jeae-volume5-no1.2019-5

Narayan R (2006) Biobased and biodegradable polymer materials: rationale, drivers, and technology exemplars. Degradable Polymers and Materials: American Chemical Society 282–306. https://doi.org/10.1021/bk-2006-0939.ch018

Nishata RRR, Sulong AB, Yuliana NY, Sahrim A (2017) Effect of surface modified rice husk (RH) on the flexural properties of recycled HDPE/RH composite. Adv Mater Process Technol 3(4):482–489. https://doi.org/10.1080/2374068X.2017.1340420

Ramesh P, Prasad BD, & Narayana KL (2019) Effect of MMT clay on mechanical, thermal and barrier properties of treated aloevera fiber/PLA-hybrid biocomposites. Silicon 1-10. https://doi.org/10.1007/s12633-019-00275-6

Ramos MA, de Medeiros PM, de Almeida ALS, Feliciano ALP, de Albuquerque UP (2008) Can wood quality justify local preferences for firewood in an area of caatinga (dryland) vegetation? Biomass Bioenerg 32(6):503–509. https://doi.org/10.1016/j.biombioe.2007.11.010

Ridzuan MJM, Majid MA, Afendi M, Kanafiah SA, Zahri JM, Gibson AG (2016) Characterisation of natural cellulosic fibre from Pennisetum purpureum stem as potential reinforcement of polymer composites. Mater Des 89:839–847. https://doi.org/10.1016/j.matdes.2015.10.052

Siakeng R, Jawaid M, Ariffin H, Sapuan SM, Asim M, Saba N (2018) Natural fiber reinforced polylactic acid composites: a review. Polym Compos 40(2):446–463. https://doi.org/10.1002/pc.24747

Sun J, Pang Y, Yang Y, Zhao J, Xia R, Li Y, ... & Guo H (2019) Improvement of rice husk/HDPE bio-composites interfacial properties by silane coupling agent and compatibilizer complementary modification. Polymers 11(12):1928. https://doi.org/10.3390/polym11121928

Tan J, Tiwari SK, Ramakrishna S (2021) Single-use plastics in the food services industry: can it be sustainable? Mater Circular Econ 3(1):1–16. https://doi.org/10.1007/s42824-021-00019-1

Tran TPT, Bénézet JC, Bergeret A (2014) Rice and Einkorn wheat husks reinforced poly (lactic acid) (PLA) biocomposites: effects of alkaline and silane surface treatments of husks. Ind Crops Prod 58:111–124. https://doi.org/10.1016/j.indcrop.2014.04.012

Wu CS, Tsou CH (2019) Fabrication, characterization, and application of biocomposites from poly (lactic acid) with renewable rice husk as reinforcement. J Polym Res 26(2):1–9. https://doi.org/10.1007/s10965-019-1710-z

Wu F, Misra M, Mohanty AK (2020) Sustainable green composites from biodegradable plastics blend and natural fibre with balanced performance: synergy of nano-structured blend and reactive extrusion. Compos Sci Technol 200:108369. https://doi.org/10.1016/j.compscitech.2020.108369

Yeh SK, Hsieh CC, Chang HC, Yen CC, Chang YC (2015) Synergistic effect of coupling agents and fiber treatments on mechanical properties and moisture absorption of polypropylene–rice husk composites and their foam. Compos A Appl Sci Manuf 68:313–322. https://doi.org/10.1016/j.compositesa.2014.10.019

Yiga VA, Pagel S, Lubwama M, Epple S, Olupot PW, Bonten C (2020a) Development of fiber-reinforced polypropylene with NaOH pretreated rice and coffee husks as fillers: mechanical and thermal properties. J Thermoplastic Composite Mater 33(9):1269–1291. https://doi.org/10.1177/0892705718823255

Yiga VA, Lubwama M, Olupot PW (2020b) Investigation on char residues and mean reactivity of compression molded rice and coffee husks bio-char reinforced polypropylene. In ASTFE Digital Library. 2020b Begel House Inc. https://doi.org/10.1615/TFEC2020.cbf.032093

Yiga VA, Lubwama M, Pagel S, Benz J, Olupot PW, Bonten C (2021a) Flame retardancy and thermal stability of agricultural residue fiber-reinforced polylactic acid: a Review. Polym Compos 42(1):15–44. https://doi.org/10.1002/pc.25835

Yiga VA, Lubwama M, Olupot PW (2021b) Effect of alkaline surface modification and carbonization on biochemical properties of rice and coffee husks for use in briquettes and fiber-reinforced plastics. J Nat Fibers 18(4):620–629. https://doi.org/10.1080/15440478.2019.1642824

Zangenberg J, & Brøndsted P (2015) Fatigue life in textile composites used for wind energy engineering. In Fatigue of Textile Composites (pp. 403–440). Woodhead Publishing. https://doi.org/10.1016/B978-1-78242-281-5.00017-1

Acknowledgements

Technical support from Yosevi Engineering Services Limited, www.yosevi.com is gratefully acknowledged.

Funding

This study received funding from the Volkswagen Foundation (Grant No. 96655 entitled “Enhanced flame retardancy of bio-composite plastics developed with rice husks and clay fillers”).

Author information

Authors and Affiliations

Contributions

VAY: conceptualization, experimental design; experimentation; writing—original draft; technical editing. ML: conceptualization; writing–original draft; technical editing; supervision; fund acquisition. PWO: methodology; investigation; technical editing; supervision. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is part of the Topical Collection on Natural Fibers: Materials of the Future

Rights and permissions

About this article

Cite this article

Yiga, V.A., Lubwama, M. & Olupot, P.W. Characterization of Rice Husks as Potential Reinforcement for Polymer Composites. Mater Circ Econ 3, 16 (2021). https://doi.org/10.1007/s42824-021-00031-5

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42824-021-00031-5