Abstract

In this study, copper bismuth oxide (CuBi2O4) absorber-based thin film heterojunction solar cell structure consisting of Al/FTO/CdS/CuBi2O4/Ni has been proposed. The proposed solar cell device structure has been modeled and analyzed by using the solar cell capacitance simulator in one dimension (SCAPS-1D) software program. The performance of the proposed photovoltaic device is evaluated numerically by varying thickness, doping concentrations, defect density, operating temperature, back metal contact work function, series and shunt resistances. The current density–voltage behaviors at dark and under illumination are investigated. To realize the high efficiency CuBi2O4-based solar cell, the thickness, acceptor and donor densities, defect densities of different layers have been optimized. The present work reveals that the power conversion efficiency can be enhanced by increasing the absorber layer thickness. The efficiency of 26.0% with open-circuit voltage of 0.97 V, short-circuit current density of 31.61 mA/cm2, and fill-factor of 84.58% is achieved for the proposed solar cell at the optimum 2.0-μm-thick CuBi2O4 absorber layer. It is suggested that the p-type CuBi2O4 material proposed in the present study can be employed as a promising absorber layer for applications in the low cost and high efficiency thin-film solar cells.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Thin-film solar cells (TFSCs) utilizing semiconducting absorber materials, such as CdTe, CIGS etc., have received as the most promising candidate for the photovoltaic device applications due to its high efficiency and compatible with the fabrication process [1,2,3,4,5,6]. However, the conventional absorber materials in the TFSCs still face some challenges such as scarcity of materials, high cost of materials processing, and device fabrication steps limiting the implementation of solar electricity on large scales. Although considerable numbers of studies have been conducted to explore alternative absorber materials in the TFSCs, unfortunately, no works have been successful in replacing the ordinary materials [7,8,9,10].

In recent years, copper (Cu)-based ternary oxide semiconductors with narrow energy band gaps have been attracted significant attention as a photocathode material for solar energy conversion [11, 12]. Particularly, p-type CuBi2O4 has been taken as one of the most encouraging photocathode material due to low cost and easily processable for the solar cell technology [13,14,15]. The advantages of CuBi2O4 are narrow energy band gap from 1.4 to 1.8 eV [13,14,15,16,17], which is near the optimum value for solar cell applications, high optical absorption coefficient exceeding 104 cm−1 [15, 17], non-toxicity, and sufficient resource. In CuBi2O4 material, Cu is a chemical element having atomic number 29, group 11, period 4, which is a soft, malleable, and ductile metal with very high thermal and electrical conductivity [18]. No other metal is verified to be more naturally diamagnetic than bismuth. Bismuth (Bi) is a soft, crystalline, brittle silvery metal having lower thermal conductivity. It is stable to oxygen and water. The atomic number of bismuth is 83, group 15 [19]. Oxygen (O) is a colorless nonmetallic chemical element of the periodic table [20]. Oxygen has reactivity which can be produced by electric discharge in oxygen or by the action of ultraviolet radiation on oxygen in the stratosphere. Oxygen is a strong oxidizing agent and has the second highest electronegativity of all reactive elements [20].

Several heterojunction architectures based on the CuBi2O4 materials have been investigated in the previous studies [13,16, 21,22,23,24,25,26]. The photocatalytic performances have studied for the p–n heterojunction structures with CuBi2O4/WO3 [13, 21], CuBi2O4/CeO2 [16], CuBi2O4/SnO2 [22], CuBi2O4/g-C3N4 [23], CuBi2O4/NiO [24], and CuBi2O4/CuO [25, 26] fabricated by hydrothermal synthesis and pulsed laser deposition processes. In addition, high-density p-type CuBi2O4 thin-film on FTO glass substrate is fabricated by spin-coating process for solar applications [27]. Thus, the thin-film of ternary oxide semiconductor CuBi2O4 is expected to be utilized as one of the most prospective absorber materials in the TFSCs due to its high absorption coefficient, narrow energy band gap, and nontoxicity. Moreover, the thin-films of CuBi2O4 material in the heterojunction structures can be fabricated by the solution processes, which would be very effective for cost-effective and high performance light harnessing elements comparing the conventional absorber materials. However, there are few reports on the CuBi2O4-based thin-film solar cell with poor light conversion efficiency [28]. Therefore, a new type of thin-film heterojunction solar cell with sufficient photovoltaic performances employing the CuBi2O4 material as an absorber layer is expected to be explored. Hence, it is necessary to understand the transport of photo-generated charge carriers in the CuBi2O4-based thin-film heterojunction devices.

In order to realize the CuBi2O4-based TFSC, in the present study, an effective heterojunction architecture with Al/SnO2:F(FTO)/CdS/CuBi2O4/Ni is designed for the first time. The SCAPS-1D simulator is used to investigate the performance parameters such as open-circuit voltage (Voc), short-circuit current density (Jsc), fill-factor (FF), and efficiency (η) of the proposed CuBi2O4-based TFSC.

2 Device and simulation

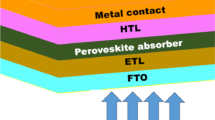

In this work, the novel heterojunction solar structure Al/FTO/n-CdS/p-CuBi2O4/Ni is designed and simulated by the SCAPS-1D software program [29]. Figure 1 illustrates the schematic diagram of the proposed CuBi2O4-based TFSC. In the proposed heterojunction structure, mostly used n-type CdS is employed as a buffer layer to couple with the p-type CuBi2O4 absorber layer in the solar cell. Also, the window layer of fluorine doped tin oxide SnO2:F (FTO) is introduced. This simulation software developed by the Department of Electronics and Information Systems, University of Gent is useful to design and simulate the TFSCs with different layered structures, as shown in Fig. 1. The energy band diagram of CuBi2O4-based solar cell is illustrated in Fig. 2. The energy band gaps and thicknesses of CuBi2O4, CdS buffer, and FTO window layers are indicated in Fig. 2. In this simulation, the detailed investigations of the proposed solar cell by changing various parameters [9,10,11, 16, 23, 30,31,32,33,34,35, 39] summarized in Table 1 have been executed using the SCAPS-1D. The photovoltaic performance parameters such as Voc, Jsc, FF, and η are measured using the simulation tool. The designed CuBi2O4-based thin-film solar structure is illuminated under AM1.5G solar spectrum with 100 mW/cm2 incident power density. The value of the absorption coefficient, (cm−1), as a function of the wavelength, (nm), for the CuBi2O4 thin-film material is taken from experimental result reported in previous work [33], on the other hand, the absorption files for the n-type CdS buffer and FTO window layers are used from the SCAPS simulation program [29]. The work function values of 4.28 eV [38] and 5.15 eV [38] are employed for the aluminum (Al) as front contact and nickel (Ni) as back contact, respectively. The thermal velocity of 1 × 107 cm/s for electrons and holes in each layer has been put during the simulation work [37, 39]. The surface recombination velocities for both electrons and holes are set to 107 and 105 cm/s at front contact 105 and 107 cm/s at back contact, respectively [36, 39]. The parameters utilized at the CdS/CuBi2O4 interface for the simulation study are illustrated in Table 2.

3 Results and discussion

In the present work, CuBi2O4-based TFSC has been investigated by the SCAPS-1D software. The structure depicted in Fig. 1 is simulated with the depth of the layers according to the sunlight illumination. Figure 3 represents the current density–voltage (J–V) characteristics of the CuBi2O4-based solar cell at dark and under illumination conditions. The thicknesses of 2.0 μm, 0.06 μm, and 0.05 μm are employed for the CuBi2O4, CdS, and FTO, respectively. Typical Schottky diode behavior is observed in the J–V curve at the dark condition. It can also be seen that the application of light on the heterojunction device results in the increasing of current density up to 31.61 mA/cm2. The photo-generated electrons and holes are increased with increasing the incident photons. This leads to suggest that the absorption of the charge carriers in the CuBi2O4 layer would be enhanced, and hence improve the performance of the solar cell. Figure 4 demonstrates the quantum efficiency of the CuBi2O4-based solar cell with varying the absorber thickness as a function of the wavelength. Here, the quantum efficiency is defined as the ratio of the number of carriers collected by the solar cell to the number of photons of a given energy incident on the solar cell. The thickness of the CuBi2O4 absorber layer is varied from 1.0 to 3.0 μm, while keeping the thicknesses of the CdS and the FTO are fixed at 0.06 μm and 0.05 μm, respectively. It can be found that the quantum efficiency increases at longer wavelength as the increase of the absorber thickness, as shown in Fig. 4. It is thus suggested that the absorption of photons would be increased as the increase of the absorber thickness at the higher wavelength.

3.1 Effects of thickness and donor density of window layer on cell performances

In the designed heterojunction TFSC, a transparent conductive oxide, namely, FTO as the window layer is employed. The output parameters of the CuBi2O4-based solar cell are evaluated by varying the window layer thickness ranged from 10 to 200 nm, as exhibited in Fig. 5a. The thicknesses of the CuBi2O4 and CdS are kept constant at the optimized values of 2000 nm and 60 nm, respectively. The simulated results show that all the solar cell output parameters are almost stable at the FTO thickness less than 100 nm. In addition, it is found that the photo-generated current is minimized a bit at the thicker FTO, and hence reduced the overall performances lightly. This result is due to the less photon reached to the absorber through the thicker window layer. Thus, the window layer thickness is preferred to be 50 nm taking into account of the overall performances.

In this numerical study, the donor density of FTO is changed from 1 × 1014 to 5 × 1020 cm−3 with 2000-nm-absorber (acceptor density of 3.7 × 1018 cm−3), 60-nm-buffer (donor density of 1 × 1017 cm−3) and 50-nm-window. Figure 5b shows the effect of the donor density on the photovoltaic performances parameters such as Voc, Jsc, FF, and η of the proposed TFSC. It can be observed that Voc, Jsc, FF, and η are approximately similar with increasing the window layer donor density. η of the proposed CuBi2O4-based solar cell is obtained about 26% at the donor density ranged from 1 × 1014 to 5 × 1020 cm−3. In this work, the FTO donor density has been picked to be 1 × 1018 cm−3 considering low cost of the solar cell fabrication.

3.2 Effects of thickness and donor density of buffer layer on cell performances

Figure 6a shows the effect of the buffer layer thickness on the CuBi2O4 solar cell output parameters. To optimize the performance of the CuBi2O4-based TFSC, the thickness of the CdS buffer layer is changed from 40 to 100 nm, while the thicknesses of the absorber (NA = 3.7 × 1018 cm−3) and the window (ND = 1 × 1018 cm−3) layers are set constant at 2000 nm and 50 nm, respectively. In Fig. 6a, it can be observed that the solar cell output parameters such as Voc, Jsc, FF, and η are almost constant as the function of the CdS buffer layer thickness. This is due to insufficient electron–hole pairs produced in the CuBi2O4 absorber layer. It is suggested that a smaller quantity of lights will come to the absorber through the thicker buffer layer, and hence resulted the insignificant current for inadequate photo-generated electrons and holes. Therefore, a thin buffer layer is anticipated to achieve outstanding solar cell performances. The optimum thickness of the buffer layer is selected to be 60 nm for the following calculations in this simulation work, which is consistent with the buffer thickness employed in the previous works [37, 39, 40].

In this simulation, the effect of the CdS donor density ranging from 1 × 1012 to 5 × 1018 cm−3 with 2000-nm-thick absorber (acceptor density of 3.7 × 1018 cm−3), 60-nm-CdS, and 50-nm-FTO (donor density of 1 × 1018 cm−3) is analyzed. Figure 6b manifests the performance parameters such as Voc, Jsc, FF, and η of the CuBi2O4-based TFSC as a function of the donor density of buffer layer. It is seen that all the output characteristics of the proposed solar cell are almost constant up to the density of 1 × 1017 cm−3. Beyond this density, the performance parameters are changed slowly with increasing the donor density of CdS. In the present study, the optimum doping concentration in the CdS buffer is evaluated to be 1 × 1017 cm−3. At the density of 1 × 1017 cm−3, η of 26.0% with Voc of 0.97 V, Jsc of 31.62 mA/cm2, and FF of 84.58% is estimated.

3.3 Effects of thickness and acceptor density of absorber layer on cell performances

The solar cell performances such as Voc, Jsc, FF, and η are analyzed by varying the CuBi2O4 absorber thickness, as depicted in Fig. 7a. The thickness of absorber (NA = 3.7 × 1018 cm−3) are changed from 100 to 3000 nm, while thicknesses of CdS (ND = 1 × 1017 cm−3) and FTO (ND = 1 × 1018 cm− 3) are kept constant at 60 nm and 50 nm, respectively. In Fig. 7a, it can be obtained that Voc increases from 0.92 to 0.98 V with increasing absorber thickness from 100 to 3000 nm. Jsc also increases as a function of the CuBi2O4 thickness. The values of Jsc at 100 nm and 3000 nm are estimated to be 7.45 mA/cm2 and 35.26 mA/cm2. The absorption of photons at the thicker absorber layer leads to increase the Jsc. It is also found that FF is increased for the CuBi2O4 thickness up to 400 nm and then reduced slightly for further increasing the thickness. This decreasing in FF is due to increase of series resistance. The conversion efficiency, η, is boosted acutely from 5.83 to 26.0% with the thickness increased from 100 to 2000 nm, and then is enhanced moderately till the 3000-nm-thick CuBi2O4 absorber layer. It is suggested that the photo-generated electrons and holes will be increased greatly at thicker absorber layer and thus improved the overall performances of the solar cell. Therefore, in this study, the CuBi2O4 absorber thickness is optimized to be 2000 nm by taking into consideration the device fabrication cost, which would be selected as the optimum thickness for the further investigation.

The effect of the acceptor density of the absorber layer on the behavior of the CuBi2O4 solar cell performances is investigated in this study, as displayed in Fig. 7b. The acceptor density is varied from 3.7 × 1014 to 5 × 1019 cm−3, while the donor densities in the CdS and the FTO layers are set fixed at 1 × 1017 cm−3 and 1 × 1018 cm−3, respectively. It can be observed in Fig. 7b that Voc is increased hardly up to 5.0 × 1018 cm−3, and then is raised greatly. The values of Voc at 3.7 × 1014 cm−3 and 5.0 × 1019 cm−3 are found to be 0.97 V and 1.02 V, respectively. Jsc is incremented from 34.56 to 43.98 mA/cm2 till 3.7 × 1016 cm−3 and then is declined notably with increasing the hole density. The increase of the hole doping in the range from 3.7 × 1016 to 5.0 × 1019 cm−3 may lead to minimize the space charge width, and thus reduced carrier collection at the junction. FF is varied lightly up to 5.0 × 1016 cm−3 and then is enlarged linearly. The conversion efficiency is increased gradually from 19.85 to 26.0% till the acceptor density of 3.7 × 1018 cm−3. It is also found that the efficiency beyond the hole doping of 3.7 × 1018 cm−3 is not progressed importantly. Therefore, the acceptor density of the CuBi2O4 absorber for the proposed solar cell is chosen to be 3.7 × 1018 cm−3 in the interest of the cost and production rate of device fabrication.

3.4 Effect of bulk defect density in absorber and buffer layers on cell performances

Here, the effect of single donor like bulk defect density in the CuBi2O4 absorber on the cell performances is investigated, as revealed in Fig. 8a. The defect density of CuBi2O4 layer is varied from 1 × 1012 to 5 × 1016 cm−3 with the fixed CdS defect density of 1 × 1014 cm−3. In Fig. 8a, Voc, Jsc, and η are decreased extremely with increasing the bulk defect density. This result is due to the high recombination rate of the charge carriers at the large defect density in the absorber. However, FF is changed moderately as a function of the CuBi2O4 defect density. The conversion efficiency for the CuBi2O4 defect density ranged from 1 × 1012 to 5 × 1016 cm−3 is estimated to be 26.0% and 3.09%, respectively.

Figure 8b shows the performances of the solar cell by varying the single acceptor like bulk defect density from 1 × 1012 to 5 × 1016 cm−3 in the CdS buffer. It can be seen that the output parameters such as Voc, Jsc, FF, and η of the proposed CuBi2O4-based solar cell are almost constant with the increasing of the CdS defect density. The efficiency from 26 to 25.87% with Voc of 0.972 V, Jsc from 31.61 to 31.60 mA/cm2 and FF from 84.58 to 84.25% is calculated for the CdS defect density in the range defined in Fig. 8b.

3.5 Effects of operating temperature and back contact metal work function on cell performances

In the present study, the impact of the operating temperature ranging from 273 to 473 K is evaluated to understand the performance and stability of the proposed solar cell. Figure 9a reports the variations in the performance parameters such as Voc, Jsc, FF, and η of the proposed CuBi2O4-based solar cell as a function of the operating temperature. As can be observed in the figure, Voc, FF, and η are decreased with increasing the operating temperature. The value of Voc at 273 K is determined to be 0.985 V and is declined to 0.876 V at 473 K. The drop of Voc is due to the reduction of the energy band gap of the semiconductors with boosting the temperature. It can be also seen that Jsc is increased with expanding the temperature. The shift in energy band gap with the operating temperature results in the change of Jsc with the temperatures [41]. Typically, the energy band gap of most semiconductors reduces with increasing the operating temperature [41, 42]. These results are in good agreement with the behaviors of the temperature dependent photovoltaic performances reported by other authors [43]. In Fig. 9a, the degradation of Voc contributes to the decrease in FF from 85.66 to 77.52% with the operating temperature varied from 273 to 473 K [43, 44]. These Voc, Jsc and FF values are used to compute the maximum conversion efficiency of the solar cell using the equation found in Ref. [43]. The efficiencies of 26.61% and 21.68% are estimated at 273 K and 473 K, respectively. This reduction in conversion efficiency with the operating temperature is due to the decrease in Voc and FF.

In this simulation work, the influence of the back contact metal work function on the device performance is also studied. The performance parameters such as Voc, Jsc, FF, and η of the proposed solar cell is evaluated by varying the back contact metal work function, as illustrated in Fig. 9b. The work function of the back metal contact is shifted from 4.6 to 5.2 eV. It can be observed that the Voc, FF, and η increase significantly with increasing the work function up to 5.0 eV, and then are saturated. This leads to suggest that the barrier height of minority carrier could be minimized with the higher work function. It can also be found that the Jsc is almost fixed with the work function in the range defined in Fig. 9b. Similar behavior is also observed in the previous report [45]. It is revealed that the power conversion efficiency is greatly affected at the back contact metal work function ≤ 5.0 eV. Therefore, the back contact metal with work function greater than 5.0 eV (such as Au, Ir, Ni and Pd) should be selected to obtain the excellent photovoltaic performances. In this work, the metal Ni as a back contact material with the work function of 5.15 eV [38] is employed to achieve the high performance of CuBi2O4-based solar cell.

3.6 Effects of series and shunt resistances on cell performances

The series (Rs) and shunt (Rsh) resistances are important parameters to understand the device performance. In the present study, the influences of series and shunt resistances on the cell of performances of the CuBi2O4-based solar cell are simulated by varying Rs from 0 to 5 Ω-cm2 and Rsh from 50 to 107 Ω-cm2. Figure 10a represents the cell performances such as Voc, Jsc, FF, and η as a function of Rs. Here, the Rsh is fixed at 105 Ω-cm2. As can be seen in the Fig. 10a, Voc and Jsc are not changed notably with the Rs. It is also seen that FF and η are decreased considerably with the increase of Rs. These results obtained in this simulation are consistent with the findings reported in previous studies [42, 46]. The efficiencies of the proposed solar cell are calculated to be 25.99% and 21.4% for the Rs at 0 Ω-cm2 and 6 Ω-cm2, respectively. Figure 10b reveals the J–V behaviors of the proposed cell for various Rs. The J–V characteristics changes with varying the Rs. It is suggested that the solar cell output parameters are influenced by increasing the Rs.

Figure 11a represents the solar cell performances as a function of the Rsh. In this case, the Rs is kept constant at 0.05 Ω-cm2. It can be found that the cell characteristics are shifted greatly up to the Rsh of 103 Ω-cm2 and then are almost saturated with the Rsh higher than103 Ω-cm2. The simulated efficiency enhances from 18.88 to 25.95% for the Rsh shifted from 102 to 107 Ω-cm2. The impact of Rsh on the J–V characteristics of proposed CuBi2O4-based TFSC is also demonstrated in Fig. 11b. These results imply that the series and shunt resistances have important effect on the performances of the photovoltaic devices.

4 Conclusions

In this study, a p-type CuBi2O4 material as the absorber layer with the n-CdS buffer layer in the thin-film heterojunction solar cell has been proposed for the first time. The SCAPS-1D simulation software program has been carried out to realize the designed heterojunction photovoltaic structure of Al/FTO/CdS/CuBi2O4/Ni. The effects of thickness, doping concentration, defect density, operating temperature, series and shunt resistances, and work function of back contact metal on the solar cell performances are analyzed extensively using the simulation tool. It is also found that the power conversion efficiency of the designed novel heterojunction structure is enhanced with increasing the CuBi2O4 absorber layer thickness. The optimum thicknesses of 2.0 μm, 0.06 μm, and 0.05 μm are found for the CuBi2O4, CdS, and FTO, respectively. The open-circuit voltage, short-circuit current density, fill-factor, and efficiency are measured to be 0.97 V, 31.61 mA/cm2, 84.58% and 26.0%, respectively, at the optimized thicknesses. The doping concentrations of the absorber, buffer, and window layers are chosen to be 3.7 × 1018 cm−3, 1 × 1017 cm−3 and 1 × 1018 cm−3, respectively. To achieve the excellent performances, the defect densities of 1 × 1012 cm−3 and 1 × 1014 cm−3 are employed for the CuBi2O4 absorber and the CdS buffer layers, respectively. In addition, the temperature dependence performance parameters have been explored for the proposed CuBi2O4-based solar cell. These results lead to suggest that the p-type CuBi2O4 material can be utilized as a potential absorber layer for the application in the highly efficient thin-film heterojunction solar cell.

References

Chopra KL, Paulson PD, Dutta V (2004) Thin-film solar cells: an overview. Prog Photovolt Res Appl 12:69–92

Amin N, Sopian K, Konagai M (2007) Numerical modeling of CdS/CdTe and CdS/CdTe/ZnTe solar cells as a function of CdTe thickness. Sol Energy Mater Sol Cells 91:1202–1208

Paudel NR, Wieland KA, Compaan AD (2012) Ultra-thin CdS/CdTe solar cells by sputtering. Sol Energy Mater Sol Cells 105:109–112

Taesooand DL, Abasifreke UE (2017) A review of thin film solar cell technologies and challenges. Renew Sustain Energy Rev 70:1286–1297

Powalla M, Paetel S, Ahlswede E, Wuerz R, Wessendorf CD, Friedlmeier TM (2018) Thin-film solar cells exceeding 22% solar cell efficiency: an overview on CdTe-, Cu(In, Ga)Se2, and perovskite-based materials. Appl Phys Rev 5:041602

Lin L, Ravindra NM (2020) Temperature dependence of CIGS and perovskite solar cell performance: an overview. SN Appl Sci 2:1361

Luo L, Luan W, Yuan B, Zhang C, Jin L (2015) High efficient and stable solid solar cell: based on FeS2 nanocrystals and P3HT:PCBM. Energy Procedia 75:2181–2186

Xue DJ, Yang B, Yuan ZK, Wang G, Liu X, Zhou Y, Hu L, Pan D, Chen S, Tang J (2015) CuSbSe2 as a potential photovoltaic absorber material: studies from theory to experiment. Adv Energy Mater 5(23):1501203

Baranowski LL, McLaughlin K, Zawadzki P, Lany S, Norman A, Hempel H, Eichberger R, Unold T, Toberer ES, Zakutayev A (2015) Effects of disorder on carrier transport in Cu2SnS3. Phys Rev Appl 4(4):044017

Razykov T, Boltaev G, Bosio A, Ergashev B, Kouchkarov K, Mamarasulov N, Mavlonov A, Romeo A, Romeo N, Tursunkulov O (2018) Characterisation of SnSe thin films fabricated by chemical molecular beam deposition for use in thin film solar cells. Sol Energy 159:834–840

Sullivan I, Zoellner B, Maggard PA (2016) Copper(I)-based p-type oxides for photoelectrochemical and photovoltaic solar energy conversion. Chem Mater 28:5999–6016

Jang YJ, Lee JS (2019) Photoelectrochemical water splitting with p-type metal oxide semiconductor photocathodes. Chem Sustain Chem 12:1835

Arai T, Yanagida M, Konishi Y, Iwasaki Y, Sugihara H, Sayama K (2007) High-throughput screening using porous photoelectrode for the development of visible-light-responsive semiconductors. J Phys Chem C 111:7574

Hahn NT, Holmberg VC, Korgel BA, Mullins CB (2012) Electrochemical synthesis and characterization of p-CuBi2O4 thin film photocathodes. J Phys Chem C 116(10):6459–6466

Berglund SP, Lee HC, Núñez PD, Bard AJ, Mullins CB (2013) Screening of transition and post-transition metals to incorporate into copper oxide and copper bismuth oxide for photoelectrochemical hydrogen evolution. Phys Chem Chem Phys 15:4554–4565

Elaziouti A, Laouedj N, Bekka A, Vannier R (2015) Preparation and characterization of p–n heterojunction CuBi2O4/CeO2 and its photocatalytic activities under UVA light irradiation. J King Saud Univ Sci 27:120–135

Wang F, Chemseddine A, Abdi F, Krol RVD, Berglund SP (2017) Spray pyrolysis of CuBi2O4 photocathodes: improved solution chemistry for highly homogeneous thin films. J Mater Chem A 5:12838–12847

The Periodic Table of elements: copper. Royal Society of Chemistry. CAS No. 7440–50–8. https://www.rsc.org/periodic-table/element/29/copper. Accessed June 2020

The Periodic Table of elements: bismuth. Royal Society of Chemistry. CAS No. 7440–69–9. https://www.rsc.org/periodic-table/element/83/bismuth. Accessed June 2020

The Periodic Table of elements: oxygen. Royal Society of Chemistry. CAS No. 7782–44–7. https://www.rsc.org/periodic-table/element/8/oxygen. Accessed June 2020

Wang L, Huanga T, Yangb G, Lud C, Dong F, Li Y, Guan W (2020) The precursor-guided hydrothermal synthesis of CuBi2O4/WO3 heterostructure with enhanced photoactivity under simulated solar light irradiation and mechanism insight. J Hazard Mater 381:120956

Abdelkader E, Nadjia L, Ahmed B (2015) Preparation and characterization of novel CuBi2O4/SnO2 p–n heterojunction with enhanced photocatalytic performance under UVA light irradiation. J King Saud Univ Sci 27:76–91

Guo F, Shi W, Wang H, Huang H, Liu Y, Kang Z (2017) Fabrication of CuBi2O4/g-C3N4 p–n heterojunction with enhanced visible light photocatalytic efficiency toward tetracycline degradation. Inorg Chem Front 4:1714–1720

Lee J, Yoon H, Kim S, Seo S, Song J, Choi BU, Choi SY, Park H, Ryu S, Oh J, Lee S (2019) Long-term stabilized high-density CuBi2O4/NiO heterostructure thin film photocathode grown by pulsed laser deposition. Chem Commun 55:12447–12450

Monny SA, Zhang L, Wang Z, Luo B, Konarova M, Du A, Wang L (2020) Fabricating highly efficient heterostructured CuBi2O4 photocathode for unbiased water splitting. J Mater Chem A 8:2498–2504

Gottesman R, Song A, Levine I, Krause M, Islam ATMN, Abou-Ras D, Dittrich T, Krol RVD, Chemseddine A (2020) Pure CuBi2O4 photoelectrodes with increased stability by rapid thermal processing of Bi2O3/CuO grown by pulsed laser deposition. Adv Funct Mater 30(21):1910832–1910844

Kim NW, Choi BU, Yu H, Ryu S, Oh J (2019) Formation of high-density CuBi2O4 thin film photocathodes with polyvinylpyrrolidonemetal interaction. Opt Express 27(4):A171–A183

Zhou X, Xie Y, Mi H, Ma J, Yang J, Cheng J (2017) Comparative study of two methods for the synthesis of CuBi2O4 particles and their application in ZnO-based dye-sensitized solar cells. J Mater Sci Mater Electron 28:13437–13444

Niemegeers A, Burgelman M, Degrave S, Verschraegen J, Decock K. 2018. SCAPS (Version: 3.3.07) Manual November 7, 2018 (Gent, Belgium: University of Gent). http://scaps.elis.ugent.be/. Accessed Jan 2020

Wang F (2017) Multinary metal oxides for solar water splitting: towards high efficiency and high stability. Doctoral Thesis. Technische Universität Berlin

Sharma G, Zhao Z, Sarker P, Nail BA, Wang J, Huda MN, Osterloh FE (2016) Electronic structure, photovoltage, and photocatalytic hydrogen evolution with p-CuBi2O4 nanocrystals. J Mater Chem A 4(8):2936–2942

Van Zeghbroeck BJ (1997) Effective density of states–Example. https://ecee.colorado.edu/~bart/book/ex019.htm. Accessed Jan 2020

Berglund SP, Abdi FF, Bogdanoff P, Chemseddine A, Friedrich D, van de Krol R (2016) Comprehensive evaluation of CuBi2O4 as a photocathode material for photoelectrochemical water splitting. Chem Mater 28(12):4231–4242

Dabbabi S, Nasr TB, Kamoun NT (2019) CIGS solar cells for space applications: numerical simulation of the effect of traps created by high-energy electron and proton irradiation on the performance of solar cells. JOM 71:602–607

Kumar A, Kumar D (2019) Effect of electron affinity on CIGS based solar cells. Int J Emerg Tech Innov Res 6:2349–5162

Burgelman M, Decock K, Niemegeers A,Verschraegen J, Degrave S (2018) SCAPS Manual (version: 3.3.07). Department of Electronics and Information Systems. University of Gent, Belgium. http://scaps.elis.ugent.be. Accessed Jan 2020

Moon MMA, Ali MH, Rahman MF, Kuddus A, Hossain J, Ismail ABM (2020) Investigation of thin-film p-BaSi2/n-CdS heterostructure towards semiconducting silicide based high efficiency solar cell. Phys Scr 95:035506

Michaelson HB (1977) The work function of the elements and its periodicity. J Appl Phys 48:4729–4733

Gharibshahian I, Orouji AA, Sharbati S (2020) Alternative buffer layers in Sb2Se3 thin-film solar cells to reduce open-circuit voltage offset. Sol Energy 202:294–303

Gharibshahian I, Orouji AA, Sharbati S (2020) Towards high efficiency Cd-Free Sb2Se3 solar cells by the band alignment optimization. Sol Energy Mater Sol Cells 212:110581

Varshni YP (1967) Temperature dependence of the energy gap in semiconductors. Physica 34:149–154

Ahmed SRA, Sunny A, Rahman S (2021) Performance enhancement of Sb2Se3 solar cell using a back surface field layer: a numerical simulation approach. Sol Energy Mater Sol Cell 221:110919

Singh P, Ravindra NM (2012) Temperature dependence of solar cell performance: an analysis. Sol Energy Mater Sol Cell 101:36–45

Singh P, Singh SN, Lal M, Husain M (2008) Temperature dependence of I–V characteristics and performance parameters of silicon solar cell. Sol Energy Mater Sol Cell 92:1611–1616

Rahman MA (2021) Design and simulation of a high-performance Cd-free Cu2SnSe3 Solar cells with SnS electron-blocking hole transport layer and TiO2 electron transport layer by SCAPS-1D. SN Appl Sci 3:253

Green MA (1992) Solar cells-operating principles. Technology and System Application. University of NSW, Kensington

Acknowledgements

The authors would like to gratefully thank Dr. Marc Burgelman and his colleagues at the Department of Electronics and Information Systems, University of Gent, Belgium for providing the SCAPS simulation program.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hosen, A., Mian, M.S. & Ahmed, S.R.A. Simulating the performance of a highly efficient CuBi2O4-based thin-film solar cell. SN Appl. Sci. 3, 544 (2021). https://doi.org/10.1007/s42452-021-04554-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-021-04554-z