Abstract

Mussel shells are often considered an abundant waste with no use. This study shows that the employment of mussel shells as a biosorbent for ammonium from water environment is completely possible. By using batch experimental method, optimal conditions for the ammonium adsorption onto mussel shells were determined. Specifically, those include a pH level of 8, contact time of 90 min, an initial ammonium concentration of 40 mg/l and the adsorbent dose of 700 mg/25 ml. With such operating conditions, experiments in laboratory aqueous solutions resulted in a maximum adsorption capacity of 2.33 mg/g, corresponded by 46.575% of efficiency. Adsorption isotherms and kinetics were well described with the Freundlich isothermal model, suggesting a heterogeneous adsorption process occurring on multilayers and both the pseudo-first-order and the pseudo-second-order, implying that the operational fundament was based on chemisorption. Analyses regarding SEM, EDS and FTIR were also implemented to identify the morphology, composition and functional groups of the adsorbent.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The importance of water is undeniable when it is the factor responsible for all human beings in terms of survival and development. However, according to WHO, 80% of human illnesses are related to contaminated water. Emerging from many impactful contaminants, ammonium is remarkable for its impacts to not only humans but also aquatic lives [1]. Particularly, ammonium and relatives can potentially lead to disorders in terms of organ activities and metabolism [2, 3]. That is exactly why urination is indispensable to excrete urea, one of ammonium’s derivatives [4, 5]. In natural water sources, ammonium comes from the decomposition of organic matters or gas exchange activities [6,7,8,9,10,11]. However, the excess of ammonium-containing compounds can cause eutrophication and consequently toxicity [12]. The existence of abundant ammonium in water is primarily due to agricultural activities, especially fertilizing, when nitrogen-containing fertilizers are essential for cultivation [13, 14]. Besides, many businesses regarding industries and living that utilize nitrogen-rich compounds also contribute to ammonium contaminating water sources [15,16,17]. In fact, it is impractical to limit those activities as their importance likely never declines. Therefore, studying and applying measures that eliminate ammonium and its derivatives in water and wastewater are a crucial and visionary orientation toward this issue.

While there have been many well-studied techniques such as reverse osmosis [18], ion exchange [19], de-nitrification [20] and coagulation [21], adsorption proves to be a more feasible method to treat ammonium in water and wastewater. That is because it has a comprehensible operational mechanism [9, 22]. Adsorption is also more affordable than other methods [23]. Yet, the effectiveness and efficiency of the technique in removing ammonium and many other contaminants are firmly assured [24, 25]. Moreover, the primary feature of adsorption, which is the adsorbent, is extremely flexible when it can be altered, modified, or employed in combination with other materials [26, 27]. In fact, adsorption has been drastically studied for removing many remarkable contaminants in water such as heavy metals, dyes and organic wastes with countless types of potential adsorbents discovered [28,29,30,31]. Regarding ammonium, there have been some valuable researches that assert the applicability of adsorption for this contaminant. Specifically, the study of Zhao et al. [11] about the adsorption of ammonium using zeolite derived from red mud is a relatively remarkable publication for the achieved results with the maximum ammonium adsorption capacity of the adsorbent reaching 17.5 mg/g. On the other hands, there are many studies have that successfully discovered and demonstrated the considerable capability of biochar derived from many agricultural sources such as coconut shells [32], maple wood [31] and rice straw [33]. The data of adsorption kinetics and isotherms in those aforementioned studies are incisive and valuable.

Nevertheless, such an exotic material as mussel shells has never been considered for adsorbing ammonium from aqueous solution. Virtually, the shell is removed after extracting the meat within, which leads to an abundance in terms of availability. More importantly, the feasibility of this material as an adsorbent has been clarified with the adsorption of dyes [35,35,36, 38], phosphate [37] and heavy metals [39]. Therefore, with the fact that no study has ever concentrated on solely treating ammonium, this study is expected to demonstrate the capability of mussel shells as a novel biosorbent for removing ammonium from aqueous environments.

The aims of the study are the evaluation of the adsorption capacities and efficiencies of the mussel shells for ammonium along with the determination of optimal parameters (pH, contact time, initial concentrations and adsorbent ratios) and their effects on the adsorption process. This target also creates the originality of the study, facilitating further studies on the removal of ammonium by the adsorption trend. In addition, the adsorption of ammonium onto mussel shells was simulated in terms of isotherms and kinetics, providing more descriptions and credibility. Finally, the operation of mussel shells as adsorbents for ammonium was brought into discussion.

2 Materials and methods

2.1 Materials

The wastes of freshwater mussel shells were collected from the Sea Food restaurant in Thai Nguyen city, Thai Nguyen Province, Vietnam [40]. Solid sodium hydroxide (NaOH), sodium potassium tartrate (C4H4KnaO6*4H2O), ammonium chloride (NH4Cl) and distilled water were purchased from Merck (Germany). Subsequently, sodium hydroxide was diluted to make an 6 M NaOH alkaline solution. Particularly, the dilution was following a formula of (240 g of solid NaOH + 1 l of distilled water)*x with x is the a constant. After added into water, the solid NaOH was stirred until it completely dissolved. While sodium potassium tartrate was dissolved in distilled water with a ratio of 50 g/100 ml. And finally, in order to make a standardized ammonium solution, 100 ml of distilled water was added gradually into 0.3819 g of ammonium chloride, which was dried at 100 °C before. Equipment: 25 ml calibration flasks, 100 ml Erlenmeyer flasks, pipettes, paraffin papers, filtering funnels. Instruments: An analytical scale, a UV–Vis spectrometer Jasco V770 Japan spectro-photometer, a spectrum FTIR 6300 Affinity-1S (SHIMADZU), an agitator (model PH-4A, China) and a pH meter (model: HI 89,107).

2.2 The preparation of mussel shells

After gathered, mussel shells were ground and sieved to achieve the adsorbent with an average particle diameter of 0.5 mm. The small particle size enhances the total contact area, facilitating adsorption.

2.3 Characterization of mussel shells

Mussel shells were characterized by determining the surface morphology, elemental composition and functional groups on the active sites. Morphologic assessment was carried out using the scanning electron microscopy (SEM) method to obtain the magnified image of the adsorbent. For elemental composition, atomic components of the adsorbent were measured in terms of weight and atomic occupancy by the energy-dispersive X-ray (EDS) spectroscopy technique. Both SEM and EDS analyses were recorded by the Hitachi S-4800 X-ray spectrometer. And finally, a Fourier-transform infrared (FTIR) spectrometer was utilized to detect and analyze the spectra indicating radicals and functional groups available on the active sites of mussel shells. The FTIR model was FTIR 6300 operating at a wavelength range of 4000–500 cm−1.

2.4 Batch experiment design

Batch adsorption experiments were conducted to evaluate the effects of pH, contact time, initial ammonium concentration and the ratios of adsorbents (mussel shells per volume of ammonium solution). From this method, it was expected to determine the interaction of mussel shells’ ammonium adsorption capacities toward the changes of these parameters and simultaneously identify the optimal pH, contact time, initial concentration and mussel shell ratio to yield the highest adsorption capacity. Each adsorption process was initiated in an Erlenmeyer flask. After adding the adsorbent and ammonium solution, experimental conditions were adjusted according to the requirement. The flasks were then shaken at 120 rpm in a certain amount of time before filtering to determine the concentration of ammonium left. For pH, the range of investigation was from 5 to 10 (increment = 1). Other conditions were set at initial ammonium concentration of 10 mg/l, contact time (agitating time) of 60 min and 400 mg adsorbent per each 25 ml of ammonium solution. For initial ammonium concentration, this study utilized 4 level of initial ammonium concentrations, which were 10, 20, 30 and 40 mg/L. pH of adsorption was maintained at the optimal value found from the previous experiment, while the contact time was 60 min and the amount of adsorbents was 400 mg. For contact time, the investigated range was in 120 min (increment = 10 min). Other parameters included the optimal pH and initial ammonium concentration found previously and 400 mg of mussel shells. Finally, for mussel shell ratios, the range of investigation was from 200 to 700 mg (increment = 100 mg). This experiment employed all the optimal parameters determined before.

2.5 Adsorption analysis

From the final concentration of ammonium, adsorption capacities and corresponding efficiency were calculated via 2 formulas below:

where q and R% are the adsorption capacity and adsorption efficiency, respectively; c0 and c are denoted for the initial and final concentration of the adsorbed (mg/L); v is the total volume (ml); and m is the amount (weight) of adsorbents (mg).

2.6 Adsorption isotherms and kinetics

The study applied the isothermal models of Langmuir and Freundlich to evaluate the adsorption equilibrium of mussel shells. The Langmuir’s theory claims that the surfaces of adsorbents are homogeneous, which means adsorption energy acting on different active sites is equivalent and independent from the presence of ammonium on adjacent sites. On the other hands, the Freundlich isothermal model describes an adsorption process where the adsorbent is porous, leading to multilayer adsorption and heterogeneous energy levels among active sites. The two models have expressing equations, respectively, as follows:

where qe (mg/g) and qm (mg/g) stand for the equilibrium and maximum adsorption capacity. Ce (mg/L) is the concentration of the adsorbed subject at equilibrium; b (L/mg) is the Langmuir constant, indicating the energy of the adsorption; KF (mg/g) is the Freundlich constant; and n is the adsorption intensity.

The study also aimed to clarify the kinetics of the adsorption of ammonium onto mussel shells by utilizing the pseudo-first-order and the pseudo-second-order as the standards for fitting and kinetic descriptions. Calculations of these two models are executed via the two following equations:

where qe (mg/g), qt (mg/g), are the adsorption capacity at equilibrium and at time t, respectively; k1 (min−1), k2 (g/mg.min) are the first-order rate constant and the second-order rate constant, respectively.

3 Results and discussion

3.1 Characterization of the adsorbent

Figure 1 consisting of 1a, 1b and 1c is the results obtained from SEM, EDS, FTIR and BET surface area analyses conducted on the adsorbent. According to Fig. 1a presenting the scanning electron micrograph (SEM) of mussel shells, the surface of the adsorbent is relatively bumpy and a nonporous material, which is a good trait for optimizing adsorption. Nevertheless, the porosity of mussel shells is virtually undetected. This description is completely compatible with the report of Salim et al. [37] regarding the characterization of mussel shells. The BET surface area and Langmuir surface area of 1.4492 m2/g and 2.0468 m2/g, respectively, and the total pore volume of < 0.001 cm3/g.

On the other hands, Fig. 1b provides the chemical composition of mussel shells. There are three elemental components detected by the energy-dispersive X-ray (EDS) microscopy method, which are carbon, oxygen and calcium. Most of the adsorbent is composed of oxygen when it occupies 60.84% of the total weight and 66.71% of the total atoms. Calcium is the second most abundant component in terms of weight when it accounts for 23.37%. However, as the atomic weight of calcium is approximately 3.3 time higher than carbon and 2.5 time higher than oxygen, its corresponding atomic percentage is only 10.23%. Finally, the weight of total carbon is 15.79%, while the percentage of total atoms is 23.06%. The co-existence of these three elements suggests that calcium carbonate is a major composite of mussel shells. In fact, this has been verified by Hamester et al. [41] who compared the composition of mussel shells and commercial calcium carbonate in 2012.

Lastly, the Fourier-transform infrared spectroscopic (FTIR) analytical results shown in Fig. 1c indicate the functional groups available on mussel shells the adsorbent. It can be seen that the C-O group was detected the most with 4 peaks representing the detection of this functional group. Particularly, there are 4 vibrational frequencies, corresponding the 4 C-O peaks, which include 705 cm−1, 862 cm−1, 1465 cm−1 and 1635 cm−1. There is also a peak representing C = O at a frequency of 1080 and 1785 cm−1 [40]. These two functional groups are both exhibited on the carbonate radical [42]. Besides, the spectra of O–H groups were found at 2520, and 3445 cm−1 and there was also C-H at 2920 cm−1 [40]. These are the fundamental radicals of organic compounds in mussel shells [41].

3.2 The effects of pH

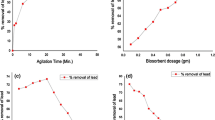

As solution pH significantly affects ionic charges of components, leading to different interactions and affinities, it is a crucial factor to the adsorption of ammonium onto any adsorbent [43]. The experiment was designed with an investigated range of pH from 5 to 10 (increment = 1). Other conditions were set as described above. The obtained adsorption capacities of mussel shell adsorbents at different pH levels are shown with corresponding efficiencies by Fig. 2 below.

It is obvious that the tendency of interaction was a sharp increase from pH 5–8 in terms of adsorption capacities and efficiencies of the adsorbent. Particularly, at the lowest examined pH, adsorption capacity of ammonium was 0.14 mg/g, corresponded by only 10.84% of removal efficiency. While at pH 8, the adsorption capacity as well as efficiency reached the highest values, which were 0.51 mg/g and 40.87%, respectively. This is primarily due to the properties of ionic ammonium in aqueous environment. Specifically, it is a weak ion with a positive charge. Therefore, acidic pH levels lead to a strong competition with the ion H+ and consequent deficiency [44, 45]. While too high pH levels can degrade NH4+ into the gas NH3 and subsequently affects adsorption. This is also the major finding of Wang et al. [31] while studying on the effect of pH on the adsorption of ammonium onto different types of adsorbents. Therefore, the optimal pH level of 8 was also going to be used for subsequent batch experiments.

3.3 The effects of initial Ammonium concentrations

The initial applied contents of ammonium are influential to both adsorption capacity and efficiency [46]. This study employed 4 concentration of initial applied ammonium, which were 10, 20, 30 and 40 mg/l. Other conditions included optimal pH (8), contact time of 60 min and an adsorbent dose of 400 mg/25 ml.

According to Fig. 3, which illustrates the adsorption capacities and their corresponding efficiency, the higher initial concentration was applied, the more ammonium was adsorbed. Particularly, at 10 mg/l, the amount of adsorbed ammonium was only 0.53 mg/g. After applying 40 mg/l, the capacity increased to 1.06 mg/g (97.97%). However, on the contrary to the adsorption capacity, the tendency of removal efficiencies was reducing from 42.63 to 21.10%. When the amount of ammonium increased in the solution, the adsorption onto mussel shells was optimized due to the rising driving force of concentration gradients. However, the constant amount of adsorbents was limited, leading to the incapability of adsorption [47,48,49]. As a result, the amount of left-over ammonium was also higher than that at lower initial concentration. This was the cause for the degradation of adsorption efficiency in spite of the increased adsorption capacities. Such a tendency of interacting with initial concentrations has been reported in not only the adsorption of ammonium but also the adsorption of many contaminants [50,51,52]. Therefore, this parameter can be selective depending on the requirements for adsorption indexes.

3.4 The effects of contact time

Contact time is the amount of time in that adsorption is conducted on the agitator. This is also an important factor for the optimization of adsorption processes when it is firmly related to the rate of interactions ween components [53]. In this experiment, the investigated time was 120 min. Data were recorded every 10 min and subsequently resulted in Fig. 4 below.

Through time, the adsorption capacities and efficiency increased significantly. However, the acceleration was analogous and most drastic from the beginning to the 90th min. Specifically, the adsorption capacity of mussel shells increased from 0.38 mg/g to 1.41 mg/g and the adsorption efficiency rose by 20.57% (from 7.58 to 28.15%). The two indexes remained growing afterward. However, at the end (the 120th min), the rate considerably slowed down by only 0.11 mg/g in terms of capacity and 2.18% in terms of efficiency. This tendency occurred depending on the abundance of active sites. At initial moments, there was overly available space for ammonium to be adsorbed onto the adsorbents, which led to the sharp increase. However, as the availability declined due to saturation, the rate of elevation was also degraded. This explanation was verified through many studies [8, 54, 58]. In this study, 90 min of contact time was concluded as the best contact time for the adsorption of ammonium onto mussel shells.

3.5 The effects of adsorbent doses

The employed conditions of this experiment were all the optimal parameters concluded from aforementioned sections. While the range of investigation was from 200 to 700 mg/25 ml of mussel shells. Data of adsorption capacities and efficiencies were collected and subsequently presented in Fig. 5 below.

With each record from the lowest dose (200 mg/25 ml) to the highest one (700 mg/25 ml), the adsorption capacity of mussel shells as well as their efficiency in removing ammonium in water grown with a homogeneous rate. While 200 mg/25 ml mussel shells were capable of adsorbing 1.19 mg/g, the capacity of 700 mg/25 ml applied mussel shells was reaching 2.33 mg/g. Simultaneously, the removal efficiency was elevated from 23.83 to 46.57%. As more mussel shells were applied, the availability of active sites for ammonium increased. As a result, adsorption was stronger and faster [55,56,57]. This tendency proves an enormous potential of mussel shells in adsorption of not only harmful ammonium but also other hazardous compounds. In fact, the study of Zhao et al. [58] on the adsorption of ammonium onto zeolite from red mud also obtained a similar result regarding the effect of adsorbent dose.

3.6 Adsorption isotherms

Figure 6 presents the fit models of Langmuir and Freundlich isotherms to the data obtained from the batch experiment that investigated the effect of initial concentrations on the adsorption of ammonium onto mussel shells. Based on the figure, it can be seen that both Langmuir and Freundlich isotherms were relatively similar in terms of providing appropriate isothermal descriptions. However, the resulted numbers in Table 1 indicate that Freundlich isotherms were more suitable to describe the adsorption process of this study. Specifically, the correlation efficient R2 of Freundlich fit model was 0.96104 in comparison with only 0.91039 of Langmuir’s. At the equilibrium of 40 mg/L, the calculated adsorption capacity of Freundlich fit model was 1.05 mg/g in comparison with the actual value of 1.06 mg/g. On the other hands, the qm of Langmuir fit model was only 1.39 mg/g. This finding suggests that the ammonium adsorption onto mussel shells is heterogeneous in terms of adsorption surface layers and the different energies at active sites [59, 60]. Moreover, as the nF value is higher than 1 (1.852), the adsorption process of this study was favorable [61, 62]. In conclusion, the ammonium adsorption onto mussel shell was better fit to the Freundlich theory in terms of adsorption isotherms. With the same adsorbent, Salim et al. [37] also came to the same conclusion when studying the adsorption of phosphate.

3.6.1 Adsorption kinetics

Figure 7 and Table 2 show the graphs and resulted numbers of adsorption data fit with the Pseudo-first-order and the Pseudo-second-order to demonstrate the kinetics of ammonium adsorption onto mussel shells. With correlation values R2 higher than 0.96, it is clear that both models were highly compatible for kinetic descriptions though R2 of the Pseudo-second-order model was slightly higher (0.97059 compared to 0.96948 of the Pseudo-first-order). In comparison to the actual values of adsorption capacity, the calculated values resulted from the Pseudo-first-order and the Pseudo-second-order were also closely the experimental data. Particularly, when the actual maximum adsorption capacity of the experimental data was 1.52 mg/g, the maximum calculated adsorption capacity of Pseudo-first-order and the Pseudo-second-order were 2.25 and 3.56 mg/g, respectively. Therefore, both kinetic models were applicable for the adsorption of ammonium onto mussel shell in order for kinetic description. The kinetic study leads to another view of Fig. 7 adsorption mechanisms when the process was chemisorption, taking ion exchange and electrostatic force as fundamental operation [63, 64]. Similar reports on adsorption kinetics of mussel shells were found in the study of EL Haddad et al. [65] and Salim et al. [37].

4 Conclusion

The ability of mussel shells in removing ammonium in aqueous environments offers a promising treatment for water contamination. Along with asserting that ability, his study has indicated the optimal conditions for the most efficient operation of the adsorbent toward ammonium. Specifically, the optimal pH for the adsorption process is 8 and the most appropriate contact time is 90 min. Regarding the dose of ammonium and mussel shells, 40 ml of ammonium/L as the optimal initial concentration should provide the highest adsorption capacity and the adsorbent dose applied should be 700 mg/ml. With the optimal conditions, conducted experiments resulted in the maximum adsorption capacity of 2.33 mg/g. The corresponding efficiency reached 46.575%. In terms of adsorption isotherms, the Freundlich model fits very well with the adsorption process. While for kinetics, both the pseudo-first-order and the pseudo-second-order shown notable compatibilities with correlation coefficients R2 > 9.6. These findings were used as the fundaments to conclude that the primary adsorption mechanisms were a based on a favorable chemisorption occurring heterogeneously on multilayers of the adsorbent. The aforementioned achievements are significantly positive data for further studies and application in a larger scale. With the abundance of mussel shells and how this material is considered, this also can simultaneously be a direction for left-over parts of, particularly, mussels to be recycled and utilized for improving water sources.

References

Asyraf M, Hashim D, Zin M (2017) The effect of the ammonium concentration in the groundwater. People: International Journal of Social Sciences. 1(5); 313–319. https://doi.org/10.20319/pijss.2015.s11.313319.

World Health Organization (WHO) (2003) Ammonia in Drinking-water. Health San Francisco 2 (20th July): http://www.who.int/water_sanitation_health/dwq/che.

Food E, Authority S (2012) Health risk of ammonium released from water filters. EFSA Journal 10(10):1–16. https://doi.org/10.2903/j.efsa.2012.2918

Weiner ID, Verlander JW (2013) Renal ammonia metabolism and transport. Comprehensive Physiology 3(1):201–220. https://doi.org/10.1002/cphy.c120010

Pourafshar N, Pourafshar S, Soleimani M (2018) Urine Ammonium, Metabolic Acidosis and Progression of Chronic Kidney Disease. Nephron 138(3):222–228. https://doi.org/10.1159/000481892

Francis C, Beman M, Kuypers M (2007) New processes and players in the nitrogen cycle: The microbial ecology of anaerobic and archaeal ammonia oxidation. ISME J 1:19–27. https://doi.org/10.1038/ismej.2007.8

Hrdina A, Moravek A, Schwartz-Narbonne H, Murphy J (2019) Summertime Soil-Atmosphere Ammonia Exchange in the Colorado Rocky Mountain Front Range Pine Forest. Soil Systems 3(1):15. https://doi.org/10.3390/soilsystems3010015

Ramsay R, Di Marco CF, Heal MR et al (2018) Surface–atmosphere exchange of inorganic water-soluble gases and associated ions in bulk aerosol above agricultural grassland pre- and postfertilisation. Atmos Chem Phys 18(23):16953–16978. https://doi.org/10.5194/acp-18-16953-2018

Romillac N (2019) Ammonification. Fath BBT-E of E (Second, E. Elsevier, Oxford, pp 256–263

Zöll U, Brümmer C, Schrader F et al (2016) Surface-atmosphere exchange of ammonia over peatland using QCL-based eddy-covariance measurements and inferential modeling. Atmos Chem Phys 16(17):11283–11299. https://doi.org/10.5194/acp-16-11283-2016

Zhang M, Wang Z, Xu J et al (2011) Ammonium, microcystins and hypoxia of blooms in eutrophic water cause oxidative stress and C-N imbalance in submersed and floating-leaved aquatic plants in Lake Taihu. China Chemosphere 82(3):329–339. https://doi.org/10.1016/j.chemosphere.2010.10.038

Abu-Elala N, Abd-Elsalam R, Marouf S et al (2016) Eutrophication, Ammonia Intoxication and Infectious Diseases: Interdisciplinary Factors of Mass Mortalities in Cultured Nile Tilapia. J Aquat Anim Health 28:187–198. https://doi.org/10.1080/08997659.2016.1185050

QU J, (2008) Research progress of novel adsorption processes in water purification: A review. Journal of Environmental Sciences 20(1):1–13. https://doi.org/10.1016/S1001-0742(08)60001-7

Ahlgren S, Baky A, Bernesson S et al (2008) Ammonium nitrate fertiliser production based on biomass – Environmental effects from a life cycle perspective. Biores Technol 99(17):8034–8041. https://doi.org/10.1016/j.biortech.2008.03.041

Van Damme M, Clarisse L, Whitburn S et al (2018) Industrial and agricultural ammonia point sources exposed. Nature 564(7734):99–103. https://doi.org/10.1038/s41586-018-0747-1

Southerland J (2003) Estimating Ammonia Emissions From Anthropogenic Non Agricultural Sources. Society. 46:805–817. https://doi.org/10.1002/ddrr.58

Shen X, Yin S, Zheng J et al (2014) Anthropogenic ammonia emission inventory and its mitigation potential in Guangdong Province. Huanjing Kexue Xuebao/Acta Scientiae Circumstantiae 34:43–53

Chrysovergi A (2015) Ammonium Removal by Reverse Osmosis Membranes. 161.

Malekian R, Eslamian S, Mousavi S-F et al (2011) Ion-exchange process for ammonium removal and release using natural Iranian zeolite. Appl Clay Sci 51:323–329. https://doi.org/10.1016/j.clay.2010.12.020

Barati Rashvanlou R, Rezaee A, Hossini H, Shiri M (2014) Ammonium removal by nitrification and denitrification in an integrated fixed film activated sludge (IFAS) process. Heal Scope. https://doi.org/10.17795/jhealthscope-18347

Meng X, Khoso SA, Jiang F et al (2020) Removal of chemical oxygen demand and ammonia nitrogen from lead smelting wastewater with high salts content using electrochemical oxidation combined with coagulation–flocculation treatment. Sep Purif Technol 235:116233. https://doi.org/10.1016/j.seppur.2019.116233

Karimi S, Tavakkoli Yaraki M, Karri RR (2019) A comprehensive review of the adsorption mechanisms and factors influencing the adsorption process from the perspective of bioethanol dehydration. Renew Sustain Energy Rev 107:535–553. https://doi.org/10.1016/j.rser.2019.03.025

De Gisi S, Lofrano G, Grassi M, Notarnicola M (2016) Characteristics and adsorption capacities of low-cost sorbents for wastewater treatment: A review. Sustainable Materials and Technologies 9:10–40. https://doi.org/10.1016/j.susmat.2016.06.002

Moreno-Castilla C (2004) Adsorption of Organic Molecules from Aqueous Solutions on Carbon Materials. Carbon 42:83–94. https://doi.org/10.1016/j.carbon.2003.09.022

Adeleke OA, Latiff AAA, Saphira MR et al (2019) 1 - Principles and Mechanism of Adsorption for the Effective Treatment of Palm Oil Mill Effluent for Water Reuse. In: Ahsan A, Ismail AFBT-N in W and WT eds Micro Nano Technol. Elsevier. pp 1–33

Kudryashov S, Kuraeva Y, Onuchak L (2006) The adsorption of organic compounds on a modified carbon adsorbent Carbopack B. Russ J Phys Chem 80:1115–1118. https://doi.org/10.1134/S003602440607020X

Sillanpää M, Metsämuuronen S, Matilainen A, Mänttäri M (2015) Chapter 9 - Integrated Methods. In: Sillanpää MBT-NOM in W ed. Butterworth-Heinemann. pp 275–301

Coelho GF, Gonçalves AC, Schwantes D et al (2018) Removal of Cd(II), Pb(II) and Cr(III) from water using modified residues of Anacardium occidentale L. Applied Water Science 8(3):1–21. https://doi.org/10.1007/s13201-018-0724-8

Agbozu IE, Emoruwa F (2014) Batch adsorption of heavy metals (Cu, Pb, Fe, Cr and Cd) from aqueous solutions using coconut husk. Afr J Environ Sci Technol 8(4):239–246. https://doi.org/10.5897/ajest2013.1577

García R, Campos J, Cruz JA et al (2016) BIOSORPTION OF CD, CR, MN and PB FROM AQUEOUS SOLUTIONS BY Bacillus SP STRAINS ISOLATED FROM INDUSTRIAL WASTE ACTIVATE SLUDGE. Tip 19(1):5–14. https://doi.org/10.1016/j.recqb.2016.02.001

Wang B, Lehmann J, Hanley K et al (2015) Adsorption and desorption of ammonium by maple wood biochar as a function of oxidation and pH. Chemosphere 138:120–126. https://doi.org/10.1016/j.chemosphere.2015.05.062

Boopathy R, Karthikeyan S, Mandal AB, Sekaran G (2013) Adsorption of ammonium ion by coconut shell-activated carbon from aqueous solution: Kinetic, isotherm and thermodynamic studies. Environ Sci Pollut Res 20(1):533–542. https://doi.org/10.1007/s11356-012-0911-3

Khalil A, Sergeevich N, Borisova V (2018) Removal of ammonium from fish farms by biochar obtained from rice straw: Isotherm and kinetic studies for ammonium adsorption. Adsorpt Sci Technol 36(5–6):1294–1309. https://doi.org/10.1177/0263617418768944

El OI, Slimani R, Hachoumi I et al (2015) Adsorption of a cationic dye (Yellow Basic 28) ontothe calcined mussel shells: Kinetics, Isotherm and Thermodynamic Parameters. Mediterranean Journal of Chemistry 4(5):261–270

El Haddad M (2016) Removal of Basic Fuchsin dye from water using mussel shell biomass waste as an adsorbent: Equilibrium, kinetics and thermodynamics. Journal of Taibah University for Science 10(5):664–674. https://doi.org/10.1016/j.jtusci.2015.08.007

Papadimitriou C, Krey G, Stamatis N, Kallaniotis A (2017) The use of waste mussel shells for the adsorption of dyes and heavy metals. J Chem Technol Biotechnol. https://doi.org/10.1002/jctb.5247

Salim N, Abdullah N, Khairuddin M et al (2018) Adsorption of phosphate from aqueous solutions using waste mussel shell. MATEC Web of Conferences 250:6013. https://doi.org/10.1051/matecconf/201825006013

Teknologi U, Bahru J (2017) Carbonized Green Mussel Shell As Heavy Metal Removal. Malaysian Journal of Civil Engineering 29(1):56–68. https://doi.org/10.11113/mjce.v29.132

Peña-Rodríguez S, Bermúdez-Couso A, Nóvoa-Muñoz JC et al (2013) Mercury removal using ground and calcined mussel shell. Journal of Environmental Sciences 25(12):2476–2486. https://doi.org/10.1016/S1001-0742(12)60320-9

Van HT, Nguyen LH, Nguyen VD et al (2019) Characteristics and mechanisms of cadmium adsorption onto biogenic aragonite shells-derived biosorbent: batch and column studies. J Environ Manage 241(1):535–548. https://doi.org/10.1016/j.jenvman.2018.09.079

Hamester MRR, Balzer PS, Becker D (2012) Characterization of calcium carbonate obtained from oyster and mussel shells and incorporation in polypropylene. Materials Research 15:204–208

Macha I, Ozyegin L, Chou J et al (2013) An Alternative Synthesis Method for Di Calcium Phosphate (Monetite) Powders from Mediterranean Mussel (Mytilus galloprovincialis) Shells. J Aust Ceram Soc 49:122–128

Pereira RC, Anizelli PR, Di Mauro E et al (2019) The effect of pH and ionic strength on the adsorption of glyphosate onto ferrihydrite. Geochem Trans 20(1):3. https://doi.org/10.1186/s12932-019-0063-1

Abdus-Salam N, Adekola F (2005) The Influence of pH and Adsorbent Concentration on Adsorption of Lead and Zinc on a Natural Goethite. African Journal of Science and Technology (AJST) Science and Engineering Series. 6 55–66. https://doi.org/10.4314/ajst.v6i2.55175.

Fathy NA, El-Shafey OI, Khalil LB (2013) Effectiveness of Alkali-Acid Treatment in Enhancement the Adsorption Capacity for Rice Straw: The Removal of Methylene Blue Dye. ISRN Physical Chemistry 2013:208087. https://doi.org/10.1155/2013/208087

Bayuo J, Kenneth B, Abukari M (2019) Optimization of Adsorption Parameters for Effective Removal of Lead (II) from Aqueous Solution. 123.

Ebrahimian A, Saberikhah E, Badrouh M, Emami M (2014) Alkali treated Foumanat tea waste as an efficient adsorbent for methylene blue adsorption from aqueous solution. Water Resour Ind. https://doi.org/10.1016/j.wri.2014.07.003

Fenti A, Salvestrini S (2018) Analytical solution of the Langmuir-based linear driving force model and its application to the adsorption kinetics of boscalid onto granular activated carbon. Reaction Kinetics, Mechanisms and Catalysis 125(1):1–13. https://doi.org/10.1007/s11144-018-1435-8

Fakhri A, Adami S (2013) WITHDRAWN: Adsorption behavior and mechanism of ammonium ion from aqueous solution onto nanoparticles zero valent iron. Arab J Chem. https://doi.org/10.1016/j.arabjc.2013.11.001

Rahimnejad M, Pirzadeh K, Mahdavi I, Peyghambarzadeh SM (2014) Pb (ΙΙ) removal from aqueous solution by adsorption on activated carbon from kiwi peel. Environ Eng Manag J. https://doi.org/10.30638/eemj.2018.128

Azman A, Ngadi N, Zaini DKA et al (2018) (2019) Effect of adsorption parameter on the removal of aspirin using tyre waste adsorbent. Chem Eng Trans 72:157–162. https://doi.org/10.3303/CET1972027

Ivanova E, Karsheva M, Koumanova B (2010) Adsorption of ammonium ions onto natural zeolite. 45

Desta M (2013) Batch Sorption Experiments: Langmuir and Freundlich Isotherm Studies for the Adsorption of Textile Metal Ions onto Teff Straw (Eragrostis tef ) Agricultural Waste. Journal of Thermodynamics 2013:6. https://doi.org/10.1155/2013/375830

Van DL, Koga Y, Wei Q et al (2016) Effect of Pretreatment on Ammonium Adsorption Properties of Sepiolite: Equilibrium, Kinetics and Thermodynamic Studies. Journal of Water and Environment Technology 14(4):260–272. https://doi.org/10.2965/jwet.15-066

Ndi Nsami J, Ketcha Mbadcam J (2013) The Adsorption Efficiency of Chemically Prepared Activated Carbon from Cola Nut Shells by on Methylene Blue. Journal of Chemistry 2013:469170. https://doi.org/10.1155/2013/469170

Tan S, Wang B (2015) Active Sites for Adsorption and Reaction of Molecules on Rutile TiO2(110) and Anatase TiO2(001) Surfaces. Chin J Chem Phys 28:383–395. https://doi.org/10.1063/1674-0068/28/cjcp1506129

Kumar KV, Gadipelli S, Wood B et al (2019) Characterization of the adsorption site energies and heterogeneous surfaces of porous materials. Journal of Materials Chemistry A 7(17):10104–10137. https://doi.org/10.1039/C9TA00287A

Zhao Y, Niu Y, Hu X et al (2015) Removal of ammonium ions from aqueous solutions using zeolite synthesized from red mud. Desalination and Water Treatment 57:1–12. https://doi.org/10.1080/19443994.2014.1000382

Van der Bruggen B (2015) Freundlich Isotherm BT - Encyclopedia of Membranes. In: Drioli E, Giorno L (eds) Berlin. Heidelberg, Springer, Berlin Heidelberg, pp 1–2

Ayawei N, Ebelegi AN, Wankasi D (2017) Modelling and Interpretation of Adsorption Isotherms. Journal of Chemistry 2017:3039817. https://doi.org/10.1155/2017/3039817

Doran PM (2013) Chapter 11 - Unit Operations. Doran PMBT-BEP (Second, E. Academic Press, London, pp 445–595

Tseng R-L, Wu F-C (2008) Inferring the favorable adsorption level and the concurrent multi-stage process with the Freundlich constant. J Hazard Mater 155(1):277–287. https://doi.org/10.1016/j.jhazmat.2007.11.061

Králik M (2014) Adsorption, chemisorption and catalysis. Chem Pap 68(12):1625–1638. https://doi.org/10.2478/s11696-014-0624-9

Simonin J-P (2016) On the comparison of pseudo-first order and pseudo-second order rate laws in the modeling of adsorption kinetics. Chem Eng J 300:254–263. https://doi.org/10.1016/j.cej.2016.04.079

Haddad EL, M, Abdelmajid R, Rachid L, et al (2014) Calcined mussel shells as a new and eco-friendly biosorbent to remove textile dyes from aqueous solutions. Journal of the Taiwan Institute of Chemical Engineers 45:533–540. https://doi.org/10.1016/j.jtice.2013.05.002

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Nguyen, V.Q., Van, H.T., Sy, H.L. et al. Application of Mussell-derived biosorbent to remove NH4+ from aqueous solution: Equilibrium and Kinetics. SN Appl. Sci. 3, 496 (2021). https://doi.org/10.1007/s42452-021-04462-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-021-04462-2