Abstract

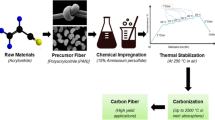

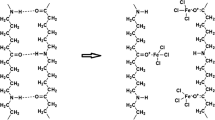

The structural transformationss of oriented poly(vinyl alcohol) (PVA) fibers impregnated with potassium bisulfate (PBS) were studied in detail on the way from PVA precursor fibers till carbonized at a temperature of 1000 °C fibers. It has been shown that the impregnation of PVA fibers with a sulfur-containing compound (PBS) is an efficient technique to decrease the thermoplasticity of PVA fibers during heat treatment at high temperatures in air and argon and contributes to a high yield of coke residue after heat treatment up to 1000 °C. TMA, TGA, DSC, mass spectrometry, FTIR, Raman spectroscopy, SEM, WAXS and SAXS were used to study the structural transformations of oriented PVA fibers impregnated with PBS at the stages of their preliminary thermal stabilization (215 °C), thermal stabilization (215–400 °C) and carbonization (400–1000 °C). A reaction scheme has been proposed that fully describes carbonization chemistry in the entire studied temperature range. The processing temperature of 215 °C was found to be optimal for preliminary thermal stabilization of PVA fibers impregnated with PBS. The heat treatment in an inert medium can be recommended as the optimal for thermal stabilization of fibers impregnated with PBS. The characteristics of the carbonized PVA fibers, such as strength, modulus and electrical conductivity, were close to the characteristics of commercial cellulose-based carbon fibers yarns.

Similar content being viewed by others

References

Zhang J, Terrones M, Park CR, Mukherjee R, Monthioux M, Koratkar N et al (2016) Carbon science in 2016: Status, challenges and perspectives. Carbon 98:708–732. https://doi.org/10.1016/j.carbon.2015.11.060

Morgan P (2005) Carbon fibers and their composites. Taylor and Francis, Boca Raton

Frank E, Steudle LM, Ingildeev D, Spörl JM, Buchmeiser MR (2014) Carbon fibers: precursor systems, processing, structure, and properties. Angew Chem Int Edit 53:5262–5298. https://doi.org/10.1002/anie.201306129

Zhang D, Sun Q (1996) Structure and properties development during the conversion of polyethylene precursors to carbon fibers. J Appl Polym Sci 62:367–373. https://doi.org/10.1002/(SICI)1097-4628(19961010)62:2%3c367:AID-APP11%3e3.0.CO;2-Z

Hunt MA, Saito T, Brown RH, Kumbhar AS, Naskar AK (2012) Patterned functional carbon fibers from polyethylene. Adv Mater 24:2386–2389. https://doi.org/10.1002/adma.201104551

Kim KW, Lee HM, Kim BS, Hwang SH, Kwac LK, An KH et al (2015) Preparation and thermal properties of polyethylene-based carbonized fibers. Carbon Lett 16:62–66. https://doi.org/10.5714/CL.2015.16.1.062

Kim JW, Lee JS (2015) Preparation of carbon fibers from linear low density polyethylene. Carbon 94:524–530. https://doi.org/10.1016/j.carbon.2015.06.074

Wortberg G, De Palmenaer A, Beckers M, Seide G, Gries T (2015) Polyethylene-based carbon fibers by the use of sulphonation for stabilization. Fibers 3:373–379. https://doi.org/10.3390/fib3030373

De Palmenaer A, Wortberg G, Drissen F, Seide G, Gries T (2015) Production of polyethylene based carbon fibres. Chem Eng Trans 43:1699–1704. https://doi.org/10.3303/CET1543284

Choi D, Kil H-S, Lee S (2019) Fabrication of low-cost carbon fibers using economical precursors and advanced processing technologies. Carbon 142:610–649. https://doi.org/10.1016/j.carbon.2018.10.028

Kaneko M, Sato H (2005) Sulphonation of poly(propylene)films with fuming sulfuric acid. Macromol Chem Phys 206:456–463. https://doi.org/10.1002/macp.200400312

Chen XY, Patton J, Barton B, Lin JC, Behr M, Lysenko Z (2017) In situ raman spectroscopy monitoring of the reaction of sulfur trioxide with polyethylene fibers in chlorinated solvents. Spectroscopy 32:42–47

Younker JM, Saito T, Hunt MA, Naskar AK, Beste A (2013) Pyrolysis pathways of sulfonated polyehtylene, an alternative carbon fibre precursor. J Am Chem Soc 135:6130–6141. https://doi.org/10.1021/ja3121845

Barton BE, Patton J, Hukkanen E, Behr M, Lin J-C, Beyer S et al (2015) The chemical transformation of hydrocarbons to carbon using SO3 sources. Carbon 94:465–471. https://doi.org/10.1016/j.carbon.2015.07.029

Shindo A, Nakanishi Y, Soma I (1969) Highly crystallite-oriented carbon fibers from polymeric fibers. Appl Polym Symp 9:305–313

Shindo A, Sawada Y (1980) Orientation structure in transverse sections of carbon fibers from dehydrated polyvinyl alcohol. Carbon 18:419–425. https://doi.org/10.1016/0008-6223(80)90034-2

Tolkachev AV, Druzhinina TV, Nazar'ina LA (1997) Thermal properties of polyvinyl alcohol fibres in the presence of a phosphorus-containing catalyst. Fibre Chem 29:26–30. https://doi.org/10.1007/BF02430682

Savel'eva EYu, Druzhinina TV (2003) Effect of phosphorus and chromium compounds on thermooxidation of polyvinyl alcohol fibres. Fibre Chem 35:17–20. https://doi.org/10.1023/A:1023815420629

Savel'eva EYu, Druzhinina TV, Kharchenko IM (2004) Fabrication of carbon fibre materials made from polyvinyl alcohol fibre impregnated with phosphorus compounds. Fibre Chem 36:26–29. https://doi.org/10.1023/B:FICH.0000025534.44293.f6

Tovmash AV, Polevov VN, Mamagulashvili VG, Chernyaeva GA, Shepelev AD (2005) Fabrication of sorption-filtering nonwoven material from ultrafine polyvinyl alcohol carbonized fibers by electrospinning. Fiber Chem 37:187–191. https://doi.org/10.1007/s10692-005-0077-6

Zhang SJ, Quing H, Feng H (2006) PVA based activated carbon fibers with lotus root like axially porous structure. Carbon 44:2059–2068. https://doi.org/10.1016/j.carbon.2005.12.047

Bin Y, Chen Q, Nakamura Y, Tsuda K, Matsuo M (2007) Preparation and characterization of carbon films prepared from poly(vinyl alcohol) containing metal oxide and nanofibers with iodine pretreatment. Carbon 45:1330–1339. https://doi.org/10.1016/j.carbon.2007.01.007

Zhang SJ, Feng HM, Wang JP, Yu HQ (2008) Structure evolution and optimization in the fabrication of PVA-based activated carbon fibers. J Colloid Interf Sci 321:96–102. https://doi.org/10.1016/j.jcis.2008.01.012

Feng HM, Zhang SJ, Chen YZ, Ding YW, Yu HQ, Lam MHW (2009) Fabrication and evaluation of mesoporous poly(vinyl alcohol)-based activated carbon fibers. Ind Eng Chem Res 48:3398–3402. https://doi.org/10.1021/ie8012852

Nakano Y, Matsuo M (2010) Carbonized properties of iodine-incorporated poly(vinyl alcohol) composite films prepared by gelation/crystallization from solution. Langmuir 26:2857–2863. https://doi.org/10.1021/la900957t

Fatema UK, Tomizawa C, Harada M, Gotoh Y (2011) Iodine-aided fabrication of hollow carbon fibers from solid poly(vinyl alcohol) fibers. Carbon 49:2158–2161. https://doi.org/10.1177/0040517510385175

Fatema UK, Ahmed JU, Uemura K, Gotoh Y (2011) Fabrication of carbon fibers from electrospun poly(vinyl alcohol) nanofibers. Text Res J 81:659–672. https://doi.org/10.1177/0040517510385175

Druzhinina TV, Kharchenko IM (2011) General characteristics of chemical and structural transformations of polyvinyl alcohol fibre in conditions of high-temperature treatment. Fibre Chem 42:293–296. https://doi.org/10.1007/s10692-011-9272-9

Penev ES, Artyukhov VI, Yakobson BI (2015) Basic structural units in carbon fibers: atomistic models and tensile behavior. Carbon 85:72–78. https://doi.org/10.1016/j.carbon.2014.12.067

Petkieva DV, Alkhanishvili GG, Kurkin TS, Ozerin AN, Perov NS, Rudakova TA (2013) Change in the structure of oriented poly(vinyl alcohol) fibers impregnated with potassium bisulfate during heat treatment in air. Polym Sci Ser A 55:121–126. https://doi.org/10.1134/S0965545X13020077

Petkieva DV, Golubev EK, Kurkin TS, Kechek’yan AS, Rudakova TA, Beshenko MA, Ozerin AN (2017) Carbonized fibers based on polyvinyl alcohol. Dokl Chem 477:274–277. https://doi.org/10.1134/S0012500817120035

Iwashita N, Park CR, Fujimoto H, Shiraishi M, Inagaki M (2004) Specification for a standard procedure of X-ray diffraction measurements on carbon materials. Carbon 42:701–714. https://doi.org/10.1016/j.carbon.2004.05.027

Cho JD, Lyoo WS, Chvalun SN, Blackwell J (1999) X-ray analysis and molecular modeling of poly(vinyl alcohol)s with different stereoregularities. Macromolecules 32:6236–6241. https://doi.org/10.1021/ma9908402

Lidin RA, Molochko VA, Andreeva LL (1996) Reactivity of inorganic substances handbook. Revised and augmented edition. Begell House Inc., New York

Gillam AE, Stern ES, Timmons CJ (1970) Gillam and Stern's introduction to electronic absorption spectroscopy in organic chemistry. Edward Arnold, London

Tolkachev AV, Druzhinina TV, Nazar'ina LA, Mosina NYu (1997) Oxidation of polyvinyl alcohol fibres in the presence of phosphorus-containing compounds. Fibre Chem 29:97–102. https://doi.org/10.1007/BF02430699

Fitzer E, Frohs W, Heine M (1986) Optimization of stabilization and carbonization treatment of PAN fibres and structural characterization of the resulting carbon fibres. Carbon 24:387–395. https://doi.org/10.1016/0008-6223(86)90257-5

Colthup N, Daly L, Wiberley S (1990) Introduction to infrared and raman spectroscopy. Academic Press, Boston

Wallace W (2020) Mass spectra. In: Linstrom P, Mallard W (eds) NIST chemistry webbook, NIST standard reference database number 69. National Institute of Standards and Technology, Gaithersburg, MD. https://doi.org/10.18434/T4D303

Sadezky A, Muckenhuber H, Grothe H, Niessner R, Pöschl U (2005) Raman microspectroscopy of soot and related carbonaceous materials: Spectral analysis and structural information. Carbon 43:1731–1742. https://doi.org/10.1016/j.carbon.2005.02.018

Ferrari AC (2007) Raman spectroscopy of graphene and graphite: disorder, electron–phonon coupling, doping and nonadiabatic effects. Solid State Commun 143:47–57. https://doi.org/10.1016/j.ssc.2007.03.052

Wang Y, Alsmeyer DC, McCreery RL (1990) Raman spectroscopy of carbon materials: structural basis of observed spectra. Chem Mater 2:557–563. https://doi.org/10.1021/cm00011a018

Cuesta A, Dhamelincourt P, Laureyns J, Martinez-Alonso A, Tascon JMD (1994) Raman microprobe studies on carbon materials. Carbon 32:1523–1532. https://doi.org/10.1016/0008-6223(94)90148-1

Dippel B, Jander H, Heintzenberg J (1999) NIR FT Raman spectroscopic study of flame soot. Phys Chem Chem Phys 1:4707–4712. https://doi.org/10.1039/A904529E

Ferrari AC, Robertson J (2001) Origin of the 1150-cm-1 Raman mode in nanocrystalline diamond. Phys Rev B 63:121405(R). https://doi.org/10.1103/PhysRevB.63.121405

Thomas PS, Guerbois JP, Russell GF, Briscoe BJ (2001) FTIR study of the thermal degradation of poly(vinyl alcohol). J Therm Anal Calorim 64:501–508. https://doi.org/10.1023/A:1011578514047

Holland BJ, Hay JN (2001) The thermal degradation of poly(vinyl alcohol). Polymer 42:6775–6783. https://doi.org/10.1016/S0032-3861(01)00166-5

Quan Y, Liu Q, Shilong Z, Shuai Z (2018) Comparison of the morphology, chemical composition and microstructure of cryptocrystalline graphite and carbon black. Appl Surf Sci 445:335–341. https://doi.org/10.1016/j.apsusc.2018.03.182

Patent application: 2019141958, 17.12.2019

Funding

This study was funded by Enikolopov Institute of Synthetic Polymeric Materials RAS according to the Research Project # 115060840012.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Petkieva, D., Ozerin, A., Kurkin, T. et al. Carbonization of oriented poly(vinyl alcohol) fibers impregnated with potassium bisulfate. Carbon Lett. 30, 637–650 (2020). https://doi.org/10.1007/s42823-020-00135-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42823-020-00135-z