Abstract

We develop a disposable and cost-effective non-enzymatic glucose sensor consisting of an extended gate field effect transistor (EG-FET) to obtain effortless operation. The sensor is fabricated by printing, gold (Au) precursor ink and copper oxide nanoparticles (CuO NPs) inks using a commercial inkjet printer on a flexible Polyimide (PI) substrate. First, sensing properties are tested electrochemically. The sensor shows a sensitivity of 728.5 μA cm−2 mM−1 and a detection limit of 0.01 mM with a correlation coefficient (R) of 0.998. The observed linear dynamic range is from 0.5 to 7 mM. After that, the sensing electrode is adapted to the EG-FET. Two linear response ranges extend from 0.1 to 4 mM of a low concentration range of glucose with a sensitivity of 1295 μA cm−2 mM−1, and from 5 to 30 mM of a high concentration range of glucose with a sensitivity of 164 μA cm−2 mM−1 are observed. The EG-FET approach can enhance the detection sensitivities using amplification for a low concentration glucose range and extending a detection range for high concentration glucose. The presented work demonstrates that simply printed CuO NPs sensors can be used at low cost for disposable wide-range glucose detection devices.

Article Highlights

-

A non-enzymatic printed glucose sensor using an inkjet printer has been successfully developed.

-

CuO nanoparticles ink is printed on thin gold electrodes on Polyimide film.

-

We evaluate the glucose detection of extended-gate field-effect transistor (EG-FET) sensors.

-

The sensitivity is estimated to be 1295 μA cm−2 mM−1.

-

The EG-FET structure has the merit of a simple operation and cost-effective personal health care devices.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Recently, glucose detection techniques have attracted attention due to their various applications, not only in clinical diagnostics [1, 2] but also in biological and chemical analyses [3,4,5,6], environmental [7,8,9], food industries [10], and industrial applications [11, 12]. Although various approaches have been successfully used to detect glucose, most of these techniques use immobilized biologically derived enzymes such as glucose oxidase (GOX) or glucose dehydrogenase (GDH) [1, 13], since these enzyme-based sensors have the advantages of good selectivity and sensitivity. However, these natural enzymes have some drawbacks, including the excessive cost of extraction and purification, instability in environmental conditions of pH, temperature, and humidity, and complicated enzyme immobilization process [14, 15]. Therefore, a non-enzymatic glucose sensor has been demanded, including a facile fabrication method with a low cost. There are many reports on non-enzymatic glucose sensors based on metal (platinum, gold) and metal alloys-based sensors, non-precious transition metal/metal oxides-based sensors, boronic acid-functionalized sensors, and molecularly-imprinted polymer (MIP)-based sensors [13, 16]. Among them, CuO NPs are regarded as a promising candidate for a non-enzymatic glucose sensing precursor due to their high catalytic activity, a wide linear response range for glucose concentrations, reproducibility, durability under appropriate protection layers, a high conductivity which is merit for faradic sensing as well as a low-cost fabrication and an ease preparation.

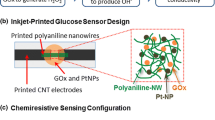

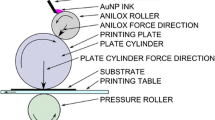

Among the cost-effective fabrication techniques, inkjet printing is recognized as a method of printing text and images onto arbitrary surfaces with a drop-on-demand process without any masks and surface treatments [17]. Various metallic inks such as copper (Cu) [18, 19], silver (Ag) [20], and gold (Au) [21, 22] are developed and are partly commercially available. Metal oxide materials are also developed, such as zinc oxide (ZnO) [23, 24] or copper oxide (CuO) [25,26,27,28] for an ink-jet printing source as precursors or nanoparticle dispersions. Ahmad et al. [25, 27] first demonstrated glucose detection using inkjet-printed CuO NPs on the Ag electrode and showed a wide linear-detecting range of 0.05 to 18.45 mM with a high sensitivity of 2762.5 μA cm−2 mM−1. Molazemhosseini et al. [26] demonstrated a single-use printed CuO NP-based film with a high sensitivity of 2419.8 μA cm−2 mM−1 in the glucose range of 0.1 to 6.5 mM. Though previous research has shown promising, they demonstrated Inkjet printing techniques using expensive drop-on-demand piezoelectric nozzle jet plotters.

Encouraged by the above developments in the nozzle jet printing techniques, we have proposed a facile fabrication of a non-enzyme printed glucose sensor by using a commercially available inkjet printer to realize a cost-effective production method. In addition to the fabrication method, a detection technique is also considered. Recently, biosensors based on a field-effect transistor (FET) have been studied, owing to the merit of the current amplification with a high signal-to-noise ratio and feasibility of various detecting target analytes as well as its low-cost fabrication, ease of operation, and fast response [29, 30]. Among FET-type biosensors, the extended-gate field-effect transistor (EG-FET) type has advantages for practical use [31]. The configuration of the EG-FET provides a lower cost than traditional FET-based biosensors since the sensing membranes are physically separated, the transistor can operate without contact with solutions, and the device can avoid environmental effects such as temperature, pH, and light. Currently, the many applications of EG-FETs are demonstrated with the detection of ionic species [32], pH [33, 34], enzymatic functionalization of sensitive surfaces for glucose [35], urea [36], and dopamine [37], etc. However, to the best of our knowledge, the non-enzymatic functionalized gate-materials FET glucose sensor is still underdeveloped.

In this study, we propose a non-enzymatic EG-FET glucose sensor consisting of a sensing membrane that is printed by an inkjet printer in both the gold electrode and the CuO NPs catalyst. The EG-FET approach can enhance the detection sensitivities using amplification for a low concentration glucose range and extending a detection range for high concentration glucose compared with the electrochemical detection mode, owing to the amplification characteristics, suggesting the proposed glucose sensor is a candidate for a cost-effective disposable glucose sensor. The paper is organized as followings. In the next section, we give the experimental details of the experimental setups used in this work, including the materials and the reagents, and the printing techniques of the non-enzyme glucose sensors. The third section presents our main results with a detailed comparison with experimental data and discusses the implications of our findings for glucose detection. The fourth section closes the paper by summarizing our main results.

2 Experimental sections

2.1 Materials and reagents

A gold nanoparticle ink (DryCure-Au) was purchased from C-Ink, Japan. Polyimide (PI) film with a thickness of 225 μm was purchased from ASONE, Japan. Copper acetate dihydride (Cu (CH3COO)2·2H2O), sodium hydroxide (NaOH), ethylene glycol, and ethanol were purchased from Kanto Chemical Co., LTD, Japan. D(+)-glucose, Ascorbic acid, Uric acid, Lactic acid, L-cysteine, Dopamine hydrochloride, K2HPO4, and NaCl were purchased from FUJIFILM Wako Chemicals, Japan. Nafion was purchased from Sigma-Aldrich, Japan. All chemicals were used without further purification.

2.2 CuO NPs ink preparation

CuO NPs were prepared by modified hydrothermal synthesis from the previous paper [26, 38]. 0.2 M of copper acetate (Cu (CH3COO)2⋅2H2O) solution, 1 mL of acetic acid (CH3COOH), and 1 g of NaOH pellets were mixed in a beaker, and then the solution was boiled at 95 °C under vigorous stirring. The solution was cooled to room temperature naturally and then the product was centrifuged at 4000 rpm for 1 min washed with distilled water and ethanol, and then dried in a vacuum at room temperature. The CuO NPs ink was obtained from the synthesized CuO NPs mixed with distilled water/ethylene glycol (95:5 v/v) and stirred for 24 h.

2.3 Inkjet printing for sensor configuration

The prepared CuO NPs ink was sonicated for 60 min before use. The ink solution was poured into an empty bottle of an ink cartridge. A commercially available inkjet printer (EPSON PX-K150) was used for Au electrodes using Au ink and depositing CuO NPs on an A4-sized polyimide film. To fabricate a non-enzymatic glucose sensor, we first printed Au electrodes by an inkjet printer on a cleaned PI film substrate using Au ink. The electrode design, which was drawn by painting software (Microsoft PowerPoint), was loaded onto the printer, and the printing was performed automatically. The electrodes were designed for two different types. One was a two-electrode configuration for an electrochemical measurement and the other was a single circular electrode for an extended-gate FET measurement. A circular area of 0.1 cm2 was printed with the Au working electrode and counter electrode. The printout film was heated by a hotplate at 80 °C for a few minutes. Next, the CuO NP ink was printed on Au/PI substrates using the same printer. CuO NP printing was repeated several times to fill the sensing area. The as-printed CuO films were post-annealed at 150 °C on a hot plate for 30 min. An epoxy resin was coated for the passivation of the tracks. Finally, the CuO film surface was coated with Nafion film by drop-casting before characterization and sensing measurements.

Figure 1a–c showed the typical photographs of as-printed Au electrodes and CuO NPs for a two-electrode configuration (electrochemical test) (a), the photograph of a Nafion coated on the sensing area, and an epoxy resin for protection for a two-electrode configuration (b), and the photograph of as-printed Au electrode and CuO NPs with Nafion and protection of an epoxy resin for an extended-gate electrode (c), respectively. The cross-sectional illustration of Nafion/CuO NPs/Au electrodes of the dot-line in (a) and (b) was shown in Fig. 1d. The surface morphology of the printed CuO film appeared as a porous structure after 17 times of overprinting. The film thickness was estimated to be ~ 1 μm thick for the Au electrode, ~ 1 μm thick for CuO film, and ~ 3 μm thick for the Nafion layer along the cross-section of the as-prepared device. The optimum number of overprinting was subject to electrochemical tests, resulting in 17 times overprinting determined in this study, which was discussed later.

a A typical image of as-printed Au electrodes and CuO NPs for a two-electrode configuration (electrochemical test). b A typical image of a Nafion coated on the sensing area and an epoxy resin for protection for a two-electrode configuration. c A typical image of as-printed Au electrode and CuO NPs with Nafion and protection of an epoxy resin for an extended-gate electrode. d A cross-sectional illustration of Nafion/CuO NPs/Au electrodes of the dot-line in a and b. e The measurement setup for the electrochemical test. The inset photograph shows the connections between the electrodes and the potentiostat device and the reference electrode. f The measurement setup for the extended-gate field-effect transistor configuration. The source and the drain electrode of the FET device are connected to the semiconductor parameter analyzer (Keithley 4200). The inset photograph shows the connections between the extended-gate electrode and the FET device with the reference electrode

2.4 Instrumentation and measurement method

In this work, a planar electrode as a two-electrode configuration consisted of working and counter electrodes for electrochemical measurement and a single-electrode configuration consisted of an extended-gate electrode for FET measurement. The reference electrode was used externally Ag/AgCl with saturated KCl solution (BAS Inc., Japan). The electrolyte was 0.1 M sodium hydroxide (NaOH) solution at room temperature. The measurement setup for the electrochemical test was shown in Fig. 1e. The planar electrodes are connected by alligator clips and lead wires to the potentiostat (ECstat-301, EC Frontier, Inc., Japan). The planar electrodes and the reference electrode were dipped into the analyte solution as shown in the inset photograph of Fig. 1e. Cyclic voltammetry (CV) and chronoamperometry (CA) measurements were performed at room temperature. The curve is an average of three trials in every three sensors. For the FET mode measurements, the sensitive membrane of the CuO NPs surface is connected to the gate electrode of the junction FET with an alligator clip terminated cable as shown in Fig. 1f. Our JFET is a commercial device 2SK369 (Trans JFET N-ch, Toshiba, Japan). The sensing structure and the reference electrode were dipped into the analyte solution with the reference electrode as shown in the inset photograph of Fig. 1f. The electrical characteristics of the FET devices were monitored by a Keithley 4200-SCS (Semiconductor Characterization System).

2.5 Characterizations

The thickness of the sensor in the stacked layer was estimated using a thickness gauge (Mitutoyo Corp., Japan). The structural properties of the luminescent thin film were investigated by XRD with Cu Kα radiation (Rigaku, RINT-Ultima III). The transmission electron microscope (TEM) was performed using a JEOL JEM-2100.

3 Results and discussion

3.1 Synthesis and characterization of CuO NPs

Figure 2 shows the structural properties of CuO NPs, the typical nanoparticle size distribution of as-prepared CuO NPs (a) and the inset shows the TEM image. The spherical shape of CuO NPs has existed uniformly with an average diameter of ∼16 nm. The XRD diffraction peaks in Fig. 2b are characterized as a monoclinic phase of CuO, which is similar to the previously reported literature [25, 26]. The average size of CuO NPs is also estimated to be ~ 15 nm from the Scherrer equation, which agrees with the TEM image. In this study, an optical photograph of CuO NPs dispersions, which is defined as CuO NPs ink, is shown in the inset of Fig. 2b. The CuO NP ink has a black color and is well-stabilized for a few hours. When the CuO NPs are inked quietly for one night, the supernatant looks transparent and the CuO NPs are separated and deposited. Therefore, the CuO NPs ink was sonicated for 10 min before use.

3.2 Non-enzymatic glucose electrochemical performance of printed CuO/Au electrode

Figure 3 shows the electrochemical behavior of the printed CuO/Au electrode at 0.1 M NaOH in the absence of glucose by cyclic voltammetry (CV). The scan rate is 100 mV s−1. As shown in Fig. 3, broad peaks can be observed in NaOH solution in the absence of glucose at around forward 0.3 V (vs. Ag/AgCl) to 0.5 V (vs. Ag/AgCl) and reverse 0.4 V, respectively, which is attributed to Cu (III)/Cu (II) redox couple (Cu (II) (OH)2 or Cu (II) O, and Cu (III) OOH) as the reaction center [39, 40]. Unfortunately, glucose oxidation peaks appear around 0.5 V (vs. Ag/AgCl), and CuO oxidation can disturb the quantitative glucose analysis of the anodic signal of glucose oxidation [13].

To determine the number of optimum overprinting for the printing in this study, the anodic current with 0.1 mM glucose concentration in 0.1 M NaOH solution at 0.5 V (vs. Ag/AgCl) was monitored with different overprint numbers as shown in Fig. 4. 0 of the overprint number means bare Au electrode. These printed CuO NPs/Au electrodes were tested without Nafion coating. The current density of the bare Au electrode was 0.64 mA cm−2 with 0.1 mM of glucose concentration at the potential of 0.5 V (vs. Ag/AgCl). When the once CuO NPs were printed on the Au electrode, the current density of the CuO NPs/Au electrode was increased to 1.08 mA cm−2. This increment of the current density is attributed to the promotion of CuO NPs. The current density increased step-wise with the overprint numbers. When 17 times the overprint, the current density reached a maximum at about 3.26 mA cm−2. When higher overprint time than 17 times, the current density had shown constantly. This is attributed to the limitation for charge transport across the CuO NPs thickness direction to the Au electrode. Hence, we utilize the overprint number of CuO NPs 17 times for further study.

Effect of the overprint number of CuO NPs ink on the CA responds with 0.1 mM of glucose concentrations at the potential of 0.5 V (vs. Ag/AgCl). The overprint number = 0 means bare Au electrode. These printed CuO NPs/Au electrodes were tested without Nafion coating. The curve is an average of three trials in every three sensors

It is well known that the Nafion film is helpful for the modification of electrode surfaces for biosensors due to its unique ion exchange, protection against large molecules, and biocompatible binders [41, 42]. Our approach requires Nafion coatings to immobilize CuO NPs on the printed Au electrodes. We compared the Nafion concentration in the glucose detection to obtain a better performance. Figure 5a shows the effect of the Nafion concentration on the CA response with different glucose concentrations at the potential of 0.5 V (vs. Ag/AgCl). It clearly shows that the current density of the glucose oxidation peak decreased with the Nafion concentration. However, for Nafion concentrations of 0.1 and 0.5 wt%, there was leakage current without glucose and the linear relationships between the glucose concentration and the current density were not obtained. Therefore, we made use of the optimum Nafion concentration of 1.0 wt.% for this study. Figure 5b shows the dependence of the peak current (at 0.5 V (vs. Ag/AgCl)) on the square root of the scan rate with different glucose concentrations. The effect of scan rate on the cyclic voltammetry of glucose electrooxidation with 1 mM, 10 mM, and 20 mM glucose, respectively. The peak of the oxidation current (Ip) at 0.5 V (vs. Ag/AgCl) increases in glucose concentration and increases with increasing scan rate. For the glucose concentration of 1 mM and 10 mM, the peak current exhibits a linear relation with the square root of the scan rate. This behavior indicates the diffusion-controlled electrochemical reaction on the electrooxidation of glucose. On the other hand, in the glucose concentration of 20 mM, the plot of the peak current versus the scan rate showed a saturation relationship. It shows the surface-controlled electrochemical reaction on the electrooxidation of glucose.

The electrochemical performance of the printed glucose sensors. a The effect of the Nafion concentration on the CA responds with different glucose concentrations at the potential of 0.5 V (vs. Ag/AgCl). The curve is an average of three trials in every three sensors. b The dependence of the peak current (at 0.5 V (vs. Ag/AgCl)) on the square root of the scan rate with different glucose concentrations. The curve is an average of three trials in every three sensors

Figure 6a shows the typical CV curves for the printed CuO/Au at 0.1 M NaOH in the absence and presence of 5 mM, 10 mM, 15 mM, and 20 mM glucose, respectively. When glucose was absent, the current signal of CuO NPs toward the oxidation of glucose was weak. On the contrary, when we added increasing concentrations of glucose, a gradual increase in current at around 0.3 V (vs. Ag/AgCl) and the broad anodic peak current at around 0.5 V (vs. Ag/AgCl) increased, which shows the oxidation of glucose owing to the catalytic behavior of the CuO NPs. Meanwhile, at the 1 mM glucose, the anodic scan exhibits a pair of redox peaks which are assigned to the Cu (II)/Cu (III) redox couple forming in an alkaline medium. The oxidation peak currents are increasing with the glucose concentrations. Possible electrochemical reactions involved in glucose oxidation through the Cu (III)/Cu (II) centers of CuO are given below [13]:

a The typical CV curves for Nafion/CuO NPs at 0.1 M NaOH in the absence and presence of 5 mM, 10 mM, 15 mM, and 20 mM glucose, respectively. The scan rate is 100 mVs−1. The curve is an average of three trials in every three sensors. b Current density—glucose concentration calibration curves. The curve is an average of three trials in every three sensors. The inset shows the focused calibration curves in the blood glucose concentration range

However, the oxidation process may start at approximately 0.3 V (vs. Ag/AgCl), and the peak shoulder current continues to increase to a potential of about 0.5 V (vs. Ag/AgCl). The exact mechanism for the oxidation of glucose in an alkaline medium at the CuO-based electrode is still not clearly understood. Another mechanism is reported that the anodic oxidation current peak shifts due to a kinetic effect by an increase in the electroactive surface area and the rate of electron transfer from glucose to the CuO-based electrode [28]. Therefore, in this study, we temporarily selected the oxidation of glucose at 0.5 (vs. Ag/AgCl) for this electrochemical study of the printed CuONPs/Au electrode.

The calibration curve of oxidation peak current density versus glucose concentration is shown in Fig. 6b. The inset represents parts of the calibration curve in the blood glucose concentration range (0–8 mM) for a linear response. At higher concentrations (above 10 mM), the oxidation peak current density was saturated, which is attributed to the saturation of the active site of the catalyst. The saturation process is reached when there is no more surface available for the surface reaction, which is supported by the result of the diffusion-controlled behavior, as shown in Fig. 5b. As shown in the inset of Fig. 6b, a typical linear calibration plot was obtained, showing a dynamic range from 0.1 to 8 mM, which includes a range of blood glucose. The linear dependence of the current density changes on the glucose concentration obeyed the slope of 728 μA cm−2 mM−1, with a correlation coefficient of 0.998. The detection limit was 0.001 mM, which is an acceptable value compared to previous reported research [13, 15, 25, 26, 28].

Further, we tested the sensor performance with interfering species to evaluate the selectivity for the interferents. Figure 7a shows the amperometric responses of the sensor for glucose with an interfering saccharide (lactose, maltose, and mannose). The response test for the interfering saccharides was done by step-by-step injection of 0.5 mM glucose and 0.05 mM of interfering saccharides, then again 0.5 mM glucose and 0.25 mM saccharides, additionally 0.5 mM glucose and 1 mM of glucose and saccharides. As shown in Fig. 7a, there appeared, causing an interfering tendency in the CA response of the sensor in glucose with interfering saccharides. The response current for 0.5 mM glucose is almost the same value as ~ 0.42 mA in each response of the interference saccharides are also observed to yield a current response of about 100% with concentration. Based on the sensing mechanism of glucose oxidation in CuO as well as transition metal catalysis involves redox reactions between CuO with lower and higher oxidation numbers. In CuO-based electrodes, the redox centers Cu(II)/Cu(III) are assigned to react with glucose (saccharides) via hydrogen abstraction of the C-1 hydrogen atom [13]. Therefore, our sensors have a sensitive ability for all kinds of saccharides without distinction. However, in general, the interfering saccharide concentration is considered to be insignificant compared with glucose in human blood.

a Amperometric responses of the Nafion/CuO NPs after mixing an environmental solution of 0.5 mM glucose and 0.25 mM of interfering saccharides (lactose, maltose, and mannose), and then 0.5 mM glucose, followed by the setting of 0.50 mm of interfering sugars, and then again 1.0 mM glucose, followed by the setting of 1.0 mM interfering sugars in 0.1 M NaOH at an applied potential of 0.30 V (vs. Ag/AgCl). b Amperometric responses for interfering test of the sensor by subsequent mixing of 0.5 mM glucose and 0.25 mM of each interfering species and chloride poisons (ascorbic acid, uric acid, lactic acid, citric acid, L-cysteine, dopamine hydrochloride, KH2PO4, and NaCl), and then again mixing 0.5 mM glucose, followed by mixing 0.5 mM of interfering species and chloride poisons in 0.1 M NaOH at an applied potential of 0.30 V (vs Ag/AgCl)

Figure 7b shows the amperometric responses for glucose with the interfering species and chloride poisons. In this case, also, considering the concentration of glucose is much higher than that of interferents in human blood, the interfering test was done by step-by-step injection of 0.5 mM glucose and 0.05 mM of a total amount of chloride poisons and interfering species, 0.5 mM glucose and 0.25 mM of a total amount of interfering species (Ascorbic acid, Uric acid, Lactic acid, and L-cysteine) and chloride poisons (Dopamine hydrochloride, K2HPO4, and NaCl). In Fig. 7b, the response of glucose was obtained well, while insignificant responses were observed for interfering species and chloride poisons. It can conclude that our sensor shows no selectivity in the saccharides. But for anti-interference performance and poison resistance.

3.3 Electrical response of EG-FET glucose sensor

Taking the results that the printed CuO NP sensing membrane can work as a non-enzymatic glucose oxidizing catalyst, we adapted the membrane for the EG-FET device configuration of the gate electrode. For the glucose-sensing performance tests, the potential response of EG-FET was performed with the different glucose concentrations. Figure 8a shows the IDS–VG transfer characteristics of the EG-FET device with different glucose concentrations to evaluate the electrode characteristics. The drain voltage VDS is 2 V. It is observed that the gate potential increases with an increasing glucose concentration of 0.1–30 mM. This is attributed to an increase in electrons through glucose oxidation and resulted in applying gate potential. The noticeable potential shifts for glucose are obtained at a higher glucose concentration range i.e. 1–30 mM. The reaction of glucose oxidation on the Nafion/CuO NPs/Au extended-gate electrode is defined as a surface catalytic reaction. Here we tried to fit the plot of the gate-potential shift to Langmuir isothermal theory [43,44,45]. The concentration of glucose adsorbed on the catalyst surface (CS) can be expressed as:

where Cglucose is the concentration of glucose in the bulk electrolyte, Cactive sites is the molar concentration of active sites on the Nafion/CuONPs/Au extended-gate electrode that is constant, and K1 is the adsorption equilibrium constant. The potential shift value (ΔV) can be approximated as \(V_{0} \approx K_{2} C_{S}\), where K2 is the constant representing the response characteristics of the EG-FET as a sensor transducer. Thus, we can express the constant \(K = K_{1} K_{2} C_{active sites}\):

As shown in Fig. 8b, the calibration data fit into the Eq. (4) moderate (R2 = 0.989) with K = K1K2Cactive sites = 0.016 and K1 = 0.067, thus ∆V can be expressed as follows:

When the glucose concentration is low (i.e. 0.067Cglucose < < 1), the equation can be expressed as ∆V = 0.016Cglucose. These results suggested that the sensitivity depends on the concentration of active sites on the catalytic electrode. There is still room for increasing the active sites to obtain a better sensitivity, for example increasing a surface area such as exchanging the electrode design as an interdigital transducer structure. The alternative solution is using an EG-FET sensing technique. The EG-FETs can convert the variation of the electrical potential connected to the transistor gate to become detectable by a variation of the FET drain current. Hence, the output characteristic of the EG-FET sensor can be modulated when the gate membrane is subject to interactions with analytes.

Figure 9a shows the IDS–VDS output characteristics of the EG-FET device configuration with different glucose concentrations. It shows the IDS of CuO NPs EG-FET vary with the concentration of glucose solution. This behavior can be explained that the IDS output being modulated by the extended-gate membrane which applied potential via the non-enzymatic reaction of glucose with CuO NPs and the formation of electrons. The generated electrons act as a negative gate potential for the n-type channel transistor. Figure 9b shows the plot of IDS as a function of glucose concentration of the EG-FET to estimate the sensitivity. The sensitivity of the EG-FET glucose sensor was calculated by dividing the slope value by the active surface area of the printed CuO/Au surface according to the following equation: Sensitivity = Slope/surface area of the printed CuO/Au sensing membrane, where the surface area of the printed CuO/Au sensing membrane is 0.1 cm2. Two linear response ranges can be observed. The first extends from 0.1 to 4 mM of a low concentration range of glucose with a sensitivity of 1295 μA cm−2 mM−1, the other from 5 to 30 mM of a high concentration range of glucose with a sensitivity of 164 μA cm−2 mM−1. The low concentration range of glucose covers a human saliva glucose level, and the high concentration range covers a human blood glucose level [46]. The first sensitivity has been comparable to electrochemical amperometric detection (728 μA cm−2 mM−1). The difference in the sensitivity values is owing to the estimation of the surface (sensing) area. In the case of the amperometric electrochemical detection, we obtained the responses, which are current densities. While, in the case of EG-FET detection, which is a voltammetry detection, the output IDS is amplified by the field-effect transistor, and then the current is divided by the sensing area. There continues to be an interpretation for what is the surface area. Moreover, the linear detection range of the subsequent sensitivity has been extended from 5 to 30 mM on behalf of saturated in the electrochemical detection. Importantly, compared with the amperometry based on electrochemical techniques, using the EG-FET approach can enhance the detection sensitivities using amplification for a low concentration glucose range and extending a detection range for high concentration glucose. Moreover, it might be a device capable of disposable, wearable devices, and effortless operation, as well as a cost-effective facile fabrication.

4 Conclusions

We developed a disposable and cost-effective glucose sensor consisting of an extended gate field effect transistor (EG-FET) to obtain effortless operation. The sensor was fabricated by printing gold (Au) precursor ink and copper oxide nanoparticles (CuO NPs) inks using a commercial inkjet printer on a flexible polyimide (PI) substrate. Electrochemically sensing tests showed the non-enzyme activity of glucose oxidation with good repeatability and reproducibility. A performance test for long-term stability will be examined in the following study. Our sensor showed no selectivity in the saccharides, but for anti-interference performance and poison resistance. The EG-FET sensor showed two linear response ranges of glucose. The first sensitivity of 1295 μA cm−2 mM−1 had a range of 0.1–4 mM glucose and the second sensitivity of 164 μA cm−2 mM−1 had a range of 5–30 mM glucose. The sensitivity and detection range was extended from the preliminary detection in the electrochemical configuration. This is due to inherent amplification and gate potentiometric detection. The presented work demonstrates that simply printed CuO NPs sensors can be operated at low cost for disposable wide-range glucose detection devices.

Data availability

All data generated or analyzed during this study are included in this published article.

References

Wang H-C, Lee A-R (2015) Recent developments in blood glucose sensors. J Food Drug Anal 23:191. https://doi.org/10.1016/j.jfda.2014.12.001

Kwon L, Long KD, Wan Y, Yu H, Cunningham BT (2016) Medical diagnostics with mobile devices: comparison of intrinsic and extrinsic sensing. Biotechnol Adv 34:291. https://doi.org/10.1016/j.biotechadv.2016.02.010

Zhao Y, Chen X, Lin S, Du D (2017) Integrated immunochromatographic strip with glucometer readout for rapid quantification of phosphorylated proteins. Anal Chim Acta 964:1. https://doi.org/10.1016/j.aca.2017.01.011

Huang H, Zhao G, Dou W (2018) Portable and quantitative point-of-care monitoring of Escherichia coli O157:H7 using a personal glucose meter based on the immunochromatographic assay. Biosens Bioelectron 107:266. https://doi.org/10.1016/j.bios.2018.02.027

Das A, Cui X, Chivukula V, Iyer SS (2018) Detection of Enzymes, Viruses, and Bacteria Using Glucose Meters. Anal Chem 90:11589. https://doi.org/10.1021/acs.analchem.8b02960

Gu C, Chen X, Liu H (2021) Portable, quantitative, and sequential monitoring of copper ions and pyrophosphate based on a DNAzyme-Fe3O4 nanosystem and glucometer readout. Anal Bioanal Chem 413:6941. https://doi.org/10.1007/s00216-021-03662-4

Xiang Y, Lu Y (2012) Portable and quantitative detection of protein biomarkers and small molecular toxins using antibodies and ubiquitous personal glucose meters. Anal Chem 84:4174. https://doi.org/10.1021/ac300517n

Bahadır EB, Sezgintürk MK (2015) Applications of commercial biosensors in clinical, food, environmental, and biothreat/biowarfare analyses. Anal Biochem 478:107. https://doi.org/10.1016/j.ab.2015.03.011

Dalgård C, Möller S, Kyvik KO (2020) Heritability of Curve Patterns in Oral Glucose Tolerance Test. Twin Res Hum Genet 23:39. https://doi.org/10.1017/thg.2020.3

Al-Mhanna N, Huebner H, Buchholz R (2018) Analysis of the sugar content in food products by using gas chromatography-mass spectrometry and enzymatic methods. Foods 7:185. https://doi.org/10.3390/foods7110185

Mitro N, Mak PA, Vargas L, Godio C, Hampton E, Molteni V, Kreusch A, Saez E (2007) The nuclear receptor LXR is a glucose sensor. Nature 445:219. https://doi.org/10.1038/nature05449

Kerzenmacher S, Ducrée J, Zengerle R, von Stetten F (2008) Energy harvesting by implantable abiotically catalyzed glucose fuel cells. J Power Sources 182:1. https://doi.org/10.1016/j.jpowsour.2008.03.031

Hwang D-W, Lee S, Seo M, Chung TD (2018) Recent advances in electrochemical non-enzymatic glucose sensors—a review. Anal Chim Acta 1033:1. https://doi.org/10.1016/j.aca.2018.05.051

Park S, Boo H, Chung TD (2006) Electrochemical non-enzymatic glucose sensors. Anal Chim Acta 556:46. https://doi.org/10.1016/j.aca.2005.05.080

Figiela M, Wysokowski M, Galinski M, Jesionowski T, Stepniak I (2018) Synthesis and characterization of novel copper oxide-chitosan nanocomposites for non-enzymatic glucose sensing. Sensors Actuators B 272:296. https://doi.org/10.1016/j.snb.2018.05.173

Williams GT, Kedge JL, Fossey JS (2021) Molecular boronic acid-based saccharide sensors. ACS Sensors 6:1508–1528. https://doi.org/10.1021/acssensors.1c00462

Perçin G, Khuri-Yakub BT (2003) Piezoelectric droplet ejector for ink-jet printing of fluids and solid particles. Rev Sci Instrum 74:1120. https://doi.org/10.1063/1.1532839

Lee Y, Choi JR, Lee KJ, Stott NE, Kim D (2008) Large-scale synthesis of copper nanoparticles by a chemically controlled reduction for applications of inkjet-printed electronics. Nanotechnology 19:415604. https://doi.org/10.1088/0957-4484/19/41/415604

Joo M, Lee B, Jeong S, Lee M (2012) Comparative studies on thermal and laser sintering for highly conductive Cu films printable on a plastic substrate. Thin Solid Films 520:2878. https://doi.org/10.1016/j.tsf.2011.11.078

Vaseem M, Lee KM, Hong A-R, Hahn Y-B (2012) Inkjet-printed fractal-connected electrodes with silver nanoparticle ink. ACS Appl Mater Interfaces 4:3300. https://doi.org/10.1021/am300689d

Määttänen A, Vanamo U, Ihalainen P, Pulkkinen P, Tenhu H, Bobacka J, Peltonen J (2013) A low-cost paper-based inkjet-printed platform for electrochemical analyses. Sensors Actuators B 177:153. https://doi.org/10.1016/j.snb.2012.10.113

Sjöberg P, Määttänen A, Vanamo U, Novell M, Ihalainen P, Andrade FJ, Bobacka J, Peltonen J (2016) Paper-based potentiometric ion sensors constructed on ink-jet printed gold electrodes. Sensors Actuators B 224:325. https://doi.org/10.1016/j.snb.2015.10.051

Ko SH, Lee D, Hotz N, Yeo J, Hong S, Nam KH, Grigoropoulos CP (2012) Digital selective growth of ZnO nanowire arrays from inkjet-printed nanoparticle seeds on a flexible substrate. Langmuir 28:4787. https://doi.org/10.1021/la203781x

Kwon J, Hong S, Lee H, Yeo J, Lee SS, Ko SH (2013) Direct selective growth of ZnO nanowire arrays from inkjet-printed zinc acetate precursor on a heated substrate. Nanoscale Res Lett 8:489. https://doi.org/10.1186/1556-276X-8-489

Ahmad R, Vaseem M, Tripathy N, Hahn Y-B (2013) Wide linear-range detecting nonenzymatic glucose biosensor based on CuO nanoparticles inkjet-printed on electrodes. Anal Chem 85:10448. https://doi.org/10.1021/ac402925r

Molazemhosseini A, Magagnin L, Vena P, Liu C-C (2017) Single-use nonenzymatic glucose biosensor based on CuO nanoparticles ink printed on a thin-film gold electrode by micro-plotter technology. J Electroanal Chem 789:50. https://doi.org/10.1016/j.jelechem.2017.01.041

Bhat KS, Ahmad R, Yoo J-Y, Hahn Y-B (2018) Fully nozzle-jet printed non-enzymatic electrode for biosensing application. J Colloid Interface Sci 512:480. https://doi.org/10.1016/j.jcis.2017.10.088

Tian K, Prestgard M, Tiwari A (2014) A review of recent advances in nonenzymatic glucose sensors. Mater Sci Eng C 41:100. https://doi.org/10.1016/j.msec.2014.04.013

Park SJ, Song HS, Kwon OS, Chung JH, Lee SH, An JH, Ahn SR, Lee JE, Yoon H, Park TH, Jang J (2015) Human dopamine receptor nanovesicles for gate-potential modulators in high-performance field-effect transistor biosensors. Sci Rep 4:4342. https://doi.org/10.1038/srep04342

Shan J, Li J, Chu X, Xu M, Jin F, Wang X, Ma L, Fang X, Wei Z, Wang X (2018) High sensitivity glucose detection at extremely low concentrations using a MoS2-based field-effect transistor. RSC Adv 8:7942. https://doi.org/10.1039/C7RA13614E

Pullano S, Critello C, Mahbub I, Mahbub I, Tasneem NT, Shamsir S, Islam SK, Greco M, Fiorillo AS (2018) EGFET-based sensors for bioanalytical applications: a review. Sensors 18:4042. https://doi.org/10.3390/s18114042

Al-Hardan N, Abdul Hamid M, Ahmed N, Jalar A, Shamsudin R, Othman NK, Keng LK, Chiu W, Al-Rawi HN (2016) High sensitivity pH sensor based on porous silicon (PSi) extended gate field-effect transistor. Sensors 16:839. https://doi.org/10.3390/s16060839

Hung S, Cheng N, Yang C, Lo Y (2014) Investigation of extended-gate field-effect transistor pH sensors based on different-temperature-annealed bi-layer MWCNTs-In2O3 films. Nanoscale Res Lett 9:502. https://doi.org/10.1186/1556-276X-9-502

Shinzawa R, Otsuka A, Nakamura A (2019) Growth of glassy carbon thin films and its pH sensor applications. SN Appl Sci 1:171. https://doi.org/10.1007/s42452-019-0181-5

Vieira NCS, Figueiredo A, de Queiroz AAA, Zucolotto V, Guimarães FEG (2011) Self-assembled films of dendrimers and metallophthalocyanines as FET-based glucose biosensors. Sensors 11:9442. https://doi.org/10.3390/s111009442

Chen J-C, Chou J-C, Sun T-P, Hsiung S-K (2003) Portable urea biosensor based on the extended-gate field-effect transistor. Sensors Actuators B 91:180. https://doi.org/10.1016/S0925-4005(03)00161-8

Palit S, Singh K, Lou B-S, Her J-L, Pang S-T, Pan T-M (2020) Ultrasensitive dopamine detection of indium-zinc oxide on PET flexible based extended-gate field-effect transistor. Sensors Actuators B 310:127850. https://doi.org/10.1016/j.snb.2020.127850

Gopinath S, Philip J (2014) Preparation of metal oxide nanoparticles of different sizes and morphologies, their characterization using small-angle X-ray scattering and study of thermal properties. Mater Chem Phys 145:213. https://doi.org/10.1016/j.matchemphys.2014.02.005

Farrell ST, Breslin CB (2004) Oxidation and photo-induced oxidation of glucose at a polyaniline film modified by copper particles. Electrochim Acta 49:4497. https://doi.org/10.1016/j.electacta.2004.05.007

Jiang L-C, Zhang W-D (2010) A highly sensitive nonenzymatic glucose sensor based on CuO nanoparticles-modified carbon nanotube electrode. Biosens Bioelectron 25:1402. https://doi.org/10.1016/j.bios.2009.10.038

Marwan J, Addou T, Bélanger D (2005) Functionalization of glassy carbon electrodes with metal-based species. Chem Mater 17:2395. https://doi.org/10.1021/cm047871i

Lim SH, Wei J, Lin J, Li Q, KuaYou J (2005) A glucose biosensor based on electrodeposition of palladium nanoparticles and glucose oxidase onto Nafion-solubilized carbon nanotube electrode. Biosens Bioelectron 20:2341. https://doi.org/10.1016/j.bios.2004.08.005

Umpleby RJ, Baxter SC, Chen Y, Shar RN, Shimizu KD (2001) Characterization of molecularly imprinted polymers with the Langmuir−Freundlich isotherm. Anal Chem 73:4584. https://doi.org/10.1021/ac0105686

Kajisa T, Sakata T (2018) Molecularly imprinted artificial biointerface for an enzyme-free glucose transistor. ACS Appl Mater Interfaces 10:34983. https://doi.org/10.1021/acsami.8b13317

Nishitani S, Sakata T (2018) Potentiometric adsorption isotherm analysis of a molecularly imprinted polymer interface for small-biomolecule recognition. ACS Omega 3:5382. https://doi.org/10.1021/acsomega.8b00627

Soni A, Jha SK (2015) A paper strip based non-invasive glucose biosensor for salivary analysis. Biosens Bioelectron 67:763–768. https://doi.org/10.1016/j.bios.2014.09.042

Acknowledgements

A part of this research is based on the Cooperative Research Project of the Research Center for Biomedical Engineering.

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study's conception and design. Material preparation, data collection, and analysis were performed by KS and AN. The first draft of the manuscript was written by AN and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Shibata, K., Nakamura, A. An extended gate field-effect transistor (EG-FET) type non-enzymatic glucose sensor with inkjet-printed copper oxide nanoparticles. SN Appl. Sci. 4, 253 (2022). https://doi.org/10.1007/s42452-022-05133-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-022-05133-6