Abstract

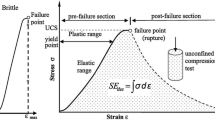

Raises are vertical or inclined openings made to connect two levels of an underground metalliferous mine. They are developed using drilling and blasting-based technique or by mechanical means. Raise boring machines (RBM) have evolved in recent years, which provide quicker and safer raise excavation. The penetration rate using RBM has influenced applied thrust. The required thrust to enhance penetration rate with optimal use of energy would be different under varying geological and geotechnical conditions. In this study, the influence of applied thrust on penetration rate using RBM has been investigated. The investigation has been made for two different rock types, amphibolite (AMP) and garnet-biotite-sillimanite-gneiss (GBSG). The numerical simulation model was developed for this purpose using Ansys-Explicit Dynamics. The induced tensile stress under different conditions of applied thrust has been analysed in the calibrated numerical model. The model output shows the power trend between the parameters. The experimental data on penetration rate was also collected along with the respective operational parameters. A statistical analysis has been carried out for the gathered data. The analysis of data also shows a power trend between thrust per cutter and penetration rate in both rock types and hence validates the numerical simulation-based output. Based on the outputs of the numerical simulation and empirical study of the experimental data, the optimum thrust per cutter for excavation in both rock types is in the range of 12–14 tons. The approach used in this study can be helpful for predicting the optimal operational parameters of raise boring machines under different geological/geotechnical conditions.

Similar content being viewed by others

Data Availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Agrawal H, Mishra AK (2020) An innovative technique of simplified signature hole analysis for prediction of blast-induced ground vibration of multi-hole/production blast: an empirical analysis. Nat Hazards 100(1):111–132

Armaghani DJ, Mahdiyar A, Hasanipanah M, Faradonbeh RS, Khandelwal M, Amnieh HB (2016) Risk assessment and prediction of flyrock distance by combined multiple regression analysis and Monte Carlo simulation of quarry blasting. Rock Mech Rock Eng 49(9):3631–3641

Barton N, Lien R, Lunde J (1974) Engineering classification of rock masses for the design of tunnel support. Rock Mech Rock Eng 6(4):189–236

Bhagat NK, Rana A, Mishra AK, Singh MM, Singh A, Singh PK (2021) Prediction of fly-rock during boulder blasting on infrastructure slopes using CART technique. Geomat Nat Haz Risk 12(1):1715–1740

Calder PN (1973) Rock mechanics aspects of large hole boring machine design. 8th Canadian rock mechanics Symposium 3:159–175

Chen G, He M, Fan F (2018) Rock burst analysis using DDA numerical simulation. Int J Geomech 18(3):04018001

Chen X, Yang J, Gao D (2018) Drilling performance optimization based on mechanical specific energy technologies. Drilling 35:133–161

Copur H, Bilgin N, Balci C, Tumac D, Avunduk E (2017) Effects of different cutting patterns and experimental conditions on the performance of a conical drag tool. Rock Mech Rock Eng 50(6):1585–1609

Fakhimi A, Lanari M (2014) DEM–SPH simulation of rock blasting. Comput Geotech 55:158–164

Farrokh E, Rostami J, Laughton C (2012) Study of various models for estimation of penetration rate of hard rock TBMs. Tunn Undergr Space Technol 30:110–123

Himanshu VK, Mishra AK, Roy MP, Vishwakarma AK, Singh PK (2021) Numerical simulation based approach for assessment of blast induced deformation pattern in slot raise excavation. Int J Rock Mech Min Sci 144:104816

Himanshu VK, Mishra AK, Vishwakarma AK, Roy MP, Singh PK (2022) Explicit dynamics based numerical simulation approach for assessment of impact of relief hole on blast induced deformation pattern in an underground face blast. Geomech Geophys Geo-energ Geo-resour 8:1–8. https://doi.org/10.1007/s40948-021-00327-5

Himanshu VK, Roy MP, Mishra AK, Paswan RK, Panda D, Singh PK (2018) Multivariate statistical analysis approach for prediction of blast-induced ground vibration. Arab J Geosci 11(16):1–11

Himanshu VK, Roy MP, Shankar R, Mishra AK, Singh PK (2021) Empirical approach based estimation of charge factor and dimensional parameters in underground blasting. Min Metall Explor 38(2):1059–1069

Hu Y, Lu W, Chen M, Yan P, Zhang Y (2015) Numerical simulation of the complete rock blasting response by SPH–DAM–FEM approach. Simul Model Pract Theory 56:55–68

Jeong HY, Cho JW, Jeon S, Rostami J (2016) Performance assessment of hard rock TBM and rock boreability using punch penetration test. Rock Mech Rock Eng 49(4):1517–1532

Kahraman S, Balci C, Yazici S, Bilgin N (2000) Prediction of the penetration rate of rotary blast hole drills using a new drillability index. Int J Rock Mech Min Sci 37(5):729–743

Lislerud A (1988) Hard rock tunnel boring: prognosis and cost. Tunn Undergr Space Technol 3(1):9–17

Lislerud A,Vainionpaa P (1997) Application of raiseboring for excavating horizontal tunnels with Rhino machines. Working report 97–56 :1–37.

Liu Z, Meng Y (2015) Key technologies of drilling process with raise boring method. J Rock Mech Geotech Eng 7:385–394

Rana A, Bhagat NK, Jadaun GP, Rukhaiyar S, Pain A, Singh PK (2020) Predicting blast-induced ground vibrations in some Indian tunnels: a comparison of decision tree, artificial neural network and multivariate regression methods. Min Metall Explor 37(4):1039–1053

Ren DJ, Shen JS, Chai JC, Zhou A (2018) Analysis of disc cutter failure in shield tunnelling using 3D circular cutting theory. Eng Fail Anal 90:23–35

Roxborough FF, Phillips HR (1975) Rock excavation by disc cutter. Int J Rock Mech Min Sci Geomech Abstr Pergamon 12:361–366

Seker SE, Ocak I (2019) Performance prediction of roadheaders using ensemble machine learning techniques. Neural Comput Appl 31(4):1103–1116

Shaterpour-Mamaghani A, Bilgin N (2016) Some contributions on the estimation of performance and operational parameters of raise borers – a case study in Kure Copper Mines Turkey. Tunn Undergr Space Technol 54:37–48

Shaterpour-Mamaghani A, Bilgin N, Balci C, Avunduk E, Polat C (2016) Predicting performance of raise boring machines using empirical models. Rock Mech Rock Eng 49(8):3377–3385

Shaterpour-Mamaghani A, Copur H, Dogan E, Erdogan T (2018) Development of new empirical models for performance estimation of a raise boring machine. Tunn Undergr Space Technol 82:428–441

Shirzadegan S, Nordlund E, Zhang P (2016) Large scale dynamic testing of rock support at Kiirunavaara-Improved test design. Tunn Undergr Space Technol 59:183–198

Wilson JW, Graham PC (1972) Raise-boring experiences in the gold mines of the Anglo American Corporation Group. J South Afr Inst Min Metall 73(3):103–114

Yi C, Sjöberg J, Johansson D, Petropoulos N (2017) A numerical study of the impact of short delays on rock fragmentation. Int J Rock Mech Min Sci 100:250–254

Yi CP, Nordlund E, Zhang P, Warema S, Shirzadegan S (2021) Numerical modeling for a simulated rockburst experiment using LS-DYNA. Undergr Space 6(2):153–162

Acknowledgements

The authors would like to thank the Director, CSIR-Central Institute of Mining and Fuel Research, India, and mine management of Rampura Agucha Underground Mine of M/s Hindustan Zinc Limited for giving permission and necessary support for conducting the investigations. This paper forms a part of the M.Tech. Dissertation work carried out at IIT(ISM) Dhanbad by the first author.

Author information

Authors and Affiliations

Contributions

Ashish K Vishwakarma: field experiment, numerical simulation, data analysis and manuscript preparation. V.M.S.R. Murthy: conceptualisation, methodology, scientific inputs. Vivek K Himanshu: numerical simulation, conceptualisation. Amar Prakash: supervision, review and editing. S. Mehrotra: field investigation, data collection.

Corresponding author

Ethics declarations

Ethical Approval

The authors had the appropriate permissions from responsible authorities to do the case study of the study site.

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Vishwakarma, A.K., Murthy, V.M.S.R., Himanshu, V.K. et al. Investigations on the Influence of Applied Thrust on Rock Penetration Rate by a Raise Boring Machine Using Numerical Simulation and Experimental Trials. Mining, Metallurgy & Exploration 40, 1187–1197 (2023). https://doi.org/10.1007/s42461-023-00779-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-023-00779-1