Abstract

This paper deals with the numerical simulation of rock cutting laboratory tests using the discrete element method. The main objective is to provide a method for calibrating numerical DEM models of rock cutting in a systematic way so that realistic results are yielded. The numerical models are developed with the discrete element code Yade, which models rocks as a collection of bonded spheres. The models are calibrated in a four-step process based on the design of experiments method and optimization. The calibrated models are evaluated both quantitatively and qualitatively against actual laboratory cutting tests, in terms of the ratio of the simulated mean cutting force to the actual one and the cutting force time series, respectively. The fully calibrated models showed that the simulated cutting process matched qualitatively the actual cutting force recordings and underestimated the mean cutting force by approximately 3%. It is concluded that well-calibrated numerical simulations of the rock cutting process can provide not only a better understanding of the process itself but also quantitative data regarding the cutting force and energy requirements.

Similar content being viewed by others

Change history

18 January 2023

A Correction to this paper has been published: https://doi.org/10.1007/s42461-023-00735-z

Abbreviations

- β i :

-

Coefficients (─)

- γ int :

-

Interaction range coefficient (─)

- ν :

-

Poisson ratio (─)

- ρ :

-

Density (kg/m3)

- σ c :

-

Macroscopic compressive strength (MPa)

- σ c /σ t :

-

Macroscopic strength ratio (─)

- BTS :

-

Brazilian tensile strength (MPa)

- φ :

-

Internal friction angle (degrees)

- a :

-

Distance from the design space to a star point

- Actual_MCF_S{1–11} :

-

Actual mean cutting force cut#{1–11} (kN)

- Actual_S{1–11} :

-

Actual cutting force curve cut#{1–11} (kN)

- c :

-

Interparticle cohesive strength (MPa)

- c/t :

-

Interparticle strength ratio (─)

- CCC :

-

Central composite circumscribed

- CCD :

-

Central composite design method

- CCF :

-

Central composite faced

- CCI :

-

Central composite inscribed

- DE :

-

Discrete element

- DEM :

-

Discrete element method

- DOE :

-

Design of experiment

- E :

-

Macroscopic Young’s modulus (GPa)

- E eq :

-

Interparticle elasticity modulus (GPa)

- KNKS :

-

Stiffness ratio (─)

- MCF :

-

Mean cutting force (kN)

- MCF PB :

-

Mean cutting force from the PB method (kN)

- MCF CCD :

-

Mean cutting force from the CCD method (kN)

- MCF lab :

-

Actual mean cutting force (kN)

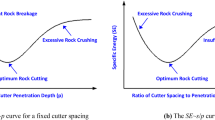

- MSE :

-

Mechanical specific energy (kJ/m3)

- N :

-

Coordination number (─)

- NIST :

-

National Institute of Standards and Technology

- OFAT :

-

One-factor-at-a-time

- PB :

-

Plackett–Burman method

- phi :

-

Interparticle friction coefficient (degrees)

- RSM :

-

Response surface methodology

- Sim_MCF-S{1–11} :

-

Simulated mean cutting force Cut#{1–11} (kN)

- Sim_S{1–11} :

-

Simulated cutting force curve Cut#{1–11} (kN)

- Sim_S{1–11}_mv :

-

Simulated cutting force curve moving average Cut#{1–11}

- SLSQP :

-

Sequential least square programming method (─)

- t :

-

Interparticle tensile strength (MPa)

- UCS :

-

Uniaxial compressive strength (MPa)

- UCS/UTS :

-

Macroscopic strength ratio (─)

- UTS :

-

Uniaxial tensile strength (MPa)

- X1, X2 :

-

Main effects of the DOE

- X1X2 :

-

Interaction

- x i :

-

Coded microparameters

- Y :

-

Response

References

Cundall PA, Hart RD (1992) Numerical modelling of discontinua. Eng Comput 9:101–113. https://doi.org/10.1108/eb023851

Smilauer V et al (2015) Yade documentation 2nd ed. Geneva: CERN- Zenodo. 10.5281/zenodo.34073

Kozicki J, Donzé FV (2009) YADE-OPEN DEM: an open-source software using a discrete element method to simulate granular material. Eng Comput 26:786–805. https://doi.org/10.1108/02644400910985170

Suhr B, Six K (2017) Friction phenomena and their impact on the shear behaviour of granular material. Comp Part Mech 4:23–24. https://doi.org/10.1007/s40571-016-0119-2

Scholtes L, Donze FV, Khanal M (2011) Scale effects on the strength of geomaterials, case study: coal. J Mech Phys Solids 59:1131–1146. https://doi.org/10.1016/j.jmps.2011.01.009

Wang X, Li J (2014) Simulation of triaxial response of granular materials by modified DEM. Sci China Phys Mech Astron 57:2297–2308. https://doi.org/10.1007/s11433-014-5605-z

Astakhov VP (2012) Design of experiment methods in manufacturing: basics and practical applications. In: Davim JP (ed) Statistical and computational techniques in manufacturing. Springer, Berlin Heidelberg, pp 1–54

Huang H, Detournay E, Bellier B (1999) Discrete element modeling of rock cutting.: In Proceedings of the 37th U.S. Rock Mechanics Symposium. Vail, Colorado

Lei ST, Kaitkay P (2003) Distinct element modeling of rock cutting under hydrostatic pressure. Key Eng Mater 250:110–117. https://doi.org/10.4028/www.scientific.net/kem.250.110

Onate E, Rojek J (2004) Combination of discrete element and finite element methods for dynamic analysis of geomechanics problems. Comput Methods Appl Mech Eng 193:3087–3128. https://doi.org/10.1016/j.cma.2003.12.056

Zhang R, Li J (2006) Simulation on mechanical behavior of cohesive soil by distinct element method. J Terramechanics 43:303–316. https://doi.org/10.1016/j.jterra.2005.05.006

Stavropoulou M (2006) Modelling of small-diameter rotary drilling tests on marbles. Int J Rock Mech Min Sci 43:1034–1051. https://doi.org/10.1016/j.ijrmms.2006.03.008

Labra C, Rojek J, Onate E, Zarate F (2008) Advances in discrete element modelling of underground excavations. Acta Geotech 3:317–322. https://doi.org/10.1007/s11440-008-0071-2

Block G, Howie J (2009) Role of failure mode on rock cutting dynamics Paper presented at the SPE Annual Technical Conference and Exhibition, New Orleans, Louisiana. https://doi.org/10.2118/124870-MS

Mendoza JA, Gamwo IK, Zhang W, Lin JS (2010) Discrete element modelling of rock cutting using crushable particles. In: Proceedings of the 44th US Rock Mechanics Symposium and 5th U.S.-Canada Rock Mechanics Symposium. Salt Lake City, Utah

Mendoza JA, Gamwo IK, Zhang W, Lin JS (2011) Considerations for discrete modeling of rock cutting. In: Proceedings of the 45th US Rock Mechanics/Geomechanics Symposium. California

Su O, Akcin NA (2011) Numerical simulation of rock cutting using the discrete element method. Int J Rock Mech Min 48:434–442. https://doi.org/10.1016/j.ijrmms.2010.08.012

Rojek J, Onate E, Labra C, Kargl H (2011) Discrete element simulation of rock cutting. Int J Rock Mech Mini Sci 48:996–1010. https://doi.org/10.1016/j.ijrmms.2011.06.003

Zhao D, Liu JQ, Guo W (2012) The simulation of cutter-rock interaction in PFC. Appl Mech Mater 170–173:3385–3389. https://doi.org/10.4028/www.scientific.net/amm.170-173.3385

Huang H, Lecampion B, Detournay E (2013) Discrete element modeling of tool-rock interaction I: rock cutting. Int J Numer Anal Meth Geomech 37:1913–1929. https://doi.org/10.1002/nag.2113

Martinez IR, Fontoura S, Inoue E, Carrapatoso C, Lourengo A, Curry D (2013) Simulation of single cutter experiments in evaporites through finite element method. Paper presented at the SPE/IADC Drilling Conference, Amsterdam, The Netherlands. https://doi.org/10.2118/163504-MS

van Wyk G, Els DNJ, Akdogan G, Bradshaw SM, Sacks N (2014) Discrete element simulation of tribological interactions in rock cutting. Int J Rock Mech Min Sci 65:8–19. https://doi.org/10.1016/j.ijrmms.2013.10.003

Ji YJ, Xu BX, Sun YJ (2014) Discrete element simulation of coal cutting. Appl Mech Mater 711:48–52. https://doi.org/10.4028/www.scientific.net/amm.711.48

Zhang QQ, Han ZN, Ning SH, Liu QZ, Guo RW (2015) Numerical simulation of rock cutting in different mode using the discrete element method. J GeoEnging 10:35–43. https://doi.org/10.6310/jog.2015.10(2).1

Carrapatoso CM, Lautenschlager CE, Lima Righetto GL, Fontoura SA, Inoue N (2016) Rock cutting analysis employing finite and discrete element methods. J Mech Eng Autom 6:100–108. https://doi.org/10.17265/2159-5275/2016.02.006

Yanxin L, Haibo L, Xiaohua Z, Liping T (2017) Bonded-cluster simulation of rock-cutting using PFC2D. Cluster Comput 20:1289–1301. https://doi.org/10.1007/s10586-017-0808-5

Zhu X, Liu W, Lv Y (2017) The investigation of rock cutting simulation based on discrete element method. Geomech Eng 13:977–995. https://doi.org/10.12989/gae.2017.13.6.977

Xuefeng L, Shibo W, Shirong G, Malekian R, Zhixiong L (2018) Investigation on the influence mechanism of rock brittleness on rock fragmentation and cutting performance by discrete element method. Measurement 113:120–130. https://doi.org/10.1016/j.measurement.2017.07.043

Zhu XH, Luo YX, Wj L (2019) The rock breaking and ROP increase mechanisms for single-tooth torsional impact cutting using DEM. Pet Sci 16:1134–1147. https://doi.org/10.1007/s12182-019-0318-6

Yu B, Zhang K, Niu G (2021) Rock strength determination based on rock drillability index and drilling specific energy: numerical simulation using discrete element method. IEEE Access 9:43923–43937. https://doi.org/10.1109/ACCESS.2021.3061552

Fu Z, Tergeist M, Kueck M, Ostermeyer G (2022) Investigation of the cutting force response to a PDC cutter in rock using the discrete element method. J Pet Sci Eng 213:110330. https://doi.org/10.1016/j.petrol.2022.110330

Zhang H, Ni H, Wang Z, Huang B, Liu S, Xu X, Liu C (2022) Discrete element modeling and simulation study on cutting rock behavior under spring-mass-damper system loading. J Pet Sci Eng 209:109872. https://doi.org/10.1016/j.petrol.2021.109872

Potyondy DO, Cundall PA (2004) A bonded-particle model for rock. Int J Rock Mech Min Sci 41:1329–1364. https://doi.org/10.1016/j.ijrmms.2004.09.011

Fakhimi A, Villegas T (2007) Application of dimensional analysis in calibration of a discrete element model for rock deformation and fracture. Rock Mech Rock Eng 40:193–211. https://doi.org/10.1007/s00603-006-0095-6

Yoon J (2007) Application of experimental design and optimization to PFC model calibration in uniaxial compression simulation. Int J Rock Mech Min Sci 44:871–889. https://doi.org/10.1016/j.ijrmms.2007.01.004

Wang H, Xu C, Li T, Liu S, Peng N (2013) The relationships between macro and micro-mechanical parameters for modeling diamond rock cutting using DEM. In: Proceedings of the 3rd International FLAC/DEM Symposium, Zhu, Detournay, Hart & Nelson (eds.):07–06. https://hdl.handle.net/2440/84046. Accessed 20 June 2022

Wang M, Cao P (2017) Calibrating the micromechanical parameters of the PFC2D(3D) models using the improved simulated annealing algorithm. Mat Probl Eng 1:1–11. https://doi.org/10.1155/2017/6401835

Li P, Jiang S, Tang D, Xu B (2017) A PFC3D-based numerical simulation of cutting load for lunar rock simulant and experimental validation. Adv Space Res 59:2583–2599. https://doi.org/10.1016/j.asr.2017.02.032

NIST/SEMATECH e-Handbook of statistical methods. https://www.itl.nist.gov/div898/handbook/. Accessed 10 June 2022

Plackett RL, Burman JP (1946) The design of optimum multifactorial experiments. Biometrica 33:305–325. https://doi.org/10.1093/biomet/33.4.305

Fowell RJ (1993) The mechanics of rock cutting. In: Hudson J.A (ed) Excavation, support and monitoring, 1st edn. Pergamon, UK, 155–176

Anagnostou V (2016) Specific energy for cutting sedimentary rocks in laboratory tests. National Technical University of Athens, MSc thesis, Greece (in Greek)

Perras MA, Diederichs MS (2014) A review of the tensile strength of rock: concepts and testing. Geotech Geol Eng 32:525–546. https://doi.org/10.1007/s10706-014-9732-0

Lei S, Kaitkay P, Shen X (2004) Simulation of rock cutting using distinct element method – PFC2D. In: Shimizu Y, Hart RD, Cundall PA (ed) Numerical modeling in micromechanics via particle methods, 1st edn. Taylor Francis Forensic Sci, 63–71

Cho N, Martin CD, Sego DC (2007) A clumped particle model for rock. Int J Rock Mech Min Sci 44:997–1010. https://doi.org/10.1016/j.ijrmms.2007.02.002

Potyondy DO (2012) A flat-jointed bonded-particle material for hard rock. In: Proceedings of the 46th US Rock Mechanics/Geomechanics Symposium. Chicago, Illinois

Scholtès L, Donzé FV (2013) A DEM model for soft and hard rocks: role of grain interlocking on strength. J Mech Phys Solids 61:352–369. https://doi.org/10.1016/j.jmps.2012.10.005

Funding

The first author was supported for this research through a Doctoral Dissertation Fellowship provided by the Research Committee of the National Technical University of Athens.

Author information

Authors and Affiliations

Contributions

The first author conducted the research, developed the DEM simulation code, run the simulations, analyzed the results, and drafted the first version of this paper. The second author supervised the research, provided the laboratory test dataset, reviewed the analysis of results, and edited the final version of this paper. Both authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kalogeropoulos, A.D., Michalakopoulos, T.N. A Method for Selecting Optimum Microparameters’ Values in the Numerical Simulation of Rock Cutting. Mining, Metallurgy & Exploration 40, 211–227 (2023). https://doi.org/10.1007/s42461-022-00724-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-022-00724-8