Abstract

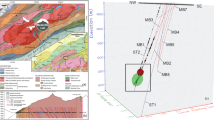

As mines continue to deepen and become more expansive, active monitoring of larger volumes of rock mass will become more critical to calibrate numerical simulations and to ensure the safety of underground workers. Monitoring larger volumes of rock mass requires low-cost sensors which are simple in construction and installation. In this study, a novel hybrid optical fiber cable (HOFC) designed for use in distributed optical fiber sensing (DOFS) via grouted boreholes was employed to monitor a bulk mining operation in an underground metal mine. The HOFC was successfully used to monitor approximately 2.7 × 103 m3 of rock mass above excavations surrounding a pillar removal area in which six large pillars were removed simultaneously. A total of six measurement boreholes (maximum depth of 22 m) were used to measure strain along the optical fiber during the pillar removal operation using the HOFC, allowing for 70 individual strain measurement points, which were constructed for under one US dollar each. Monitoring of the excavation area took place over a 44-day period after pillar removal. Extensional strains were noted in the areas closest to the removed pillars, while areas of compression were noted directly above the remaining pillar in the area. The results of the case study demonstrate that a low-cost optical fiber strain sensing network can be rapidly installed in a large excavation area and can provide highly sensitive strain measurements in a manner that would be cost-prohibitive via other methods.

Similar content being viewed by others

Data Availability

The datasets generated and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Bao X, Chen L (2012) Recent progress in distributed fiber optic sensors. Sensors 12(7):8601–8639

Brady BHG, Brown ET (1985) Monitoring rock mass performance. In: Rock Mechanics. Springer, Dordrecht. https://doi.org/10.1007/978-94-011-6501-3_18

NIOSH (2022) Number and percentage of occupational fatalities by accident class at underground mining locations, 2000 - 2021 (N=403). U.S. Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health. Available: https://wwwn.cdc.gov/NIOSH-Mining/MMWC/Fatality/Count?StartYear=2000&EndYear=2021&SelectedMineType=1. 05/08/2024

Cecchetti M, Rossi M, Coppi F, Bicci A, Coli N, Boldrini N, Preston C (2017) A novel radar-based system for underground mine wall stability monitoring’, In Underground Mining Technology. In: Hudyma M, Potvin Y (eds) Australian Centre for Geomechanics: Perth, Australia. pp 431–443.https://doi.org/10.36487/ACG_rep/1710_34_Cecchetti

Dadashzadeh Sayar A, Khalilpasha M (2012) Using extensometer as a monitoring system, case study: Taloun Pilot Tunnel in Tehran-North of Iran Freeway. J Basic Appl Sci Res 2(2):1696–1700

Gholamzadeh B, Nabovati H (2008) Fiber optic sensors. Int J Electron Commun Eng 2(6):1107–1117

Guan Z (2015) Study on monitoring and early warning of karst collapse based on BOTDR technique. In: Proceeding: 14th Sinkhole Conference, NCKRI Symposium 5. Carlsbad, New Mexico, USA, pp 407–414. https://doi.org/10.5038/9780991000951.1054

Horiguchi T, Kurashima T, Tateda M (1989) Tensile strain dependence of Brillouin frequency shift in silica optical fibers. IEEE Photonics Technol Lett 1(5):107–108

Hu T, Gongyu H, Li Z (2020) The field monitoring experiment of the roof strata movement in coal mining based on DFOS. Sensors 20(5):1318. https://doi.org/10.3390/s20051318

Iannacchione A, Prosser L, Grau R, Oyler D, Dolinar D, Marshall T, Compton C (2000) Roof monitoring helps prevent injuries in stone mines. Min Eng 52(11):32–37

Michael I, Dominik H, Alexander MP (2011) Distributed fiber optic sensor development, testing, and evaluation for geotechnical monitoring applications. In: Proc. SPIE 7982. Smart Sensor Phenomena, Technology, Networks, and Systems 2011: 7–9 March 2011, San Diego, California, United States. https://doi.org/10.1117/12.881228

Kontogianni V, Tzortzis A, Stiros S (2004) Deformation and failure of the Tymfristos tunnel, Greece. J Geotech Geoenviron Eng 130(10):1004–1013

Kontogianni VA, Stiros SC (2005) Induced deformation during tunnel excavation: evidence from geodetic monitoring. Eng Geol 79(1–2):115–126

Lalam N, Ng WP, Dai X, Wu Q, Fu YQ (2016) Analysis of brillouin frequency shift in distributed optical fiber sensor system for strain and temperature monitoring. In: Proceedings of the 4th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2016), Rome, Italy, pp 333–340

Marshall TE, Prosser LJ, Iannacchione AT, Dunn M (2000) Roof monitoring in limestone—experience with the Roof Monitoring Safety System (RMSS). In: Peng SS, Mark C (eds) Proceedings: 19th International Conference on Ground Control in Mining. Morgantown, West Virginia, United States, pp 185–191

Moffat R, Sotomayor J, Beltrán JF (2015) Estimating tunnel wall displacements using a simple sensor based on a Brillouin optical time domain reflectometer apparatus. Int J Rock Mech Min Sci 75:233–243

Moffat RA, Beltran JF, Herrera R (2015) Applications of BOTDR fiber optics to the monitoring of underground structures. Geomech Eng 9(3):397–414

Mudd GM, Weng Z, Jowitt SM, Turnbull I, Graedel T (2013) Quantifying the recoverable resources of by-product metals: the case of cobalt. Ore Geol Rev 55:87–98

Naruse H, Uehara H, Deguchi T, Fujihashi K, Onishi M, Espinoza R, Guzman C, Pardo C, Ortega C, Pinto M (2007) Application of a distributed fibre optic strain sensing system to monitoring changes in the state of an underground mine. Meas Sci Technol 18(10):3202

Nowak S, Sherizadeh T, Brooks P, Guner D (2022) Installation and preliminary results of a novel fiber optic distributed strain monitoring system in an active underground room and pillar metal mine. In: Murphy M et al (eds) Proceedings of the 41st International Conference on Ground Control in Mining. (Canonsburg, PA: July 26–28, 2022) Paper ICGCM2022–0302. Society for Mining, Metallurgy, and Exploration, Inc. (SME), Englewood, CO, p 12

Nowak S, Sherizadeh T, Esmaeelpour M, Guner D, Karadeniz KE (2022) Hybrid fiber optic cable for strain profiling and crack growth measurement in rock, cement, and brittle installation media. Sensors 22(24):9685

Ohno H, Naruse H, Kihara M, Shimada A (2001) Industrial applications of the BOTDR optical fiber strain sensor. Opt Fiber Technol 7(1):45–64

Seabrook BC, Ellmauthaler A, LeBlanc M, Jaaskelainen M, Maida JL, Wilson GA (2022) Comparison of Raman, Brillouin, and Rayleigh distributed temperature measurements in high-rate wells. Petrophysics 63(06):685–699

Shen B, King A, Guo H (2008) Displacement, stress and seismicity in roadway roofs during mining-induced failure. Int J Rock Mech Min Sci 45(5):672–688

Shentu N, Zhang H, Li Q, Zhou H, Tong R, Li X (2011) A theoretical model to predict both horizontal displacement and vertical displacement for electromagnetic induction-based deep displacement sensors. Sensors 12(1):233–259

Sun BY, Zhang PS, Wu RX, Guo LQ (2018) Dynamic detection and analysis of overburden deformation and failure in a mining face using distributed optical fiber sensing. J Geophys Eng 15(6):2545–2555. https://doi.org/10.1088/1742-2140/aad1c6

Wang X, Xie J, Zhu W, Xu J (2022) The field monitoring experiment of the high-level key stratum movement in coal mining based on collaborative DOFS and MPBX. Sci Rep 12(1):1–13

Wang Z, Li W, Wang Q et al (2021) Monitoring the dynamic response of the overlying rock–soil composite structure to underground mining using BOTDR and FBG sensing technologies. Rock Mech Rock Eng 54:5095–5116. https://doi.org/10.1007/s00603-021-02530-y

Windsor CR (1993) Measuring stress and deformation in rock masses. In: Szwedzicki (ed) Geotechnical Instrumentation and Monitoring in Open Pit and Underground Mining. CRC Press, Rotterdam, pp 33–55

Funding

This research is funded by the National Institute of Safety and Health (NIOSH) under contract 75D30120C09233.

Author information

Authors and Affiliations

Contributions

Conceptualization: SN, TS, ME, and PB; sensor installation: SN, TS, PB, DG, and GW; data analysis: SN, DG, KK, and AK; manuscript preparation: SN, TS, ME, DG, KK, AK, and PB.

Corresponding author

Ethics declarations

Ethics Approval

Not applicable.

Consent for Publication

All authors agree to publication in the journal.

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• A novel hybrid optical fiber cable (HOFC) is used with distributed strain sensing to quantify geomechanical deformation after a bulk mining/pillar removal operation at an active underground metal mine.

• The use of the novel fiber optic cable for distributed strain sensing in the pillar recovery area allowed for the simple collection of data over a large area from a single or few access points, in a manner which is impractical or excessively expensive using comparable sensing technologies, such as borehole extensometers.

• Strain measurements collected directly after bulk mining are presented and used to guide interpretations on rock mass behavior in response to rapid underground excavation.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nowak, S., Sherizadeh, T., Esmaeelpour, M. et al. Geomechanical Monitoring of an Underground Bulk Mining Operation Using a Novel Distributed Optical Fiber Strain Sensing Method. Mining, Metallurgy & Exploration 41, 1553–1565 (2024). https://doi.org/10.1007/s42461-024-00991-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-024-00991-7