Abstract

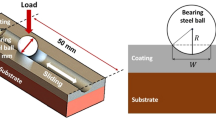

A novel approach was presented for deposition of nickel–graphene nanocomposite coating on copper. Unlike conventional methods, graphene and graphene oxide nanosheets were not used. The basis of the method is to synthesize graphene oxide by oxidation of graphite anode during the electrochemical deposition process. The obtained graphene oxide sheets were reduced during the deposition in the cathode and co-formed with the nickel deposition in the coating. The pulsed ultrasonic force was applied during the deposition process. When the ultrasonic force stops, the deposition process begins. Scanning electron microscopy, Raman spectroscopy, atomic force microscopy, X-ray diffraction and X-ray photoelectron spectroscopy confirmed the presence of graphene nanosheets in the coating. The amount of graphene nanosheets increases up to a maximum of 14.8 wt% by increasing the time of applying ultrasonic force to 6 s. In addition, with the presence of graphene in the nickel coating, the wear rate dramatically decreased.

Graphic abstract

Similar content being viewed by others

References

Medvedev AG, Mikhaylov AA, Grishanov DA, Yu DYW, Gun J, Sladkevich S, Lev O, Prikhodchenko PV (2014) Nanocrystalline tin disulfide coating of reduced graphene oxide produced by the peroxostannate deposition route for sodium ion battery anodes. J Mater Chem A 2:8431

Mattevi C, Kim H, Chhowalla M (2011) A review of chemical vapour deposition of graphene on copper. J Mater Chem 21:3324

Szeptycka B, Midzialek AG, Babul T (2016) Electrodeposition and corrosion resistance of Ni–graphene composite coatings. J Mater Eng Perform 25:3134

Badrayyana S, Bhat DK, Shenoy S, Ullal Y, Hegde AC (2015) Novel Fe–Ni–graphene composite electrode for hydrogen production. Int J Hydrogen Energy 40:10453

Dong LL, Chen W, Deng N, Zheng C (2016) A novel fabrication of graphene by chemical reaction with a green reductant. Chem Eng J 306:754–762

Dong LL, Ding YC, Huo WT, Zhang W, Lu JW, Jin LH, Zhao YQ, Wu GH, Zhang YS (2019) A green and facile synthesis for rGO/Ag nanocomposites using one-step chemical co-reduction route at ambient temperature and combined first principles theoretical analyze. Ultrason Sonochem 53:152–163

Chen W, Dong L, Wang J, Zuo Y, Ren S, Fu Y (2017) Synergistic enhancing effect for mechanical and electrical properties of tungsten copper composites using spark plasma infiltrating sintering of copper coated graphene. Sci Rep 7:17836

Xue Y, Chen W, Wang J, Dong L, Zhao Q, Fu Y (2018) Formation mechanism and cohesive energy analysis of metal-coated graphene nanocomposites using in-situ co-reduction method. Materials 11:2071

Nazir MH, Khan ZA, Saeed A, Siddaiah A, Menezes PL (2018) Synergistic wear-corrosion analysis and modeling of nanocomposite coatings. Tribol Int 121:30

Li B, Zhang W, Zhang W, Huan Y (2017) Preparation of Ni-W/SiC nanocomposite coatings by electrochemical deposition. J Alloys Compd 702:38

Hassannejad H, Nouri A (2017) Formation of β-NiAl nanocomposite coating by electrodeposition and effect of cerium ion doping on its oxidation mechanism. Ceram Int 43:9979

Waware US, Hamouda AMS, Pradhan AK (2018) Effect of codeposition of mixed nanoparticles (V2O5 and ZrO2) on the structure and properties of Ni–B nanocomposite coating. J Alloys Compd 752:253

Allahyarzadeh MH, Aliofkhazraei M, Sabour Rouhaghdam AR, Torabinejad V (2016) Gradient electrodeposition of Ni–Cu–W(alumina) nanocomposite coating. Mater Des 107:74

Shafiee Z, Bahrololoom ME, Hashemi B (2016) Electrodeposition of nanocrystalline Ni/Ni–Al2O3 nanocomposite modulated multilayer coatings. Mater Des 108:19

Wasekar NP, Madhavi Latha S, Ramakrishna M, Rao DS, Sundararajan G (2016) Pulsed electrodeposition and mechanical properties of Ni-W/SiC nano-composite coatings. Mater Des 112:140

Hassannejad H, Nouri A, Molavi FK, Barati A (2017) A novel approach to prepare Ni–Al mesoporous powder using electrochemical method in one step. J Alloys Compd 705:226

Jiang J, Feng C, Qian W, Zhu L, Han S, Lin H (2017) Effect of graphene oxide nanosheets and ultrasonic eletrodeposition technique on Ni–Mo/graphene oxide composite coatings. Mater Chem Phys 199:239

Kumar CMP, Venkatesha TV, Shabadi R (2013) Preparation and corrosion behavior of Ni and Ni–graphene composite coatings. Mater Res Bull 48:1477

Tamilarasan TR, Sanjith U, Shankar MS, Rajagopal G (2017) Effect of reduced graphene oxide (rGO) on corrosion and erosion and erosion–corrosion behavior electroless Ni–P coatings. Wear 390–391:385

Zhou C, Szpunar JA, Cui X (2016) Synthesis of Ni/graphene nanocomposite for hydrogen storage. ACS Appl Mater Interfaces 24:15232

Jabbar A, Yasin G, Khan WQ, Anwar MY, Korai RM, Nizam MN, Muhyodin G (2017) Electrochemical deposition of nickel graphene composite coatings: effect of deposition temperature on its surface morphology and corrosion resistance. RSC Adv 7:31100

Berlia R, Kumar MKP, Srivastava C (2015) Electrochemical behavior of Sn–graphene composite coating. RSC Adv 5:71413

Zhang W, Li Y, Zeng X, Peng S (2015) Synergetic effect of metal nickel and graphene as a cocatalyst for enhanced photocatalytic hydrogen evolution via dye sensitization. Sci Rep 5:10589

Johra FT, Lee JW, Jung WG (2014) Facile and safe graphene preparation on solution based platform. J Ind Eng Chem 20:2883–2887

Gurzeda B, Florczak P, Kempinski M, Peplinska B, Krawczyk P, Jurga S (2016) Synthesis of graphite oxide by electrochemical oxidation in aqueous perchloric acid. Carbon 100:540

Low CTJ, Walsh FC, Chakrabarti MH, Hashim MA, Hussain MA (2013) Electrochemical approaches to the production of graphene flakes and their potential applications. Carbon 54:1

Singh BP, Nayak S, Nanda KK, Jena BK, Bhattacharjee S, Besra L (2013) The production of a corrosion resistant graphene reinforced composite coating on copper by electrophoretic deposition. Carbon 61:47

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hassannejad, H., Nouri, A., Farrokhi-rad, M. et al. In situ fabrication of high-percent Ni–graphene nanocomposite coating. Carbon Lett. 30, 63–71 (2020). https://doi.org/10.1007/s42823-019-00071-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42823-019-00071-7