Abstract

The regulation of the pyrolysis process is a key step in increasing the carbon sequestration capacity of biochar. The effect of K3PO4 addition on the yield, chemical composition, characteristic functional groups, macromolecular skeleton, graphite crystallites, and stability of biochar was studied in this paper using two-dimensional infrared correlation spectroscopy (2D-PCIS), X-ray photoelectron spectroscopy, Raman spectrum, and other characterization methods combined with thermal/chemical oxidation analysis. It is discovered that adding K3PO4 may effectively minimize the graphitization temperature range and increase biochar's yield, aromaticity, H/C ratio, and proportion of refractory/recalcitrant organic carbon. The 2D-PCIS and Raman analysis revealed that K3PO4 mostly promoted the dehydrogenation and polycondensation process of the aromatic rings in the char precursor, transforming the amorphous carbon structure of biochar into an ordered turbostratic microcrystalline structure. K3PO4 enhanced biochar stability mostly at medium-high temperatures (350 ~ 750℃) by stimulating the transformation of unstable structures of biochar to stable carbon-containing structures or by inhibiting the interaction of its active sites with oxidants through the mineralization process. A 20% phosphorus addition increased biochar's refractory index (R50) by roughly 11%, and it also boosted biochar's oxidation resistance (H2O2 or K2CrO4) efficiency, reducing carbon oxidation loss by up to 7.31%. However, at higher temperatures (> 750 ℃), the doping of phosphorus atoms into the carbon skeleton degraded the biochar structure's stability. The results of this study suggest that using exogenous phosphorus-containing additives is an efficient way to improve the stability of biochar.

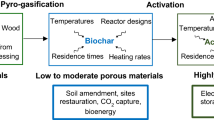

Graphical abstract

Highlights

-

K3PO4 promoted biochar precursor's dehydrogenation/polycondensation process to form fused-ring aromatic structures.

-

K3PO4 increased recalcitrant carbon proportion and shielded biochar's active sites through the mineralization process.

-

By adding 20 wt% of K3PO4, the thermal and chemical stability of biochar were enhanced by 11% and 7%, respectively

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The carbon-neutral, net-zero, and climate-positive properties of biomass make it an ideal asset in the worldwide quest for sustainable energy alternatives (Rosa et al. 2021). Biochar, as one of the primary products of biomass thermochemical conversion, has the benefits of high carbon content, good stability, and amenability to functionalization. The production and utilization of biochar for carbon sequestration is an urgent global need. Biochar has been widely employed in sewage treatment, soil remediation, precision agriculture, and other industries in recent years (Bartoli et al. 2022; Qu et al. 2023). It is estimated that the worldwide emission reduction potential of biochar production and usage is projected to be 8.67 billion tons of CO2 equivalent, which is comparable to 38% of total fossil fuel emissions (Lee et al. 2010).

Pyrolysis is a significant conversion process that may convert biomass directly into bio-oil, syngas, and biochar in an inert environment. However, pristine biochar is challenging to satisfy current needs due to its underdeveloped pore structure, scarce surface functional groups, and insufficient active sites (Vijayaraghavan 2019). To increase biochar's application potential in adsorption, catalysis, and energy storage, the pyrolysis and carbonization of biomass should be managed directionally. Applying pyrolysis additive is one of the most effective ways to increase the porosity and surface properties of biochar. In recent years, phosphate has been widely studied as a cheap and easily available pyrolysis catalyst due to its potential to upgrade both bio-oil and biochar. Li et al. (2020a, b) found that addition of phosphorus-containing additives could decrease the acidity, viscosity, and moisture of bio-oil. Zhurinsh et al. (2021) used a hydrothermal approach to treat birch biomass and discovered that H3PO4 impregnation enhanced the production of L-glucose in bio-oil, with the highest yield exceeding 20%. The presence of phosphate also has a positive impact on the pore structure and surface functional groups of biochar. Yang et al. (2018) observed that co-pyrolysis of sawdust and Ca(H2PO4)2 at 600 ºC increased the BET-specific surface area of biochar by almost 7 times. Chen et al. (2019) also found that adding H3PO4 during pyrolysis increased the surface area of biochar; moreover, the content of oxygen-containing functional groups (for example, –COOH and –OH) rose by 14%.

Because of its superior adsorption capability and high phosphorus concentration, phosphorus-enriched pyrolytic biochar is frequently utilized as heavy metal adsorbents or carbon-based fertilizers. Our findings have demonstrated that K3PO4 may enhance the pore structure and surface chemical characteristics of biochar, boosting its Cd(II) adsorption capacity from 25 to 289 mg g−1 (Zhang et al. 2022). Luo et al. (2022) discovered that Ca(H2PO4)2 modified biochar enhanced the fixation efficiency of Pb(II) and Cd(II) by 31% and 92%, respectively. Furthermore, Tumbure et al. (2020) produced the biochar-based phosphate fertilizer via co-pyrolysis of maize stover and igneous phosphate rock. Pogorzelski et al. (2020) also discovered that biochar treated with TSP-Ca(H2PO4)2 has the potential to be employed as a slow-release fertilizer.

With an increasing interest in enhancing the characteristics of biochar via the use of phosphorus-containing additives, a new concern about the carbon stability of biochar has emerged. Biochar's stability is critical for its long-term usage and carbon sequestration performance. According to existing research, less than 50% of the carbon in biochar is preserved after direct pyrolytic carbonization (Nan et al. 2022). And, after being applied to the soil, 5 ~ 20% of the unstable carbon will be released into the atmosphere in the form of CO2, resulting in a considerable drop in the effective carbon sequestration rate (Jaffé et al. 2013). Because phosphate mostly alters the surface characteristics of biochar, the carbon sequestration potential of biochar may be impacted. The larger surface area of designed biochar may be related to a greater likelihood of interacting with the oxidizing components (e.g., O2), which would likely increase biochar's carbon loss (Wang et al. 2020). The change in surface functional groups and carbon structure would also have a direct impact on biochar's carbon retention rate (Kim et al. 2021). Therefore, understanding the effect of phosphorus-containing additives on the evolution of carbon structure and stability of biochar is critical to developing strategies for biochar preparation and utilization.

Based on the above, we chose corncob as a typical biomass and K3PO4 as a phosphorus-containing additive to conduct a series of pyrolysis experiments in a microwave fixed-bed pyrolysis reactor at 350, 550, 750, and 950 ℃. We hypothesize that the addition of K3PO4 has a significant impact on the structure and stability of biochar. To verify this hypothesis, we thoroughly investigated the effect of K3PO4 on the evolution of chemical composition, organic functional groups, carbon skeleton, graphite crystallite structure, and thermal/chemical stability of the biochar. The conclusions presented in this study may expand the understanding concerning the effect mechanism of phosphorous-containing additives on biochar's carbon sequestration capacity.

2 Materials and methods

2.1 Biomass materials

The corncob was collected in a neighborhood of Wuhan, China. They were air-dried at room temperature before being pulverized and sieved to collect tiny particles less than 0.25 μm in size.

2.2 Biochar preparation

The samples were impregnated with K3PO4 by adding 250 mL of 0.095 M K3PO4 solution to a beaker holding 20 g of corncob particles. The mixture was magnetically stirred in a water bath at 80 °C for 6 h and then cooled to room temperature. Then the mixture was dried out by using the oven at 105 ℃ for 36 h, which achieved a 4:1 corncob-to-K3PO4 impregnation ratio.

The microwave-assisted pyrolysis of the samples was performed in a single-mode microwave oven (SINEO MAS-II, Shanghai, China), with the power of 1000 W at a frequency of 2450 MHz. For each trial, 10 g of the K3PO4-impregnated corncob was securely placed inside the reactor before purging the air in the reactor with an N2 flow of 1.5 L min−1 for 30 min. After the purging, the PIC control panel, microwave power meter, water cooling system, and data acquisition program were all started, and the flow rate of the N2 was decreased to 0.5 L min−1. Full microwave power (1000 W) was then applied to heat the sample to the target pyrolysis temperature (350 ~ 950℃), after which the microwave power was reduced to 800 W to maintain the temperature for 30 min. Since the microwave-assisted pyrolysis of pure corncob (without K3PO4 catalyst) could not reach the desirable temperature, 20 wt% of microwave absorbent (SiC) was added to speed up the microwave heating and promote pyrolysis reactions. The biochar collected from the pyrolysis of pure corncob was marked as BC, while the phosphorus-enriched biochar was marked as KPBC.

The biochar yield could be calculated from the following equation:

where Ybiochar denotes the yield of biochar, mtol denotes the mass of pyrolysis residue (including phosphates), ωp denotes the mass ratio of phosphates to pyrolysis residue (for pristine biochar, ωp = 0), and mbiomass is the mass of biomass.

2.3 Characterization of biochar

Ultimate analysis was carried out using an elemental analyzer (EA; Vario EL II, Elementar, Germany) to determine the C, H, N, and S contents of samples. Proximate analysis was performed using an automated analyzer (PA; THERMOSTEP, ELTRA, Germany) to obtain the fixed carbon, ash, and volatile contents of biochar. A Fourier transform infrared spectrometer (FTIR; VERTEX 70, Bruker, Germany) in the wavenumber range of 4000 ~ 400 cm−1 with a resolution of 4 cm−1 was used to determine the composition of the surface functional groups of the samples. The FTIR samples were generated using the KBr tableting technique, with a 100:1 KBr to biochar mixing mass ratio. A two-dimensional correlation infrared spectrum (2D-PCIS) was constructed based on the FTIR data, and the relevant concepts and analysis methods are presented in Additional file 1: Text S1.

The crystalline species were investigated using an X-ray diffraction analyzer (XRD; X'Pert PRO, PANalytical B.V., Netherlands) with Cu-K radiation at a scanning speed of 5° min1 and 2 angles ranging from 5° to 90°. The binding energy on the surface of biochar was measured using X-ray photoelectron spectroscopy (XPS; Axis Ultra DLD, Kratos, UK), with an Al K line (15 kV, 10 mA, 150W) as the radiation source. To determine the total P content of biochar, each 0.1 g sample was digested using a microwave digester (Metash, China, MWD-600) at 210 ℃ for around 20 min with a variety of acid solutions (6 mL HNO3 + 1 mL H2O2 + 1 mL HF).

A Fourier Raman spectrometer (Ramman; LabRAM HR800, Horiba JobinYvon, France) was used for the Raman analysis. This Raman spectrometer employs a Nd:YAG laser emitter with a 532 nm laser wavelength. Under high-power laser intensity, it is easy to absorb light and generate a large number of thermal signals, and therefore spectral-grade potassium bromide must be employed to dilute the biochar sample. The biochar percentage in the test mixture was 0.5 wt%.

2.4 Thermal stability analysis

The thermal oxidation resistance of biochar was evaluated using recognized approaches published in previous studies (Leng et al. 2019). The mass loss due to thermal oxidation of these various biochar samples was measured in an ambient air environment using thermogravimetry/derivative thermogravimetry (TG/DTG). Thermal profiling began at 30 ℃ and progressed at a controlled ramping rate of 10 ℃ min−1 up to 1000 ℃. A measure known as "R50" was used to assess the recalcitrance of biochar oxidation during the TG study (Eq. 1).

T50, biochar and T50, graphite are the temperatures for biochar and graphite reflecting the corresponding values at which a 50% weight drop occurs owing to the oxidation process for each material. Due to the relatively stable chemical structure of graphite, a significant number of experimental findings demonstrate that the temperature at which 50% mass loss occurs in graphite materials is constant (about 885 ℃). Hence this value is specified as an external standardization factor for assessing other carbon materials' thermal oxidation resistance.

2.5 Chemical stability analysis

The assessment of biochar's resistance to chemical oxidation was carried out using the H2O2 and K2Cr2O7 oxidation methods, as outlined in other studies (Leng et al. 2019; Yang et al. 2016). Briefly, for the H2O2 oxidation, 0.1 g of C of biochar was treated with 7 mL of 5% H2O2 at 80 ℃ for 48 h. For the K2Cr2O7 oxidation, approximately 0.1 g of biochar was introduced into individual glass test tubes and subjected to a temperature of 55 ℃ for 60 h, with triplicate experiments performed. The proportion of carbon loss was subsequently computed based on the carbon content inherent to the biochar, as determined through elemental analysis (EA).

3 Results and discussion

3.1 Biochar's chemical composition

Figure 1a depicts the distribution of biochar's fixed carbon, ash, and volatile matter contents. The volatile matter content of the BCs decreased from 47.94 to 20.10% when the pyrolysis temperature rose from 350 to 950 ℃, whereas the fixed carbon content increased from 25.25 to 50.15%. This phenomenon is linked to the gradual escape of volatile within the biomass as the temperature rises. Furthermore, the ash content of the BCs first increased with increasing temperature and then decreased after reaching 750 ℃. This phenomenon is principally caused by the breakdown of certain inorganic salts (such as carbonates and silicates) contained in the biochar, which is induced by the high temperature (Masiá et al. 2007). The concentration of volatile matter, fixed carbon, and ash of KPBCs showed the same changing trend. With increasing temperature, it initially rose and then fell. At each temperature, the KPBCs had lower volatile matter and fixed carbon content than the BCs. This is mostly because the addition of K3PO4 accelerates the carbonization of biomass and concentrates in the solid residue as ash. It should be noted that the volatile content of the BCs remained unchanged at 750 ℃, but after the addition of K3PO4, the volatile content reached the minimum at 950 ℃, indicating that phosphate may promote the dehydrogenation and depolymerization of polymers, which increases the biochar's carbonization degree.

Figure 1b depicts the fluctuation of O/C and H/C ratios with pyrolysis temperature, and the corresponding elemental analysis and biochar yield are shown in Additional file 1: Table S2. The yield of BC declined from 49.36 to 35.23% as the temperature climbed from 350 to 950 ℃, while the yield of KPBC decreased from 64.26 to 56.10%. K3PO4 additive boosted biochar production by around 18% on average, and in addition to the higher ash content in KPBC, phosphate mineralization may have decreased some of the solid-phase carbon loss. The O/C ratio of BCs declined from 0.22 to 0.01 considerably as the temperature changed from 350 to 950 ℃. This might be because high temperatures facilitate the shedding of oxygen-containing functional groups and the breakdown of oxygen-containing inorganic salts (Bartoli et al. 2022). Increasing the pyrolysis temperature also intensifies the deoxygenation reaction, so the O content in biochar continues to decrease while the C content continues to increase (Lv et al. 2010). However, the O/C of the KPBCs climbed from 0.20 to 0.29, then fell to 0.21 as the pyrolysis temperature increased. Although numerous investigations have established that the O/C ratio can, to some extent, indicate the stability of biochar, this approach is not relevant in our study because PO43− introduces foreign O atoms. However, the shift in H/C still allows us to make certain inferences. The H/C of BCs and KPBCs fell from 0.57 to 0.06 and from 0.49 to 0.04, respectively. It is important to note that at each temperature, the H/C value of KPBCs was lower than that of pristine biochar. This suggests that K3PO4 may accelerate biochar's dehydration and decarboxylation degree. As Chen et al. (2023) discovered in their experiment, with K3PO4 accelerating the hydrothermal liquefaction of straw, K3PO4 encouraged the dehydration and rearrangement of fructose to form small-molecule organic acids. K3PO4 also increases the dehydration, decarbonylation, and hydrodeoxidation activities of L-Arabinos and xylose, resulting in the production of alkanes and esters.

3.2 Evolution of biochar's functional group

3.2.1 FTIR analysis

Additional file 1: Table S3 outlines the primary functional group types and corresponding wavenumbers utilized in this work. As is shown in Additional file 1: Fig. S1, the O–H stretching vibration peak with a wavenumber of 3400 ~ 3800 cm−1, the C=O stretching vibration peak with a wavenumber of about 1700 cm−1, and the C–O stretching vibration peak located at about 1260 cm−1 are the most prominent functional groups on the surface of BCs. The above-mentioned infrared peaks gradually faded as temperature increased, showing that high temperatures accelerated the decarboxylation and decarbonylation process on the surface of biochar, causing the organic functional groups to fall off from biochar (Hassan et al. 2020). The surface of KPBCs likewise contained the oxygen-containing functional groups indicated above, and the peak intensity at each temperature was much higher than that of BCs. This might be because K3PO4 functioned as a catalyst, boosting the synthesis of certain small-molecule products (such as phenols, oxygenates, and so on) and sticking to the surface of biochar (Lu et al. 2018). Furthermore, KPBCs contained various phosphorus-containing groups, such as PO43−, P=O, and P–O, which were scattered between 700 and 1100 cm−1 and were visible on the KPBCs at 350 ~ 750℃. The presence of similar infrared characteristic peaks indicates that the chemical characteristics of these phosphorus-containing groups are relatively stable. The organic functional groups on the surface of KPBCs vanished as the temperature climbed to 950℃. On the one hand, high temperatures accelerate the decarboxylation/decarbonylation process of biochar, on the other hand, the oxygen-containing compounds generated at low temperatures volatilize at higher temperatures (Tian et al. 2022).

3.2.2 2D-PCIS analysis

The fluctuation trend of infrared peak intensity for BCs with temperature rise is shown in Additional file 1: Fig. S2. BCs have extremely limited information about its 2D-PCIS spectrum, and the reaction of functional groups to temperature is only seen in synchronous correlation items Φ (v1, v2) in the 4000 ~ 2800 cm−1 region. These functional groups include –CH2 groups (3100 ~ 3050 cm−1) in naphthenes, –CH bonds (2930 ~ 2900 cm−1) in aliphatic chains, and hydroxyl groups (3420 ~ 3380 cm−1) linked to intermolecular hydrogen bonds. This might be due to that BC itself has fewer organic functional groups and that most of their decomposition occurs during the escape of volatile, specifically during the dehydration process at the primary pyrolysis stage and the decarbonylation or decarboxylation reaction at the secondary pyrolysis stage (Xue et al. 2023). The number of functional groups on the surface of BCs continued to decline during the carbonization process, and only groups connected to aromatic compounds were visible. The polycondensation of the benzene ring, the dehydroxylation of phenolic compounds, and the cleavage of the side chain of lignin phenylpropane may have taken place at this point.

The 2D-PCIS spectrum of KPBCs (Fig. 2), in contrast, offers more detailed information. Functional groups such as –C=C (730 ~ 665 cm−1) in alkenes and –CH (730 ~ 700 cm−1) at various locations on the benzene ring are seen in the synchronous spectra (Φ (v1, v2)) in the 800 ~ 400 cm−1 region. The above functional groups exhibit a strong temperature response when compared to BCs, indicating that K3PO4 increases the degree of aromatization of biochar through processes such as the rearrangement of oxygen-containing heterocycles, D-A reactions of small-molecules olefins, addition reactions of small-molecules benzene rings, etc. Furthermore, cross peaks (682, 670) seen in the synchronous spectra were positive and negative in the asynchronous spectra. According to Noda's law, the polycondensation of tiny molecular aromatic rings on biochar proceeds in a certain order, with the change of –C=C in the olefin occurring before the change of -CH on the benzene ring.

The synchronous correlation spectrum that can be observed in the 1600 ~ 800 cm−1 band includes the aromatic ring structure –CH (1030 ~ 950 cm−1), the –C–O–C (1090 ~ 1040 cm−1) in the inner skeleton of the ring, and the –C–O (1260 ~ 1100 cm−1), –CH on hydrocarbon groups/acids/phenols/alcohols (1470 ~ 1260 cm−1), –OH on benzene rings (1540 ~ 1500 cm−1), –C=C on cycloalkenes (1600 ~ 1560 cm−1) and –C=O on cyclic ketones (1650 ~ 1610 cm−1). The cross peaks with positive values among them are (1480, 1400), (1480, 1010), (1480, 940), (1230, 940), and (1220, 1010), showing that -CH2 in aliphatic structure, –CH in acid/phenol/alcohol, and –C–O on the aliphatic chains have the same changing trend. This could be because K3PO4 encourages the decomposition of aliphatic molecules' –C–C bonds and cleavage of –C–O bonds. The tiny-molecule alkanes are produced by the former, whereas oxygen-containing small-molecule products, such as acetic acid and acetone, are produced by the latter (Wang et al. 2017). The produced tiny-molecule products go into the volatile phase, which weakens the biochar's associated –CH bending and –C–O stretching vibrations.

The synchronous correlation spectrum contains the following negative cross peaks: (1590, 1400), (1660, 1380), (1590, 1100), (1380, 1100), (1380, 978), (1380, 960), and (980, 890). According to the above analysis, the –CH bending vibration on the hydrocarbon group, acid, phenol, and alcohol exhibits the same shifting trend as the –C=C stretching vibration on the cyclic olefin, and it is opposite to the –C–O–C in the ring skeleton and the –C–H on the aromatic ring structure. This may be because as the pyrolysis temperature rises, small-molecular acids, alcohols, ketones, and aldehydes undergo ketone-aldehyde isomerization and cyclization processes and produce oxygen-containing heterocyclic compounds with –C–O–C structures, while molecular rearrangement processes cause cycloalkenes to produce aromatic structures (Wu et al. 2023). Furthermore, a peculiar peak located at (1380, 978) was observed, which is negative in the synchronous spectrum and positive in the asynchronous spectrum. According to Noda's rule, the change of –CH on the hydrocarbon group/acid/phenol/alcohol occurs before the aromatic transition. The development of –CH in ring structure implies that there is a link between the two. When combined with the preceding analysis, it is possible to deduce that small-molecule oxygen-containing compounds first undergo cyclization to produce oxygen-containing heterocyclic compounds, and then undergo internal deoxygenation to form the benzene rings (Ren et al. 2023). Another peculiar peak is situated at (1660, 1380), which is negative in both the synchronous and asynchronous spectrum, showing that the change of –C=O on the cyclic ketone is followed by –CH on the hydrocarbon group/acid/phenol/alcohol. It also demonstrates that cyclic ketones may be synthesized from small-molecular oxygenated molecules via ketone-aldehyde isomerization and cyclization processes (Qi et al. 2022).

3.3 Evolution of biochar's carbon skeleton

3.3.1 Raman analysis

Figure 3 depicts the Raman spectrum of biochar produced by Fourier transform infrared Raman scattering, and the peak splitting results are shown in Additional file 1: Figs. S3 and S4. The peak splitting concept, as well as the location and meaning of each peak, are based on the experience described by Keown et al. (2007) from a series of Raman analyses on charcoal. Additional file 1: Table S4 shows the Raman peak locations and related carbon structures. The G peak in the region of 1750 ~ 1550 cm−1 is created by the vibration of the aromatic ring in char, and the D peak in the range of 1350 ~ 1290 cm−1 represents an organized carbon structure with six or more than six fused rings. The area ratio of the D peak to the G peak (ID/IG) indicates the concentration of big aromatic rings (at least six rings). Between the G and D peaks, there are three peaks, namely Gr, Vl, and Vr, with peak locations of 1540, 1465, and 1380 cm−1, respectively. These three peaks are hypothesized to be caused by semicircular vibrations of aromatic rings, which are generally caused by the amorphous carbon structure with 3 ~ 5 aromatic rings. As a result, the area ratio of the sum of the above three peaks to the D peak (I(Gr+V1+Vr)/ID) may be utilized to measure the degree of internal carbon transition from a disordered to an ordered state. Furthermore, because the four peaks of Sl, S, Sr, and R all correspond to the variation of the C–H bond in the aromatic ring, the degree of aromatic ring dehydrogenation and polycondensation in char may be represented by the value of I(Sl+S+Sr+R)/ID. The IG/ID of BCs declined from 2.27 to roughly 1.33 as the temperature climbed from 350 to 950℃, showing that the concentration of bigger aromatic rings was considerably increased (Nan et al. 2018). This increase is the consequence of ring system expansion during pyrolysis via ring polycondensation processes. I(Sl+S+Sr+R)/ID steadily increases from 350 to 750℃, showing that the principal reactions at this temperature are the cyclization of aliphatic chains and the deoxygenation of oxygen-containing heterocycles. As a result, Raman peaks such as C–H bonds in the aromatic ring and C–C bonds in the hydrogen atom in the aromatic ring become more intense. When the temperature rises over 750℃, the I(Sl+S+Sr+R)/ID falls, which might be owing to the C–H bond breaking and the demethylation/methoxy process. Simultaneously, the small-molecule aromatic ring polymerizes into macromolecular aromatic rings, producing small molecular CH4, H2, and other compounds (Xu et al. 2020). I(Gr+Vl+Vr)/ID reduced as the pyrolysis temperature increased, showing that the amorphous carbon in biochar eventually changed into a turbostratic microcrystalline structure. It is found that K3PO4 would facilitate the polymerization and charring reactions of biomass toward char formation (Lu et al. 2013). In particular, the potassium was thought to expedite the cross-linking reactions to generate biochar by enhancing the initial dehydration of the substrate to form double bonds. Additionally, the enhanced heating by the introduction of K3PO4 would also promote the recombination reactions between neighboring heavy volatile fragments toward biochar (Zaror et al. 1985). When the temperature exceeded 750 ℃, the I(Gr+Vl+Vr)/ID of KPBCs rose, which might be due to the entrance of P atoms into the graphite sheet structure at high temperatures, resulting in a doped graphite sheet structure.

Relative ratio of Raman peaks of pristine biochar (BCs) and phosphorus-enriched biochar (KPBCs) prepared at various temperatures. ID/IG indicates the concentration of big aromatic rings (at least six rings); I(Gr+V1+Vr)/ID represents the degree of internal carbon transition from a disordered to an ordered state; I(Sl+S+Sr+R)/ID represents the degree of aromatic ring dehydrogenation and polycondensation

3.3.2 XPS analysis

The XPS results supported the idea that phosphorus atoms had an adverse effect on the carbon skeleton at high temperatures. As illustrated in Fig. 4, the C1s spectra of modified biochar generated at 550℃ have three peaks linked to the C element: C–C/C–H (284.85 ± 0.15 eV), C–O–C/C–O–P (286.10 ± 0.15 eV), and C=O (288.78 ± 0.15 eV) (Valero-Romero et al. 2017). These peaks correspond to carbon atoms in aromatic structures and oxygen-containing functional groups on the carbon skeleton. Modified biochar prepared at 950℃ includes related peaks at 284.5 ± 0.15 eV, 288.25 ± 0.15 eV, and 291.81 ± 0.15 eV, which correspond to the peaks of C–C/C–H, C=O, and π–π satellite, respectively. In contrast, the KPBC950's C1s spectrum lacks peaks denoting C–O–C and C–O–P. The former might be ascribed to the high-temperature decarbonylation reaction of biomass, while the latter could be related to the high-temperature conversion of the C–O–P structure into other phosphorus-containing configurations. The relative peak intensity of C=O dropped as well, confirming the enhanced decarboxylation at high temperatures. At high temperatures, the oxygen-containing functional group content of phosphorus-rich biochar drops, and the degree of aromatization rises due to the above-mentioned reactions. This may also be observed in the π–π satellite peak at 291.81 ± 0.15 eV, which is generated by aromatic ring diffraction, according to Li et al. (2020a, b). Furthermore, the peak of K2p3/2 was found with a binding energy of around 294.5 eV ± 0.15, interfering with the C1s peak. This is caused by potassium ions in K3PO4, particularly in KPBC950, suggesting that at high temperatures, K becomes more active and the K+ vapor may be formed and etch the biochar, resulting in a significant number of pores. KPBC550 contains just one peak that corresponds to P2p, which is situated at 134.65 ± 0.15 eV and denotes the C–O–P structure (Valero et al. 2017). KPBC950's P2p spectrum has two peaks: C3PO at 131.10 ± 0.15 eV and C–P/C–PO3 at 132.89 ± 0.15 eV. It can be observed that when the pyrolysis temperature rises, the phosphorus speciation changes. At 550 ℃, the phosphate group is connected to the oxygen atom next to the carbon atom, but at 950 ℃, the phosphate group is bonded directly to the carbon atom. In other words, when the pyrolysis temperature rises, phosphorus atoms begin to penetrate the carbon skeleton and replace some of the carbon atoms, rather than just interacting with the oxygen-containing functional groups on the surface of biochar. This process most likely occurs near the margins of biochar's graphite sheet structure (Huang et al. 2023). When P atoms enter the carbon skeleton at high temperatures, the biochar's stability might be decreased. P atoms, however, having lower electronegativity (2.19) than carbon atoms (2.54), can change the electron transfer and disturb the electronic and spin characteristics of the biochar. According to Wang et al. (2023), Phosphorus doping into the carbon structure can efficiently accelerate the transfer of electrons from adsorbed organic molecules to oxidizing agents through the carbon bridge effect.

3.4 Evolution of biochar's graphite crystallites

Figure 5a depicts the XRD patterns of biochar produced at various temperatures. Two peaks arise at 20° ~ 30° and 40° ~ 45° for unmodified biochar, signifying the (002) crystal plane and the (100) crystal plane of amorphous carbon in biochar, respectively. The d002 peak is used to characterize the stacking of single-atom carbon layers in amorphous carbon crystallites. The d100 diffraction peak is created by the steady growth of the amorphous carbon crystallite plane size. The graphite-like structure size of each biochar was determined using Scherrer's formula (see Additional file 1: Text S2), including the size (La) and thickness (Lc) of the graphite-like crystal plane, as well as the crystallinity. The change curve of the aforesaid parameters with pyrolysis temperature is shown in Fig. 5b. The crystallite plane size La and crystallite thickness Lc of biochar rose with increasing temperature, and the variable range of La was substantially larger. This demonstrates that when the temperature rises, the development sequence of biochar graphite-like crystallites begins with horizontal planar expansion and subsequently progresses to vertical accumulation. The graphite crystallite diffraction peaks reported at roughly 24° (d002) and 42° (d100) earlier vanished for KPBCs. On the one hand, phosphate crystals may interfere with the crystal peaks of biochar's amorphous carbon, influencing the former's diffraction via covering. K3PO4, on the other hand, may enhance the transition of amorphous carbon into turbostratic microcrystalline carbon (Nan et al. 2018). As a result, determining the effect of K3PO4 on biochar graphite crystallites is challenging. Although the amorphous carbon diffraction peak cannot be observed in KPBCs, the phosphate diffraction peak can be identified and its crystallinity (KPBC-Crys) may be calculated using Jade software. The KPBC-Crsy grew initially and then declined with increasing temperature, reaching a maximum of 750 ℃. This might be attributed to the breakdown and volatilization of a portion of the phosphate crystals at higher temperatures, as validated by our prior research (Zhang et al. 2022).

3.5 Biochar's stability

3.5.1 Thermal stability

Figure 6a depicts the thermal oxidation experimental results acquired by TG analysis in an air environment. The weight loss of BCs occurs mostly between 350 and 500 ℃. The recalcitrance index (R50) of each biochar was computed using the temperature at which 50% mass loss of graphite occurred as a reference. The R50 value of the BCs increased from 50.79 to 56.21% as the preparation temperature climbed from 350 to 950 ℃. Furthermore, KPBCs followed a similar pattern, with its R50 value increasing from 60.27 to 65.91%. The R50 value of KPBCs rose by around 11% on average when compared to BCs. This might be related to the fact that the formed phosphates coat the surface of biochar, impeding its heat breakdown; on the other hand, K3PO4 changes the carbon speciation, resulting in the more stable carbon species. Higher R50 values may suggest lower carbon mineralization rates during abiotic and biotic culture processes, partially indicating biochar's environmental durability (Gómez et al. 2016).

Carbon species can be classified as volatile organic carbon (with a decomposition temperature of 20 ~ 200℃), labile organic carbon (including cellulose, aliphatic carbon, and carbohydrates, with a decomposition temperature of 200 ~ 380℃), recalcitrant organic carbon (including lignin and aromatic carbons, with the decomposition temperature of 380 ~ 475℃), and refractory organic carbon (including polycondensed forms of lipid and aromatic carbohydrate) (Xiao et al. 2014). As shown in Fig. 6b, the main carbon form of BCs is recalcitrant organic carbon, and increasing the pyrolysis temperature can increase the proportion of refractory organic carbon, indicating that increasing the pyrolysis temperature promotes the cyclization and condensation of fatty chains to generate aromatic carbon structures. Furthermore, even at a lower pyrolysis temperature (< 550 ℃), biochar includes 8 ~ 10% readily degradable organic carbon, which might be due to insufficient carbonization following the primary pyrolysis of biomass macromolecules. The major carbon species (> 74%) in KPBCs was refractory organic carbon, which may be due to that K3PO4 enhanced polymerization and addition processes of aromatic structures, resulting in polycondensed aromatic carbon structures. According to Mohamed's findings, the addition of K3PO4 boosts the formation of phenolic and aromatic chemicals significantly (Mohamed et al. 2021). It is primarily because K3PO4 promotes H-abstraction processes, which activate aromatic molecules, and the addition of acetylene promotes the production of polycyclic aromatic hydrocarbons via cyclization.

3.5.2 Chemical stability

Based on the EA results, the carbon loss ratios of several biochar during the chemical oxidation of H2O2 and K2Cr2O7 were estimated to assess their carbon stability against chemical oxidation (Fig. 7a). It can be seen that as the pyrolysis temperature increased from 350 to 750℃, the H2O2 carbon dioxide loss of BCs decreased from 21.08 to 11.38%, since as the pyrolysis temperature increased, the degree of carbonization and aromatization of charcoal increased, and the aliphatic structure on the surface of biochar that is easily oxidized decreased, being replaced by heterocyclic aromatic structures and fused ring macromolecular structures (Chen et al. 2017). When the temperature was raised to 950 ℃, the carbon loss of BCs steadily climbed to 14.25%, indicating that biochar's reactivity increased at high temperatures. On the one hand, this could be due to the collapse of the pore structure of biochar at high temperatures, exposing more active sites within the biochar, and on the other hand, it could be due to the stronger electron transfer ability of the graphitized structure produced at high temperatures, which promotes oxidation of biochar by oxidant. The oxidation impact of H2O2 on biochar, for example, may be stated using the following formula:

The H2O2 carbon loss at 350 ~ 750℃ for KPBCs followed the same pattern, however, when compared to BCs, and the carbon loss rate was decreased by 3.59 to 7.31%. Exogenous potassium phosphate addition improved the chemical stability of low-temperature biochar in biochar. This might be due to two factors. The first is that potassium phosphate promotes the transformation of unstable structures on biochar (such as glycosidic bonds of cellulose, methoxy groups of lignin) to stable carbon-containing structures (such as aromatic rings) during pyrolysis (Zhang et al. 2022). The second is that phosphates such as K3PO4 may mineralize biochar, covering the surface of biochar and preventing contact of its active sites with oxidants. The carbon loss rate of KPBCs rose not only at 950℃ but was also around 1% greater than that of BCs. This might be because phosphorus atoms penetrate the biochar skeleton at high temperatures and have a doping function on the biochar, undermining the structure's stability.

The findings of utilizing K2Cr2O7 as an oxidant are comparable to those of H2O2, as shown in Fig. 7b. It's merely that the carbon loss rate of biochar is lower overall, owing to the poorer oxidation of K2Cr2O7 than that of H2O2. The oxidation impact of K2Cr2O7 on biochar, for example, may be represented using the following formula:

Similarly, the average K2Cr2O7 carbon oxidation loss rate of KPBCs was 5.32% lower than that of BCs at 350 ~ 750 ℃. However, at 950 ℃, the carbon loss rate of KPBCs rose by 0.5 to 4.35%, confirming the doping impact of phosphate on carbon structure at high temperatures.

3.6 Key factors affecting biochar's stability

Pearson correlation coefficient (PCC) study between carbon stability index and other biochar parameters was done to determine the key factors affecting biochar's thermal oxidation resistance and chemical oxidation resistance (Fig. 8). The recalcitrance index (R50) was proposed by Harvey et al. (2012), who discovered a significant negative exponential association between biochar degradability (abiotic + biotic) and thermal oxidative recalcitrance during thermal degradation after a year of incubation. Cross and Sohi (2013) came up with an accelerated oxidation method by adding 5% hydrogen peroxide (H2O2) to biochar samples and heating at 80 ℃ for 2 days until the solution was dry. This approach, also known as the Edinburgh Stability Tool, is used to simulate the oxidative property of biochar decomposition in soil. Simultaneously, K2Cr2O7 is utilized as an oxidant. It differs from the idea of utilizing H2O2 as an oxidant and is often used to assess biochar's antioxidant effectiveness (Knicker et al. 2007). Therefore, the R50 value, H2O2 or K2Cr2O7 oxidation carbon loss values were chosen as indicators of thermal and chemical oxidation resistance. The basic properties of biochar include volatile and fixed carbon content, elemental composition (O/C ratio and H/C ratio), specific surface area (the data were collected from our previous study (Zhang et al. 2022)), content of typical O-containing functional groups and phosphorus-containing functional groups (derived from the results of XPS peak splitting and peak area integration), and degree of graphitization (such as IG/ID), organic carbon speciation (recalcitrant carbon and refractory carbon) are all taken into consideration.

According to PCC analysis, there is a significant association (p ≤ 0.05) between the modified biochar's distinctive oxygen-containing functional groups (–OH, C=O, C–O, P=O, and P–O) and the degree of graphitization. This is mostly due to the presence of more heteroatoms in the structure of biochar with greater oxygen concentration. These heteroatoms not only obstruct the ordered organization of carbon atoms but also lower the concentration of aromatic carbon, so impairing biochar graphitization. Furthermore, there is no significant link (p > 0.05) between the chemical and thermal stability of modified biochar, showing that there are major changes in critical aspects between them. The R50 of various biochar is favorably connected (p ≤ 0.05) with fixed carbon content (0.96) and refractory organic carbon (0.98), but negatively correlated (p ≤ 0.05) with P=O content (− 0.96), P–O content (− 0.96), and recalcitrant carbon (− 0.96). This demonstrates that aromatic carbon, whether in the form of refractory organic carbon or inorganic carbon with better thermal stability, plays an important role in determining the thermal oxidation resistance stability of modified biochar. More aromatic carbon in biochar gives increased stability during thermal oxidation.

However, no significant relation was discovered between the carbon loss and the chemical composition, specific surface area, and organic carbon speciation of biochar. The sole significant factor was biochar's I(Sl+S+Sr+R)/ID, which was inversely linked (p ≤ 0.05) with biochar's chemical oxidation carbon loss, with the correlation coefficient of − 0.99 and − 0.98 for H2O2 or K2Cr2O7 oxidation. It stands to reason that the greater the degree of dehydrogenation and condensation polymerization of modified biochar's carbon skeleton, the lower the chemical oxidation carbon loss. This is mostly because C–C and C=C in the benzene ring structure are more stable than C=O, C–O, and C–H near the ring's edge, and are less prone to break bonds under high oxidizing conditions. Previous researchers have found a substantial relationship between biochar specific surface area, O/C or H/C ratio, and biochar's chemical stability (Liu et al. 2020). This is mostly because the biochar utilized in the preceding experiments was generated at lower temperatures (< 700 ℃), and the detrimental influence of high temperatures on the pore structure of biochar was not considered. Furthermore, these experiments do not entail the degradation of carbon structural integrity induced by the high-temperature doping of phosphorus atoms into the biochar skeleton. However, given the small sample size and several unquantifiable variables (such as the P doping impact), additional in-depth study is required to investigate the factors influencing the chemical stability of biochar.

3.7 Environmental significance

The addition of K3PO4 boosted the specific surface area and oxygen-containing functional group content of biochar, while additional phosphorus-containing groups were also introduced. According to our prior study, the larger specific surface area indicates a higher adsorption affinity for contaminants (Zhang et al. 2022). The ability of phosphate-modified biochar to adsorb heavy metals can be increased by 8 ~ 10 times. More oxygen-containing functional groups indicate that biochar can stabilize more heavy metals (HMs) via organic complexation (Miao and Li 2021). The phosphate group may form stable chelates and mineral precipitation with most HMs, preventing them from entering the organism body in ionic form (Zhang et al. 2020). Furthermore, biochar contains extremely few nutrients (N, K, and P), therefore adding exogenous phosphorus can boost biochar's nutritional availability to the soil. A previous study has shown that phosphorus-containing compounds are accumulated in the biochar pores, slowing the release of phosphorus (Liu et al. 2021). Compared to phosphate alone, phosphorus-loaded biochar can minimize phosphorus leaching by more than 50% (Zhang et al. 2021). However, this type of biochar is insufficient to be employed as a slow-release phosphate fertilizer, and encapsulation or coating can further regulate the release of phosphorus (Zhang et al. 2023). Although phosphorus-containing additives can significantly increase biochar's stability, we must also consider the environmental significance behind it. It must initially address the requirement for biochar to heal soil pollution, while concurrently evaluating the phosphorus release issue (Cui et al. 2022). In general, adding biochar with an acceptable phosphorus concentration to polluted or phosphorus-deficient soil can serve both soil remediation and carbon sequestration purposes.

4 Conclusion

To study the effect mechanism of phosphorous-containing additives on carbon structure evolution and biochar stability enhancement, the corncob was used as a typical biomass and K3PO4 was employed as a phosphorus-containing additive. A series of pyrolysis studies were performed in a fixed-bed microwave pyrolysis reactor at 350 ~ 950 ℃. The impact of K3PO4 addition on the chemical composition, organic functional groups, carbon skeleton, and graphite microcrystalline structure, as well as the thermal/chemical stability, was investigated. It is discovered that adding K3PO4 may effectively minimize the graphitization temperature range and increase biochar's yield, aromaticity, H/C ratio, and proportion of refractory/recalcitrant organic carbon. The 2D-PCIS and Raman analysis revealed that K3PO4 mostly promoted the dehydrogenation and polycondensation process of the aromatic rings in the char precursor, transforming the amorphous carbon structure of biochar into an ordered turbostratic microcrystalline structure.

Adding 20% K3PO4 boosted the R50 value of biochar by roughly 11% while also improving its thermal stability. The carbon loss induced by the oxidation of H2O2 and K2Cr2O7 diminished when the pyrolysis temperature rose from 350 to 750 ℃, and the carbon loss rate of KPBCs fell by 7.31% when compared to BCs. K3PO4 primarily enhanced the transition of unstable structures on biochar (such as volatile organic carbon) into stable carbon-containing structures (such as refractory organic carbon) at < 950 ℃. Above 950 ℃, KPBC's carbon loss rate rose and was approximately 1% greater than BC's. This might be related to the effect of phosphorus atom doping, which lowers the stability of the biochar structure. The findings of this study might help researchers better understand the mechanism of action of phosphorus-containing compounds in carbon sequestration during pyrolysis.

Data availability

The datasets used or analyzed during the current study are available from the corresponding author upon reasonable request.

References

Bartoli M, Troiano M, Giudicianni P et al (2022) Effect of heating rate and feedstock nature on electrical conductivity of biochar and biochar-based composites. Appl Energ Combust 12:100089. https://doi.org/10.1016/j.jaecs.2022.100089

Chen Y, Zhang X, Chen W, Yang H, Chen H (2017) The structure evolution of biochar from biomass pyrolysis and its correlation with gas pollutant adsorption performance. Fuel 246:101–109. https://doi.org/10.1016/j.biortech.2017.08.138

Chen H, Li W, Wang J, Xu H, Liu Y, Zhang Z et al (2019) Adsorption of cadmium and lead ions by phosphoric acid-modified biochar generated from chicken feather: selective adsorption and influence of dissolved organic matter. Bioresour Technol 292:121948. https://doi.org/10.1016/j.biortech.2019.121948

Chen F, Wang Y, Zheng L et al (2023) Hydrothermal liquefaction of lignocellulosic biomass with potassium phosphate and iron and their binary mixture: a comprehensive investigation on the yields and compositions of biocrude and solid residue. Bioresource Technol 386:129532. https://doi.org/10.1016/j.biortech.2023.129532

Cross A, Sohi SP (2013) A method for screening the relative long-term stability of biochar. Gcb Bioenergy 5(2):215–220. https://doi.org/10.1111/gcbb.12035

Cui H, Dong T, Hu L, Xia R, Zhou J (2022) Adsorption and immobilization of soil lead by two phosphate-based biochars and phosphorus release risk assessment. Sci Total Environ 824:153957. https://doi.org/10.1016/j.scitotenv.2022.153957

Gómez N, Rosas JG, Singh S, Ross AB, Sánchez ME, Cara A et al (2016) Development of a gained stability index for describing biochar stability: relation of high recalcitrance index (R50) with accelerated ageing tests. J Anal Appl Pyrol 120:37–44. https://doi.org/10.1016/j.jaap.2016.04.007

Harvey OR, Kuo LJ, Zimmerman AR, Louchouarn P, Amonette JE, Herbert BE (2012) An index-based approach to assessing recalcitrance and soil carbon sequestration potential of engineered black carbons (biochars). Environ Sci Technol 46:1415–1421. https://doi.org/10.1021/es2040398

Hassan M, Liu Y, Naidu R, Parikh SJ, Du J, Qi F et al (2020) Influences of feedstock sources and pyrolysis temperature on the properties of biochar and functionality as adsorbents: a meta-analysis. Sci Total Environ 744:140714. https://doi.org/10.1016/j.scitotenv.2020.140714

Huang P, Zhang P, Wang C, Du X, Jia H, Sun H (2023) P-doped biochar regulates nZVI nanocracks formation for superefficient persulfate activation. J Hazard Mater 450:130999. https://doi.org/10.1016/j.jhazmat.2023.130999

Jaffé R, Ding Y, Niggemann J, Vähätalo AV, Stubbins A, Spencer RG et al (2013) Global charcoal mobilization from soils via dissolution and riverine transport to the oceans. Science 340:345–347. https://doi.org/10.1126/science.1231476

Keown DM, Li XJ, Hayashi JI, Li C (2007) Characterization of the structural features of char from the pyrolysis of cane trash using Fourier transform-Raman spectroscopy. Energ Fuel 21:1816–1821. https://doi.org/10.1021/ef070049r

Kim HB, Kim JG, Kim T, Alessi DS, Baek K (2021) Interaction of biochar stability and abiotic aging: Influences of pyrolysis reaction medium and temperature. Chem Eng J 411:128441. https://doi.org/10.1016/j.cej.2021.128441

Knicker H, Müller P, Hilscher A (2007) How useful is chemical oxidation with dichromate for the determination of “Black Carbon” in fire-affected soils? Geoderma 142(1–2):178–196. https://doi.org/10.1016/j.geoderma.2007.08.010

Lee JW, Hawkins B, Day DM, Reicosky DC (2010) Sustainability: the capacity of smokeless biomass pyrolysis for energy production, global carbon capture and sequestration. Energ Environ Sci 3:1695–1705. https://doi.org/10.1039/C004561F

Leng L, Huang H, Li H, Li J, Zhou W (2019) Biochar stability assessment methods: a review. Sci Total Environ 647:210–222. https://doi.org/10.1016/j.scitotenv.2018.07.402

Li H, Hu J, Yao L et al (2020a) Ultrahigh adsorbability towards different antibiotic residues on fore-modified self-functionalized biochar: competitive adsorption and mechanism studies. J Hazard Mater 390:122127. https://doi.org/10.1016/j.jhazmat.2020.122127

Li S, Li S, Wang C, Zhu X (2020b) Catalytic effects of ammonium dihydrogen phosphate on the pyrolysis of lignocellulosic biomass: selective production of furfural and levoglucosenone. Fuel Process Technol 209:106525. https://doi.org/10.1016/j.fuproc.2020.106525

Liu G, Pan X, Ma X, Xin S, Xin Y (2020) Effects of feedstock and inherent mineral components on oxidation resistance of biochars. Sci Total Environ 726:138672. https://doi.org/10.1016/j.scitotenv.2020.138672

Liu Q, Li D, Cheng H, Cheng J, Du K (2021) High mesoporosity phosphorus-containing biochar fabricated from Camellia oleifera shells: impressive tetracycline adsorption performance and promotion of pyrophosphate-like surface functional groups (C-O-P bond). Bioresour Technol 329:124922. https://doi.org/10.1016/j.biortech.2021.124922

Lu Q, Zhang Z, Yang X, Dong C, Zhu X (2013) Catalytic fast pyrolysis of biomass impregnated with K3PO4 to produce phenolic compounds: analytical Py-GC/MS study. J Anal Appl Pyrol 104:139–145. https://doi.org/10.1016/j.jaap.2013.08.011

Lu Q, Zhang Z, Wang X, Guo H, Cui M, Yang Y (2018) Catalytic fast pyrolysis of biomass impregnated with potassium phosphate in a hydrogen atmosphere for the production of phenol and activated carbon. Front Chem 6:32. https://doi.org/10.3389/fchem.2018.00032

Luo Y, Li Z, Xu H, Qiu H, Cao X, Zhao L (2022) Development of phosphorus composite biochar for simultaneous enhanced carbon sink and heavy metal immobilization in soil. Sci Total Environ 831:154845. https://doi.org/10.1016/j.scitotenv.2022.154845

Lv D, Xu M, Liu X, Zhan Z, Li Z, Yao H (2010) Effect of cellulose, lignin, alkali and alkaline earth metallic species on biomass pyrolysis and gasification. Fuel Process Technol 91:903–909. https://doi.org/10.1016/j.fuproc.2009.09.014

Masiá AT, Buhre B, Gupta R, Wall T (2007) Characterising ash of biomass and waste. Fuel Process Technol 88:1071–1081. https://doi.org/10.1016/j.fuproc.2007.06.011

Miao Q, Li G (2021) Potassium phosphate/magnesium oxide modified biochars: interfacial chemical behaviours and Pb binding performance. Sci Total Environ 759:143452. https://doi.org/10.1016/j.scitotenv.2020.143452

Mohamed BA, Bi X, Li LY, Leng L, Salama ES, Zhou H (2021) Bauxite residue as a catalyst for microwave-assisted pyrolysis of switchgrass to high quality bio-oil and biochar. Chem Eng J 426:131294. https://doi.org/10.1016/j.cej.2021.131294

Nan H, Yang F, Zhao L et al (2018) (2018) Interaction of inherent minerals with carbon during biomass pyrolysis weakens biochar carbon sequestration potential. ACS Sustain Chem Eng 7(1):1591–1599. https://doi.org/10.1021/acssuschemeng.8b05364

Nan H, Mašek O, Yang F, Xu X, Qiu H, Cao X et al (2022) Minerals: a missing role for enhanced biochar carbon sequestration from the thermal conversion of biomass to the application in soil. Earth Sci Rev. https://doi.org/10.1016/j.earscirev.2022.104215

Pogorzelski D, Filho J, Matias P, Santos W, Vergütz L (2020) Biochar as composite of phosphate fertilizer: characterization and agronomic effectiveness. Sci Total Environ 743:140604. https://doi.org/10.1016/j.scitotenv.2020.140604

Qi H, Yang Q, Li Z, Yang C, Ma X, Ben H et al (2022) Reaction mechanism of syngas produced via pyrolysis of enteromorpha polysaccharides. J Anal Appl Pyrol 167:105634. https://doi.org/10.1016/j.jaap.2022.105634

Qu J, Li Z, Bi F et al (2023) A multiple Kirkendall strategy for converting nanosized zero-valent iron to highly active Fenton-like catalyst for organics degradation. Proc Natl Acad Sci 120(39):e2304552120. https://doi.org/10.1073/pnas.2304552120

Ren L, Wang F, Cheng F, Yang F, Zhang K (2023) Mechanisms of gas generation from conventional and microwave pyrolysis of coal slime. Chem Eng J 452:139388. https://doi.org/10.1016/j.cej.2022.139388

Rosa L, Sanchez DL, Mazzotti MJ (2021) Assessment of carbon dioxide removal potential via BECCS in a carbon-neutral Europe. Science 14:3086–3097. https://doi.org/10.1039/D1EE00642H

Tian H, Chen L, Huang Z, Cheng S, Yang Y (2022) Increasing the bio-aromatics yield in the biomass pyrolysis oils by the integration of torrefaction deoxygenation pretreatment and catalytic fast pyrolysis with a dual catalyst system. Appl Energ 187:561–571. https://doi.org/10.1016/j.renene.2022.01.096

Tumbure A, Bishop B, Bretherton M, Hedley M (2020) Co-pyrolysis of maize stover and igneous phosphate rock to produce potential biochar-based phosphate fertilizer with improved carbon retention and liming value. ACS Sustain Chem Eng 8:4178–4184. https://doi.org/10.1021/acssuschemeng.9b06958

Valero-Romero MJ, García-Mateos FJ, Rodríguez-Mirasol J et al (2017) Role of surface phosphorus complexes on the oxidation of porous carbons. Fuel Process Technol 157:116–126. https://doi.org/10.1016/j.fuproc.2016.11.014

Vijayaraghavan K (2019) Recent advancements in biochar preparation, feedstocks, modification, characterization and future applications. Environ Technol Rews 8:47–64. https://doi.org/10.1080/21622515.2019.1631393

Wang S, Dai G, Yang H, Luo Z (2017) Lignocellulosic biomass pyrolysis mechanism: a state-of-the-art review. Prog Energ Combust 62:33–86. https://doi.org/10.1016/j.pecs.2017.05.004

Wang L, O’Connor D, Rinklebe JrOkTsangShen JYSDCZ et al (2020) Biochar aging: mechanisms, physicochemical changes, assessment, and implications for field applications. Environ Sci Technol 54:14797–14814. https://doi.org/10.1021/acs.est.0c04033

Wang C, Holm PE, Andersen ML et al (2023) Phosphorus doped cyanobacterial biochar catalyzes efficient persulfate oxidation of the antibiotic norfloxacin. Bioresour Technol 388:129785. https://doi.org/10.1016/j.biortech.2023.129785

Wu Y, Gui Q, Zhang H, Li H, Li B, Liu M et al (2023) Effect of biomass components’ interaction on the pyrolysis reaction kinetics and small-molecule product release characteristics. J Anal Appl Pyrol 173:106039. https://doi.org/10.1016/j.jaap.2023.106039

Xiao X, Chen B, Zhu L (2014) Transformation, morphology, and dissolution of silicon and carbon in rice straw-derived biochars under different pyrolytic temperatures. Environ Sci Technol 48:3411–3419. https://doi.org/10.1021/es405676h

Xu J, Liu J, Ling P, Zhang X, Xu K, He L et al (2020) Raman spectroscopy of biochar from the pyrolysis of three typical Chinese biomasses: a novel method for rapidly evaluating the biochar property. Energy 202:117644

Xue P, Liu M, Yang H, Zhang H, Chen Y, Hu Q et al (2023) Mechanism study on pyrolysis interaction between cellulose, hemicellulose, and lignin based on photoionization time-of-flight mass spectrometer (PI-TOF-MS) analysis. Fuel 338:127276. https://doi.org/10.1016/j.fuproc.2023.107701

Yang F, Zhao L, Gao B, Xu X, Cao X (2016) The interfacial behavior between biochar and soil minerals and its effect on biochar stability. Environ Sci Technol 50:2264–2271. https://doi.org/10.1021/acs.est.5b03656

Yang L, Tan WF, Mumford K, Ding L, Lv JW, Zhang XW et al (2018) Effects of phosphorus-rich sawdust biochar sorption on heavy metals. Sep Sci Technol 53:2704–2716. https://doi.org/10.1080/01496395.2018.1470641

Zaror CA, Hutchings IS, Pyle DL et al (1985) Secondary char formation in the catalytic pyrolysis of biomass. Fuel 64(7):990–994. https://doi.org/10.1016/0016-2361(85)90156-5

Zhang H, Shao J, Zhang S, Zhang X, Chen H (2020) Effect of phosphorus-modified biochars on immobilization of Cu (II), Cd (II), and As (V) in paddy soil. J Hazard Mater 390:121349. https://doi.org/10.1016/j.jhazmat.2019.121349

Zhang H, Ke S, Xia M, Bi X, Shao J, Zhang S (2021) Effects of phosphorous precursors and speciation on reducing bioavailability of heavy metal in paddy soil by engineered biochars. Environ Pollut 285:117459. https://doi.org/10.1016/j.envpol.2021.117459

Zhang H, Liao W, Zhou X, Shao J, Chen Y, Zhang S et al (2022) Coeffect of pyrolysis temperature and potassium phosphate impregnation on characteristics, stability, and adsorption mechanism of phosphorus-enriched biochar. Bioresour Technol 344:126273. https://doi.org/10.1016/j.biortech.2021.126273

Zhang H, Yang H, Shao J, Chen Y, Zhang S, Chen H (2023) Multifunctional carboxymethyl cellulose sodium encapsulated phosphorus-enriched biochar composites: multistage adsorption of heavy metals and controllable release of soil fertilization. Chem Eng J 453:139809. https://doi.org/10.1016/j.cej.2022.139809

Zhurinsh A, Dobele G, Pomilovskis R, Volperts A, Jurkjane V (2021) Evolution of 1, 6-anhydrosugars in the pyrolysis of biomass with phosphoric acid and P-containing activated carbon. Catal Today 367:51–57. https://doi.org/10.1016/j.cattod.2020.09.032

Acknowledgements

The authors wish to express their great appreciation for the financial support from the National Natural Science Foundation of China, the China Postdoctoral Science Foundation, and the Postdoctoral Innovative Research Position of Hubei Province. The study also benefits from the technical support from the Analytical and Testing Center at Huazhong University of Science & Technology (http://atc.hust.edu.cn).

Funding

This study was funded by the National Natural Science Foundation of China (52306243, 52125601) and the China Postdoctoral Science Foundation (2023M731182).

Author information

Authors and Affiliations

Contributions

Conceptualization, Methodology, Investigation, Visualization, and Writing-Original Draft were performed by Haiping Yang, Yamian Yu, Wanwan Wang and Han Zhang. The first draft of the manuscript was written by Han Zhang. Review and Editing were performed by Wanwan Wang, Jinjiao Zhu, Yingquan Chen, Shihong Zhang, and Hanping Chen. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Handling editor: Jun Meng

Supplementary Information

Additional file 1: Text S1.

2D-PCIS analysis. Text S2. Methods for calculating crystal size. Table S1. Noda’s rule. Table S2. Ultimate analysis results of samples. Table S3. The FTIR functional groups in studied biochars. Table S4. The Raman functional groups in studied biochars. Table S5. Correlation coefficient and probability values of among the physic-chemical properties of biochar. Fig. S1. FTIR spectrum of samples prepared at various temperatures. Fig. S2. 2D-PCIS spectrum of BCs prepared at various temperatures. Fig. S3. Peak splitting results for BCs prepared at different temperatures. Fig. S4. Peak splitting results for KPBCs prepared at different temperatures.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Yang, H., Yu, Y., Zhang, H. et al. Effect mechanism of phosphorous-containing additives on carbon structure evolution and biochar stability enhancement. Biochar 6, 39 (2024). https://doi.org/10.1007/s42773-024-00330-5

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42773-024-00330-5