Abstract

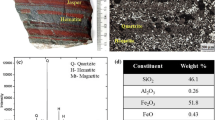

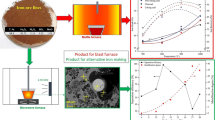

The current study investigates the effect of microwave processing on low-grade banded iron ore using charcoal, coking coal, and non-coking coal. Charcoal showed better microwave heating response at low temperatures, and the coals exhibit better heating response at higher temperatures. Low carbon dosage ~ 12% is sufficient to generate concentrate with 61.8% iron grade and ~6% for 94.8% iron recovery comprising of magnetite phase suitable for iron-making applications. The process separation efficiency of ~ 95% is achieved at 6% carbon dosage and decreases with an increase in carbon due to formation of the fayalite phase. The metallization degree showed a strong dependency on reductant dosage and achieved a maximum value of 22.7% at 18% charcoal. The comparison of ore with pure iron oxide and the synthetic mixture of iron oxide indicated that the underlying bonding due to banded structure enhances the Joule heating during microwave irradiation and thereby aids in attaining higher temperature and better separation.

Similar content being viewed by others

References

Rayapudi V, Agrawal S, Dhawan N (2019) Optimization of microwave carbothermal reduction for processing of banded hematite jasper ore. Min Eng 132:202–210

Hara K, Hayashi M (2011) Continuous pig iron making by microwave heating with 12.5 kW at 2.45 GHz. J Microw Power Electromagn Energy 45:137–147

Hayashi M, Takeda K, Kashimura K, Watanabe T, Nagata K (2013) Carbothermic reduction of hematite powders by microwave heating. ISIJ Int 53:1125–1130

Pickles CA (2009) Microwaves in extractive metallurgy: part 2–a review of applications. Min Eng 22(13):1112–1118

Zhou J, Xu W, You Z, Wang Z, Luo Y, Gao L, Lan L (2016) A new type of power energy for accelerating chemical reactions: the nature of a microwave-driving force for accelerating chemical reactions. Sci Rep 6:25149

Hunt J, Ferrari A, Lita A, Crosswhite M, Ashley B, Stiegman AE (2013) Microwave-specific enhancement of the carbon–carbon dioxide (Boudouard) reaction. J Phys Chem C 117(51):26871–26880

Stir M, Ishizaki K, Vaucher S, Nicula R (2009) Mechanism and kinetics of the reduction of magnetite to iron during heating in a microwave E-field maximum. J Appl Phys 105:124901

Standish N, Huang W (1991) Microwave application in carbothermic reduction of iron ores. ISIJ Int 31(3):241–245

Kashimura K, Nagata K, Sato M (2010) Concept of furnace for metal refining by microwave heating -a design of microwave smelting furnace with low CO2 emission. Mater Trans 51:1847–1853

Amini A, Ohno KI, Maeda T, Kunitomo K (2018) Effect of the ratio of magnetite particle size to microwave penetration depth on reduction reaction behaviour by H2. Sci Rep 8(1):1–7

Barani K, Koleini SJ, Rezaei B (2011) Magnetic properties of an iron ore sample after microwave heating. Separ Purif Technol 76(3):331–336

Rayapudi V, Dhawan N (2020) Evaluation of carbothermal reduction for processing of banded hematite quartzite iron ore. Can Metall Q 59(2):125–133

Agrawal S, Dhawan N (2020) Microwave carbothermic reduction of low-grade iron ore. Metall Mater Trans B Process Metall Mater Process Sci 51:1576–1586. https://doi.org/10.1007/s11663-020-01883-z

Wills BA, Finch J (2015) Wills’ mineral processing technology: an introduction to the practical aspects of ore treatment and mineral recovery. Butterworth-Heinemann

Han H, Duan D, Yuan P, Chen S (2015) Recovery of metallic iron from high phosphorus oolitic hematite by carbothermic reduction and magnetic separation. Ironmak Steelmak 42(7):542–547

Harrison PC (1997) A fundamental study of the heating effect of 2.45 GHz microwave radiation on minerals. Dissertation, University of Birmingham

Williams O, Ure A, Stevens L, Binner E, Dodds C, Kingman S, Das B, Dash PS, Lester E (2019) Formation of metallurgical coke within minutes through coal densification and microwave energy. Energy Fuel 33(7):6817–6828

Lester E, Kingman S, Dodds C, Patrick J (2006) The potential for rapid coke making using microwave energy. Fuel. 85:2057–2063

Huang J, Xu G, Liang Y, Hu G, Chang P (2020) Improving coal permeability using microwave heating technology—a review. Fuel 266:117022. https://doi.org/10.1016/j.fuel.2020.117022

Mishra S, Roy GG (2016) Effect of amount of carbon on the reduction efficiency of iron ore-coal composite pellets in multi-layer bed rotary hearth furnace (RHF). Metall Mater Trans 47(4):2347–2356

Agrawal S, Rayapudi V, Dhawan N (2019) Comparison of microwave and conventional carbothermal reduction of red mud for recovery of iron values. Miner Eng 132:202–210

Whittaker G (1997) A basic introduction to microwave chemistry. Accessed, 1(02), 20

Funding

The authors acknowledge the Science Engineering Research Board for providing financial assistance via Early career research Grant (ECR/874/2016).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Agrawal, S., Mir, S. & Dhawan, N. Microwave Processing of Low-Grade Banded Iron Ore with Different Reductants. Mining, Metallurgy & Exploration 38, 151–160 (2021). https://doi.org/10.1007/s42461-020-00304-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-020-00304-8