Abstract

Extruded snacks are commonly made with cereals with good expansion properties but low in essential nutrients such as protein and vitamins. The incorporation of legume and vegetable crops into cereal improves the nutritional value of cereal-based extruded snacks. This study aimed to develop a nutrient-rich optimized extruded snack by incorporating orange-fleshed sweet potato, finger millet, and soybean flour. The extrusion processing conditions were barrel temperature (90–130 °C) and feed moisture content (20–26%). Thirteen treatment combinations were generated for this experiment using a face-centered central composite design. Standard methods were used to evaluate the effect of barrel temperature and feed moisture content on extruded snacks' nutritional, anti-nutritional, physical, functional, and sensory acceptability. The data were analyzed, and processing conditions were optimized using the response surface methodology of Design Expert software version 13. Multiple regression analysis showed significant effects (p < 0.05) of the independent variables on moisture, protein, fat, beta-carotene, bulk density (BD), hardness, expansion ratio (ER), water absorption index (WAI), water solubility index (WSI), and overall acceptability of the extrudates. The optimum response of 14.06% protein, 3.26% ash, 69.12% carbohydrate, 6.477 mg/100 g beta-carotene, 0.36 g/ml bulk density, 2.72 Expansion ratio, 87.28 N hardness, 4.34 g/g Water absorption index, 22.34% Water solubility index, and overall acceptability of 3.30 was achieved at an optimal barrel temperature of 114.5 °C and feed moisture content of 20%. The obtained result suggests that barrel temperature and feed moisture content had a significant influence (p < 0.05) on the measured quality properties of the extrudates.

Article Highlights

-

1.

The study developed a nutrient-rich extruded snack using orange-fleshed sweet potato, finger millet, and soybean flour.

-

2.

The optimized conditions showed substantial improvements in the nutritional and physicochemical qualities of the extrudates.

-

3.

These findings underscore the potential of optimizing extrusion processing conditions for better-quality snack products.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Cereals are commonly used in extrusion processing to produce snack foods because of their high starch content. However, they lack other essential nutrients, such as proteins and micronutrients [1]. To address this issue, researchers have extensively studied the inclusion of legumes like soybeans, lentils, and peas in extruded foods due to their high protein content and other nutritional benefits [2]. In recent years, there has been a growing interest in incorporating alternative ingredients like orange-fleshed sweet potato and soybean into cereal blends to enhance the overall nutritional value of extruded snacks; this is an essential step towards promoting healthy food choices and addressing malnutrition, which is a significant health problem in developing countries like Ethiopia [3].

Finger millet (Eleusine coracana L), or ragi, is a highly nutritious cereal crop grown and consumed widely in India and Africa. It is considered one of the best plant-based sources of fiber, carbohydrates, calcium, and iron [4]. Due to the high fiber content in finger millet flour, it is characterized by high bulk density. Orange-fleshed sweet potatoes (Ipomoea batatas L) are an excellent source of beta-carotene, a type of carotenoid that converts to vitamin A. The nutritional composition of orange fleshed sweet potato is not only limited to this one but is also a good source of starch and fiber. Since this vegetable crop is rich in starch and fiber, they have a high water solubility index and bulk density [5,6,7]. Soybean (Glycine max) is a versatile and nutritious crop that has been used as a source of protein for centuries. In addition to being a good source of high-quality proteins, it is also a good source of oils, carbohydrates, and minerals. From a functional point of view, soybeans have a high water absorption capacity and a low water solubility index [8].

Extrusion cooking is a popular method for producing a wide variety of ready-to-eat food products, including extruded snack products like puffs and runs, breakfast cereals, instant soups, meat analogs, and sports foods [9]. This thermal and mechanical cooking process combines raw materials and forces them through a screw die under different combinations of moisture, heat, pressure, and mechanical shear [9]. Several studies have been conducted to identify the key factors that affect the quality of extruded snack foods. According to Muteki et al. [10], the raw materials, blending ratios, and processing conditions are the most critical factors to consider when controlling the characteristics of the final product. The processing conditions of the extruder machine significantly influence product quality. Nahemiah et al. [11] investigated the effect of feed soybean composition, barrel temperature, and feed moisture content on rice-soybean extrudates' nutritional quality and other characteristics. They found that feed soybean composition, barrel temperature, and feed moisture content significantly influenced the extrudates' nutritional properties and other characteristics. Many authors described the effects of extrusion conditions on the quality characteristics of snack food [12,13,14]. The finding of this study indicates that developing new snack food products requires a thoughtful approach to ingredient selection and processing conditions. The extrusion processing conditions, such as temperature, pressure, and moisture content, can affect the product's nutrient and physical properties. Therefore, achieving high-quality extruded snacks with optimal nutrient content requires carefully controlling the extrusion cooking conditions, especially the feed moisture content and barrel temperature. This research aims to develop nutritionally rich and optimized extruded snacks from finger millet, orange-fleshed sweet potato, and soybean composite flours.

2 Materials and methods

2.1 Experimental materials

The raw materials used in this study were finger millet, Orange fleshed sweet potato (OFSP), and soybean. The finger millet used was the Addis 01 variety, while the OFSP was the Alamura variety. The soybean used was the Clark 63 K variety. These raw materials were obtained from the Jimma Agricultural Research Centre. The selection of these varieties was based on their production and nutritional composition.

2.2 Sample flour preparation

First, the soybean was cleaned and boiled for 30 min. The husk was removed, dried at 60 °C for 16 h, and milled (KARLKOLB D-6072 Dreich, West Germany) into flour (0.5-mm sieve) [15]. Finger millet was cleaned to remove different impurities that came together with grains. After draining, it was dried at a mild temperature (60 °C for 10 h) to facilitate the milling process and milled into flours (0.5 mm sieve) [16]. OFSP was cleaned, washed, peeled, and sliced (3-mm thick pieces), followed by soaking in NaCl for 30 min. Finally, it was dried at 55 °C for 8 h and milled into flour (0.5 mm) [17]. The initial moisture contents of finger millet, OFSP, and soybean flours (wet basis) were 10.6%, 11.4%, and 3.1%, respectively. The sample flours were stored at refrigeration temperature (4 °C) in airtight polyethylene bags until analysis.

2.3 Experimental design and treatment combination

The experimental design used was the design expert software version 13, which uses the Response Surface Methodology to optimize the extrusion processing conditions. For this purpose, the central composite experimental design with a three-level, two-factor face-centered design was applied, generating 13 experimental runs using an expert's design, which includes 8 non-central points, 5 center point total, and 1 alpha value. This study used three levels of two critical numerical factors: barrel temperature at 90, 110, and 130 °C and feed moisture contents at 20%, 23%, and 26%. Based on past literature and preliminary work, the barrel temperature and feed moisture content levels were selected [18,19,20,21,22].

The full-term second-order polynomial response surface models were fitted to each variable (Y) using the following Eq. (1).

where Y represents the response, βo—intercept, A—Barrel Temperature (°C), B—Feed Moisture contents (%) ꞵ1 and ꞵ2 are linear, β11 and β22 are quadratic, β12 are interaction regression coefficient terms respectively.

2.4 Extrusion processing

A pilot scale co-rotating twin screw food extrusion cooker (Clextral, BC-21 NO 194, Firminy, France) was used to conduct the extrusion cooking (Fig. 1). The length and diameters of the screw of the extruder were 300 mm and 25 mm, respectively. The Length-to-diameter (L/D) ratio for the extruder was 20:1, and the diameter of the hole in the die was 2 mm. Before extrusion processing, a mixture of 47.46% finger millet, 34.54% orange-fleshed sweet potato, and 17.99% soybean flour was blended and homogenized in a planetary cake mixer (H.LB20/ Hungary). This optimum blending ratio was obtained from preliminary experiments. The temperatures of the extruder's third zone are controlled by a Eurotherm controller (Eurotherm Ltd., Worthing, UK) and displayed on the extruder's control board. The die's overall diameter was 2 mm. A twin-screw volumetric feeder type (KMV-KT20) is a feeding device that transfers raw flour to the extruder inlet.

Before the extrusion cooking process was conducted, the necessary calibration and adjustment of the material feed and water flow rates were performed. After the preliminary test, the barrel temperature of the metering zone, located just before the die, was allowed to operate at different temperatures starting from 90 to 130 °C. Meanwhile, the barrel temperatures of zones 1 and 2 were kept constant at 70 and 80 °C, respectively. The feed moisture content was adjusted by water injection to give moisture from 20 to 26% using the hydration equation. This adjustment was also made following the preliminary test. The moisture content of the material was adjusted by altering the pump's water injection rate (stroke level). A positive displacement pump (DKM- Clextral, France) delivers water into the extruder via an inlet port. The screw speed and feed rate were set at 300 rpm and 48.54 g/min, respectively. The torque examined from the control panel of the extruder was 4 bars.

The extrudates were collected and cooled on aluminum foil at ambient temperature (25 °C). Physical qualities such as hardness and expansion ratio were measured before milling and sieving (0.5 mm sieve). Finally, the flour was kept in plastic bags at 4 °C for further examination [23].

The feed moisture content was adjusted from 20 to 26% (on a wet basis) using the following hydration equation.

where: -. Wa—the weight of water added (g); Sw—sample flour weight (g); Mo—original flour moisture content (%); M—Required dough moisture level (%).

2.5 Chemical analysis

2.5.1 Proximate analysis

Moisture content, Crude protein, crude fiber, crude fat, and ash contents (on a dry matter basis) were examined following AOAC methods, 925.09, 923.03, 979.09, 962.09 and 923.05, respectively [24]. The carbohydrate content of the samples was calculated by subtracting the sum percentages of moisture (M), crude protein (P), fat (F), fiber (FI), and ash content (A) from 100%.

2.5.2 Beta-carotene content determination

It is essential to determine the ß-carotene content of the product since it is used to calculate the vitamin A content of the extrudates. The ß-carotene content was determined according to Park [25]. Briefly, 1 g of sample flour was mixed with 1 g CaCl2·2H2O and 50 ml extraction solvent (50% hexane, 25% acetone, and 25% ethanol, containing 0.1% BHT) and gently shaken for 30 min. To draw the calibration curve, beta-carotene standard stock solution was prepared by accurately weighing 0.01 g beta-carotene standard and dissolved in 20 ml solvent, which was similar to the extraction solvent used to extract samples (50% hexane, 25% acetone, and 25% ethanol) and made the volume to 100 ml using the same solvent. From the stock solution, 0, 2, 3, 4, and 5 ml were added to a 100 ml flask and diluted to give 0, 0.1, 0.2, 0.4, and 0.8 μg/L of beta-carotene standard in the same solvent. Extracted beta carotenes were determined using a UV–Vis spectrophotometer (T80, UK) at 450 nm wavelength. Finally, the β-carotene of each sample was calculated using the standard calibration curve equation.

2.5.3 Phytate content analysis

The procedure explained by Vaintraub and Lapteva [25] was used to calculate the phytate contents. 0.5 g of dried sample was weighed and extracted with 10 ml of 1% HCl in a mechanical shaker (HY-2(A) speed adjusting multipurpose vibrator) for 1 h at an ambient temperature and centrifuge at (3000 rpm/30 min). A clear supernatant was used to estimate phytate. 1 ml of wade reagent (containing 0.03% solution of FeCl3·6H2O and 0.3% of sulfosalicylic acid in 100 ml of water) was added to 3 ml of the sample solution (supernatant), and the mixture was mixed on a vortex for 5 s. The absorbance at 500 nm was measured using a UV–Vis spectrophotometer. A standard curve was made from absorbance versus concentration, and the slope and intercept were used for calculation. The sodium salt of phytic acid was used as a standard for constructing calibration curves. The equation of the line is y = − 0.0066x + 1.025 with R2 of 0.992.

2.5.4 Tannin content analysis

Tannin content was analyzed according to the method disclosed by Maxson and Rooney [26]. 1 g of the sample was weighed and mixed with 10 ml of 2.4% HCl solution in methanol in a screw cap test tube. Then, the tube was shaken for 24 h at room temperature on a mechanical shaker. The solution was centrifuged at 1000 rpm for 10 min. One ml of supernatant was inserted into another test tube and mixed with 5 ml of vanillin-HCl reagent (prepared by combining an equal volume of 8% concentrated HCl in methanol and 4% vanillin in methanol). D-catechin was used as a standard for condensed tannin determination. A 40 mg of Dcatechin was weighed and dissolved in 1000 ml of 1% HCl solution in methanol, which was used as stock solution. The blank sample consisted of 1 ml of extract solution with 5 ml of 1% HCl without vanillin-HCl reagent (+) catechin (0.5–12 mg /100 ml) was used as a standard for the construction of the calibration curve. A standard curve was made from absorbance versus concentration, and the slope and intercept were used for calculation. The equation OF the line is y = 0.0945x + 0.0797 with R2 of 0.999.

2.6 Physical and functional properties determination

The methods indicated by Oladele and Aina [27] were used to calculate bulk density. The bulk density was determined as the weight of the grounded flour in (g) divided by its volume (ml) after tapping. The expansion ratio (ER) was determined according to the procedure explained by Srivastava and Genitha [28], which defined ER as the ratio of the diameter of the extrudates to the diameter of the die. The \(\mathrm{ QUOTE \,BD\, g}/{\text{ml}}=\frac{\mathrm{Weight\, of \,extrudate}}{100-\mathrm{Volume \,of \,Ym}} \frac{\mathrm{weight \,of \,sample}}{\mathrm{ volume \,of \,the \,sample \,after \,trapping}}\) water absorption index of the flour was calculated according to Anderson [29]. It was computed as the weight of sediments (gel) per gram of the weight of dry sample mass. The supernatant preserved from WAI measurement was dried for 5 h at 100 °C, and the Water solubility index was determined as the weight of the dried supernatant divided by the weight of the dry sample. To calculate oil absorption capacity, one gram of flour sample was mixed in a mixer with 10 ml of oil kept at ambient temperature for 30 min and centrifuged at 3000 rpm for 30 min. Excess oil was decanted, and each sample was allowed to drain by inverting the tube over absorbent oil. Finally, Oil absorption capacity was calculated by subtracting the weight of the sample after centrifugation from the weight of the sample before centrifugation, dividing by the weight of the sample, and multiplying by one hundred [30].

2.7 Textural analysis

A Universal Texture Analyzer (TA-XT plus) was used to measure the force required to break (hardness) of the extruded products. The sample was placed on a specimen holder platform and operated in compression mode with a sharp testing blade. The texture meter head moved the probe (compression probe) down at a 5 mm/3.38 s rate until it broke the extrudates [31].

2.8 Sensory quality evaluation

The sensory quality was evaluated by 20 semi-trained panelists selected from Jimma University College of Agriculture and Veterinary Medicine Food Science and Post-harvest Technology staff. Before the evaluation, the panelists were correctly oriented regarding the sensory quality determination procedure. The panelists were asked to evaluate the organoleptic attributes, namely visual color, appearance, crispiness, flavor, and overall acceptability, using 5 points hedonic scale (5 = like very much, 4 = like moderately, 3 = neither like nor dislike, 2 = dislike moderately, 1 = dislike very much) [32]. The panelist’s average age was 34 years.

2.9 Statistical analysis

The statistical data was examined using design expert software version 13. The significant effect of the independent variables on each response was determined using the ANOVA results of the regression analysis. Significance was accepted at 0.05 level of probability (p < 0.05). The lack of fit and R-square was determined using regression analysis to check the adequacy of the model. Response surface plots were generated for all parameters to show the effects of independent variables on the response variables.

3 Results and discussions

3.1 Proximate composition of the extrudates

3.1.1 Moisture content

ANOVA table from multiple regression analysis showed that barrel temperature and feed moisture contents had strong significant (p < 0.01) quadratic effects on the moisture contents of the extrudates (Table 1). The minimum and maximum values of moisture contents of the extruded snack ranged from 4.39 to 5.80% (Table 2). This result suggested that the moisture content of current studies is found below the recommended level (< 10%) and enough to have an extended shelf life [33]. The maximum (5.80%) moisture contents were obtained at 90 °C BT and 26% of FMC, while the minimum (4.39%) moisture contents were recorded at 130 °C BT and 20% of FMC. The moisture content of current studies was lower than that of Adem et al.[12]. Enhancing the level of barrel temperature and decreasing the feed moisture contents reduced the moisture contents of extrudates, whereas increasing the feed moisture contents increased the moisture contents of the extrudates, as shown by the 3D response surface plot (Fig. 2A). This finding is consistent with the work of Adem et al. [12], who found a rise in the moisture content of extrudates as the feed moisture content enhanced in maize-lupine extruded snacks. Maximum extrudate moisture was obtained at higher feed moisture contents (26%) due to high amounts of water in the dough [11]. The other probable reason is low vaporization, resulting in high feed moisture content since moisture acts as a lubricant that decreases the products' vaporization.

3.1.2 Protein content

Multiple regression analysis indicated that barrel temperature had a strong negative significant quadratic effect (p < 0.01) while feeding moisture contents had no significant quadratic effects (p > 0.05) on the protein contents of the extrudates (Table 1). The recorded protein contents of the extrudates varied from 13.69 to 14.5% (Table 2). Increasing the barrel temperature resulted in a reduction of the protein contents of the extrudates. The protein contents decreased from 14.5 to 13.69%, with the barrel temperature rising from 90 to 130 °C. This trend is shown by 3D response surface plots (Fig. 2B). The related results supporting these findings were noted by Rosentrater et al. [34], who reported a decrease in protein contents as the barrel temperature of the extrusion rose in the teff-oat extruded snack. This decline could be due to the Millard reaction between amino groups of proteins and reducing sugars, such as glucose and fructose, at high temperatures and low moisture levels. This reaction could lead to the loss of amino acids, especially lysine, which reduces the protein content of the food [35]. The recommended dietary intake of protein content for adolescent children is 34 g/day [36]. This product can provide adolescent children with a recommended dietary allowance protein requirement of 40.26–42.26%.

3.1.3 Fat content

The barrel temperature had a highly negative significant quadratic effect at (p < 0.01), while feed moisture contents had significant effects at (p < 0.05) on the fat contents of the extrudates (Table 1). The minimum and maximum values of fat contents of the extrudates were found to be between 4.58 and 5.51% (Table 2). The response surface plot in Fig. 2C illustrates that increasing the barrel temperature and decreasing the feed moisture contents decreased the fat contents of the extrudates. The highest fat content (5.51%) of the extrudates was recorded at the lowest barrel temperature (90 °C) and highest feed moisture contents (26%) and vice versa. So, increasing the barrel temperature from 90 to 130 °C, the fat contents of the extrudates decreased from 5.51 to 4.48%. This decline is due to losing some free oil at the die when exposed to high temperatures [37]. Another potential reason for reducing fat content is the formation of complexes between starch and lipids or protein during extrusion processing, which reduces fat extractability [35].

3.1.4 Fiber content

ANOVA table illustrates that barrel temperature had a highly negative significant quadratic effect (p < 0.01). At the same time, feed moisture contents had no significant effects (p > 0.05) on the fiber contents of the extrudates (Table 1). The statistical analysis indicates that only the barrel temperature had significant effects on the fiber contents of the extrudates. The fiber content values of this study's extrudates varied from 3.62 to 3.72% (Table 2), with decreased barrel temperature and increased feed moisture content, which increased fiber content retention. The influence of the independent variables on the fiber content of the extrudates was indicated by the response surface plot (Fig. 2D). The fiber content of the extrudates decreased from 3.72 to 3.62% as the barrel temperature increased from 90 to 130 °C. Larrea et al. [38] indicated that total dietary fiber content in orange pulps decreased under high barrel temperatures and lower feed moisture contents. This decline is due to the fragmentation of insoluble dietary fiber into soluble dietary fiber, which could be degraded at high temperatures, leading to decreased fiber content [38]. The recommended daily requirement of fiber content for adolescent children is 31 g/day [36]. The produced extruded snack can supply about 11.6–12% of the recommended daily requirement of fiber content for adolescent children.

3.1.5 Ash content

ANOVA table has shown that barrel temperature and feed moisture contents had no significant quadratic effects (p > 0.05) on the ash contents of the extrudates (Table 1). The recorded result of the prepared extruded snack's ash content was between 3.11 and 3.34% (Table 2). Lower results were observed from the current finding than those reported by Omohimi et al. (2013), who stated between 3.81 and 4.95%. Adem et al. also observed the insignificant effects of barrel temperature and feed moisture on the ash contents [12] in their corn-based extruded snacks. Figure 2E shows the effects of barrel temperature and feed moisture contents on the ash content of the extrudates.

3.1.6 Carbohydrate content

ANOVA table indicated that the barrel temperature and feed moisture contents had strong significant (p < 0.01) quadratic effects on the carbohydrate contents of the extrudates (Table 1). The lower and upper results of the carbohydrates of the extrudates were between 67.32 and 70.39% (Table 2). The rise in barrel temperature and decrease in feed moisture contents enhance the carbohydrate content retention of the extrudates, as shown by 3D surface plots in Fig. 2F. The carbohydrate contents of the extrudates increase as the barrel temperature increases and are reduced as the feed moisture content rises. The increment could be due to A maximum temperature, which leads to the breakage of bonds, breaking some carbohydrate materials within the matrix and releasing some hitherto unavailable carbohydrate materials into the matrix [39]. The other potential reason is that the decrease in other proximate compositions increased the carbohydrates.

Carbohydrates are important nutrients that provide energy for our bodies. FAO/WHO [36] indicated that the recommended dietary allowance of carbohydrates for adolescent children is 130 g/day. Utilization of 100 g of extruded daily snacks would contribute about 51.7–54.1% of the recommended daily carbohydrate intake.

3.2 Beta-carotene content of the extrudates

ANOVA table indicated that the barrel temperature and feed moisture contents had strong significant (p < 0.01) quadratic effects on the beta-carotene contents of the extrudates (Table 1). The beta-carotene content of the composite flour was 7.908 mg/100 g, while the beta-carotene content of extrudates ranged from 6.345 to 6.802 mg/100 g (Table 2). As indicated by the response surface plot Fig. 2G, the increase in barrel temperature and reduction in feed moisture content decreased the beta-carotene contents of the extrudates. Similar findings were investigated by Singh et al. [40], who noted that high temperatures and low moisture content resulted in a high reduction of pro-vitamin A during extrusion cooking. This decline is because pro-vitamin A (carotenoids) are heat-sensitive and most likely sensitive to shear, pressure, and barrel temperature [41]. Beta-carotene is an intensely colored red–orange pigment available in vegetables and fruits, mostly in carrots and colorful vegetables [42]. The beta-carotene contents were used to determine vitamin A, where one retinol equivalence (RAE) equals to12 μg of β-carotene [41]. According to FAO/WHO [36], the recommended dietary allowance of vitamin A for adolescent children is 600 μg per day.

The vitamin A content of the extruded snack developed from finger millet, OFSP, and soybean ranges from 528.7 to 566.8 μg (RAE). Thus, this product will meet adolescent children's recommended dietary allowance vitamin A requirement of 88.1–94.4%.

3.3 Anti-nutritional factors of the extrudates

3.3.1 Phytate

ANOVA table implies that barrel temperature and feed moisture contents had strong significant (p < 0.01) quadratic effects on the phytate contents of the extrudates (Table 1). The extrudates' minimum and maximum phytate values varied from 149.59 to 199.46 mg/100 g (Table 2). A high temperature and low feed moisture content reduced the phytic acid contents of the extrudates Fig. 2H. As the barrel temperature increased from 90 to 130 °C, the phytate content of the extrudates decreased from 199.46 to 149.59 mg/100 g. A reduction may be attributed to the effect of extrusion temperature on the structure of phytic acid and hydrolysis of inositol hexa-phosphate fractions to penta and tetra inositol phosphate fractions [43]. Phytic acid creates an insoluble complex with particular trace elements zinc, iron, and copper, decreasing their bioavailability, decreasing hemoglobin production's tune-over, and influencing the metabolic process [44].

3.3.2 Tannin

ANOVA table indicated that barrel temperature and feed moisture contents had highly significant (p < 0.01) quadratic effects on the condensed tannin contents of the extrudates (Table 1). According to Table 2, the extrudates' tannin concentration ranged from 23.26 to 43.26 mg/100 g. The increase in barrel temperature and reduction in feed moisture contents resulted in a reduction of the tannin contents of the extrudates. At 130 °C of BT and 20% of FMC, the maximum tannin content reduction (75.9%) was examined. Figure 2I implies that the tannin content in the extrudates tended to decrease at greater temperatures. Condensed tannins may be destroyed at high temperatures or converted to other compounds, resulting in this reduction [16]. The reduction of tannin contents decreased as the feed moisture content level enhanced. Less reduction of tannin content at high feed moisture content could be due to the maximum lubricating effect of the high feed moisture content, which reduces tannin content degradation [33].

3.4 Physical and functional properties of the extrudates

Physical and Functional properties are essential sources of food characteristics and an important aspect in determining its competitiveness in the marketplace, as they can influence a food's sensory and chemical properties [42]. They have a direct and indirect relationship with the nutritional properties of the product. For instance, higher fiber content in food products will have a higher bulk density and hardness. Products with high starch content will constitute a high water solubility index.

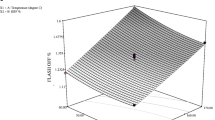

3.4.1 Bulk density

The barrel temperature and feed moisture contents had highly significant (p < 0.01) quadratic effects on the bulk density of the extrudates (Table 3). The obtained extrudates' lowest and highest bulk density values ranged from 0.3 to 0.61 g/ml, respectively (Table 4). The study by Adem et al. [12], which found that maize-based extruded snacks had concentrations ranging from 0.33 to 0.92 g/ml, was in line with these results.

The response surface plot Fig. 3A illustrates that increasing the barrel temperature and decreasing the feed moisture contents decreases the bulk density of the extrudates. The results show that maximum bulk density (0.61 g/ml) was recorded at 90 °C of BT and 26% of FMC, while the minimum BD (0.31 g/ml) was recorded at 130 °C of BT and 20% of FMC.

The current study was in line with the findings of Ding et al. [45], who noticed that High extrusion temperature and low feed moisture content had been stated to reduce the bulk density of rice-based extrudates. Because at high temperatures, the extrudates will become more gelatinized due to more significant expansion, which reduces the bulk density [1]. Also, a high feed moisture content during extrusion causes plasticization. It reduces the elasticity of the melt, leading to decreases in the expansion and enhancing the density of extrudates [31].

Bulk density measures a material's compactness or weight and is affected by several elements, including particle size and shape [46]. Foods with lower bulk densities usually have more air, making them easier to digest because they take up more space in the stomach and trigger feelings of fullness. On the other hand, high bulk density means the product is more compact and has less air, making it challenging to digest [31]. This result is particularly relevant for snack foods, where consumers typically want a product that is easy to eat and enjoy.

3.4.2 Expansion ratio

ANOVA table showed that barrel temperature and feed moisture contents have a strong, significant quadratic effect on the expansion ratios of the extrudates (p < 0.001) (Table 3). The recorded values of the expansion ratio of the prepared extrudates varied from 1.24 to 3.18 (Table 4). The maximum expansion ratio (3.18) was obtained at 130 °C of BT and 20% of FMC. At the same time, the minimum expansion ratio (1.24) was obtained at 90 °C of BT and 26% of FMC. The current values were similar to the findings of Balwant et al. [47], who reported between 2.16 and 3.30.

The rise in barrel temperature and decrease in feed moisture contents enhanced the extrudates expansion ratios, as shown by 3D response surface plots (Fig. 3B). In this study, the result showed that high feed moisture content and low barrel temperature reduced the expansion ratios of the extrudates. Several researchers have stated that an increase in barrel temperature and a decrease in feed moisture contents increase the expansion ratios of extrudates [1, 22, 23]. The rise in feed moisture content decreased the expansion ratio of the extrudate. The possible reason for this is a rise in the extrudates' bulk density at higher feed moisture contents, which leads to a decrease in the expansion ratio [31]. On the other hand, the expansion ratio is amplified by enhancing the barrel temperature of the extruder. This is due to the degree of superheating of water at higher temperatures, which means that when it comes into contact with the starch in the feed material, it causes the starch granules to swell and burst, releasing their contents. This expansion ratio is directly proportional to the degree of superheating, so higher temperatures lead to higher expansion ratios [14]. The expansion ratio (the puffing factor) is a crucial quality parameter for breakfast cereals and ready-to-eat snack foods [19]. A higher expansion ratio is generally preferable in producing extruded snacks because it is directly related to the product's degree of starch gelatinization and crispness [47].

3.4.3 Hardness

ANOVA table has shown that barrel temperature and feed moisture contents had a highly significant quadratic effect (p < 0.01) on the hardness of the extrudates, and a significant variation (p < 0.05) was observed in the interaction of barrel temperature and feed moisture contents (Table 3). The hardness values of the extrudates ranged from 70.44 to 122.1 N (Table 4). The product's breaking strength decreased from 122.1 to 70.44 N as the barrel temperature rose from 90 to 130 °C, and the feed moisture content decreased from 26 to 20%. The result obtained from the hardness test fell within the 60.23–222.7 N range proposed by Minweyelet et al. [22] for extruded snacks made from teff and rice.

The 3D Response surface plot below (Fig. 3C) indicates that increasing Barrel temperature decreases hardness while enhancing Feed moisture contents increases the breaking force of the extrudates. A temperature rise resulted in a decline in the breaking strength due to decreased melt viscosity, increasing expansion, and lowering the density, giving less hard extrudates. Hardness is the maximum force required for a probe to penetrate the extrudates [48]. When an extruded snack is too hard, it can reduce the crispness and increase the product's density. This is undesirable for consumers who prefer a light and crispy texture.

3.4.4 Water absorption index

ANOVA table has shown that barrel temperature and feed moisture contents had a strong, significant quadratic effect (p < 0.01) on the WAI of the extrudates (Table 3). The lower and upper results of the WAI of the extrudates were 3.75 and 4.71 g/g, respectively (Table 4). The values of current studies were similar to the finding of Kharat et al. [19], who recorded a range of 3.51–4.18 g/g. Increasing the barrel temperature and feed moisture contents improves the WAI of the extrudates. The effects of process variables on the WAI are indicated by response surface plots (Fig. 3D). This finding agrees with the results of Kharat et al. [19], who investigated an increment in the extrudates' WAI as the feed moisture content level increased. This increment is becausewater acts as a lubricant in the extrusion process, consequential in decreasing friction between the screw and inner wall of the barrel and starch molecules.

This results in less degradation of the amylose and amylopectin, leading to a rise in the WAI of the extrudates [49]. Initially, a rise in temperature increases the WAI, and further, it declines at high temperatures. This fluctuation is because, under lower temperatures, more undamaged polymer chains and a higher occurrence of hydrophilic groups could bind ample water, resulting in higher values of WAI. The water absorption index (WAI) is commonly used as an indicator of starch gelatinization, which is the process by which starch granules absorb water and swell, forming a gel-like structure [49].

3.4.5 Water solubility index

ANOVA table from Regression analysis has shown that barrel temperature and feed moisture contents had a highly significant quadratic effect (p < 0.01) on the WSI of the extrudates (Table 3). The minimum and maximum values of WSI of the extrudates were 18.11% and 24.4%, respectively (Table 4). The potential reason for the variation in WSI is the difference in the raw material, ingredient proportion, and processing condition.

The influence of process variables on WSI was illustrated in Fig. 3E using response surface plots. Increasing the barrel temperature and decreasing feed moisture contents enhance the WSI of the extrudates. The output of this study was consistent with Kebede et al. [48], who documented that the WSI of the extrudates was at its maximum at the maximum barrel temperature. Enhancement in WSI with extrusion temperature could expect a high level of starch degradation, which leads to an increased release of many soluble components [50]. In contrast, enhancing the feed moisture contents reduced the WSI of the extrudates. Moisture content acts as a plasticizer during extrusion cooking, making the product more viscous and reducing starch granules' degradation [19]. Since starch degradation was reduced at high feed moisture content, releasing fewer soluble molecules may lead to a decline in the extrudates' WSI.

The WSI measures the amount of soluble polysaccharides released from the starch and other components in the tested material [49]. By measuring the WSI, the degree of dextrinization or degradation of the material can be determined, which could provide valuable information about its suitability for various applications in the food industry.

3.4.6 Oil absorption capacity

ANOVA table has indicated that barrel temperature had a highly negative significant quadratic effect at (p < 0.01). At the same time, feed moisture contents had no significant quadratic effects at (p > 0.05) on the OAC of the extrudates (Table 3). The extrudates' Oil Absorption Capacity ranged from 80.1 to 86.3% (Table 4). The increase in barrel temperature and decrease in feed moisture content reduced the oil absorption capacity of the extrudates (Fig. 3F). When the barrel temperature is increased, it can cause protein denaturation, aggregation, and hydrophobic group interaction. These changes can reduce the hydrophobicity of the sample, which in turn can result in a decline in the OAC. This result is consistent with Ghumman et al. [23], who observed decreased OAC with increased barrel temperature. The oil absorption capacity is an essential functional property for improving and increasing the mouthfeel and retaining the flavor of food products. This property is critical in extruded food products, where the interaction between oil and starch can significantly impact product quality [51].

3.5 Sensory properties of the extrudates

3.5.1 Color

ANOVA table has shown that barrel temperature had a highly negative significant quadratic effect (p < 0.01). At the same time, feed moisture contents had no significant quadratic effects at (p > 0.05) on the color of the extrudates (Table 3). Increasing feed moisture content slightly enhances the color score values but has no significant effect (p > 0.05). The lower and upper color values of the extrudates evaluated by the panelist ranged from 2.98 to 3.65 (Table 4). The results showed that increasing the barrel temperature from 90 to 130 °C reduces the color acceptance of the extrudates from 3.65 to 2.98. Color gives information about the formulation and quality of the product. Barrel temperature significantly affected the color acceptance of the extruded products. Figure 4A demonstrates that increasing the barrel temperature seems to have decreased the color acceptance of the extruded products. A higher temperature produces a darker color of extrudates than a lower temperature due to non-enzymatic browning, which results from the Maillard reaction between proteins and reducing sugar [35].

3.5.2 Flavor

ANOVA table has indicated that barrel temperature had a highly positive significant quadratic effect at (p < 0.01). At the same time, feed moisture contents had no significant quadratic effects (p > 0.05) on the flavor of the extrudates (Table 3). The recorded flavor value of the extrudates varied from 3.09 to 3.51 (Table 4). Increasing the barrel temperature and feed moisture contents increased the flavor of the extrudates, as indicated by the 3D response surface plot (Fig. 4B). Tadesse et al. [33] also reported that increasing the barrel temperature improves the flavors of the extrudates. This improvement is due to increased volatile compounds as the barrel temperature rises, increasing the flavor profile and intensity because of a high degree of Maillard and caramelization reaction.

3.5.3 Crispness

ANOVA table has shown that barrel temperature and feed moisture contents, as well as their interaction, had a highly significant quadratic effect at (p < 0.01) on the crispness of the extrudates (Table 3). The maximum and minimum mean scores by panelists for crispness were 3.69 and 2.93, respectively (Table 4). The crispness of expanded extrudates is a perception of the human being and is related to the expansion and cell structure of the product [52].

The effects of process variables on the crispness of the extrudates were presented by response surface plot (Fig. 4C). The rise in barrel temperature increased the crispness of the extrudates, while the increase in feed moisture content declined the crispness of the products. This result agrees with Ding et al. [52], who found that increasing feed moisture content significantly decreased the crispness of rice extrudates. However, increasing the barrel temperature improves the extrudates' crispness due to more significant expansion. The more expanded product becomes crispier and easily brittle [31].

3.5.4 Appearance

ANOVA table has shown that barrel temperature and feed moisture contents had a highly significant quadratic effect at (p < 0.01) on the appearance of the extrudates (Table 3). The panelists' lowest and highest score appearance of the extrudates was between 3.21 and 3.84 (Table 4). The result indicated that increasing the barrel temperature and decreasing feed moisture contents decreases the extrudates' appearance. Figure 4D implies the influence of independent variables on the appearance of the extrudates. Alemayehu [16] also investigated a decrease in the appearance of the extrudates as the barrel temperature rose. The potential reason is a decrease in the color acceptance of the extrudates at higher barrel temperatures since the color is an important quality characteristic and influences the consumers' perception of the product's appearance.

3.5.5 Overall acceptability

ANOVA table has shown that barrel temperature had a strong positive significant quadratic effect (p < 0.01). At the same time, feed moisture contents had significant quadratic effects at (p < 0.05) on the OAA of the extrudates (Table 3). The overall acceptability of the prepared extrudate products varied from 2.99 to 3.39 (Table 4). The response surface plot in Fig. 4E implies that increasing feed moisture contents and decreasing barrel temperatures decline the overall acceptability of the extruded products. Similar trends were observed by Lotfi Shirazi et al. [53], who reported that a rise in feed moisture contents could decrease the OAA of the extruded snack made from barley and carrot pomace. This decrement is because the denser structures of the extrudates and the reduction in the crispness of the extrudates at high feed moisture content resulted in a reduction of the overall acceptability of the products. Meanwhile, increasing temperature enhances the OAA of the extrudates. This finding could be related to the higher expansion ratio of the extrudates at higher temperatures, which might increase the OAA of the extrudates [53]. Due to the positive relationship of the barrel temperature with the expansion ratio, a significant parameter that influences the panelists' overall acceptability of the extrudates with a high expansion ratiowas more favorable to the consumers [54].

3.6 Optimization of the extrusion processing conditions

Optimization aims to determine the ideal values of independent variables to achieve optimum response variables. This study employed numerical optimization using Design Expert version 13, with a specific target for each response. The independent variables were optimized using this approach. All the measured parameters have been targeted for optimization. Nutritional composition such as protein, fat, ash, and beta-carotene were maximized, and anti-nutritional factors were minimized. Bulk density and hardness were minimized, while the expansion ratio was maximized. WAI and WSI were set in range. All sensory quality was maximized. Finally, the optimal processing conditions for better response values were obtained at 114.5 °C of Barrel temperature and 20% of feed moisture contents with the desirability of 0.611 (Table 5).

4 Conclusion

This experiment aimed to develop a nutrient-rich extruded snack by optimizing the extrusion cooking's barrel temperature (BT) in °C and feed moisture content (FMC) in percentage. The result showed that BT (°C) and FMC (%) influenced most measured responses. However, the barrel temperature was the most significantfactor influencing product quality rather than feed moisture content. Maximum barrel temperature decreased the protein, fat, beta-carotene content, and color but improved the expansion ratio, WSI, flavor, crispness, and overall acceptability. Enhancing the FMC (%) level increased the extrudates' WAI, hardness, and bulk density. The optimum processing conditions for better quality products were accomplished at 114.5 °C of Barrel temperature and 20% of Feed moisture. The current study established the potential of OFSP at industrial levels for manufacturing nutrient-rich extruded snacks. Small and large-scale snack food-producing industries could use the achieved optimum values to develop nutrient-rich snacks with acceptable sensory quality.

Availability of data and materials

All data generated or analyzed during this study are included in this manuscript. However, raw data related to this work will be shared upon reasonable request from the corresponding author. Corresponding author email: chalagowe@gmail.com or chala.gowe@ju.edu.et.

References

Meng X, Threinen D, Hansen M, Driedger D. Effects of extrusion conditions on a chickpea flour-based snack’s system parameters and physical properties. Food Res Int. 2010;43(2):650–8. https://doi.org/10.1016/j.foodres.2009.07.016.

Shah FH, Sharif MK, Bashir S, Ahsan F. Role of healthy extruded snacks to mitigate malnutrition. Food Rev Int. 2019;35(4):299–323.

Low JW, Arimond M, Osman N, Cunguara B, Zano F, Tschirley D. A food-based approach introducing orange-fleshed sweet potatoes increased vitamin A intake and serum retinol concentrations in young children in rural Mozambique. J Nutr. 2007;137(5):1320–7.

Patel S, Naik RK, Sahu R, Nag SK, Kendra KV, Entrepreneurship development through finger millet processing for better livelihood in production catchment. 2014; 223–227.

Tadesse TF, Nigusse G, Kurabachew H. Nutritional, microbial, and sensory properties of flat-bread (kitta) prepared from blends of maize (Zea mays L.) and orange-fleshed sweet potato (Ipomoea batatas L.) flours. Int J Food Sci Nutr Eng. 2015;5(1):33–9.

Kuyu CG, Tola YB, Abdi GG, Study on post-harvest quantitative and qualitative losses of potato tubers from two different road access districts of Jimma zone, South West Ethiopia. Heliyon. 2019; 5(8).

Kuyu CG, Tola YB, Mohammed A, Ramaswamy HS. Determination of citric acid pretreatment effect on nutrient content, bioactive components, and total antioxidant capacity of dried sweet potato flour. Food Sci Nutr. 2018;6(6):1724–33.

Fabiyi EF. Soybean processing, utilization, and health benefits. Pak J Nutr. 2006;5(5):453–7.

Alam MS, Kaur J, Khaira H, Gupta K. Extrusion and extruded products: changes in quality attributes as affected by extrusion process parameters: a review. Crit Rev Food Sci Nutr. 2016;56(3):445–73. https://doi.org/10.1080/10408398.2013.779568.

Muteki K, MacGregor JF, Ueda T. Mixture designs and models for the simultaneous selection of ingredients and their ratios. Chemom Intell Lab Syst. 2007;86(1):17–25.

Nahemiah D, Nkama I, Bada MH, Gbenyi DI, Idakwo PY, Ndindeng SA, Moreira J. Multiple parameter optimization of hydration characteristics and proximate compositions of rice-soybean extruded foods. Open Access Libr J. 2017;4(2):1–22.

Adem M, Sadik JA, Worku A, Neela S. Optimization of lupine (Lupinus albus L.) composition, feed moisture content, and barrel temperatures for best quality maize-based extruded snack food. Nutr Food Sci. 2019;50(5):853–69.

Omwamba M, Mahungu SM. Development of a protein-rich ready-to-eat extruded snack from a composite blend of rice, sorghum, and soybean flour. Food Nutr Sci. 2014;05(14):1309–17. https://doi.org/10.4236/fns.2014.514142.

Gopirajah R, Muthukumarappan K. Effect of extrusion process conditions on the physical properties of tef-oat healthy snack extrudates. J Food Process Preserv. 2018. https://doi.org/10.1111/jfpp.13559.

Aye PA. Comparative nutritive value of Moringa oleifera, Tithonia diversifolia, and Gmelina arborea leaf meals. Am J Food Nutr. 2016;6(1):23–32.

Alemayehu H, product development and quality characterization of pulse-based extruded ready-to-eat snacks, 2017

Singh N, Kamath V, Narasimhamurthy K, Rajini PS. Protective effect of potato peel extract against carbon tetrachloride-induced liver injury in rats. Environ Toxicol Pharmacol. 2008;26(2):241–6.

Seth D, Badwaik LS, Ganapathy V. Effect of feed composition, moisture content and extrusion temperature on extrudate characteristics of yam-corn-rice based snack food. J Food Sci Technol. 2015;52(3):1830–8. https://doi.org/10.1007/s13197-013-1181-x.

Kharat S, Medina-Meza IG, Kowalski RJ, Hosamani A, Ramachandra CT, Hiregoudar S, Ganjyal GM. Extrusion processing characteristics of whole grain flours of select major millets (foxtail, finger, and pearl). Food Bioprod Process. 2019;114:60–71. https://doi.org/10.1016/j.fbp.2018.07.002.

Kumar N, Sarkar BC, Sharma HK. Development and characterization of extruded product using carrot pomace and rice flour. Int J Food Eng. 2010;6(3):703–17. https://doi.org/10.2202/1556-3758.1824.

Chakraborty SK, Singh DS, Kumbhar BK, Singh D. Process parameter optimization for textural properties of ready-to-eat extruded snack food from millet and legume pieces blends. J Texture Stud. 2009;40(6):710–26. https://doi.org/10.1111/j.1745-4603.2009.00207.x.

Minweyelet M, Solomon WK, Bultosa G. Effects of extrusion operating conditions and blend proportion on the physico-chemical and sensory properties of teff-rice blend extruded products. Food Res. 2021;5(2):173–83. https://doi.org/10.26656/fr.2017.5(2).467.

Ghumman A, Kaur A, Singh N, Singh B. Effect of feed moisture and extrusion temperature on lentil and horse gram’s protein digestibility and extrusion behavior. LWT Food Sci Technol. 2016. https://doi.org/10.1016/j.lwt.2016.02.032.

AOAC. Association of Official Analytical Chemists. Official methods of analysis (Vol, II 17th edition) of AOAC International. Washington, DC, USA. Official methods of 925.09, 923.03, 979.09, 962.09, 923.05 and 4.5.01. AOAC Arlington, VA; 2000

Vaintraub IA, Lapteva NA. Colorimetric determination of phytate in unpurified extracts of seeds and the products of their processing. Anal Biochem. 1988;175(1):227–30.

Maxson ED, Rooney LW. Two Methods of Tannin Analysis for Sorghum Bicolor (L.) Moenchgrain 1. Crop Sci. 1972;12(2):253–4.

Oladele AK, Aina JO, Chemical composition and functional properties of flour produced from two varieties of tigernut (Cyperus esculentus). Afr J Biotechnol 2007;6(21).

Srivastava S, Genitha TR, Yadav V. Preparation and quality evaluation of flour and biscuits from sweet potato. J Food Eng. 2012;66(3):283–9. https://doi.org/10.1016/j.jfoodeng.2004.03.019.

Anderson RA. Gelatinization of corn grits by roll-and extrusion-cooking. Cereal Sci Today. 1969;14:4–12.

Sosulski F, Garratt MD, Slinkard AE, Functional properties of ten legume flours. Can Inst Food Technol J. 1976.

Wondimu A, Admassu Emire S. Process parameters optimization for the manufacture of extruded Teff-based Gluten-Free Snacks. Adv J Food Sci Technol. 2016;11(4):299–307. https://doi.org/10.19026/ajfst.11.2414.

Muhimbula HS, Issa-Zacharia A, Kinabo J. Formulation and sensory evaluation of complementary foods from local, cheap, and readily available cereals and legumes in Iringa, Tanzania. Afr J Food Sci. 2011;5(1):26–31.

Tadesse SA, Beri GB, Abera S. Chemical and sensory quality of sorghum-based extruded product supplemented with defatted soy meal flour. Cogent Food Agric. 2019;5(1):1–19. https://doi.org/10.1080/23311932.2019.1653617.

Rosentrater KA, Muthukumarappan K, Kannadhason S. Effects of ingredients and extrusion parameters on aquafeeds containing DDGS and corn starch. J Aquac Feed Sci Nutr. 2009;1(2):44–60.

Singh S, Gamlath S, Wakeling L. Nutritional aspects of food extrusion: a review. Int J Food Sci Technol. 2007;42(8):916–29. https://doi.org/10.1111/j.1365-2621.2006.01309.x.

FAO/WHO, Vitamin A in Human Vitamin and Mineral Requirements. Report on joint FAO/WHO expert consultation in Bangkok, Thailand: World Health Organization; (2002), p. 87–107.

Hegazy H, El-Fath A, El-Bedawey A, Rahma ES, Gaafar A. Effect of extrusion processs on nutritional, functional properties and antioxidant activity of germinated chickpea incorporated corn extrudates. Am J Food Sci Nutr Res. 2017;4:59–66.

Larrea MA, Chang YK, Bustos FM. Effect of some operational extrusion parameters on the constituents of orange pulp. Food Chem. 2005;89(2):301–8.

Omohimi CI, Sobukola OP, Sarafadeen KO, Sanni LO. Effect of process parameters on the proximate composition. Funct Sens Prop. 2013;7(4):269–78.

Singh J, Dartois A, Kaur L. Starch digestibility in food matrix: a review. Trends Food Sci Technol. 2010;21(4):168–80.

Beswa D, Dlamini NR, Amonsou EO, Siwela M, Derera J. Effects of amaranth addition on the pro-vitamin A content and physical and antioxidant properties of extruded pro-vitamin A-biofortified maize snacks. J Sci Food Agric. 2016;96(1):287–94.

Tiruneh Y, Biochemical compositions, functional properties of orange fleshed sweet potato varieties and effect of treatment on its beta carotene retention. In: Doctoral dissertation. School of Graduate Studies, Addis Ababa University; 2017.

Anton AA, Fulcher RG, Arntfield SD. Physical and nutritional impact of fortification of corn starch-based extruded snacks with common bean (Phaseolus vulgaris L.) flour: effects of bean addition and extrusion cooking. Food Chem. 2009;113(4):989–96.

James S, Nwabueze TU, Quality evaluation of extruded full fat blend of African Breadfruit-Soybean-Corn Snack. 2013; March 2015.

Ding QB, Ainsworth P, Tucker G, Marson H. The effect of extrusion conditions on the physicochemical properties and sensory characteristics of rice-based expanded snacks. J Food Eng. 2005;66(3):283–9.

Osibanjo AA, Elemo GN, Henshaw FO, Awonorin SO. Effect of pretreatment conditions and varietal differences on the functional properties of sweet potato flour. IOSR J Environ Sci Toxicol Food Technol. 2017;11(04):53–9.

Balwant R, Engineering S, Campus T. Effect of extrusion processing on microstructural, physical, functional, antioxidant, and textural properties of jackfruit flesh flour, rice flour, and pigeon pea flour-based extrudates. Int Food Res J. 2019;26(June):1045–58.

Kebede L, Worku S, Bultosa G, Yetneberek S. Effect of extrusion operating conditions on the physical and sensory properties of tef (Eragrostis tef [Zucc.] Trotter) flour extrudates. Ethiop J Appl Sci Technol. 2010;1(1):27–38.

Maseta E, Mosha TC, Nyaruhucha C, Laswai H. Nutritional quality of quality protein maize-based supplementary foods. Nutr Food Sci. 2017;47(1):42–52.

Singh JP, Kaur A, Shevkani K, Singh N, Singh B. Original article Physicochemical characterization of corn extrudates prepared with varying levels of beetroot (Beta vulgaris) at different extrusion temperatures. Int J Food Sci Technol. 2016. https://doi.org/10.1111/ijfs.13051.

Awolu OO, Oluwaferanmi PM, Fafowora OI, Oseyemi GF. Optimization of the extrusion process for the production of ready-to-eat snacks from rice, cassava, and Kersting’s groundnut composite flours. LWT Food Sci Technol. 2015;64(1):18–24. https://doi.org/10.1016/j.lwt.2015.05.025.

Ding QB, Ainsworth P, Plunkett A, Tucker G, Marson H. The effect of extrusion conditions on wheat-based expanded snacks’ functional and physical properties. J Food Eng. 2006;73(2):142–8. https://doi.org/10.1016/j.jfoodeng.2005.01.013.

Lotfi Shirazi S, Koocheki A, Milani E, Mohebbi M. Production of high fiber ready-to-eat expanded snacks from barley flour and carrot pomace using extrusion cooking technology. J Food Sci Technol. 2020;57(6):2169–81.

Pasqualone A, Costantini M, Coldea TE, Summo C. Use of legumes in extrusion cooking: a review. Foods. 2020;9(7):958.

Funding

We sincerely thank Jimma University, College of Agriculture and Veterinary Medicine, for providing financial support for this study.

Author information

Authors and Affiliations

Contributions

I.M; Wrote the draft paper and manuscript, C.G.K and S.F.F, Wrote and standardized the manuscript. All authors reviewed and approved the manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

The study adhered to the ethical principles outlined in Jimma University's approved rules and regulations for conducting research. The Research and Ethical Review Board (RERB) of the College of Agriculture and Veterinary Medicine of Jimma University comprehensively reviewed the project. Upon registration, it provided a serial code of AgVmPHM/16/1.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mohammed, I., Forsido, S.F. & Kuyu, C.G. Optimization of barrel temperature and feed moisture content for better physicochemical and sensory properties of extruded snacks from blends of finger millet, sweet potato, and soybean composite flour using response surface methodology. Discov Appl Sci 6, 183 (2024). https://doi.org/10.1007/s42452-024-05822-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-024-05822-4