Abstract

This study aims to investigate the effects of operational variables on concentrate grade, recovery, separation efficiency, and kinetic parameters of the copper flotation process. For this purpose, the effects of the pulp solids content, collector and frother dosage, and preparation and concentrate collection time were studied using a Taguchi experimental design. The results of statistical analyses indicated that the concentrate collection time and pulp density were the most influential parameters on concentrate grade. Considering copper recovery, concentrate collection time, collector dosage, and pulp density were the most significant variables, in decreasing order of importance. Also, the separation efficiency was mostly influenced by the concentrate collection time. Furthermore, kinetic studies showed that the second-order rectangular distribution model perfectly matched the experimental flotation data. The highest kinetic constant of 0.0756 s−1 was obtained from the test, which was performed with 35% solids content and 40 and 20 g/t collector and frother, respectively. The highest predicted copper recovery of 99.57% was obtained from the test at 30% solids content, and the collector and frother dosages of 40 and 15 g/t, respectively.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Froth flotation is a physicochemical process that has been used for more than a century in the concentration of copper sulfide minerals [19]. This process is based on the wettability of copper mineral particles to recover the mineral species of interest and depress unwanted gangue. A very important aspect of flotation is its kinetics. In fact, kinetics is one of the most important aspects of any separation process [38]. The flotation rate is measured as the recovery change of the floating material in the flotation product per unit time and it is characterized by a rate constant and kinetics order [5, 36]. Kinetic models and its parameters are often used to analyze batch flotation data and to evaluate various parameters such as flotation chemical and equipment operating conditions [40]. They can be effectively used to evaluate variables affecting the flotation process [16].

Particle size, reagent type and dosage, air flow rate, pulp density, and wash water rate are some of the influential parameters on flotation process efficiency [8, 28, 33, 34, 39]. Although copper flotation and the effect of key parameters and operational conditions have been studied previously [2, 3, 10, 31], the main focus of these studies have been the impact of each individual operational condition on the recovery of the flotation process. The combined effect of these factors on each other and on the efficiency and flotation kinetics has not been considered. On the other hand, although the fundamentals of kinetic models have been developed; detailed information about the factors which affect flotation kinetics has still not been obtained. In addition, the influence of chemical factors such as solids content, collector and frother dosage, and concentration time, on flotation kinetics has not been investigated to a great extent. Therefore, the remaining problems not only include the effect of factors on the parameters of flotation models, but also the flotation model itself, since most of the models are not well constructed in representing true flotation behavior.

This paper aimed to evaluate the kinetic models and to investigate the influence of some controlling operational factors on concentrate grade, recovery, separation efficiency, and kinetic parameters of the copper flotation process. For this purpose, flotation tests were conducted with different conditions of pulp density, collector and frother dosages, and preparation and froth collection time. This study was carried out on a Sungun porphyry copper sulfide ore which was obtained from East Azerbaijan Province in the northwest part of Iran. The factors mentioned in the design were selected based on the parameters that can be changed at the Sungun processing plant.

2 Materials and Methods

2.1 Ore Sample

A bulk sample of copper ore was obtained from the Sungun copper complex treating a porphyry copper-molybdenite deposit which is located in the geographical coordination of 43′ 46° east and 42′ 38° north in the East Azerbaijan Province. The sulfide minerals in the deposit are pyrite, molybdenite, galena, sphalerite, marcasite, pyrrhotite, chalcopyrite (the main copper-bearing mineral), bornite, chalcocite, and covellite with different paragenesis in supergene and hypogene oxide mineralization fields [1]. The major metals beside copper are gold and silver, and iron-containing oxide minerals such as ilmenite, rutile, magnetite, and goethite.

In the Sungun Concentrator Plant, the crushed ore is fed into a semi-autogenous (SAG) mill to produce a product with a P80 = 3 mm. The SAG mill products are then transferred to the two ball mills, where the ore is ground to a level of P80 = 80 μm. Lime and collectors Z11 and AP407 are added to the ball mill feed as well. Then, the product is discharged into a rougher flotation conditioning tank. The pH of the feed with respect to rougher flotation is measured in this conditioning tank and lime slurry is added for adjustment. Additionally, the frothers AF65 and AF70 are added to the conditioning tank. The conditioning tank overflow enters the 12 rougher flotation tank cells which are grouped into 6 banks of 2 cells each. Further reagents (collectors) are added to the flotation cells 3, 5, and 9. The collector distribution pattern is 32% for ball mill feed, 32% for the third rougher flotation cell, 20% for the fifth rougher flotation cell, and 16% for the ninth rougher flotation cell. Tailings from the last rougher flotation bank together with cleaner scavenger tailing form the final plant tailing output stream. The rougher concentrate obtained from each cell is combined with the cleaner scavenger concentrate and pumped to the regrind hydrocyclone clusters. Hydrocyclone underflow, after lime addition, reports to the regrind ball mill. The regrind ball mill is operated in a closed circuit with the hydrocyclone cluster. The hydrocyclone overflow (P80 = 40 μm) is transferred to two cleaner column cells. Concentrate obtained from the cleaner columns is transferred to the re-cleaning column cell to produce the final concentrate with a 30% (nominal) copper grade and about 84% total Cu recovery [37].

2.2 Sample Analysis

According to mineralogical studies, the sulfide minerals contained within the sample were chalcocite, chalcopyrite, bornite, covellite, and pyrite. Table 1 shows the chemical composition of the feed sample as determined by the XRF method. Mineralogical studies, such as particle size and degree of liberation were determined by using a Leitz SM-LUX-POL model microscope.

In order to determine the particle size distribution (PSD) of the flotation circuit feed, the particle size analysis was performed using a set of sieves according to the ASTM standard. Figure 1 presents the PSD of the sample.

2.3 Flotation Experiments

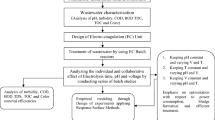

The first step in conducting an experiment is to determine the variable and dependent parameters and design the experimental approach. The drive of using different techniques in designing experiments is to identify the influential factors in the process and determine the optimal values. The Taguchi method is one of the design of experiments (DOE) methods which, compared with other commonly used engineering design tests, uses a completely different methodological approach. The Taguchi method emphasizes the quality in designing of products and processes, while other commonly used methods are emphasizing inspection and quality control during the production process and/or after the product is formed. In this study, the Taguchi method is used to design the experimental approach, considering its application in similar studies [12, 22] as well as the compatibility of the number of designed experiments with laboratory conditions and facilities. Although there are many different types of the Taguchi designs, a L18 design, the most popular Taguchi design approach, was selected to design the experiments.

The independent parameters were pulp density, collector and frother dosages, and preparation and concentrate collection time. Also, the response variables were concentrate grade, recovery, and separation efficiency. The selected design includes a two-level and seven three-level parameters for which three were dedicated to calculate the experimental error (A, G, and H). The factors mentioned in the design were selected based on the parameters that can be changed on the operating plant. The parameter levels were also selected based on the quantities consumed by each of the parameters in the factory and the values close to it. It should be noted that due to limitations with respect to laboratory conditions, the parameter quantities were limited to three levels. Table 2 includes the runs and responses designed using Minitab 18 software.

Flotation experiments were conducted using a 4.5-L Denver D12 flotation cell with a 1250-rpm agitation rate. The feed weight was 1175 g, and sodium O,O-di-sec-butyl dithiophosphate + sodium mercaptobenzothiazole (Flomin 7240) and sodium isopropyl xanthate (Z11) were employed as collectors. The selectivity index (SI) results showed that the combination of Z11 + F7240 provides the highest selectivity of chalcopyrite against pyrite [17]. Also, polypropylene glycol (A70) and methyl isobutyl carbonyl (A65) were selected as frothers. The chemical analysis of the applied water (that was used for flotation tests) is shown in Table 3.

To perform flotation tests, after preparing the feed pulp at the defined percent solids, collector was added to the cell and mixed; afterward, frother was also added at the end of the collector conditioning time. Then, the air valve was opened and froth was collected. During operation, the pulp level in the cell was kept constant by replacing the concentrate with tap water.

In order to do a kinetic study on the copper flotation process, the generated froth was collected after 20, 60, 180, 300, 600, and 900 s. Then, the final products were filtered and dried and analyzed by the atomic absorption method using a Shimatsu 7000 unit, and copper recovery (R) was calculated using Eq. (1) [38].

The separation efficiency (SE) was calculated according to Eq. (2) [38].

where C is the dried concentrate weight, c is concentrate grade, T is the dried tailing weight, t is the tailing grade, F is the feed weight, f is the feed grade, and m is the maximum metal content of the sample.

3 Results and Discussion

3.1 The Effect of Experimental Parameters on Grade, Recovery, and Separation Efficiency

Considering the grade-time graph in Fig. 2a, as the flotation time increases, the concentrate grade (% Cu) decreases with a similar trend for all tests. Initially, as a result of the flotation of a large portion of the valuable mineral, the concentrate grade is high. However, by increasing the flotation time, the gangue particles also report to the concentrate and decrease the grade. The highest total concentrate grade is associated with test run 15 (see Fig. 2a) with 25% solids in the pulp, 30 g/t collector, and 20 g/t frother. As the recovery-time graphs show in Fig. 2b, increasing the experimental time enhances the flotation recovery of copper. The maximum recovery value was achieved in test 5 which performed with 35% solids in the pulp, 30 g/t collector, and 20 g/t frother.

Table 4 presents the results of the analysis of variances on the experimental design, regarding the concentrate grade as the response variable. Based on statistical analysis, the froth collection time and pulp density are the most influential parameters on the concentrate grade, listed in decreasing order of importance. Among the parameters studied, the concentration time has the greatest impact on the product grade in comparison to other sets of parameters such as bubble/particle contact time, bubble size, and froth stability.

The solids in pulp is the most important parameter that will influence the flotation of minerals. Similar results showing the effect of pulp density on the grade of zinc in the flotation process have been reported by Luo et al. [24]. Other variables did not show a significant influence on the response. The correlation coefficient (R2) of the derived model is 76.6%. With additional of variables A, G, and H, the value of R2 will increase to over 90%. Since these variables are anonymous and without meaning, they cannot be added to the model. In addition, by including these variables, the model will not be statistically significant (i.e., the value of the p statistic will be greater than 0.1). In general, decreasing the amount of R2 in the designed model is due to the deletion of the variables A, G, and H.

Figure 3 illustrates the effect of experimental factors on the copper grade. In all charts, the highest points indicate the optimal state for achieving the highest grade. Also, by increasing the gradient of the graphs (or the average intensity of the response changes), the result is that the relevant factor will have a greater effect on the target (grade). Therefore, the optimum value of froth collection time is 60 s and, increasing the time, decreases the copper grade due to the entrainment of gangue particles to the concentrate. The pulp density should be set at the lower level (25%), i.e., the most dilute pulp, because the selectivity is higher and the chance of gangue entrainment is lower.

Regarding copper recovery as the dependent variable, results of the analysis of variance are presented in Table 5. According to the table, froth collection time, frother dosage, and pulp density are the most influential factors, listed in decreasing order of importance. Similar results have previously been reported for sulfide copper flotation [7]. The remaining parameters do not have a significant effects on recovery, and the correlation coefficient of the model is 89.9%.

Furthermore, Fig. 4 indicates that increasing the froth collection time improves the copper recovery. Also setting the collection time at its maximum value is better for flotation recovery, because more copper-bearing particles have the chance of reporting to the concentrate. Nevertheless, as mentioned before, this phenomenon lowers the concentrate grade. Increasing the amount of frother enhances the flotation recovery due to reducing the bubble size and increasing the bubble specific surface area and carrying capacity. Decreasing bubble size can pick up more fine and ultrafine particles in the pulp zone [30], thus resulting in higher bubble loading, which in turn can enhance froth stability as more intensive coverage of bubble surface by hydrophobic particles inhibits bubble coalescence and bursting [4]. The significance of the froth zone in affecting the overall flotation recovery has been widely acknowledged [14, 29, 41]. The optimum solids content of the pulp is 35%, because by increasing the pulp density, more particles report to the concentrate and increase copper recovery (also reducing concentrate grade). Drawing on the literature in the flotation area, a dependence of mineral recovery upon pulp density can be seen [24, 26, 32]. The results of this research indicate that the recovery of mineral increased with the increase of percent of solids-in-pulp concentration.

In determination of the optimum values of the process parameters, separation efficiency can also be used. The result of the analysis for variance based on this response is shown in Table 6. According to the statistical information, concentrate collection time has the highest influence on the separation efficiency, and frother dosage is second in importance. Other variables do not show a significant influence on the response. The correlation coefficient of the model is 81.3%.

Figure 5 presents the influence of the design parameters on separation efficiency. It is clear that increasing the concentrate collection time improves the response, and consequently the third level (300 s) is preferred for this factor. Additionally, using the frother at its highest dosage level enhances the separation efficiency of the experiment.

3.2 The Kinetic Order of Copper Flotation

Determination of the kinetic constant is necessary in designing flotation circuits. However, before obtaining the flotation rate, the kinetic order should be known [9]. If the amount of valuable mineral in the pulp is more than the bubbles capacity, the flotation process displays zero-order kinetics. But if just one mineral floats or the pulp is diluted (solids content of less than 15% by weight), the flotation process displays first-order kinetics. Finally, if the grade of the valuable mineral is low or the pulp density is high, kinetics is of the second order [25]. Another way to find the kinetic order is to measure the required time to achieve 50% recovery (half-time) for pulps with different solids percentages in the pulp. If the half-times for different pulp densities are equal, the flotation process displays first-order kinetics, and if not, it displays higher order kinetics.

As mentioned before, all of the tests were carried out using percent solids values of more than or equal to 25%, and chalcopyrite, chalcocite, covellite, and pyrite are the floatable minerals. So, it is estimated that the kinetic order is probably of the second order. Considering the experimental design, all of the parameters of the test runs 8 and 10 are similar except their pulp densities (25% for run 8, and 30% for run 10). Thus, the required time to reach 50% copper recovery was obtained for both the runs according to Fig. 2. The half-time of the two tests are 145 and 45 s, respectively. The clear difference in the half-times of these tests is an indication of following second-order flotation kinetics. The experimental data were correlated with different first- and second-order models, and finally, the best model was introduced (Table 7).

3.3 The Kinetic Parameters of the Copper Flotation Models

Kinetic study of the flotation process includes the determination of all the factors which influence the amount of concentrate produced. Concentrate production can be defined in various ways, but is generally presented as recovery against time. If most of the variables are held constant, the amount of material transferred to the concentrate is directly proportional to the valuable mineral concentration [13]:

where C is the concentration of the remaining floatable material in the cell, k is the kinetic constant for the flotation rate, and n is the kinetic order. In order to calculate the kinetic parameters for the Sungun copper flotation, the results of the flotation tests at different conditions were matched with various kinetic models using nonlinear multivariable regression [20, 21, 23, 27, 35, 36, 42]. According to nonlinear multivariable regression, the results match very well with the rectangular distribution second-order kinetic model.

The final calculated values are listed in Table 8. According to the table, the runs (expect 15 and 18) match very well with the correlation coefficients of more than 90%. The highest kinetic constant with the value of 0.0756 s−1 was related to test run 16. In this experiment, percent solids, collector, and frother dosages were set at 35% and 40 and 20 g/t, respectively. In this case, the chalcopyrite mineral has a maximum recovery [18]. The predicted copper recovery using the values for the fitted parameters was 98.71% (Table 8) for test run 16, and the correlation coefficient was 99.54%. The highest predicted copper recovery of 99.57% in Table 8 was obtained for test run 10 (30% solid, 40 g/t collector, and 15 g/t frother), with the kinetic constant and correlation coefficient of 0.0536 s−1 and 98.36%, respectively.

3.4 Analysis of the Kinetic Diagrams

There are many graphical representations of separation results involving time as a crucial parameter determining the kinetics of a process. The graphical representations of results of separation are usually in the form of 2D plots relating two parameters of which one of them is time. Time can also be utilized as a complex parameter such as a process rate. The plots involving time are called kinetic curves. Theoretically, the number of kinetic curves is infinite. The basic process kinetic curves relating either yield (or recovery) and time can be modified to obtain numerous local and global efficiency curves. The global efficiency kinetic curves provide characteristic constants which do not change with the time and yield of a process [11].

Process rate is one of the main parameters of the flotation process which has a physical and operational meaning. It is the derivative of recovery with time and is defined as the slope of the process kinetic curve. Approximation of recovery vs. time experimental data can be accomplished using equations other than polynomial equations. Very useful is a family of formulas:

For n ≠ 1 and n = 1

where R∞ is the final recovery (last data point) of the process, while k and n are constant. These formulas are based on the so-called n-order kinetic equations [6, 15]. The rate of the process, dR/dt, obtained by the differentiation of Eqs. (5) and (6) is as follows:

Application of the n-order type kinetic equations with n = 2 for approximation of the separation data for Sungun copper flotation is shown in Fig. 6. The process rate was calculated using Eq. (7). A process efficiency kinetic parameter is measurable via the local curve at any time of the procedure.

Depicting \( \ln \left(\frac{\mathrm{dR}}{\mathrm{dt}}\right) \) against \( \frac{\raisebox{1ex}{$\mathrm{dR}$}\!\left/ \!\raisebox{-1ex}{$\mathrm{dt}$}\right.}{{\left({R}_{\infty }-R\right)}^2} \), another local efficiency curve is derived based on the process rate and time. Figure 7 illustrates the curves for each test which are obtained by graphing \( \ln \left(\frac{\mathrm{dR}}{\mathrm{dt}}\right) \) versus time using the data obtained from the flotation experiments. As the kinetic efficiency changes with time, the curve presents the local kinetic efficiency of the conducted experiments. The illustrated information can be exploited to compare the differences between the separation kinetic data. Regarding Fig. 7, it can be said that the relationship between \( \ln \left(\frac{\mathrm{dR}}{\mathrm{dt}}\right) \) and time follows a second-order polynomial equation. According to the figure, the maximum efficiency is associated with test run 5. This confirms the previous results reported in Section 3.1 (and Table 2).

In further investigations, \( \frac{\raisebox{1ex}{$\mathrm{dR}$}\!\left/ \!\raisebox{-1ex}{$\mathrm{dt}$}\right.}{{\left({R}_{\infty }-R\right)}^2} \) was depicted against time for all of the flotation experiments (Fig. 8). These curves show the slope of recovery-time curve which is the flotation kinetic constant. Therefore, the flotation rate is constant during the process time and equals to k, previously calculated from the rectangular distribution kinetic model.

Another graph which may be used to calculate the flotation kinetic constant for each test is the global curve of \( \frac{\mathrm{dR}}{\mathrm{dt}} \) versus(R∞ − R). To obtain this curve, the limits of R∞ should be determined, initially. According to numerous papers on kinetics of separation [6, 15], there are many different approaches to determine the global kinetic efficiency of a process. They are based on three elements: scattered data points, approximating equations, and a criterion of approximation, which is usually either visual matching or statistics.

Depicting \( \frac{\mathrm{dR}}{\mathrm{dt}} \) versus R∞ − R, for all of the flotation experiments performed in the present research, indicates that the obtained curves perfectly matched the second-order polynomial equations for which their slopes equal the calculated kinetic constant using the rectangular distribution second-order kinetic model. Table 9 shows the polynomial equations related to curves and the R2 coefficient for each test. Since a large number of the flotation experiments were carried out in this work and many curves were obtained, Fig. 9 just shows the curves related to runs 1, 8, 12, and 17.

4 Conclusion

Studying the combined effects of percentage solids (by weight) of the pulp, collector and frother dosages, and froth collection and conditioning time parameters on the response variables includes copper grade, recovery, and separation efficiency led to the following conclusions.

Concentrate grade is greatly affected by froth collection time and pulp density. Also, froth collection time, frother dosage, and pulp densities are the most influential parameters on copper recovery, in decreasing order of importance.

Correlating the recoveries of the flotation experiments with different kinetic models, it was observed that the results of the experiments matched the rectangular distribution second-order kinetic model with a correlation coefficient exceeding 90% for all tests except tests 15 and 18. The highest kinetic constant was 0.0756 s−1, which was associated with the pulp density of 35% solids content and collector and frother dosages of 40 and 20 g/t, respectively. The recovery after infinite flotation time (R∞) in this run was 85.90% with a correlation coefficient of 99.54%. The highest calculated copper recovery using the fitted kinetic parameters was 99.57% which was obtained with the highest correlation coefficient for all the tests (98.36), which were related to the pulp solids content of 30% and the collector and frother dosages of 40 and 15 g/t, respectively. Therefore, the results perfectly matched the second-order polynomial equation and the slope values were similar to the kinetic constant calculated by the second-order model with a rectangular distribution of floatability.

References

Alavi G, Hosseinzadeh MR, Moaeed M (2014) Petrography and petrography of porphyry mass of Sungun copper deposit and post-mineralogy dikes, with a view on the associated skarn (north of Varzaghan East Azarbaijan). J Petrol 17(5):17–32 (in Persian)

Azizi A, Shafaei SZ, Noaparast M, Karamoozian M (2013) The effect of pH, solid content, water chemistry and ore mineralogy on the galvanic interactions between chalcopyrite and pyrite and steel balls. Front Chem Sci Eng 7(4):464–471

Azizi A, Hassanzadeh A, Fadaei B (2015) Investigating the first-order flotation kinetics models for Sarcheshmeh copper sulfide ore. Int J Min Sci Technol 25(5):849–854

Barbian N, Cilliers JJ, Morar SH, Bradshaw DJ (2007) Froth imaging, air recovery and bubble loading to describe flotation bank performance. Int J Miner Process 84:81–88

Brozek M, Mlynarczykowska A (2013) An analysis of effect of particle size on batch flotation of coal. Physicochem Probl Miner Process 49(1):341–356

Bu X, Xie G, Peng Y, Ge L, Ni C (2017) Kinetics of flotation. Order of process, rate constant distribution and ultimate recovery. Physicochem Probl Miner Process 53(1):342–365

Celik IB, Can NM, Sherazadishvili JOHN (2010) Influence of process mineralogy on improving metallurgical performance of a flotation plant. Miner Process Extr Metall Rev 32(1):30–46

Changunda K, Harris M, Deglon DA (2008) Investigating the effect of energy input on flotation kinetics in an oscillating grid flotation cell. Miner Eng 21(12–14):924–929

Dowling EC, Klimpel RR, Aplan FF (1985) Model discrimination in the flotation of a porphyry copper ore. Miner Metall Process 2:87

Drzymala J, Kowalczuk PB, Oteng-Peprah M, Foszcz D, Muszer A, Henc T, Luszczkiewicz A (2013) Application of the grade-recovery curve in the batch flotation of Polish copper ore. Miner Eng 49:17–23

Drzymala J, Ratajczak T, Kowalczuk P (2017) Kinetic separation curves based on process rate considerations. Physicochem Probl Miner Process 53(2):983–995

Du Plessis BJ, De Villiers GH (2007) The application of the Taguchi method in the evaluation of mechanical flotation in waste activated sludge thickening. Resour Conserv Recycl 50(2):202–210

Ek C (1992) Flotation kinetics. In: Mavros P, Matis KA (eds) Innovation in Flotation Technology. Springer, Netherlands, pp 183–210

Franzidis JP, Harris MC (2013) Froth recovery factor – what is it and why is it so difficult to measure? Can Metall Q 49:337–344

Gharai M, Venugopal R (2016) Modeling of flotation process – an overview of different approaches. Miner Process Extr Metall Rev 37(2):120–133

Hanumantha Roa K, Su F, Forssberg KSE (1999) Flotation kinetics of apatite from magnetite. In: Zhang P, El-Shall H, Wiegel R (eds) Beneficiation of phosphates: advances in research and practice. pp 103–125

Hassanzadeh A, Hasanzadeh M (2016) A study on selective flotation in low and high pyritic copper sulphide ores. Sep Sci Technol 51(13):2214–2224

Hassanzadeh A, Karakaş F (2017) The kinetics modeling of chalcopyrite and pyrite, and the contribution of particle size and sodium metabisulfite to the flotation of copper complex ores. Part Sci Technol 35(4):455–461

Herrera-Urbina R (2003) Recent developments and advances in formulations and applications of chemical reagents used in froth flotation. Miner Process Ext Metall 24:139–182

Imaizumi T, Inoue T (1963) Kinetic considerations of froth flotation, 6th International Mineral Processing Congress, Cannes, pp 581–593

Klimpel RR (1980) Selection of chemical reagents for flotation, 2nd ed. In: Mullar AL, Bhappu RB (eds) Mineral processing plant design. AIME, New York, pp 907–934

Kumar S, Chary GHVC, Dastidar MG (2015) Optimization studies on coal–oil agglomeration using Taguchi (L16) experimental design. Fuel 141:9–16

Lazic P, Calic N (2000) Boltzmann’s model of flotation kinetics. Proc XXI IMPC (Rome) B(B8a):87–93

Luo X, Feng B, Wong C, Miao J, Ma B, Zhou H (2016) The critical importance of pulp concentration on the flotation of galena from a low grade lead–zinc ore. J Mater Res Technol 5(2):131–135

Mehrotra SP, Kapur PC (1974) The effects of aeration rate, particle size and pulp density on the flotation rate distributions. Powder Technol 9(74):213–219

Mowla D, Karimi G, Ostadnezhad K (2008) Removal of hematite from silica sand ore by reverse flotation technique. Sep Purif Technol 58(3):419–423

Oliveira JF, Saraiva SM, Pimenta JS, Oliveira APA (2001) Kinetics of pyrochlore flotation from Araxa mineral deposits. Miner Eng 14(1):99–105

Pecina ET, Rodríguez M, Castillo P, Díaz V, Orrantia E (2009) Effect of Leptospirillum ferrooxidans on the flotation kinetics of sulphide ores. Miner Eng 22:462–468

Rahman R, Ata S, Jameson GJ (2013) Froth recovery measurements in an industrial flotation cell. Miner Eng 53:193–202

Reay D, Ratcliff GA (1973) Removal of fine particles from water by dispersed air flotation – effects of bubble size and particle size on collection efficiency. Can J Chem Eng 51:178–185

Reyes-Bozo L, Herrera-Urbina R, Sáez-Navarrete C, Otero AF, Godoy-Faúndez A, Ginocchio R (2011) Rougher flotation of copper sulphide ore using biosolids and humic acids. Miner Eng 24:1603–1608

Sarrafi A, Rahmati B, Hassani HR, Shirazi HHA (2004) Recovery of copper from reverberator furnace slag by flotation. Miner Eng 17(3):457–459

Shahbazi B, Rezai B, Koleini SMJ, Noparast M (2013) The effect of Bubble surface area flux on flotation efficiency of pyrite particles. Iran J Chem Chem Eng 32(2):109–118

Suazo CJ, Kracht W, Alruiz OM (2010) Geometallurgical modelling of the Collahuasi flotation circuit. Miner Eng 23:137–142

Trahar WJ, Warren LJ (1976) The floatability of very fine particles—a review. Int J Miner Process 3:103–131

Vapur H, Bayat O, Uçurum M (2010) Coal flotation optimization using modified flotation parameters and combustible recovery in a Jameson cell. Energy Convers Manag 51(10):1891–1897

Vazifeh Y, Jorjani E, Bagherian A (2010) Optimization of reagent dosages for copper flotation using statistical technique. Trans Nonferrous Metals Soc China 20:2371–2378

Wills BA, Napier-Munn T (2006) Mineral processing technology. An introduction to the practical aspects of ore treatment and mineral recovery, 7th edn. Elsevier Science & Technology Books

Xian-ping L, Xue-kun T, Li-ping H, Li-ying L (2011) Effects of size distribution on flotation kinetics of Chalcopyrite, In: 2011 International Conference on Environment Science and Engineering IPCBEE. 8, 81–85 pp

Xu M (1998) Modified flotation rate constant and selectivity index. Miner Eng 11(3):271–278

Yianatos JB, Moys MH, Contreras F, Villanueva A (2008) Froth recovery of industrial flotation cells. Miner Eng 21:817–825

Zhang H, Liu J, Cao Y, Wang Y (2013) Effects of particle size on lignite reverse flotation kinetics in the presence of sodium chloride. Powder Technol 246:658–663

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Bahrami, A., Ghorbani, Y., Hosseini, M.R. et al. Combined Effect of Operating Parameters on Separation Efficiency and Kinetics of Copper Flotation. Mining, Metallurgy & Exploration 36, 409–421 (2019). https://doi.org/10.1007/s42461-018-0005-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-018-0005-y