Abstract

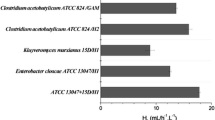

Microbial electrolysis cell (MEC) is a potential technology to meet the increasing interest in finding new sources of energy that will not harm the environment. MEC is an alternative energy conversion technology for the production of biofuels. It is possible to produce hydrogen by fermenting biogenous wastes with hydrogen-producing bacteria. This study investigated the biohydrogen production from co-substrates using electrogenic bacteria such as Escherichia coli, Salmonella bongori, and Shewanella oneidensis in pure culture and as a co-culture, which has the potential to be used as co-substrate in MECs. Briefly, 150 mL working-volume reactors were constructed for batch biohydrogen production. The hydrogen production rate (HPR) from the co-substrate was maximum at a ratio of 75:25 g/L with a co-culture of 2.35 mL/(L h). Fabricated a single-chamber membrane-free microelectrolysis cell to evaluate the power density, current density, voltage, HPR, chemical oxygen demand (COD) removal efficiency and Columbic efficiency. Scanning electron microscope (SEM) imaging confirmed the binding of electrogenic bacteria to anode and cathode. The efficiency of electrical conductivity of MEC was analyzed by three different electrodes, namely, nickel, copper and aluminum. The HPR was high using nickel when compared to the other two electrodes. The HPR of a single chamber using a nickel electrode was 2.8 HPR ml/L H2 d−1 and provided a power density of 17.7 mW/m2 at pH 7. This study suggests that the nickel cathode in a single chamber could be a promising sustainable source for stable power generation.

Graphical abstract

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this published article.

References

Gawusu, S., Zhang, X., Jamatutu, S.A., et al. 2022. The dynamics of green supply chain management within the framework of renewable energy. International Journal of Energy Research 46: 684–711. https://doi.org/10.1002/er.7278.

Xu, S., Yin, Z., Zhang, H., et al. 2022. Research on performance optimization method of proton exchange membrane fuel cell for vehicle. Highlights in Science, Engineering and Technology 3: 168–181. https://doi.org/10.54097/hset.v3i.705.

Yilanci, A., Dincer, I., and Ozturk, H.K. 2009. A review on solar-hydrogen/fuel cell hybrid energy systems for stationary applications. Progress in Energy and Combustion Science 35: 231–244. https://doi.org/10.1016/j.pecs.2008.07.004.

ElMekawy, A., Hegab, H.M., Losic, D., et al. 2017. Applications of graphene in microbial fuel cells: The gap between promise and reality. Renewable and Sustainable Energy Reviews 72: 1389–1403. https://doi.org/10.1016/j.rser.2016.10.044.

Kondaveeti, S., Govindarajan, D., Mohanakrishna, G., et al. 2023. Sustainable bioelectrochemical systems for bioenergy generation via waste treatment from petroleum industries. Fuel 331: 125632. https://doi.org/10.1016/j.fuel.2022.125632.

Yu, G., Chen, J., Wang, G., et al. 2023. Recent advances in constructed wetlands methane reduction: Mechanisms and methods. Frontiers in Microbiology 14: 1–19. https://doi.org/10.3389/fmicb.2023.1106332.

Das, S., and Calay, R.K. 2022. Experimental study of power generation and COD removal efficiency by air cathode microbial fuel cell using Shewanella baltica 20. Energies 15: 4152. https://doi.org/10.3390/en15114152.

Abd-Elrahman, N.K., Al-Harbi, N., Basfer, N.M., et al. 2022. Applications of nanomaterials in microbial fuel cells: A review. Molecules 27: 1–28. https://doi.org/10.3390/molecules27217483.

Gong, L., Abbaszadeh Amirdehi, M., Sonawane, J.M., et al. 2022. Mainstreaming microfluidic microbial fuel cells: A biocompatible membrane grown in situ improves performance and versatility. Lab on a Chip 22, 1905–1916. https://doi.org/10.1039/d2lc00098a.

Tripathi, B., Pandit, S., Sharma, A., et al. 2022. Modification of graphite sheet anode with iron (II, III) oxide-carbon dots for enhancing the performance of microbial fuel cell. Catalysts 12: 1040. https://doi.org/10.3390/catal12091040.

Rossi, R., and Logan, B.E. 2022. Impact of reactor configuration on pilot-scale microbial fuel cell performance. Water Research 225: 119179. https://doi.org/10.1016/j.watres.2022.119179.

Sharma, T., Mohana Reddy, A.L., Chandra, T.S., et al. 2008. Development of carbon nanotubes and nanofluids based microbial fuel cell. International Journal of Hydrogen Energy 33: 6749–6754. https://doi.org/10.1016/j.ijhydene.2008.05.112.

Da Silva, A.N., Macêdo, W.V., Sakamoto, I.K., et al. 2019. Biohydrogen production from dairy industry wastewater in an anaerobic fluidized-bed reactor. Biomass and Bioenergy 120: 257–264. https://doi.org/10.1016/j.biombioe.2018.11.025.

Sonawane, J.M., Patil, S.A., Ghosh, P.C., et al. 2018. Low-cost stainless-steel wool anodes modified with polyaniline and polypyrrole for high-performance microbial fuel cells. Journal of Power Sources 379: 103–114. https://doi.org/10.1016/j.jpowsour.2018.01.001.

Kumar, R., Ghosh, A.K., and Pal, P. 2020. Synergy of biofuel production with waste remediation along with value-added co-products recovery through microalgae cultivation: A review of membrane-integrated green approach. Science of the Total Environment 698: 134169. https://doi.org/10.1016/j.scitotenv.2019.134169.

Nitisoravut, R., Thanh, C.N.D., and Regmi, R. 2017. Microbial fuel cells: Advances in electrode modifications for improvement of system performance. International Journal of Green Energy 14: 712–723. https://doi.org/10.1080/15435075.2017.1326049.

Mahmoodi-Eshkaftaki, M., Rafiee, M.R., and Mahmoudi, M. 2023. Efficiency of ultrasonic pretreatment on improving biodegradability of tomato wastes and increasing biohydrogen production. Bioenergy Research https://doi.org/10.1007/s12155-023-10601-x.

Amulya, K., Morris, S., and Lens, P.N.L. 2023. Aquatic biomass as sustainable feedstock for biorefineries. Biofuels, Bioproducts and Biorefining 17: 1012–1029. https://doi.org/10.1002/bbb.2471.

Sathees Kumar, V., Raja Murugadoss, J., Gokulan, R., et al. 2023. Studies on influence of process parameters in upgradation of bio-oil derived from HTL of domestic household waste: Application of response surface methodology. Global Nest Journal 25: 40–46. https://doi.org/10.30955/gnj.004445.

Alvarado-Ramírez, L., Santiesteban-Romero, B., Poss, G., et al. 2023. Sustainable production of biofuels and bioderivatives from aquaculture and marine waste. Frontiers in Chemical Engineering 4: 1–26. https://doi.org/10.3389/fceng.2022.1072761.

Yi, G., Wang, B., Feng, Y., et al. 2022. The ins and outs of photo-assisted microbial electrochemical systems for synchronous wastewater treatment and bioenergy recovery. Resources, Conservation and Recycling 181: 106230. https://doi.org/10.1016/j.resconrec.2022.106230.

Sybirna, K., Antoine, T., Lindberg, P., et al. 2008. Shewanella oneidensis: A new and efficient system for expression and maturation of heterologous [Fe-Fe] hydrogenase from Chlamydomonas reinhardtii. BMC Biotechnology 8: 1–8. https://doi.org/10.1186/1472-6750-8-73.

Kadier, A., Kalil, M.S., Abdeshahian, P., et al. 2016. Recent advances and emerging challenges in microbial electrolysis cells (MECs) for microbial production of hydrogen and value-added chemicals. Renewable and Sustainable Energy Reviews 61: 501–525. https://doi.org/10.1016/j.rser.2016.04.017.

Saket, P., Mittal, Y., Bala, K., et al. 2022. Innovative constructed wetland coupled with microbial fuel cell for enhancing diazo dye degradation with simultaneous electricity generation. Bioresource Technology 345: 126490. https://doi.org/10.1016/j.biortech.2021.126490.

Hu, R., Lin, L., Liu, T., et al. 2008. Reducing sugar content in hemicellulose hydrolysate by DNS method: A revisit. Journal of Biobased Materials and Bioenergy 2: 156–161. https://doi.org/10.1166/jbmb.2008.306.

Wagner, M., and Loy, A. 2002. Bacterial community composition and function in sewage treatment systems. Current Opinion in Biotechnology 13: 218–227. https://doi.org/10.1016/S0958-1669(02)00315-4.

Kiely, P.D., Cusick, R., Call, D.F., et al. 2011. Anode microbial communities produced by changing from microbial fuel cell to microbial electrolysis cell operation using two different wastewaters. Bioresource Technology 102: 388–394. https://doi.org/10.1016/j.biortech.2010.05.019.

Lovley, D.R. 2008. The microbe electric: Conversion of organic matter to electricity. Current Opinion in Biotechnology 19: 564–571. https://doi.org/10.1016/j.copbio.2008.10.005.

Ghimire, A., Frunzo, L., Pirozzi, F., et al. 2015. A review on dark fermentative biohydrogen production from organic biomass: Process parameters and use of by-products. Applied Energy 144: 73–95. https://doi.org/10.1016/j.apenergy.2015.01.045.

Morero, B., Montagna, A.F., Campanella, E.A., et al. 2020. Optimal process design for integrated municipal waste management with energy recovery in Argentina. Renewable Energy 146: 2626–2636. https://doi.org/10.1016/j.renene.2019.08.085.

Yang, G., and Wang, J. 2021. Biohydrogen production by co-fermentation of antibiotic fermentation residue and fallen leaves: Insights into the microbial community and functional genes. Bioresource Technology 337: 125380. https://doi.org/10.1016/j.biortech.2021.125380.

Freguia, S., Rabaey, K., Yuan, Z., et al. 2007. Non-catalyzed cathodic oxygen reduction at graphite granules in microbial fuel cells. Electrochimica Acta 53: 598–603. https://doi.org/10.1016/j.electacta.2007.07.037.

Park, S.G., Rajesh, P.P., Sim, Y.U., et al. 2022. Addressing scale-up challenges and enhancement in performance of hydrogen-producing microbial electrolysis cell through electrode modifications. Energy Reports 8: 2726–2746. https://doi.org/10.1016/j.egyr.2022.01.198.

Mumtha, C., Subashri, D., and Mahalingam, P.U. 2022. Biohydrogen Producing Facultative Anaerobic Bacteria from Different Anaerobic sludge. Journal of Pure and Applied Microbiology 16: 1861–1872. https://doi.org/10.22207/JPAM.16.3.32.

Karadag, D., Mäkinen, A.E., Efimova, E., et al. 2009. Thermophilic biohydrogen production by an anaerobic heat treated-hot spring culture. Bioresource Technology 100: 5790–5795. https://doi.org/10.1016/j.biortech.2009.06.035.

Reddy, K., Nasr, M., Kumari, S., et al. 2017. Biohydrogen production from sugarcane bagasse hydrolysate: Effects of pH, S/X, Fe2+, and magnetite nanoparticles. Environmental Science and Pollution Research 24: 8790–8804. https://doi.org/10.1007/s11356-017-8560-1.

Zhang, F., Merrill, M.D., Tokash, J.C., et al. 2011. Mesh optimization for microbial fuel cell cathodes constructed around stainless steel mesh current collectors. Journal of Power Sources 196: 1097–1102. https://doi.org/10.1016/j.jpowsour.2010.08.011.

El-Chakhtoura, J., El-Fadel, M., Rao, H.A., et al. 2014. Electricity generation and microbial community structure of air-cathode microbial fuel cells powered with the organic fraction of municipal solid waste and inoculated with different seeds. Biomass and Bioenergy 67: 24–31. https://doi.org/10.1016/j.biombioe.2014.04.020.

Ju, Y.H., Huynh, L.H., Kasim, N.S., et al. 2011. Analysis of soluble and insoluble fractions of alkali and subcritical water treated sugarcane bagasse. Carbohydrate Polymers 83: 591–599. https://doi.org/10.1016/j.carbpol.2010.08.022.

American Public Health Association, American Water Works Association, Water Environment Federation. 2012. Standard Methods for examination of water and wastewater. 22nd ed. Washington, American Public Health Association. Anales de Hidrología Médica pp. 1360. https://doi.org/10.5209/rev_ANHM.2012.v5.n2.40440. ISBN 978-087553-013-0

Murugan, R.S., Dinesh, G.H., Raja, R.K., et al. 2021. Dark fermentative biohydrogen production by Acinetobacter junii-AH4 utilizing various industry wastewaters. International Journal of Hydrogen Energy 46: 11297–11304. https://doi.org/10.1016/j.ijhydene.2020.07.073.

Vieira, R.F., Sydney, E.B., Fiametti, K.G., et al. 2023. Production of volatile fatty acids by dark fermentation in whey-based media: Effects of supplementation and hydrolysis. Waste and Biomass Valorization https://doi.org/10.1007/s12649-023-02122-7.

Su, H., Cheng, J., Zhou, J., et al. 2009. Combination of dark- and photo-fermentation to enhance hydrogen production and energy conversion efficiency. International Journal of Hydrogen Energy 34: 8846–8853. https://doi.org/10.1016/j.ijhydene.2009.09.001.

Obileke, K.C., Onyeaka, H., Meyer, E.L., et al. 2021. Microbial fuel cells, a renewable energy technology for bio-electricity generation: A mini-review. Electrochemistry Communications 125: 107003. https://doi.org/10.1016/j.elecom.2021.107003.

Lekshmi, G.S., Bazaka, K., Ramakrishna, S., et al. 2022. Microbial electrosynthesis: Carbonaceous electrode materials for CO2 conversion. Materials Horizons 10: 292–312. https://doi.org/10.1039/d2mh01178f.

Perez, L., Hafidi, Z., Pinazo, A., et al. 2023. Zein nanoparticles containing arginine-phenylalanine-based surfactants: Stability, antimicrobial and hemolytic activity. Nanomaterials 13: 200. https://doi.org/10.3390/nano13010200.

Betancur-Murillo, C.L., Aguilar-Marín, S.B., and Jovel, J. 2023. Prevotella: A key player in ruminal metabolism. Microorganisms 11: 1–18. https://doi.org/10.3390/microorganisms11010001.

Karim, A., Islam, M.A., Mishra, P., et al. 2021. Technical difficulties of mixed culture driven waste biomass-based biohydrogen production: Sustainability of current pretreatment techniques and future prospective. Renewable and Sustainable Energy Reviews 151: 111519. https://doi.org/10.1016/j.rser.2021.111519.

Pachiega, R., Sakamoto, I.K., Varesche, M.B., et al. 2019. Obtaining and characterization of mesophilic bacterial consortia from tropical sludges applied on biohydrogen production. Waste and Biomass Valorization 10: 1493–1502. https://doi.org/10.1007/s12649-017-0185-6.

Ali, N., Anam, M., Yousaf, S., et al. 2017. Characterization of the electric current generation potential of the pseudomonas aeruginosa using glucose, fructose, and sucrose in double chamber microbial fuel cell. Iranian Journal of Biotechnology 15: 216–223. https://doi.org/10.15171/ijb.1608.

Ebadinezhad, B., Ebrahimi, S., and Shokrkar, H. 2019. Evaluation of microbial fuel cell performance utilizing sequential batch feeding of different substrates. Journal of Electroanalytical Chemistry 836: 149–157. https://doi.org/10.1016/j.jelechem.2019.02.004.

Spilimbergo, S., Mantoan, D., Quaranta, A., et al. 2009. Della: Real-time monitoring of cell membrane modification during supercritical CO2 pasteurization. Journal of Supercritical Fluids 48: 93–97. https://doi.org/10.1016/j.supflu.2008.07.023.

Kaewkannetra, P., Chiwes, W., and Chiu, T.Y. 2011. Treatment of cassava mill wastewater and production of electricity through microbial fuel cell technology. Fuel 90: 2746–2750. https://doi.org/10.1016/j.fuel.2011.03.031.

Kalathil, S., Patil, S.A., Pant, D 2018. Microbial fuel cells: Electrode materials. In Encyclopedia of interfacial chemistry: Surface science and electrochemistry, pp. 309–318. Amsterdam: Elsevier. https://doi.org/10.1016/B978-0-12-409547-2.13459-6.

Wang, W., Zhang, B., and He, Z. 2019. Bioelectrochemical deposition of palladium nanoparticles as catalysts by Shewanella oneidensis MR-1 towards enhanced hydrogen production in microbial electrolysis cells. Electrochimica Acta 318: 794–800. https://doi.org/10.1016/j.electacta.2019.06.038.

Hermon, S., Grange, D., Pellet, Y., et al. 2008. Zero Liquid Discharge approach in plating industry: Treatment of degreasing effluents by electrocoagulation and anodic oxidation. Water Science and Technology 58: 519–527. https://doi.org/10.2166/wst.2008.690.

Din, M.I., Iqbal, M., Hussain, Z., et al. 2020. Bioelectricity generation from waste potatoes using single chambered microbial fuel cell. Energy Sources, Part A: Recovery, Utilization and Environmental Effects. https://doi.org/10.1080/15567036.2020.1797944.

Elgarahy, A.M., M.G. Eloffy, A. Hammad, et al. 2022. Hydrogen production from wastewater, storage, economy, governance and applications: A review. New York: Springer. https://doi.org/10.1007/s10311-022-01480-3.

Shen, X., Zhang, J., Liu, D., et al. 2018. Enhance performance of microbial fuel cell coupled surface flow constructed wetland by using submerged plants and enclosed anodes. Chemical Engineering Journal 351: 312–318. https://doi.org/10.1016/j.cej.2018.06.117.

Offei, F., Mensah, M., Kemausuor, F., et al. 2019. A biorefinery approach to bioethanol and bioelectricity co-production from tropical seaweeds. Journal of Applied Phycology 31: 3899–3913. https://doi.org/10.1007/s10811-019-01887-6.

Zhou, Q., Li, R., Zhang, X., et al. 2022. Innovative cost-effective nano-NiCo2O4 cathode catalysts for oxygen reduction in air-cathode microbial electrochemical systems. International Journal of Environmental Research and Public Health 19: 11609. https://doi.org/10.3390/ijerph191811609.

Tolar, J.G., Li, S., and Ajo-Franklin, C.M. 2022. The differing roles of flavins and quinones in extracellular electron transfer in Lactiplantibacillus plantarum. Applied and Environmental Microbiology 89. https://doi.org/10.1128/aem.01313-22.

Peera, S.G., Maiyalagan, T., Liu, C., et al. 2021. A review on carbon and non-precious metal based cathode catalysts in microbial fuel cells. International Journal of Hydrogen Energy 46: 3056–3089. https://doi.org/10.1016/j.ijhydene.2020.07.252.

Gil, G.C., Chang, I.S., Kim, B.H., et al. 2003. Operational parameters affecting the performance of a mediator-less microbial fuel cell. Biosensors and Bioelectronics 18: 327–334. https://doi.org/10.1016/S0956-5663(02)00110-0.

Ryue, J., Lin, L., Kakar, F.L., et al. 2020. A critical review of conventional and emerging methods for improving process stability in thermophilic anaerobic digestion. Energy for Sustainable Development 54: 72–84. https://doi.org/10.1016/j.esd.2019.11.001.

Lalitha Priya, R., Ramachandran, T., and Suneesh, P.V. 2016. Fabrication and characterization of high power dual chamber E. coli microbial fuel cell. IOP Conference Series: Materials Science and Engineering 149: 012215. https://doi.org/10.1088/1757-899X/149/1/012215.

Mohd Zaini Makhtar, M., and Tajarudin, H.A. 2020. Electricity generation using membrane-less microbial fuel cell powered by sludge supplemented with lignocellulosic waste. International Journal of Energy Research 44: 3260–3265. https://doi.org/10.1002/er.5151.

Sonu, K., Sogani, M., Syed, Z., et al. 2023. The effects of waste jasmine flower as a substrate in a single chamber microbial fuel cell. Biomass Conversion and Biorefinery. https://doi.org/10.1007/s13399-023-04196-8.

Yaqoob, A.A., Ibrahim, M.N.M., Yaakop, A.S., et al. 2022. Utilization of biomass-derived electrodes: A journey toward the high performance of microbial fuel cells. Applied Water Science 12: 1–20. https://doi.org/10.1007/s13201-022-01632-4.

Nimje, V.R., Chen, C.Y., Chen, C.C., et al. 2011. Glycerol degradation in single-chamber microbial fuel cells. Bioresource Technology 102: 2629–2634. https://doi.org/10.1016/j.biortech.2010.10.062.

Sonu, K., Sogani, M., Syed, Z., et al. 2022. Improved degradation of dye wastewater and enhanced power output in microbial fuel cells with chemically treated corncob anodes. Biomass Conversion and Biorefinery. https://doi.org/10.1007/s13399-021-02254-7.

Zhang, C., Liang, P., Yang, X., et al. 2016. Binder-free graphene and manganese oxide coated carbon felt anode for high-performance microbial fuel cell. Biosensors and Bioelectronics 81: 32–38. https://doi.org/10.1016/j.bios.2016.02.051.

Mansoorian, H.J., Mahvi, A.H., Jafari, A.J., et al. 2016. Evaluation of dairy industry wastewater treatment and simultaneous bioelectricity generation in a catalyst-less and mediator-less membrane microbial fuel cell. Journal of Saudi Chemical Society 20: 88–100. https://doi.org/10.1016/j.jscs.2014.08.002.

Zhao, G., Ma, F., Wei, L., et al. 2012. Electricity generation from cattle dung using microbial fuel cell technology during anaerobic acidogenesis and the development of microbial populations. Waste Management 32: 1651–1658. https://doi.org/10.1016/j.wasman.2012.04.013.

Wang, Y.Z., Zhang, L., Xu, T., et al. 2017. Influence of initial anolyte pH and temperature on hydrogen production through simultaneous saccharification and fermentation of lignocellulose in microbial electrolysis cell. International Journal of Hydrogen Energy 42: 22663–22670. https://doi.org/10.1016/j.ijhydene.2017.07.214.

Chang, J.J., Chou, C.H., Ho, C.Y., et al. 2008. Syntrophic co-culture of aerobic Bacillus and anaerobic Clostridium for bio-fuels and bio-hydrogen production. International Journal of Hydrogen Energy 33: 5137–5146. https://doi.org/10.1016/j.ijhydene.2008.05.021.

Lewis, A.J., Ren, S., Ye, X., et al. 2015. Hydrogen production from switchgrass via an integrated pyrolysis-microbial electrolysis process. Bioresource Technology 195: 231–241. https://doi.org/10.1016/j.biortech.2015.06.085.

Cercado-Quezada, B., Delia, M.L., and Bergel, A. 2010. Testing various food-industry wastes for electricity production in microbial fuel cell. Bioresource Technology 101: 2748–2754. https://doi.org/10.1016/j.biortech.2009.11.076.

Zhang, J., Zhang, B., Tian, C., et al. 2013. Simultaneous sulfide removal and electricity generation with corn stover biomass as co-substrate in microbial fuel cells. Bioresource Technology 138: 198–203. https://doi.org/10.1016/j.biortech.2013.03.167.

Acknowledgements

In recognition of the necessary experimental resources provided by GRI-DTBU, we thank the Head of the Department of Biology, GRI. We are grateful to the GRI General Library for supplying the Grammarly and Ithenticate software. We thank the Laboratory of Bioenergy and Bioremediation, Department of Microbiology, Alagappa University, Karaikudi, Tamil Nadu, India for their support in GC-TCD instrumental analysis.

Funding

This research was not supported by any public, commercial, or nonprofit organizations.

Author information

Authors and Affiliations

Contributions

All authors have made a significant, direct, and intellectual contribution, Chelladurai Mumtha carried out the experiment. Chelladurai Mumtha and Jesuraj Kabiriyel wrote the manuscript and Pambayan Ulagan Mahalingam supervise the projects and timely advised for the improvement to the work.

Corresponding author

Ethics declarations

Conflict of interest

All the authors of this paper reveal that they do not have any significant conflicts of interest.

Ethics statement

None of the authors conducted any research with humans or animals.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mumtha, C., Kabiriyel, J. & Mahalingam, P.U. Enhancing the biological hydrogen production in a novel way of using co-substrates. Waste Dispos. Sustain. Energy 5, 511–524 (2023). https://doi.org/10.1007/s42768-023-00160-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42768-023-00160-4