Abstract

The pressing challenge of reducing human-induced environmental and climate impacts requires a massive transformation in the construction sector, a major contributor to energy consumption and CO2 emissions. The potential for implementing circular strategies in construction is increasingly supported by current standards and reports. Emerging technologies, like cross-laminated reclaimed timber, render cascading options potentially comparable to direct reuse. Simultaneously, wood possesses a high heating value, meaning that incineration remains a competitive alternative to recycling seen from a contemporary market perspective. This study seeks to identify the most environmentally beneficial end-of-life strategy for structural timber elements under diverse future scenarios, taking into account systemic changes occurring over time. It introduces novelty by combining elements that are relevant to this context: (1) the circular economy of timber; (2) structural calculations accounting for material quality and losses; (3) dynamic prospective life-cycle assessments (LCAs); and (4) matching different circular-economy strategies with compatible future scenarios suggested by the Shared Socioeconomic Pathways (SSPs) mentioned in the IPCC’s sixth assessment report. The results indicate that the reuse of timber is beneficial only when there is no need for additional steel brackets, underscoring the importance of a meticulous definition of the unit with all adjoining structures to ensure accurate and appropriate results. Furthermore, the cascading options are valuable primarily in preserving the high performance of the element during its subsequent use.

-

Environmental assessment of various end of life scenarios applying Prospective Life Cycle Assessment matched with Shared Socioeconomic Pathways

-

A well-defined functional unit is crucial when conducting Life-Cycle Assessments of low-impact elements like structural timber, especially in relation to the circular economy

-

Prolongation of a building’s service life constitutes a key strategy in mitigating environmental impacts

-

Cascading structural timber across multiple life-cycles proves beneficial primarily when utilized in high-performance elements like cross-laminated timber

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

1.1 Background

The reduction of environmental impacts is widely acknowledged as an urgent concern in both policy [1, 2] and the dynamic research discourse. Given that buildings and the construction sector together are currently accountable for approximately 36% of global final energy consumption and 37% of energy-related CO2 emissions [3], it becomes evident that effectively addressing the pressing challenge of reducing environmental impacts necessitates an appropriate and massive transformation of the construction sector. However, until now, the reduction of environmental impacts in the sector has been focused on the operational energy of buildings, which in turn has led to an increase in the amount of materials used and the complexity of building envelopes when it comes to influencing a building’s inherent greenhouse gas emissions [4]. The currently published standards [5, 6] and reports [7, 8] highlight the environmental potential offered by the circular economy (CE) and call upon the construction sector to “avoid the extraction and production of raw materials by galvanizing a circular economy, which requires building with less materials through better data-driven design, while reusing buildings and recycled materials wherever feasible” [7].

Recognized strategies supporting circularity within the construction sector include Design for Disassembly (DfD) and Design for Adaptability (DfA), which facilitate the future reuse of building elements (BE) by implementing appropriate strategies at the design stage [9]. Studies of DfD and DfA strategies have led to the development of several methods and related scores or indicators that reflect the ability of buildings to be easily disassembled and rebuilt in the future. However, a common standard method has not yet been developed [10].

Among the methodologies enabling the quantification of environmental impacts (EI), Life-Cycle Assessment (LCA) is a widely accepted approach that is recognized by scientific communities, industry experts and policymakers alike. LCA evaluates the environmental impacts associated with the entire life-cycle of a product or service, from the extraction to the production of materials to the manufacturing process, use and maintenance, all the way to the end-of-life phase (EoL). In the initial application phase of the LCA method, its use was limited to estimating global warming potentials (GWPs), an application which was later extended to encompass several other environmental areas of protection leading to more impact categories (beyond and including global warming) now covered by contemporary LCAs. For instance, the widely used ReCiPe 2016 impact assessment method includes characterization models for eighteen environmental impact categories [11]. Recent evolutions of the LCA methodology [10] enabled the assessment of additional sustainability dimensions, assessments of less tangible impact indicators, more understandable communication of the impact results and more applicable LCA results. These methodological advances include LCA for social assessment, assessments of biodiversity impacts, life-cycle costing, absolute sustainability assessments, future-oriented decision support, and assessment of circular economy strategies and business models [12]. Initial studies that included LCAs of building elements from a circular perspective, such as the reuse of building elements [13] or multiple life-cycles [14] revealed that DfD and DfA strategies would only benefit the environment under certain conditions. For instance, demountable connections designed for DfD will only yield environmental benefits if future reuse is ensured, e.g. via take-back solutions [15].

1.2 Literature review

The literature review focused on environmental impact assessments covering the multiple life-cycles of a building or BE and revealed two adopted approaches (the applied search keywords can be found in Online Resource 1, Sect. 1). Specifically, some publications conduct LCAs simultaneously with circularity evaluations, with the aim to find an objective weighting method in which the EI and the circularity of the buildings are expressed in one single score [16,17,18]. Due to the lack of a commonly accepted methodology on how to measure circularity, studies employ various circularity indicators, such as the Predictive Building Systemic Circularity Indicator [16] and the Detachability Index [17], making the comparison difficult. Another way of assessing multiple life-cycles is to expand the system boundaries of LCA to include the secondary life-cycles of building elements and/or its cascading possibilities (the reuse of one unit of material for several subsequent uses). One notable advantage of this approach is the ability to evaluate the different parameters and durations of life-cycles [15, 19], as well as treatment and recycling processes. Regardless of the adopted methodology, all identified papers revealed a significant influence of including circularity options, such as reuse or recycling, on the final environmental impact score. In extreme cases, this influence can lead to a shift in conclusions [17], which are also highly dependent on the spatio-temporal scopes of the individual LCAs. For instance, countries with well-developed infrastructures for the utilization of wood as an energy carrier might benefit less from direct reuse due to the energy being recovered and replacing the combustion of gas for district heating and electricity production. The value of timber as a fuel will be even greater in countries with a more carbon-intensive electricity grid, as it offers a more environmentally friendly alternative to traditional energy sources like coal and gas. In this regard, the temporal dimension is paramount, as the technological context also changes over time. Gas incineration processes will likely see an increase in efficiency, the electricity grids continually become less burdensome in terms of climate change, and increased population might increase the demand for construction wood and arable land for food production. Such developments are considered in the field of prospective LCA [20, 21]. Bruhn et al. [22] argue the importance of considering prospective elements in the LCA of buildings, as these have an extensive lifespan, often of around 60–80 years. Furthermore, Bruhn and colleagues argue the need for considering a dynamic system, as the processes of construction, maintenance and EoL occur at different points along a timeline, and hence in very different technological contexts (see Fig. 1).

Adapted from Bruhn et al. [22]

The life-cycle of a building has an extensive time horizon, and hence the LCA should be modelled with background databases that are temporally adjusted according to the year of each life-cycle stage.

Although some case studies assessing the reuse and recycling of building elements and components at the latter’s EoL based on observation and qualitative expert assessments exist [18, 23], the situation changes when considering multiple life-cycles. Publications on secondary life-cycles lack sensitivity analyses regarding potential variations due to factors such as maintenance, material quality, or material losses, indicating the need for further research [24, 25]. This research gap, which is related to systematic approaches to the quantity and quality of reusable building materials, is highlighted for mass timber, such as cross-laminated timber (CLT) and mass plywood panels by Ahn et al. [24]. Similarly, Piccardo and Hughes [25] pointed out that the level of implementation of material-efficient practices in new buildings is unknown, and the reuse potential of salvaged wood is expected to vary significantly among case studies. They revealed that this variance is influenced by factors such as upstream and downstream strategies, the possible presence of hazardous chemicals and the standards which the new building must adhere to.

1.3 Scope of the study

The study presented here compares the environmental performance of various EoL scenarios for structural building elements, applying prospective Life-Cycle Assessment (LCA). This assessment will include a sensitivity analysis of future scenarios by integrating the Shared Socioeconomic Pathways (SSP). Designed circular approaches rely on systemic data provided by our industrial partner Jjensen, specifically addressing the need for quality-based circular methodologies. Employing the SSP LCA methodology ensures a comprehensive evaluation of the environmental, social and economic impacts associated with different strategies [26]. These strategies are anticipated to be adopted in future scenarios, aligning with the dynamic approach needs highlighted by Passarelli [27].

2 Methods

2.1 LCA: goal and scope

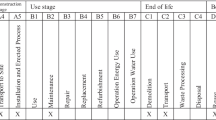

The study aims to determine which EoL strategy for structural timber elements is most beneficial to the environment under various future scenarios that take into account dynamic changes in the surrounding society. The functional unit is defined as ‘a timber column 2.50 m high as a part of a wall with a load-bearing capacity of at least 20 kN/m per meter exterior wall for 250 years, applied in a small-scale, double-storey residential building in Denmark’. The structural element is assumed to be placed inside the wall structure shielding it from the outside environment, so that no maintenance, repairs, or refurbishment processes were included. Since the technical lifespan (TL) of the element is longer than the lifespan of the building, replacement is not considered. As a result, the whole of stage B according to EN15804 is excluded from the assessment. The recycling and reuse processes are taken into account through boundary extensions in accordance with a consequential perspective on LCA (see Sect. 2.2, “LCA Methods”).

2.2 LCA methods

As far as possible the LCA applied here has been conducted in accordance with ISO 14040 and the International Reference Life Cycle Data System Handbook 2010 [28]. The results are considered relevant for researchers, designers and policy-makers alike. Consequential system boundaries were adopted, which include expanding the modelling to involve potential supply-and-demand driven consequences of the decision based on the LCA results [29]. The ReCiPe 2016 Midpoint (H) [11] impact assessment method was applied to quantify the environmental impacts, ensure the accuracy and transparency of the results and prevent burden-shifting. The Hierarchical (H) culture orientation perspective was chosen, being recognized as a consensus perspective suitable for scientific modelling [11, 30]. Finally, the ReCiPe normalization factors were applied to standardize all category indicators into a common unit, specifically by normalizing the results to the average annual per-capita emissions (unit: Person Equivalents). This approach facilitates the comparison of impact scores and enhances comprehension of the relative scale within the results.

For durable products with long lifespans, such as buildings and BE, the application of dynamic LCA (DLCA) accounting for future changes is recommended [31]. To avoid the potential drawbacks of partial DLCA implementation, the sensitivity analysis approach recommended by Sohn et al. [32] was adopted. This approach includes (a) development of scenarios and (b) life-cycle assessment, considering both static and prospective LCA. Diverse reuse and recycle scenarios linked to relevant SSP variants cover the dynamics of both the foreground and background system The management of foreground dynamics involves tailoring recycling processes to suit specific timespans. For instance, in the CASCADING scenario, current recycling practices cater to the immediate present, while future recycling processes are envisaged as engaging in longer or more complex cascading value chains. The dynamics of the background system are addressed by applying appropriate SSP scenarios. The detailed description of the linkage between developed scenarios and the SSPs is provided in Sect. 2.3.1, “Scenarios development”.

2.3 Methods for prospective LCA

The Prospective Life Cycle Assessment (PLCA), which focuses on evaluating a single point in the future (e.g. evaluating the results according to technological projections for year 2050), was chosen as the most suitable method. These single points were specified for each scenario individually and are described in the Sect. 2.3.1 Scenarios Development. The processes taking part after the year 2100 go beyond the dataset quantifying the SSPs, and are assumed constant after 2100 in order to enable the calculation, which is in line with the approach of the widely used tool LCAbyg [22].

The premise v1.8.0 (software) was utilized to create prospective versions of the ecoinvent 3.9 databasePremise couples the inventories from ecoinvent with the data from Integrated Assessment models (IAMs) REMIND [33, 34]. These IAM’s work by considering different socioeconomic future contexts (the SSP scenarios) coupled with different scenarios of climate target policy (RCP’s—Representative Concentration Pathways). Based on these models, premise calculates the technological changes necessay are currently supported: electricity production, alternative fuels, transport, and production of cement and steel [33]. The data exist as timeseries for the years 2005–2100, and the user chooses a year, for instance 2050, for which to base the future dataset on.

Finally, premise systematically implements these changes across the more than 20,000 unit processes that are covered by ecoinvent, consequently making a copy of ecoinvent that has been transformed according to an SSP-derived future scenario. This new database could, for example, be “ecoinvent 3.9.1 consequential, SSP1, RCP-2.6, 2050”, which correspond to the year 2050, reaching the Paris agreement objectives in the future SSP narrative called “taking the green road”. Usually, several variations are assessed to cover a range of possible future scenarios and/or years. For example, the changes to the above database result in the process “medium voltage electricity, from municipal waste incineration, DK”, which would have a GWP impact of 25 kgCO2-eq/MWh, compared to the 41 kg CO2-eq/MWh in the standard ecoinvent database. We emphasize that the impact results of all 20,000 processes can vary considerably depending on the systems boundaries and the impact assessment used.

For in-depth discussions of the implications of using premise for future decision support in the built environment, refer to Bruhn et al. [22]. In the following paragraphs, we provide a brief summary on IAMs, SSPs and RCPs. Towards the end of the first decade of the twenty-first century, various research teams began to formulate contemporary climate-change scenarios that extended to the year 2100. This led to the creation of Representative Concentration Pathways (RCPs), which outline potential future concentrations of greenhouse gases and the consequent climate warming that could transpire [35]. In an effort to supplement this, O’Neill and colleagues devised the Shared Socioeconomic Pathways (SSPs), which envisage five potential future global developments in the absence of climate policy, taking into account elements such as population dynamics, economic expansion, educational progress, urbanization trends and the pace of technological innovation [36]. Each of the five SSP scenarios (e.g. SSP1,nicknamed taking the green road) is characterized by a unique future narrative defined by Riahi et al. [37]. The SSPs were made public in 2016 and were utilized in the Coupled Model Intercomparison Project version 6 (CMIP6) as part of the preparations for the IPCC’s sixth assessment report [38].

The SSP scenarios represent quantified paths for societal demand, technological evolution and the associated environmental consequences (primarily focused on climate change). Integrated Assessment Models (IAMs), which are computational models that analyse a wide spectrum of physical, economic and social data to support decision-making processes, are employed to refine SSPs. In the realm of climate research, IAMs offer strategies for achieving specific political emissions goals (RCP’s) in light of socio-economic scenarios (SSPs) [39].

2.4 LCA-inventory

The Ecoinvent Consequential 3.9.1 database was used for the background processes. The foreground data, comprising literature sources, as well as inputs from experts and the project partner, was utilized. A precise description of the inventory and assumptions is available in the Online Resource 1, Sect. 2.

2.4.1 Scenario development

The development of future scenarios for LCA was based on the stepwise approach for Scenario-based Inventory Modelling for Prospective LCA (SIMPL) proposed by Langkau [40]. The time horizon of the REUSE scenario served as the baseline for all scenarios, assuming the longest lifespans, against which the shorter lifespans of the other scenarios were compared. Scenarios aligned with the lifespan of elements are depicted in Fig. 2; furthermore, the detailed Process Flow Diagrams (PFD) for each scenario are available in the Online Resource 1.

Scenarios depicting varied End-of-Life (EoL) variants aligned with expected lifespans. In the CASCADE and BAU scenarios, the service lifespan of the building plays a critical role in determining the repetition ratio. Following their initial application, the elements are either incinerated or recycled. In the REUSE option, the technical lifespan also has significance due to the assumption that, after the initial service life (application of structural elements in the building), reusing the elements in a second life-cycle with the remaining lifespan is contemplated

We adopted the PESTEL approach [41], which takes into account the political, economic, sociocultural, technological, environmental and legal factors, to comprehensively understand the potential key factors that affect future scenarios (Table 1). Subsequently, three scenarios were created by systematically combining different assumptions related to the development of these key factors. Finally, three scenarios were defined representing an optimistic green path (REUSE), the “middle of the road” green path (CASCADE) and the Business As Usual path (BAU), as shown in Table 2. A more detailed description of the scenarios is provided below.

2.4.2 BAU

2.4.2.1 Background

Fossil-fuelled Development SSP5 is foreseen for this scenario, and the focus is on rapid technological progress and the development of human capital. The push for economic and social development is coupled with the exploitation of abundant fossil-fuel resources and the adoption of resource- and energy-intensive lifestyles around the world.

2.4.2.2 Assumptions for the construction sector

Recent practices utilized in the construction sector continue. The anticipated lifespan of the building is fifty years, based on the DGNB guidelines (German Sustainable Building Council) [42]. Similar to current practice, once the building reaches its service end-of-life, its elements are no longer utilized in structural construction. Thus, to achieve the projected 250-year time horizon, the utilization of five virgin elements, with one allocated for each new construction, is considered. According to the Ministry of Environment and Food in Denmark, less than half of the Construction Demolition Waste (CDW) wood was recycled in 2012 [43]. The discrepancy between the assumed overall CDW recycling rate of 87% and the registered recycling rate of less than 50% for wood can be mainly attributed to the impregnation, rendering wood-recycling challenging [43]. The increase in the recycling rate is unlikely due to the limited demand for chipboard in Denmark [43], along with the extensive transportation distances and strict wood-quality requirements associated with recycling abroad. This preference often leans towards incineration, especially given its higher profit margin resulting from elevated energy costs [44]. Therefore, in this scenario it is expected that after the service life (SL) 50% of the wood will be recycled into chipboard, while the remaining 50% will be incinerated.

2.4.3 CASCADE

2.4.3.1 Background

Middle of the Road SSP2 is applied. Global and national institutions are slowly progressing toward sustainable development goals. Environmental systems are degrading despite some improvements, while resource and energy use are decreasing overall. Challenges in reducing vulnerability to societal and environmental changes remain.

2.4.3.2 Assumptions for the construction sector

Population growth in industrialized countries is low, leading to an expected decrease in the rate of new building constructions. Consequently, we consider current lifespans based on SBI 2013: 30 [45], which indicate a service life expectancy of 63 years for buildings and 120 years for structural elements. In order to synchronize these lifespans with the overall horizon of 250 years, four virgin elements, the first two of 60 years and the next two of 65 years, are applied.

The reuse of building elements (BE) within the construction sector has failed, yet the recycling processes of CDW have been improved due to government support. Policies supporting timber quality and banning the use of preservatives aim to achieve 100% recycling of construction timber.

For the first recycling process, current practices are assumed. These are similar to the assumptions made for the BAU scenario i.e., half of construction demolition wood is recycled for chipboard, and the other half is incinerated [43]. For future recycling that will take place in 120 years, our assumption is that initially 100% of the reclaimed timber will undergo processing to become Cross Laminated Secondary Timber (CLST), thereby retaining its original load-bearing functionality. The procedures for processing and the efficiency ratios have been developed based on the findings outlined by Risse [46], and through the according parameterization of the Ecoinvent database. A comprehensive description of these processes can be accessed in the Online Resource 1, Sect. 2. At the EoL stage of CLST it is projected that the timber will be repurposed for oriented strand board (OSB) applications for an additional sixty years. Subsequently, the wood chips resulting from this phase will be utilized in the production of particleboard (PaB). Adhesives are added to each of these wood-based products. The most commonly used adhesives include urea–formaldehyde (UF) and phenol–formaldehyde, while synthetic adhesives (e.g. polyurethane resin) are increasingly employed, particularly in eco-friendly products [47, 48]. UF adhesives pose challenges for recycling due to the cross-linked nature of the glue particles, which do not readily react with new adhesives to form a polymer network [47]. Therefore, this study assumes the use of polyurethane adhesives, which allows for subsequent recycling into structural elements, as claimed in the Environmental Product Declaration [49]. However, due to the high adhesive content and relatively low market value, particleboard is unlikely to undergo further recycling, leading to its anticipated incineration at EoL. This cascading pathway is illustrated in Fig. 2.

Exploration of extended wood compound utilization supported by emerging technologies, such as the promising lignin-based adhesives highlighted by Sander-Titgemmeyer [50], could potentially extend the cascading pathway. Nevertheless, these were considered too complex and uncertain for the scope of this study, which does not focus solely on actual recycling processes.

2.4.4 Reuse

2.4.4.1 Background

The Green Road SSP1 is used as representative, the world gradually shifts toward a more sustainable path, and consumption is oriented toward low material growth and lower resource and energy intensity.

2.4.4.2 Assumptions for the construction sector

Circular strategies such as the reuse and prolongation of a functional lifespan are increasingly supported by policies, thus enhancing the availability and quality of salvaged materials. The remaining lifespan of the reclaimed building elements serves as the starting point for the REUSE scenario and has been defined as sixty years. Determination of this is based on the initially evaluated lifespan, which corresponds to the age of the timber when used initially and the TL specified by SBI 2013:30 [37], i.e., 200 years. The same technical lifespan (TL) was initially assumed for the second life-cycle; however, a slight adjustment was made to 190 years. This modification aimed to align with the fifty-year service lifespan (SL) of the BAU-scenario multiple, given that the first cycle was assumed to have a duration of sixty years (see Fig. 3). In the second cycle, an extensive service lifespan of 120 years for the building was anticipated, aligning with future estimates from SBI. The third 7seventy-year lifecycle is envisaged as fully utilizing the lifespan of structural elements.

The data on the processes required for the reuse of elements are based on current procedures and entail demolition, transport to the warehouse, refining, lifting and moving, and storage (C1-2, D). Exact data were provided by our industrial partner Jjensen, and are described in the Online Resource 1, Sect. 2.

2.4.5 Structural assumptions

To fulfil the functional unit that includes the load-bearing capacity of the whole wall, both dimensions of columns and the spacing between them are included for the calculations. Regarding the baseline variant of the BAU and CASCADE scenarios, we anticipate using new structural timber of grade C24, with a cross-section size of 16 × 6 cm and a spacing of 62.5 cm. These specifications are derived from prior research conducted within the manufacturer's facilities in Poland and align with the German RAL certificate for timber houses. Consequently, they are deemed suitable for the European market in timber-frame houses. Given the utilization of commonly available 13-m long structural timber, the inclusion of a 10 cm cut-off is necessary when resizing it into the required 2.50 m long columns, resulting in process efficiency of 96%. Furthermore, the study incorporates metal brackets and fasteners to ensure the structural integrity of the timber column. Specifically, we anticipate using a total of four brackets for the mounting of each individual column—two at the top and two at the bottom. The total weight of brackets and fasteners calculated for one column in the baseline variant is 0.759 kg. The detailed calculations are depicted in the Online Resource 2.

Integrating the application of reclaimed wood presents challenges in relation to both structural capacity assumptions [51] and the design process [52], which needs adaptation according to the available materials. In order to address these challenges, we designed a simplified structure for a single-family house specifically for the sole purpose of facilitating the case-study calculations (for details, see the Online Resource 1, Sect. 3.2). Our industrial partner, the source of the reclaimed wood, provided information on structural timber availability during the preparation of this publication (i.e. October 2023), as documented in the Online Resource 1, Sect. 3.1). Half-timber of good quality was located, with a cross-section measuring 19.5 × 9.5 cm and lengths from 500 to 700 cm. The simple quality assessment of the reclaimed timber indicated minimal damage from deconstruction. While some holes from removed fasteners like nails were present, they were classified as not significant and non-clustered. Based on expert testimony, a 5 mm cross-section reduction was determined as the most appropriate remedy for addressing the impacts of the material damage related to nail and screw holes upon timber reuse. Moreover, having an inventory of 100 pieces of double-length half-timber greatly exceeds the required 40 columns. This surplus allows a careful selection process to minimize potential cut-offs and material losses. Consequently, it is estimated that only a 10 cm reduction in length is necessary to resize the elements to fit the new house's structure. Ultimately, a total processing efficiency ratio of 82% was calculated, enabling reuse of the elements in the new house. For detailed calculations, see Online Resource 1, Sect. 3.2.

A study by Bergsagel [51] reinforced the practical recommendation provided by the Forest Products Laboratory, suggesting a reduction in the designed values of wood elements by one grade as an appropriate design method. In their research, the design team members were not certified visual inspectors qualified to assign material to visual grades, nor could the team complete a wood species identification. Nevertheless, further analysis incorporating wood species identification and static bending tests have been proved to have a potential additional bending capacity of 46–133% when compared to the one-grade reduction strategy applied initially [51]. Thus, in our case study, we employ the one-grade reduction strategy for its recognized safety and reliability. Assuming that the reclaimed wood has initially complied with grade C18, the Danish industry standard for general-use structural wood, we anticipate a reduced grade of C16 for its second life-cycle.

Finally, calculations were performed for seven variants, assuming varied timber grades and spacing between columns, as depicted in Table 3. Consequently, in the REUSE scenario, the variants with structural capacities closest to the baseline were adopted. These include V4 for the first cycle, considering currently available reclaimed timber C16 sized at 18.5 × 8.5x250 cm with a column spacing of 125 cm and 1.551 kg of metal brackets/fasteners; and V2 for the third cycle, involving the reuse of newly applied timber, C22 sized at 15 × 5x250 cm with a column spacing of 50 cm and 0.759 kg of metal brackets/fasteners.

To analyse the feasibility of a second reuse, variants V3 and V5 were also evaluated. While not utilized for LCA calculations, they will provide valuable input for discussions on multiple reuse scenarios in the future.

3 Results and discussion

The impact assessment using ReCiPe 2016 Midpoint (H) methodology provided four impact categories, which will serve as focus points in interpreting the results. These are Freshwater ecotoxicity potential (FETP), Marine ecotoxicity potential (METP), Human toxicity potential carcinogenic (HTPc) and Human toxicity potential non-carcinogenic (HTPnc) (see Table 4). The focus on these focus points is due to their normalized impact scores exceeding 0.1 person/years. In other words, we focus the interpretation on the impact categories, where the results are more than 10% of an average contemporary world citizen’s annual emissions. Furthermore, despite its low normalized impact, the global warming potential (GWP100) was considered for interpretation, though its low normalized impact did not justify this choice. Nevertheless, significantly lower normalized GWP impacts compared to other categories hinders a detailed analysis of GWP components within a grouped graph. Therefore, the analysis of GWP is addressed in a separate chapter that follows. The impact category GWP100, calculated using the widely respected impact assessment method ReCiPe 2016, is based on radiative forcing given in the report of IPCC 2013 [53]. The underlying characterization model presents the total GWP without distinguishing between the biogenic and fossil origins, as both are equally significant contributors to climate change.

3.1 Scenario comparison

The BAU scenario shows the largest impact across all relevant categories except within the GWP impact category, as depicted in Fig. 3. However, its substantial impact stems primarily from the assumed number of cycles over a 250-year time span (see Figs. 4, 5 and 6). The cumulative impact is a reflection of the number of life-cycles, hence the greatest impact is attributed to BAU, which is based on five full life-cycles. Next is CASCADING, which relies on four full life-cycles, while the least impact is shown by REUSE, based on only three full life-cycles. Each life-cycle includes the construction process, including the production of metal brackets and structural timber, which contributes significantly to the overall impact, surpassing all other processes. This dominance is substantial; neither the recycling processes nor the use of reclaimed timber offsets the impacts from construction. This suggests that the number of life-cycles, and thus the length of the estimated SL of elements, has a paramount influence on the environmental impact calculated for the total time horizon.

Results for predefined impact categories of the BAU scenario. a shows the total results for 250 years. Multiple life-cycles are marked by gradations of colour intensity. b depicts the most relevant processes within a single recycling cycle for the scenario. A single cycle is marked with a red box in a. For the results with integrated SSP-5 base scenario, see Online Resource 1, Sect. 4.2

Results for predefined impact categories of the CASCADE scenario. a shows the total results for 250 years. Multiple life-cycles are marked by gradations of colour intensity. b depicts the most relevant processes within a single cascading-cycle for the scenario. A single cycle is marked with a red box in a. A second cycle is marked because the recycling processes for the first cycle are identical to those recognized for the BAU scenario. Depicted processes for the 2nd-4th recycling cycles are the same and include an extended cascading strategy. For the results with integrated SSP-5 base scenario, see Online Resource 1, Sect. 4.2

Results for predefined impact categories of the REUSE scenario. a shows the total results for 250 years. Multiple life-cycles are marked by gradations of colour intensity. b depicts the most relevant processes within the entire REUSE scenario, which does not contain any repetitive cycles. For the results with integrated SSP-5 base scenario, Online Resource 1, Sect. 4.2

Upon analysing the individual cycles within each scenario and their respective processes, it becomes evident that the construction stage plays a substantial role, whereas the dismantling and refining processes play a comparatively minor role, despite the energy expended during their execution (see Figs. 4, 5 and 6). The impacts avoided through cascading, i.e., the application of recycled wood to other timber components after the initial service lifespan, are almost negligible. In the best-case scenario in which reclaimed timber is used in CLT production, crediting the sawlog and sawn wood results in an offset of 0.092 Person Equivalents (PE) when normalized and summed across all four categories. However, this offset falls short of balancing the impact of cleaning and cutting, i.e., 0.100 PE. Examining the same impacts in the case of pulpwood substitution in OSB, the impacts resulting from cleaning and cutting amount to 0.079 PE, which exceeds the gains from the substitution, constituting barely −0.025 PE. In the SSP2-Base future scenario, the dynamics shift significantly. In particular, gains from substitution surpass the impacts of cleaning and cutting across all three cases (CLT, OSB, and PaB). Specifically, when crediting the sawlog and sawn wood in CLT, the offset is −0.109 PE, compared to the −0.009 PE caused by cleaning and cutting. Similarly, when substituting pulpwood in the PaB, the offset is −0.045, as opposed to the −0.006 induced by cleaning and cutting. This shift is attributed to future projections of a reduced impact caused by cleaning and cutting, which is more than four times lower than in the present scenario, combined with impacts related to pulpwood production that are 2.7 times higher for the future scenario.

Particular attention should be directed to the minimal difference in impact between constructing a timber column from virgin material and constructing it from reclaimed timber (RT). The modest improvement resulting from the full replacement of new timber (NT) with RT in the initial cycle of the REUSE scenario contributes to a mere 7% impact reduction. Moreover, the third cycle, involving the reuse of timber columns from the second construction cycle, leads to the most significant environmental burdens, surpassing those caused by construction using virgin materials. A closer examination of the construction process revealed that the minimal offsets of cascading and reuse are mainly attributable to the significant contributions of steel connectors.

Evidently, within the analysed impact categories, steel accounts for the majority of impacts, while timber emerges as the primary contributor only to the global warming potential (Table 5). This is despite steel having a considerably smaller mass flow compared to timber—0.759 kg of steel versus 10.08 kg of timber in the case of construction utilizing virgin materials. The large impact induced by steel can be attributed to transportation (16%) and energy-intensive production processes such as sinter and pig-iron production (41%), which involve the use of resources like coke. Additionally, the production of ferronickel, which enhances the steel’s resistance to corrosion, heat and wear, significantly contributes to these impacts (29%). In the third cycle of the REUSE scenario, the use of timber columns reclaimed from the second cycle imposes a reduction in spacing between the columns, requiring an additional 23.7% of new timber and metal brackets per functional unit. The increased amount of steel needed for metal brackets makes the reuse option introduced in the third cycle more burdensome than a construction employing BAU strategies.

3.1.1 Global warming potential

The Global Warming Potential (GWP) shows results that contradict those of all other relevant impact categories (Fig. 7). In this case, the cumulative impact aggregations, resulting from considering multiple life-cycles, works in favour of the BAU and CASCADE scenarios. This stems mostly from avoiding certain energy sources that are replaced by energy derived from wood-chip incineration. The offsets from incineration obtained from energy recovery decisively outweigh the negative impact caused during construction processes (Figs. 8, 9 and 10). Additionally, significant advantages are introduced in the CASCADE scenario through the substitution of sawn wood/sawlog and pulpwood, placing CASCADE as the top-ranking option (i.e., lowest environmental impacts). Furthermore, the adverse impact of steel, which was predominant in other impact categories, is decisively lower in the case of GWP compared to the gains from incineration.

In the REUSE scenario, new timber used in the second cycle is repurposed as reclaimed timber in the third cycle, thereby eliminating one incineration process. Consequently, only two cycles involve wood chips as an energy source, making the scenario less favourable in terms of GWP reduction. Significant gains attributed to energy resulting from incineration are projected to increase even further in the future, while the impact caused during construction is expected to decrease (see Figs. 8, 9 and 10). Consequently, in the SSP scenarios, the Business as Usual (BAU) option, including five cycles, emerges as the preferred choice.

4 Discussion

These analyses of three scenarios designed for a structural timber column, involving various lengths and numbers of cycles, as well as their end-of-life considerations, have highlighted a significant influence of service lifespan prolongation, which is in line with the conclusion presented by Eberhardt [15]. This study suggests that, when using materials with relatively low environmental impact, such as timber, the inclusion of energy-intensive adjoining materials like metals can significantly influence the overall impact assessment results of multiple life-cycles, despite their low mass-flow. Therefore, the load-bearing element should not be evaluated in complete isolation; rather, particular attention should be given to the proper design of all adjoining structures. This shows the importance and complexity of a well-defined functional unit when conducting LCA for structural elements, as Gislason et al. also found [54].

Moreover, the difficulty in cutting timber to precise lengths and the consequent reduction in both the cross-section and the structural grade category may hinder the reuse of timber elements, particularly when the aim is for the construction to maintain the same function or service. Firstly, the case study revealed that these reductions necessitated a decrease in spacing between the supporting columns, thereby increasing the number of columns needed. Consequently, not only did this result in a 23.7% increase in the use of new timber, but more importantly, it also required the same surplus of steel for additional metal brackets, making the reuse option less favourable when seen in a holistic perspective. Static calculations showed that opting for a second reuse would further escalate these additions to as much as 87%. This would not only lead to significantly higher environmental impacts, it would also pose challenges for designers and difficulties in ensuring compatibility with the building’s components. Secondly, in our study, we optimistically assumed that in the Green Road future scenario (SSP1), specialized metal brackets, e.g., column shoes demounted together with a column, could facilitate the reuse of wooden columns without the need to reduce their length. However, the use of such brackets might require additional steel, again leading to an overall increase in the environmental impact. Alternatively, if cutting is unavoidable, the reused wooden columns may fail to meet the minimum room-height standards, making them unsuitable for the intended purpose, such as serving as structural components in residential walls.

In the case of structural timber, optimization could be sought in the application of alternative connections such as reversible and reusable metal brackets or carpentry joints. Reusable metal brackets could be implemented multiple times, reducing the need for new connections in future life cycles. However, currently available reversible brackets require more material due to their durability and complexity [19], leading to increased environmental impacts. Therefore, further studies on streamlining the reversible connections and implementing an appropriate business model, such as a take-back service, are essential to ensure the overall climate and/or environmental benefits. Carpentry joints, on the other hand, could potentially reduce the environmental impact of the components by decreasing the utilization of high-impact metal elements. Furthermore, actual case studies have revealed challenges in the industrial processing of reclaimed wood, mainly due to the potential presence of metal screws left in the wood that can damage machinery [52]. Implementing pure wood fasteners would reduce this risk, thereby increasing the economic viability of reusing structural wood.

Notably, all structural calculations assumed a one-grade reduction in bearing capacity and reduced cross-sectional dimensions to ensure a reliable and safe design, eliminating the need for experts in assessing timber quality. This pragmatic approach mirrors real-world scenarios, as such experts are not typically involved in the design and construction process. However, it is conceivable that the optimization of timber utilization could be significantly enhanced if specialized experts were readily available for stakeholders.

Analysis of the cascading options showed that the most significant impact reductions could be achieved by the application of wood in high-performance elements as CLT. Utilizing reclaimed wood in wood-based elements like OSB and PaB results in minimal gains, primarily attributed to the high energy efficiency achieved through incineration in co-generation plants. However, the incorporation of SSP-2 indicates a potential for increased gains through the cascading of timber in the future.

5 Conclusions

Finally, we conclude that, under certain conditions, a circular economy has the potential to mitigate the environmental impacts. This potential, however, is quantitatively dependent on the context and what the future looks like. Therefore, it is imperative to adopt a comprehensive and suitable assessment approach for circular economic strategies, recognizing the dynamic nature of our circumstances. This necessitates:

-

The establishment of certification centres for reclaimed materials

-

Training experts to assess the suitability and load-bearing capacity of secondary materials

-

The provision of support for take-back services targeting materials with a high environmental impact

-

The provision of support for recycling processes that maintain the high-performance properties of materials

Furthermore, within the design community, it is essential to consider strategies such as:

-

Striving to extend the life of a building and its components.

-

Seeking slightly oversized elements for reused structural timber to counter any reduction in cross-section or structural integrity.

-

Selecting reclaimed structural timber that maintains or increases spacing comparable to business-as-usual scenarios

-

Meticulous design of high-impact elements, targeting lean construction

The research presented here revealed further research needs to support:

-

Development of quality-based guidelines for end-of-life (EoL) strategies for other structural materials such as steel and concrete, with a focus on reuse practices

-

Exploration of recycling methods and technologies that maintain the high-performance properties of the materials

-

Streamlining or slimming down reversible metal connections

6 Limitations

The data on the reuse of timber elements were collected in cooperation with a Danish company, and the calculations were tailored specifically to Danish conditions. Consequently, the findings may not be directly applicable to other regions or contexts.

In this study, the ReCiPe 2016 methodology was employed for impact assessment. While ReCiPe 2016 is a recognized full characterization methodology allowing normalization, weighting and damage (endpoint) characterization, it should be noted that the Global Warming Potential (GWP) is presented as a 'total' value within this framework. Should a more detailed analysis of GWP, including the differentiation between fossil and biogenic sources, be required, an alternative methodology may need to be considered.

Data availability

Data utilized in Manuscript is available in Online Resources. Online Resource 1 contains documentation of the literature-searching methodology, the assumptions made for the inventory analysis, including structural calculations, and the supplementary results, including tables and figures. Complete static calculations are available in Online Resource 2. The results of the LCA calculations are available in Excel format in Online Resource 3.

Code availability

Not applicable.

References

“The European Green Deal,” EUROPEAN COMMISSION, no. Brussels, 11.12.2019 COM(2019) 640 final, 2019.

WEF, “Net-Zero Challenge: The supply chain opportunity,” 2021. Accessed: Nov. 29, 2022. Available: https://www.weforum.org/reports/net-zero-challenge-the-supply-chain-opportunity

2021, “2021 Global Status Report for Buildings and Construction: Towards a Zero-emission, Efficient and Resilient Buildings and Construction Sector. Nairobi.” Available: www.globalabc.org.

Nordby AS, Berge B, Hestnes AG, Salvageability of building materials. 2007.

ISO 20887:2020(E), “Sustainability in buildings and civil engineering works-Design for disassembly and adaptability-Principles, requirements and guidance.”

Canadian Standards Association (CSA), Z782–06 Guideline for design for disassembly and adaptability in buildings, 2012.

Building Materials and the Climate: Constructing a New Future, United Nations Environment Programme, & Yale Center for Ecosystems + Architecture, 2023, Accessed: Sep. 20, 2023. Available: https://wedocs.unep.org/20.500.11822/43293

A pathway to circular construction finance A report by: With the support of the Community of Practice: Building Value.

Eberhardt LCM, Birkved M, Birgisdottir H. Building design and construction strategies for a circular economy. Archit Eng Des Manag. 2020. https://doi.org/10.1080/17452007.2020.1781588.

Kręt-Grześkowiak A, Baborska-Narożny M. Guidelines for disassembly and adaptation in architectural design compared to circular economy goals - A literature review. Sustain Prod Consum. 2023;39:1–12. https://doi.org/10.1016/j.spc.2023.04.020.

Huijbregts MAJ, ReCiPe 2016 A harmonized life cycle impact assessment method at midpoint and endpoint level Report I: Characterization.

Yılmaz Y, Seyis S, Mapping the scientific research of the life cycle assessment in the construction industry: A scientometric analysis, Build Environ, 204, 2021, https://doi.org/10.1016/j.buildenv.2021.108086.

Vandenbroucke M, Galle W, De Temmerman N, Debacker W, Paduart A. Using life cycle assessment to inform decision-making for sustainable buildings. Buildings. 2015;5(2):536–59. https://doi.org/10.3390/buildings5020536.

Buyle M, Galle W, Debacker W, Audenaert A. Sustainability assessment of circular building alternatives: Consequential LCA and LCC for internal wall assemblies as a case study in a Belgian context. J Clean Prod. 2019;218:141–56. https://doi.org/10.1016/j.jclepro.2019.01.306.

Malabi Eberhardt LC, van Stijn A, Kristensen Stranddorf L, Birkved M, Birgisdottir H, Environmental design guidelines for circular building components: The case of the circular building structure, Sustainability (Switzerland), 2021;13(10). https://doi.org/10.3390/su13105621.

Antwi-Afari P, Ng ST, Chen J, Zheng XM, Determining the impacts and recovery potentials of a modular designed residential building using the novel LCA-C2C–PBSCI method. J Clean Prod. 2022;378, https://doi.org/10.1016/j.jclepro.2022.134575.

Lam WC, Claes S, Ritzen M, Exploring the missing link between life cycle assessment and circularity assessment in the built environment. Buildings 2022;12(12). https://doi.org/10.3390/buildings12122152.

Kayaçetin NC, Verdoodt S, Lefevre L, Versele A, Integrated decision support for embodied impact assessment of circular and bio-based building components. J Build Eng 2023;63. https://doi.org/10.1016/j.jobe.2022.105427.

van Stijn A, Eberhardt LCM, Wouterszoon Jansen B, Meijer A, Environmental design guidelines for circular building components based on LCA and MFA: Lessons from the circular kitchen and renovation façade. J Clean Prod 2022;357. https://doi.org/10.1016/j.jclepro.2022.131375.

Arvidsson R, Svanström M, Sandén BA, Thonemann N, Steubing B, Cucurachi S. Terminology for future-oriented life cycle assessment: review and recommendations. Int J Life Cycle Assess. 2023. https://doi.org/10.1007/s11367-023-02265-8.

Arvidsson R, et al., Environmental assessment of emerging technologies: recommendations for prospective LCA. J Ind Ecol 22(6). Blackwell Publishing, 2018;1286–1294. https://doi.org/10.1111/jiec.12690.

Bruhn S, Sacchi R, Cimpan C, Birkved M, Ten questions concerning prospective LCA for decision support for the built environment. Build Environ 2023;242. https://doi.org/10.1016/j.buildenv.2023.110535.

Di Ruocco G, Melella R, Sabatano L, Timber buildings deconstruction as a design solution toward near zero CO2e emissions. Buildings 2023;13(1). https://doi.org/10.3390/buildings13010157.

Ahn N, Dodoo A, Riggio M, Muszynski L, Schimleck L, Puettmann M, Circular economy in mass timber construction: State-of-the-art, gaps and pressing research needs. J Build Eng 2022;53. https://doi.org/10.1016/j.jobe.2022.104562.

Piccardo C, Hughes M, Design strategies to increase the reuse of wood materials in buildings: Lessons from architectural practice. J Clean Prod, 2022;368. https://doi.org/10.1016/j.jclepro.2022.133083

Peña C, et al. Using life cycle assessment to achieve a circular economy. Int J Life Cycle Assess. 2021;26(2):215–20. https://doi.org/10.1007/s11367-020-01856-z.

Passarelli RN, Mouton BJ, Embodied life cycle impacts of lightweight building methods for affordable houses in the USA: Comparison of conventional, circular, and regenerative strategies. J Build Eng 2023;77. https://doi.org/10.1016/j.jobe.2023.107513.

ILCD Handbook: Framework and requirements for LCIA models and indicators First edition. https://doi.org/10.2788/38719.

Hauschild MZ, Rosenbaum RK, Olsen SI, Life Cycle Assessment.

https://helpcenter.ecochain.com/lcia-methods, viewed on 05.2024.

Arehart JH, Hart J, Pomponi F, D’Amico B, Carbon sequestration and storage in the built environment. Sustain Prod Consum 27. Elsevier B.V., 2021;1047–1063, Jul. 01. https://doi.org/10.1016/j.spc.2021.02.028.

Sohn J, Kalbar P, Goldstein B, Birkved M, Defining temporally dynamic life cycle assessment: A review. Integr Environ Assess Manag 16(3). Wiley-Blackwell, pp. 314–323, May 01, 2020. https://doi.org/10.1002/ieam.4235.

Luderer G, et al., REMIND—REgional Model of INvestments and Development—Overview—Version 3.0.0. Accessed: Jan. 26, 2024. Available: https://www.pik-potsdam.de/research/transformation-pathways/models/remind

Integrated Assessment of Global Environmental Change with IMAGE 3.0.

van Vuuren DP, et al. The representative concentration pathways: An overview. Clim Change. 2011;109(1):5–31. https://doi.org/10.1007/s10584-011-0148-z.

O’Neill BC, et al. A new scenario framework for climate change research: The concept of shared socioeconomic pathways. Clim Change. 2014;122(3):387–400. https://doi.org/10.1007/s10584-013-0905-2.

Riahi K, et al. The Shared Socioeconomic Pathways and their energy, land use, and greenhouse gas emissions implications: An overview. Glob Environ Chang. 2017;42:153–68. https://doi.org/10.1016/j.gloenvcha.2016.05.009.

Climate Change 2022—Mitigation of Climate Change. Cambridge University Press, 2023. https://doi.org/10.1017/9781009157926.

https://www.carbonbrief.org/explainer-how-shared-socioeconomic-pathways-explore-future-climate-change/, viewed on 05.2024.

Langkau S, et al. A stepwise approach for scenario-based inventory modelling for prospective LCA (SIMPL). Int J Life Cycle Assess. 2023;28(9):1169–93. https://doi.org/10.1007/s11367-023-02175-9.

Issa DT, Chang AV, Issa DT, Sustainable Business Strategies and PESTEL Framework. GSTF Int J Comput 2010;1(1), https://doi.org/10.5176/2010-2283_1.1.13.

Framework for carbon neutral buildings and sites. Available: www.dgnb.de.

Establishing effective markets for secondary building materials. Danish Environmental Protection Agency, 2019.

Winder GM, Bobar A. Responses to stimulate substitution and cascade use of wood within a wood use system: Experience from Bavaria, Germany. Appl Geogr. 2018;90:350–9. https://doi.org/10.1016/j.apgeog.2016.09.003.

Aagaard N-J, Brandt E, Aggerholm S, Haugbølle K, Levetider af bygningsdele ved vurdering af bæredygtighed og totaløkonomi; SBI 2013:30, Kopenhagen.

Risse M, Weber-Blaschke G, Richter K. Eco-efficiency analysis of recycling recovered solid wood from construction into laminated timber products. Sci Total Environ. 2019;661:107–19. https://doi.org/10.1016/j.scitotenv.2019.01.117.

Besserer A, Troilo S, Girods P, Rogaume Y, Brosse N, Cascading recycling of wood waste: A review. Polymers 2021;13(11). MDPI AG. https://doi.org/10.3390/polym13111752.

Shirmohammadli Y, Pizzi A, Raftery GM, Hashemi A, One-component polyurethane adhesives in timber engineering applications: A review. Int J Adhes Adhes 2023;123. Elsevier Ltd. https://doi.org/10.1016/j.ijadhadh.2023.103358.

Sonae Arauco, Oriented Strand Board, EPD as per ISO 14025 and EN 15804+A2, Berlin, Germany, Sep. 2022. Available: www.sonaearauco.com/dop

Sander-Titgemeyer A, Risse M, Weber-Blaschke G. Applying an iterative prospective LCA approach to emerging wood-based technologies: three German case studies. Int J Life Cycle Assess. 2023;28(5):495–515. https://doi.org/10.1007/s11367-023-02139-z.

Bergsagel D, Heisel F, Structural design using reclaimed wood—A case study and proposed design procedure. J Clean Prod 2023;420. https://doi.org/10.1016/j.jclepro.2023.138316.

van Stijn A, Wouterszoon Jansen B, Gruis V, van Bortel GA, Towards implementation of circular building components: A longitudinal study on the stakeholder choices in the development of 8 circular building components. J Clean Prod 2023;420. https://doi.org/10.1016/j.jclepro.2023.138287.

Stocker TF, et al., IPCC, 2013: Climate Change 2013: The Physical Science Basis. Contribution of Working Group I to the Fifth Assessment Report of the Intergovern- mental Panel on Climate Change. 2013. Accessed: Mar. 06, 2024. Available: https://www.ipcc.ch/report/ar5/wg1/

Gislason S, Bruhn S, Breseghello L, Sen B, Liu G, Naboni R. Porous 3D printed concrete beams show an environmental promise: a cradle-to-grave comparative life cycle assessment. Clean Technol Environ Policy. 2022. https://doi.org/10.1007/s10098-022-02343-9.

Funding

The Wrocław University of Science and Technology Doctoral School Scholarship was funded by the Polish Ministry of Education and Science. Simon Bruhn acknowledges PhD-position funding from Innovation Fund Denmark Grand Solutions (0225-00003B), The Velux Foundation (34214) and the EU’s Horizon 2020 Alternative fuels and mobile energy sources program (101006799). The data on reclaimed timber was provided within the CIRCUE project: Innovation Fund Denmark—Grand Solutions (0225-00003B); Link: https://circue.dk/

Author information

Authors and Affiliations

Contributions

AK-G, SB and MB contributed to the study’s conception and design. The preparation of the paper for publication was supervised by MB. Material preparation and data collection were prepared by AK-G and SB. All static assumptions and calculations were performed by AAVJ. Data analysis and the first draft of the manuscript were written by AK-G. All authors commented on previous versions of the manuscript, and all authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kręt-Grześkowiak, A., Bruhn, S., Jensen, A.A.V. et al. Quantifying the environmental impact of structural timber across multiple future lifecycles. Discov Appl Sci 6, 197 (2024). https://doi.org/10.1007/s42452-024-05860-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-024-05860-y