Abstract

Developing efficient microbiological methods to convert polysaccharide-rich materials into fermentable sugars, particularly monosaccharides, is vital for advancing the bioeconomy and producing renewable chemicals and energy sources. This study focused on optimizing the production conditions of an enzyme cocktail from Aspergillus niger ATCC 9642 using solid-state fermentation (SSF) and assessing its effectiveness in saccharifying mango peels through a simple, rapid, and efficient one-step process. A rotatable central composite design was employed to determine optimal conditions of moisture, time, and pH for enzyme production in SSF medium. The optimized enzyme cocktail exhibited cellulase activity (CMCase) at 6.28 U/g, filter paper activity (FPase) at 3.29 U/g, and pectinase activity at 117.02 U/g. These optimal activities were achieved with an SSF duration of 81 h, pH of 4.66, and a moisture content of 59%. The optimized enzyme cocktail effectively saccharified the mango peels without the need for chemical agents. The maximum saccharification yield reached approximately 81%, indicating efficient conversion of mango peels into sugars. The enzyme cocktail displayed consistent thermal stability within the tested temperature range of 30-60°C. Notably, the highest sugar release occurred within 36 h, with glucose, arabinose, galactose, and xylose being the primary monosaccharides released during saccharification. This study highlights the potential application of Aspergillus niger ATCC 9642 and SSF for enzymatic production, offering a simple and high-performance process for monosaccharide production. The optimized enzyme cocktail obtained through solid-state fermentation demonstrated efficient saccharification of mango peels, suggesting its suitability for industrial-scale applications.

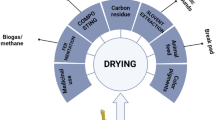

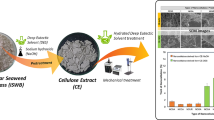

Graphical Abstract

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Ravindran R, Hassan SS, Williams GA, Jaiswal AK (2018) A review on bioconversion of agro-industrial wastes to industrially important enzymes. Bioengineering (Basel) 5:93. https://doi.org/10.3390/bioengineering5040093

Diaz AB, Blandino A, Caro I (2018) Value added products from fermentation of sugars derived from agro-food residues. Trends Food Sci Technol 71:52–64. https://doi.org/10.1016/j.tifs.2017.10.016

Geng B, Jia X, Peng X, Han Y (2022) Biosynthesis of value-added bioproducts from hemicellulose of biomass through microbial metabolic engineering. Metab Eng Commun 15:e00211. https://doi.org/10.1016/j.mec.2022.e00211

Lin C-Y, Eudes A (2020) Strategies for the production of biochemicals in bioenergy crops. Biotechnol Biofuels 13:71. https://doi.org/10.1186/s13068-020-01707-x

Sadh PK, Duhan S, Duhan JS (2018) Agro-industrial wastes and their utilization using solid state fermentation: a review. Bioresour Bioprocess 5:1. https://doi.org/10.1186/s40643-017-0187-z

Zahid HF, Ranadheera CS, Fang Z, Ajlouni S (2021) Utilization of mango, apple and banana fruit peels as prebiotics and functional ingredients. Agriculture 11:584. https://doi.org/10.3390/agriculture11070584

Ajila CM, Prasada Rao UJS (2013) Mango peel dietary fibre: composition and associated bound phenolics. J Funct Foods 5:444–450. https://doi.org/10.1016/j.jff.2012.11.017

Marçal S, Pintado M (2021) Mango peels as food ingredient / additive: nutritional value, processing, safety and applications. Trends Food Sci Technol 114:472–489. https://doi.org/10.1016/j.tifs.2021.06.012

Serna Cock L, Torres León C (2015) Potencial agroindustrial de cáscaras de mango (Mangifera indica) variedades Keitt y Tommy Atkins. Acta Agron 64:110–115. https://doi.org/10.15446/acag.v64n2.43579

Banerjee S, Arora A (2021) Sustainable bioprocess technologies for urban waste valorization. Case Stud Chem Environ Eng 4:100166. https://doi.org/10.1016/j.cscee.2021.100166

Ungureanu N, Vlăduț V, Biriș SȘ (2022) Sustainable valorization of waste and by-products from sugarcane processing. Sustainability 14:11089. https://doi.org/10.3390/su141711089

Kim JS, Lee YY, Kim TH (2016) A review on alkaline pretreatment technology for bioconversion of lignocellulosic biomass. Bioresour Technol 199:42–48. https://doi.org/10.1016/j.biortech.2015.08.085

Kumar AK, Sharma S (2017) Recent updates on different methods of pretreatment of lignocellulosic feedstocks: a review. Bioresour Bioprocess 4:7. https://doi.org/10.1186/s40643-017-0137-9

Scarpa JD, Marques NP, Monteiro DA et al (2019) Saccharification of pretreated sugarcane bagasse using enzymes solution from Pycnoporus sanguineus MCA 16 and cellulosic ethanol production. Ind Crop Prod 141:111795. https://doi.org/10.1016/j.indcrop.2019.111795

Ghaffar A, Yameen M, Aslam N et al (2017) Acidic and enzymatic saccharification of waste agricultural biomass for biotechnological production of xylitol. Chem Cent J 11:97. https://doi.org/10.1186/s13065-017-0331-z

Osuna-Laveaga DR, García-Depraect O, Vallejo-Rodríguez R et al (2020) Integrated ozonation-enzymatic hydrolysis pretreatment of sugarcane bagasse: Enhancement of sugars released to expended ozone ratio. Processes 8:1274. https://doi.org/10.3390/pr8101274

Gandla ML, Martín C, Jönsson LJ (2018) Analytical enzymatic saccharification of lignocellulosic biomass for conversion to biofuels and bio-based chemicals. Energies 11:2936. https://doi.org/10.3390/en11112936

Navarro RR, Otsuka Y, Nojiri M et al (2018) Simultaneous enzymatic saccharification and comminution for the valorization of lignocellulosic biomass toward natural products. BMC Biotechnol 18:79. https://doi.org/10.1186/s12896-018-0487-1

Marques NP, de Cassia PJ, Gomes E, da Silva R, Araújo AR, Ferreira H, Rodrigues A, Dussán KJ, Bocchini DA (2018) Cellulases and xylanases production by endophytic fungi by solid state fermentation using lignocellulosic substrates and enzymatic saccharification of pretreated sugarcane bagasse. Ind Crop Prod 122:66–75. https://doi.org/10.1016/j.indcrop.2018.05.02

Oberoi HS, Sandhu SK, Vadlani PV (2012) Statistical optimization of hydrolysis process for banana peels using cellulolytic and pectinolytic enzymes. Food Bioprod Process 90:257–265. https://doi.org/10.1016/j.fbp.2011.05.002

Scott BR, Huang HZ, Frickman J et al (2016) Catalase improves saccharification of lignocellulose by reducing lytic polysaccharide monooxygenase-associated enzyme inactivation. Biotechnol Lett 38:425–434. https://doi.org/10.1007/s10529-015-1989-8

Martínez-Trujillo MA, Bautista-Rangel K, García-Rivero M et al (2020) Enzymatic saccharification of banana peel and sequential fermentation of the reducing sugars to produce lactic acid. Bioprocess Biosyst Eng 43:413–427. https://doi.org/10.1007/s00449-019-02237-z

Li P, Xia J, Nie Z, Shan Y (2016) Saccharification of orange peel wastes with crude enzymes from new isolated Aspergillus japonicus PJ01. Bioprocess Biosyst Eng 39:485–492. https://doi.org/10.1007/s00449-015-1531-3

Chilakamarry CR, Mimi Sakinah AM, Zularisam AW et al (2022) Advances in solid-state fermentation for bioconversion of agricultural wastes to value-added products: opportunities and challenges. Bioresour Technol 343:126065. https://doi.org/10.1016/j.biortech.2021.126065

Oiza N, Moral-Vico J, Sánchez A et al (2022) Solid-state fermentation from organic wastes: a new generation of bioproducts. Processes 10:2675. https://doi.org/10.3390/pr10122675

Salikin NH, Makhtar MMZ (2022) Microbial factory; utilization of pectin-rich agro-industrial wastes for the production of pectinases enzymes through Solid State Fermentation (SSF). In: Yaser AZ, Tajarudin HA, Embrandiri A (eds) Waste management, processing and valorisation. Springer, Singapore, pp 175–206

Desai SV, Patil LR, Hombalimath VS et al (2022) Bioprocessing of agricultural waste (Banana Pseudostem) by Solid-State Fermentation (SSF) for production of cellulase. J Pharm Res Int 15–26. https://doi.org/10.9734/jpri/2022/v34i5A35405

Kumar V, Ahluwalia V, Saran S et al (2021) Recent developments on solid-state fermentation for production of microbial secondary metabolites: Challenges and solutions. Bioresour Technol 323:124566. https://doi.org/10.1016/j.biortech.2020.124566

Leite P, Sousa D, Fernandes H et al (2021) Recent advances in production of lignocellulolytic enzymes by solid-state fermentation of agro-industrial wastes. Curr Opin Green Sustain Chem 27:100407. https://doi.org/10.1016/j.cogsc.2020.100407

Couri S, Farias AX (1995) Genetic manipulation of aspergillus niger for increased synthesis of pectinolytic enzymes. Rev Microbiol 26:314–317

Shrestha P, Ibáñez AB, Bauer S et al (2015) Fungi isolated from Miscanthus and sugarcane: biomass conversion, fungal enzymes, and hydrolysis of plant cell wall polymers. Biotechnol Biofuels 8:38. https://doi.org/10.1186/s13068-015-0221-3

AOAC (1998) Association of Official Analytical Chemists (AOAC). Official methods of analysis of the association of analytical chemists, 16th edn. Association of Official Analytical Chemists, Washington, DC

Browning BL (1967) Methods of wood chemistry. John Wiley & Sons, Incorporated

Camargo LA, Pereira SC, Correa AC, Farinas CS, Marconcini JM, Mattoso LHC (2016) Feasibility of manufacturing cellulose nanocrystals from the solid residues of second-generation ethanol production from sugarcane bagasse. Bioenergy Res 9:894–906. https://doi.org/10.1007/s12155-016-9744-0

Gao J, Weng H, Zhu D et al (2008) Production and characterization of cellulolytic enzymes from the thermoacidophilic fungal Aspergillus terreus M11 under solid-state cultivation of corn stover. Bioresour Technol 99:7623–7629. https://doi.org/10.1016/j.biortech.2008.02.005

Mrudula S, Murugammal R (2011) Production of cellulase by Aspergillus niger under submerged and solid state fermentation using coir waste as a substrate. Braz J Microbiol 42:1119–1127. https://doi.org/10.1590/S1517-838220110003000033

Yupanqui-Mendoza SL, Vaz de Arruda P, Castelo da Silva GM (2022) Statistical sequential optimization of process parameters for inulinase production by Kluyveromyces marxianus ATCC 36907 in solid-state fermentation using beer residue. Biocatal Agric Biotechnol 39:102252. https://doi.org/10.1016/j.bcab.2021.102252

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428. https://doi.org/10.1021/ac60147a030

Rodríguez-Fernández DE, Rodríguez-León JA, de Carvalho JC et al (2011) The behavior of kinetic parameters in production of pectinase and xylanase by solid-state fermentation. Bioresour Technol 102:10657–10662. https://doi.org/10.1016/j.biortech.2011.08.106

Wang J, Chio C, Chen X, Su E, Cao F, Jin Y, Qin W (2019) Efficient saccharification of agave biomass using Aspergillus niger produced low-cost enzyme cocktail with hyperactive pectinase activity. Bioresour Technol 272:26–33. https://doi.org/10.1016/j.biortech.2018.09.069

Berardini N, Knödler M, Schieber A, Carle R (2005) Utilization of mango peels as a source of pectin and polyphenolics. Innovative Food Sci Emerg Technol 6:442–452. https://doi.org/10.1016/j.ifset.2005.06.004

Chaiwarit T, Masavang S, Mahe J et al (2020) Mango (cv. Nam Dokmai) peel as a source of pectin and its potential use as a film-forming polymer. Food Hydrocoll 102:105611. https://doi.org/10.1016/j.foodhyd.2019.105611

Filho LBS, Coelho RC, Muniz EC, HDS B (2022) Optimization of pectin extraction using response surface methodology: a bibliometric analysis. Carbohydr Polym Technol Appl 4:100229. https://doi.org/10.1016/j.carpta.2022.100229

Wongkaew M, Kittiwachana S, Phuangsaijai N et al (2021) Fruit characteristics, peel nutritional compositions, and their relationships with mango peel pectin quality. Plants 10:1148. https://doi.org/10.3390/plants10061148

Indrayan A (2012) Medical Biostatistics. CRC Press

Kumar A, Naraian R (2019) Chapter 6 - Differential expression of the microbial β-1,4-Xylanase, and β-1,4-Endoglucanase genes. In: Singh HB, Gupta VK, Jogaiah S (eds) New and future developments in microbial biotechnology and bioengineering. Elsevier, Amsterdam, pp 95–111

Nagl M, Haske-Cornelius O, Skopek L et al (2021) Biorefining: the role of endoglucanases in refining of cellulose fibers. Cellulose 28:7633–7650. https://doi.org/10.1007/s10570-021-04022-2

Kumar A, Dutt D, Gautam A (2016) Production of crude enzyme from Aspergillus nidulans AKB-25 using black gram residue as the substrate and its industrial applications. J Genet Eng Biotechnol 14:107–118. https://doi.org/10.1016/j.jgeb.2016.06.004

Bonnin E, Alvarado C, Crépeau M-J et al (2019) Mobility of pectin methylesterase in pectin/cellulose gels is enhanced by the presence of cellulose and by its catalytic capacity. Sci Rep 9:12551. https://doi.org/10.1038/s41598-019-49108-x

Cruz-Paredes C, Tájmel D, Rousk J (2021) Can moisture affect temperature dependences of microbial growth and respiration?. Soil Biol Biochem 156:108223. https://doi.org/10.1016/j.soilbio.2021.108223

He Q, Peng H, Sheng M et al (2019) Humidity control strategies for solid-state fermentation: capillary water supply by water-retention materials and negative-pressure auto-controlled irrigation. Front Bioeng Biotechnol 7:263. https://doi.org/10.3389/fbioe.2019.00263

Oumer OJ, Abate D (2018) Comparative studies of pectinase production by bacillus subtilis strain Btk 27 in submerged and solid-state fermentations. Biomed Res Int 2018:1514795. https://doi.org/10.1155/2018/1514795

Patidar MK, Nighojkar S, Kumar A, Nighojkar A (2018) Pectinolytic enzymes-solid state fermentation, assay methods and applications in fruit juice industries: a review. 3 Biotech 8:199. https://doi.org/10.1007/s13205-018-1220-4

Webb C, Manan M (2017) Design aspects of solid state fermentation as applied to microbial bioprocessing. J Appl Biotechnol Bioeng 4:511–532. https://doi.org/10.15406/jabb.2017.04.00094

Balkan B, Ertan F (2007) Production of a-amylase from penicillium chrysogenum under solid-state fermentation by using some agricultural by-products. Food Technol Biotechnol 45:439–442

Prabhu G, Bhat D, Bhat RM, Selvaraj S (2022) A critical look at bioproducts co-cultured under solid state fermentation and their challenges and industrial applications. Waste Biomass Valor 13:3095–3111. https://doi.org/10.1007/s12649-022-01721-0

Darabzadeh N, Hamidi-Esfahani Z, Hejazi P (2019) Optimization of cellulase production under solid-state fermentation by a new mutant strain of Trichoderma reesei. Food Sci Nutr 7:572–578. https://doi.org/10.1002/fsn3.852

Lodha A, Pawar S, Rathod V (2020) Optimised cellulase production from fungal co-culture of Trichoderma reesei NCIM 1186 and Penicillium citrinum NCIM 768 under solid state fermentation. J Environ Chem Eng 8:103958. https://doi.org/10.1016/j.jece.2020.103958

Praveen KD (2020) Parametric optimizations for pectinase production by Aspergillus awamori. GSC Biol Pharm Sci 12:93–98. https://doi.org/10.30574/gscbps.2020.12.2.0247

Zehra M, Syed MN, Sohail M (2020) Banana peels: a promising substrate for the coproduction of pectinase and xylanase from aspergillus fumigatus MS16. Pol J Microbiol 69:19–26. https://doi.org/10.33073/pjm-2020-002

Goukanapalle PKR, Kanderi DK, Rajoji G et al (2020) Optimization of cellulase production by a novel endophytic fungus Pestalotiopsis microspora TKBRR isolated from Thalakona forest. Cellulose 27:6299–6316. https://doi.org/10.1007/s10570-020-03220-8

Amaeze NJ, Okoliegbe IN, Francis ME (2015) Cellulase production by Aspergillus niger and Saccharomyces cerevisiae using fruit wastes as substrates. IJAMBR 3:36–44

Ezugwu AL, Ezike TC, Ibeawuchi AN et al (2014) Comparative studies on pectinases obtained from Aspergillus fumigatus and Aspergillus niger in submerged fermentation system using pectin extracted from mango, orange and pineapple peels as carbon sources. Niger J Biotechnol 28:26–34. https://doi.org/10.4314/njb.v28i1

Kc S, Upadhyaya J, Joshi DR et al (2020) Production, characterization, and industrial application of pectinase enzyme isolated from fungal strains. Fermentation 6:59. https://doi.org/10.3390/fermentation6020059

El Enshasy HA, Elsayed EA, Suhaimi N et al (2018) Bioprocess optimization for pectinase production using Aspergillus niger in a submerged cultivation system. BMC Biotechnol 18:71. https://doi.org/10.1186/s12896-018-0481-7

Lin C, Shen Z, Qin W (2017) Characterization of xylanase and cellulase produced by a newly isolated aspergillus fumigatus n2 and its efficient saccharification of barley straw. Appl Biochem Biotechnol 182:559–569. https://doi.org/10.1007/s12010-016-2344-9

Sulyman AO, Igunnu A, Malomo SO (2020) Isolation, purification and characterization of cellulase produced by Aspergillus niger cultured on Arachis hypogaea shells. Heliyon 6:e05668. https://doi.org/10.1016/j.heliyon.2020.e05668

Thite VS, Nerurkar AS (2020) Crude xylanases and pectinases from bacillus spp. along with commercial cellulase formulate an efficient tailor-made cocktail for sugarcane bagasse saccharification. Bioenergy Res 13:286–300. https://doi.org/10.1007/s12155-019-10050-5

Da Silva PO, De Alencar Guimarães NC, Serpa JDM et al (2019) Application of an endo-xylanase from Aspergillus japonicus in the fruit juice clarification and fruit peel waste hydrolysis. Biocatal Agric Biotechnol 21:101312. https://doi.org/10.1016/j.bcab.2019.101312

Marzo C, Díaz AB, Caro I, Blandino A (2019) Valorization of agro-industrial wastes to produce hydrolytic enzymes by fungal solid-state fermentation. Waste Manage Res: J Sustain Circ Econ 37(2):149–156. https://doi.org/10.1177/0734242X18798699

Jang Y, Lee K, Yoo H (2021) Improved sugar recovery from orange peel by statistical optimization of thermo-alkaline pretreatment. Processes 9(3):409. https://doi.org/10.3390/pr9030409

Utekar PG, Kininge MM, Gogate PR (2021) Intensification of delignification and enzymatic hydrolysis of orange peel waste using ultrasound for enhanced fermentable sugar production. Chem Eng Process Process Intensif 168:108556. https://doi.org/10.1016/j.cep.2021.108556

Macedo KM, Azevedo RA, Da Silva EG et al (2023) Saccharification of agricultural wastes and clarification of orange juice by penicillium rolfsii CCMB 714 pectinase. Fermentation 9(10):917. https://doi.org/10.3390/fermentation9100917

Santos Gomes MMOD, Nicodemos IS, Costa Silva MD et al (2024) Optimization of enzymatic saccharification of industrial wastes using a thermostable and halotolerant endoglucanase through Box-Behnken experimental design. Prep Biochem Biotechnol 54(1):1–11. https://doi.org/10.1080/10826068.2023.2201936

Karp SG, Rozhkova AM, Semenova MV, Osipov DO et al (2021) Designing enzyme cocktails from Penicillium and Aspergillus species for the enhanced saccharification of agro-industrial wastes. Bioresour Technol 330:124888. https://doi.org/10.1016/j.biortech.2021.124888

Pinheiro VE, Horváth IS, Lundin M, Polizeli M (2021) Screening and cocktail optimization using experimental mixture design: Enzymatic saccharification as a biological pretreatment strategy. Biofuels Bioprod Biorefin 15(5):1447–1460. https://doi.org/10.1002/bbb.2251

Chaudhari R, Khadke P, Joglekar S, Pathak PD (2023) Applications of life cycle assessment in biorefinery: Case study on mango peel waste biorefinery. In: Pathak PD, Mandavgane SA (eds) Biorefinery: A Sustainable Approach for the Production of Biomaterials. Biochemicals and Biofuels Springer Nature, Singapore, pp 359–375. https://doi.org/10.1007/978-981-19-7481-6_13

de Oliveira JAR, da Conceição AC, da Silva Martins LH et al (2021) Evaluation of the technological potential of four wastes from Amazon fruit industry in glucose and ethanol production. J Food Process Eng 44:e13610. https://doi.org/10.1111/jfpe.13610

Favaretto DPC, Rempel A, Lanzini JR et al (2023) Fruit residues as biomass for bioethanol production using enzymatic hydrolysis as pretreatment. World J Microbiol Biotechnol 39:144. https://doi.org/10.1007/s11274-023-03588-2

John I, Pola J, Muthukumar K, Thanabalan M, Appusamy A (2022) Production of bioethanol from sweet lime peel via a statistically optimized simultaneous saccharification and fermentation process using isolated enzymes. Energy Sources A: Recovery Util Environ Eff 44:1327–1335. https://doi.org/10.1080/15567036.2019.1640811

Kaur B, Panesar PS, Anal AK, Chu-Ky S (2023) Recent trends in the management of mango by-products. Food Rev Intl 39:4159–4179. https://doi.org/10.1080/87559129.2021.2021935

Lorenci A, Dalmas Neto CJ, Porto L et al (2020) Lignocellulosic biomass: Acid and alkaline pretreatments and their effects on biomass recalcitrance – Conventional processing and recent advances. Bioresour Technol 304:122848. https://doi.org/10.1016/j.biortech.2020.122848

Manhongo TT, Chimphango A, Thornley P, Röder M (2021) Techno-economic and environmental evaluation of integrated mango waste biorefineries. J Clean Prod 325:129335. https://doi.org/10.1016/j.jclepro.2021.129335

Mujtaba M, Fernandes L, Fazeli M et al (2023) Lignocellulosic biomass from agricultural waste to the circular economy: a review with focus on biofuels, biocomposites and bioplastics. J Clean Prod 402:136815. https://doi.org/10.1016/j.jclepro.2023.136815

Palacios AS, Ilyina A, Ramos-González R, Aguilar CN et al (2021) Ethanol production from banana peels at high pretreated substrate loading: comparison of two operational strategies. Biomass Convers Biorefinery 11:1587–1596. https://doi.org/10.1007/s13399-019-00562-7

Safwan A, Shaharuddin S, Razealy M et al (2018) Extraction of glucose by using alkaline hydrolysis from Musa Sapientum Peels, Ananas Comosus and Mangifera Indica Linn. Materials today: proceedings, the 3rd International conference on green chemical engineering and technology (3rd GCET): Materials science, 07-08 November 2017 5:22148–22153. https://doi.org/10.1016/j.matpr.2018.07.083

Shukla A, Kumar D, Girdhar M, Kumar A et al (2023) Strategies of pretreatment of feedstocks for optimized bioethanol production: distinct and integrated approaches. Biotechnol Biofuels Bioprod 16:44. https://doi.org/10.1186/s13068-023-02295-2

Ullah AA, Noreen S, Zohra RR, Kazmi SK (2023) Improved production of bioethanol from alkali-pretreated lignocellulosic feedstock using Saccharomyces cerevisiae under simultaneous saccharification and fermentation. Int J Biol Chem 16:96–103. https://doi.org/10.26577/ijbch.2023.v16.i1.010

Varghese S, Demeke MM, Verhé R et al (2023) Process optimization for saccharification and fermentation of the Organic Fraction of Municipal Solid Waste (OFMSW) to maximize ethanol production performance. Bioresour Technol Rep 24:101681. https://doi.org/10.1016/j.biteb.2023.101681

Funding

The work was supported by the OAS-GCUB (Organization of American States- International Cooperation Group of Brazilian Universities) scholarship program (Coimbra Group of Brazilian Universities). S.L.Y.M. and B.L.C. acknowledge the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior-Brasil (CAPES)-Financing Code 001 and the Fundação de Amparo à Pesquisa do Estado de São Paulo (FAPESP) (2021/04324-1) for financial support through grants. B.J.S.M. and A.P.C.A. acknowledge the special fund of the Universidad Nacional del Santa for the purchase of equipment during the research.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. The data collection, material preparation, performance of experiments, interpretation of results and writing of the manuscript were performed by Sergio Luis Yupanqui Mendoza and Benji Jhonatan Sánchez Moncada. The revisions to the scientific content, stylistic/grammatical revisions to manuscript and supervision of experiments were performed by Angel Pablo Castro Alvarado and Bruno Las-Casas. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this research paper.

Additional information

Responsible Editor: Gisele Monteiro

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

ESM 1

(DOCX 3046 kb)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yupanqui-Mendoza, S.L., Sánchez-Moncada, B.J., Las-Casas, B. et al. Simple one-step treatment for saccharification of mango peels using an optimized enzyme cocktail of Aspergillus niger ATCC 9642. Braz J Microbiol (2024). https://doi.org/10.1007/s42770-024-01303-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42770-024-01303-3