Abstract

Plastic waste is one of the world’s most pressing human health and environmental concerns. Plastic constitutes the third highest waste source globally, with the total volume of plastic waste growing in-line with increases in the global population and per capita consumption. Malaysia is tracking global trends in both the overall generation of plastic waste and the consumption of single-use plastics and since 2017 has been the world’s largest importer of plastic waste. These elements create a number of major challenges for the country’s waste management system. This review outlines the current state of plastic waste production and management in Malaysia, including options for landfill, recycling and incineration. It presents information on the scale and both the human and ecological risks of plastic waste in the country (i.e. microplastics, landfill, incineration), outlines key plastic waste management policy initiatives (including plastics alternatives such as biodegradable plastics) and highlights key constraints on the success of these. Significant internal constraints stem from the inconsistent application of policy initiatives by state governments, in addition to the lack of public awareness and interest in household recycling. The paper closes by discussing options for and constraints on the switch to biodegradable alternatives and proposes a model of plastic management based on a circular economy approach and solid waste management hierarchy. Success in reducing the problems posed by plastic in Malaysia will require sustained effort at many levels, but positive experiences in other countries give some cause for optimism.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Plastics are made out of synthetic organic polymers and are durable, lightweight, versatile, and relatively inexpensive to produce, making them one of the most utilised materials [1, 2]. The first plastics were produced in the 1860s, but it was not until the 1940s that plastic manufacturing became one of the fastest-growing industries globally [3]. Since then, plastics have gradually replaced traditional materials, such as wood, metal and leather [4, 5]. Due to the versatility of plastics, they are now central to the textile, automotive, manufacturing and packaging industries [1, 4]. The packaging industry, owing to the worldwide transition from reusable to single-use containers, is currently the largest market in the plastic industry worldwide [6].

Plastic packaging accounts for more than a third of the production of all plastic polymers [7] and constitutes 42 and 40 per cent of the plastic demand in the USA and Europe, respectively [4]. According to the United Nations Environment Programme (UNEP) [8], single-use plastics, which include grocery bags, containers and bottles, constitute the majority of plastic packaging. These plastics, which are designed for immediate disposal after use, are often discarded within the same year of production. Their increased use has contributed significantly to the increased generation of plastic wastes. In 2016, plastic wastes constitute over 12 per cent of the global waste composition, the third-highest after food and paper wastes [9]. Geyer et al. [6] estimated that there will be 12,000 million metric tonnes of plastic waste on Earth by 2050 if current trends in plastic consumption persist.

Plastics are typically generated and remoulded until they reach the end of their useful life, at which point a product is disposed of and becomes waste [10, 11]. There are two main routes after this point: (1) landfilling, which results in leakage out of the plastic system and (2) recovery through incineration and recycling for energy and resources [8]. Landfill, a form of solid waste management that is favoured by most countries in the world, often involves the burial of wastes [12, 13] while waste recovery involves the reuse and recycling of plastic wastes as secondary raw materials [14, 15]. UNEP [8] statistics suggest that only 21 per cent of plastic wastes are recovered, with incineration and recycling constituting 12 per cent and 9 per cent, respectively, of disposal methods, and the remainder of plastics are disposed in landfill.

Environmental and social concerns around plastic waste has made it the subject of a rapidly expanding scientific literature: a Scopus search conducted on 27/01/2020, for example, shows that 1415 papers using the term ‘plastic pollution’ were published in 2019 alone, with another 265 published in the first month of 2020. Plastics have driven an increase in plastic pollution and have contributed to an array of major environmental problems. Plastic wastes, which contain flame retardants, bisphenol A (BPA), phthalates and heavy metals such as lead and cadmium, can leach from landfills and bioaccumulate. Consequently, the ingestion of marine organisms by humans may cause cardiovascular diseases, reproductive abnormalities and obesity [16]. In addition, discarded plastic bags, bottles and plastic straws have become iconic symbols of the global plastic problem, with most visible and disturbing impacts being the entanglement and suffocation of turtles, mammals and pelagic birds [17,18,19]. Derraik [20] reported that the ingestion of plastic causes reduced food consumption, internal injury and formation of fat deposits, reducing the fitness of marine organisms and eventually may cause death.

In many developing countries, the mismanagement of plastic wastes poses a threat to both the ecosystem and human health. As one of the world’s major importer of plastic waste, together with the increasing urbanisation and population growth rates, Malaysia too faces problems with the management of waste, in particularly plastic wastes [21, 22]. Additionally, as a biodiversity hotspot with some of the world’s most biodiverse coral reefs, plastic waste is a major concern in Malaysia, threatening both the terrestrial and marine ecosystems [23].

This paper reviews the major current challenges for plastic waste management systems in Malaysia. It starts by outlining the plastic waste issue, followed by the plastic waste cycle, which details the recovery of plastic wastes in Malaysia. It then examines policies related to plastic wastes and plastic resource recovery in Malaysia. This is followed by an assessment of Malaysia’s contribution to the global plastic waste trade. The final part of the paper provides recommendations for addressing the key challenges of plastic wastes management in the country. The review and the perspectives represented in this paper are based on the sparse academic literature on plastic waste management systems in Malaysia and discussions with local experts, in addition to our own expertise.

2 Plastic waste issue in Malaysia

The plastic manufacturing industry has one of the highest growth rates of all industries since 2000 [24]. With over 1,300 plastic manufacturers, Malaysia has one of the largest plastic production industries globally [25] and in 2016, resins of a value of 30 billion Malaysian Ringgits (MYR) were exported to plastic producers around the world [25]. The Malaysian plastic industry has been categorised into 7 main sectors, comprising agriculture, household, packaging, construction, electronics, automotive and other subsectors that include plastic furniture and medical devices [24]. Matching global patterns, packaging is the largest end-use for plastic produced in Malaysia [26]

In common with the majority of developing countries in Southeast Asia, Malaysia has waste management systems that are inadequate for dealing with the amount of plastic waste produced [9]. The main ways of dealing with plastic waste in the country are disposal in landfills and domestic burning [22]. Malaysian household waste generation varies geographically and by economic status, and ranges from 0.85 kg to 1.5 kg per person per day [22, 27]. The generation of household waste in Malaysia is higher than other developing countries such as Indonesia and Philippines, with 0.22 kg and 0.4 kg generated per person per day, respectively [28, 29].

Malaysia is tracking global trends in both the overall generation of plastic waste and the consumption of single-use plastics, where an overall upward trajectory since the 1970s is observed in Fig. 1. In 2007, plastic wastes constituted 19 per cent of the total waste generated in Malaysia [30]. Of this waste, the majority (74 per cent) comprised single-use plastic films, with rigid plastics and foam plastics, constituting 17 and 9 per cent, respectively [30]. In Asia, the percentage of plastic in solid wastes generated in Malaysia is second only to the Philippines [22]. Significantly, by 2018, Malaysia produces more than 0.94 million tonnes of mismanaged plastic wastes per year [25, 31].

Moh and Manaf [32] suggested that solid waste management is one of the main environmental problems in Malaysia owing to the country’s population growth and the development of landfill sites. These problems include air, water and land pollution, as well as climate change due to the release of greenhouse gases to the atmosphere during the manufacturing processes [5, 33, 34]. Many of the problems stem from the durability and hence longevity of plastics in the environment.

3 Plastic waste cycle in Malaysia

3.1 Overview

Like many other countries, municipal solid wastes in Malaysia are either discarded and transported directly to landfill sites by privatised waste collection companies or separated at source for recycling purposes (Fig. 2) [35]. Recycled wastes are either (1) collected by scavengers and waste collectors, or (2) sent to private or charity recycling centres by waste generators before being transported to recycling factories via traders [35]. That being said, landfill is the favoured form of solid waste management in Malaysia, with 85 percent of material going to landfill; this high percentage stems from the low cost of this form of solid waste management [36,37,38].

source to landfill or recycling industry. In the recycling industry, a portion of wastes are returned to the resource cycle to be reused again, adapted from [35]

Flow chart of municipal solid waste in Malaysia, showing the general flow of municipal solid wastes from

A key problem for the disposal of plastics within the solid waste management cycle is, unlike food and paper wastes which are biodegradable, plastics cannot be permanently eliminated from the environment when left to degrade in landfills [6]. Plastics take hundreds to thousands of years to breakdown into smaller plastics fragments, otherwise known as microplastics (i.e. plastics that are smaller than 5 mm in length) [8, 39, 40]. Consequently, plastics will accumulate on Earth and decrease landfill space whilst simultaneously contributing to an almost ineradicable contamination of the natural environment [6, 41].

Due to the rapidly increasing population and consequences for consumption patterns, current landfills are close to their maximum capacity [22]. The identification of locations for additional landfill sites is constrained by land scarcity and potential impacts on the environment [22, 42]. The total waste generated in Malaysia can be reduced greatly by plastic waste recovery and also by ensuring the utilization of materials of potential economic value [43], but so far there has been little attention given to alternative waste disposal methods.

In Malaysia, the majority of municipal solid domestic waste is commonly disposed in both sanitary and unsanitary landfill and there is very little recycling of post-consumer plastic in Malaysia [44]. For some jurisdictions, post-consumer plastics are segregated at source and collected by private waste contractors paid for by municipal councils [45]. However, these quantities are very low compared to the total amount of plastics in waste [24]. Community collection initiatives or “gotongroyong” communal activities also have a role in collection in Malaysia [45]. Recyclable plastics are also sent directly to plastics recyclers by industry, landfill scavengers and consumers through charity bodies and junk shops, though data on the total amount and type of plastics is sparse [24]. Industrial plastic waste in the form of pre-consumer industrial waste is homogenous and clean in nature and therefore are much easier to be recycled. In Malaysia, the majority of states and territories support municipal solid waste collection, either kerbside or drop-off [24]. While scavengers and manual sorting of certain recyclables with market values (mainly plastic and metal) from landfills or other sources does occur, the quantity of recyclables sorted from a landfill is very small [24]. The quality, quantity and the form of collection, sorting and recycling vary significantly across Malaysia. Even within the same municipality, privately managed gated communities (which are common in Malaysia) may organise their own municipal waste collection. Due to the decentralised nature of the waste management systems in Malaysia, there are no comprehensive datasets which describe current trends, especially detailed data on the percentage of each type of plastics, from its generation to end-of-life recycling or landfilling. While there are some quantitative assessments [24], data is mostly based on extrapolation and/or of very small case studies and thus unreliable and difficult to generalise.

3.2 Waste recovery process

There are several reasons for the general lack of plastic recovery across the world. When raw materials are used, plastic production costs are lower compared using recycled materials [46] Fig. 3. Recycling of plastics is limited due to their low commodity prices, which discourages recycling industries (refer Fig. 3 [26]). In Malaysia, for example, Wahab et al. [33] found that 81 percent of plastic manufacturing companies will opt for a cheaper and higher quality virgin resin rather than recycled plastic pellets. Plastics are highly versatile and can be produced in various forms, and this poses problems for recycling. The majority of the recyclers in Malaysia have pointed out that mixed, multi-layered and soiled plastics limit recycling, as well as the cost, time and energy-consuming nature of the processes [26, 47]. The number of steps involved in recycling, the heterogeneous chemical makeup, thermal properties and chemical behaviour all limits recycling processes, plastic waste is therefore most commonly disposed in landfill [47].

Flow chart of plastic recycling in Malaysia; thick and dashed lines represent greater and lesser quantities of plastics flowing through the recycling system, respectively, adapted from Japan International Cooperation Agency, cited in NSWMD [26]

Several studies have compared the cost-effectiveness of incineration and recycling. Lea [48] reported that incineration maximises energy cost savings in terms of energy consumption and can reduce dependence on landfill. While similar findings have been reported by others [49], Morris [50] found that recycling of plastic wastes consumes far less energy and has a reduced environmental burden compared to landfill or incineration. This is because the construction of incineration plants is costly, despite having technologies to filter out most of the air pollutants, as importing plastic waste is commonly required to ensure a steady supply for an economically viable production operation of incineration plants [49, 51]. Recycling allows for an overall reduction in fossil fuel use and minimises overall emissions of carbon dioxide, although the consumption of energy and emissions are required for recycling [52, 53]. All in all, the societal benefits of recycling, such as human health, greatly outweighs the costs of recycling [50].

Though the majority of the plastics are disposed of in landfill, recycled or incinerated, plastic wastes can be lost from the collection system. For example, in 2016, 32 per cent of the world’s plastic was estimated to have lost from the disposal system [8, 54]. Globally, an estimated 10 to 20 million tonnes of plastic finds its way into the oceans annually, through direct dumping, losses during transport and material on landfills escaping through wind transport [4, 6, 55]. A major source of ocean contamination is the direct disposal by coastal populations worldwide. This is a concern in Malaysia, which has been estimated to be the 8th largest producer of mismanaged plastic waste globally, with 140–370 million kilograms of plastic wastes entering the ocean annually [31]. A particular problem in Malaysia is that very little is known about the levels of microplastic pollution in the environment. For instance, a Google Scholar search conducted in January 2020 have only returned nine studies of microplastic pollution that have been published in Malaysia, of which two are related to freshwater systems. Of those on freshwater, one was a study of microplastic present in riverbed sediments [56] and the other an assessment of loads in a lake dwelling fish [57]. Thus, no published studies of loads carried by rivers, uptake by river organisms or risks to humans from contaminated potable water supplies or food derived from rivers (notably fish) have been conducted in Malaysia.

In Malaysia, most rigid plastics can be recycled, especially mono-material plastics. However, multi-material plastics can be a challenge for recycling. For flexible plastics, the most commonly recycled flexible plastic is LDPE, but must be supplied in dry and clean conditions and therefore is mostly sourced from factories. Flexible HDPE can also be recycled, while flexible PP is not recycled because of factors such as economy of scale, multi-layers laminated condition, etc. The most commonly recycled plastics in Malaysia are Type 1; polyethylene terephthalate (PET), Type 2; high-density polyethylene (HDPE) and Type 5; polypropylene (PP). While there is no comprehensive list of the types of plastics recycled in Malaysia, the ENF Recycling directory lists the following plastics HDPE, ABS, PP, PVC, LLDPE, PET, PC, LDPE [58] offered by 38 companies, whereas GESB [24] identified 173 plastics recyclers in Peninsular Malaysia.

There are three main options for recycling plastic: mechanical recycling, feedstock recycling and energy via incineration [59]. Mechanical recycling process includes washing, shredding, drying and classifying [11, 47]. The final product of this process is granules/pellets or flakes, which are used for various applications, such as for playground, photo frames and kitchenware. Feedstock recycling uses chemical processes to break down plastics into chemical components with heat or chemical reactions. This process is particularly suited to multi-layers plastics, where the chemicals produced are mostly oil. The recycling of e-waste is less common in Malaysia; however, there are a number of emerging organisations.

4 Institutional and legal frameworks towards plastic waste management in Malaysia

Under the Ministry of Housing and Local Government (MHLG), the National Solid Waste Management Department (NSWMD) is currently responsible for plastic waste management in Malaysia [26]. Prior to the establishment of NSWMD, waste was managed independently by local and state governments [60]. Clause 72 of the Local Government Act 1976 allowed local and state governments to establish, maintain and carry out sanitary services [61]. The lack of a consistent solid waste management in Malaysia has led to an estimated waste recovery rate of less than 5 per cent [62]. As a result, the government of Malaysia has taken several initiatives to address different waste management problems in Malaysia. These are detailed in the following sections.

4.1 Reducing single-use plastics

In 2011, a No Plastic Bag Day (NPBD) campaign was launched by the Ministry of Domestic Trade Cooperatives and Consumerism (MDTCC), under which the provision of free plastic bags in grocery stores was banned nationwide [63,64,65]. The launch of NPBD was aimed at raising awareness and reducing the use of single-use plastics in Malaysia [64, 66]. Through this campaign, a levy of 0.20 MYR was also added per plastic bag consumed in grocery stores and supermarkets in an attempt to change consumer behaviour [65]. Studies have suggested very different levels of support for the campaign—from 66 per cent willingness to participate in the campaign in Selangor, to only 35 per cent in Kuala Lumpur [63, 66]. Asmuni et al. [64] suggested that a higher levy may need to be used in regions such as Kuala Lumpur with higher incomes.

Subsequently, the Ministry of Energy, Science, Technology, Environment and Climate Change (MESTECC) has implemented Malaysia’s Roadmap towards Zero Single-Use Plastics 2018–2030 [25]. Through this Roadmap, pollution charges will be incurred by consumers and manufacturers of single-use plastics. In 2019, the state governments of Selangor and all 3 federal territories in Malaysia banned the use of plastic straws [67,68,69]. A nationwide ban on the use of straws was set to be launched in 2020 [70], but no enforcement has been made to date. Nevertheless, newspaper reports have shown a negative response to the plastic straw ban in Kuala Lumpur, Putrajaya and Selangor [68, 69, 71]. Similar to NPBD campaign, the public may need time to adjust, since plastic straws in Malaysia are commonly perceived as a necessity. Despite the government’s strong motivation for reducing single-use plastics, waste separation and recycling and the ratio of plastic manufacturing to recycling is relatively low, as discussed above. This is due to costs for recycling plastics being higher than the costs of purchasing newly manufactured plastics.

4.2 Awareness of recycling

The first National Recycling Programme (NRP) was initiated in 1993 by the MHLG, to encourage the habit of applying the 3Rs (Reduce, Reuse, Recycle). It aims to achieve an annual increase in the recycling rate of 1 per cent [72]. Under Chapter 19 of the Eighth Malaysia Plan,Footnote 1 the government of Malaysia has stated that awareness campaigns will be carried out to encourage waste minimisation as well as recycling practices [73]. In 2001, a National Recycling Day was initiated. Subsequently, the public has shown a 30 per cent increase in recycling awareness [74]. In 2006, the percentage of waste recovery remained at 3–5 per cent, even though 70–80 per cent of the solid wastes generated in Malaysia are recyclables [22]. In 2007, the Solid Waste and Public Cleansing Management Act 2007 (Act 672) was developed, along with a mandatory separation of household waste at source [60].

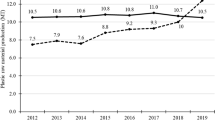

In 2015, the government set a household recycling rate target of 22 per cent by the year 2020 (Chapter 6 of the Eleventh Malaysia Plan; [75]). While there is evidence of a gradual increase in plastic recycling (Fig. 4) [24], significant impacts of waste minimisation and participation in recycling programmes have yet to be seen 10 years after the re-launching of NRPs [74]. This is because not all states in Malaysia have ratified Act 672. As of 2019, only 6 states (Perlis, Kedah, Melaka, Negeri Sembilan, Pahang and Johor, as well as 2 federal territories, Putrajaya and Kuala Lumpur) have ratified Act 672 [76]. More recent studies carried out in Kuala Lumpur, Putrajaya and Selangor have shown a 47 per cent recycling rate [77]. In 2019, the MHLG also announced that waste separation at source will apply to commercial organisations, industries, and institutions [76].

Recyclable plastics collection in Peninsular Malaysia from 2007 to 2010, adapted from [24]

4.3 Waste-to-energy initiative

The 10th and 11th Malaysia Plans state that the government will initiate the development of waste-to-energy incineration plants [75, 78]. The Government of Malaysia [75] states that the utilisation of waste as a resource will ensure efficient use of natural resources while minimising pollution in the country. Although the public has opposed this government policy, MHLG has insisted that incineration plants are necessary for the future of waste management [79]. In 2019, MHLG established a waste-to-energy plant to phase out the use of landfills in Malaysia, primarily for plastic wastes. MHLG has also suggested that incineration plants will be constructed in every state in Malaysia to allow the conversion of plastic wastes into “green energy” [80].

5 Global plastic trade

5.1 Shift in global plastic trade

Along with the worldwide increase in plastic production, there has been an emerging global trade market in plastic wastes. Owing to the shortage of domestic supply of raw material for domestic and export production demands, since 1993 China has been the world’s primary importer of secondary raw materials, including plastic and scrap metal [81]. China imports 45 to 56 per cent of the world’s plastic wastes annually to support the plastic production [8, 81,82,83,84,]. These plastic imports are far less expensive to use in production than domestic plastic waste [81]. Between 1993 and 2016, global imports and exports of plastic waste grew by 817 per cent, with the largest exporters being Hong Kong, the USA, Japan, Germany and the UK [82, 83,84,].

According to Brooks et al. [82], countries with a high GDP contribute to 87 per cent of all plastic exports, despite having developed waste management systems in their respective countries. This is because the processing fees for the management of wastes are relatively high compared to developing nations such as China [82]. However, dissimilarities in the definition of waste in individual countries have resulted in the imports of low-quality and contaminated plastic waste [81]. Consequently, the Chinese government introduced restrictions requiring all imported plastic wastes to have a very low level of contamination, and most recently (2017) there has been a ban on import of plastic wastes [82, 84]. China’s ban will result in the displacement of an estimated of 111 million metric tonnes of plastic wastes by the year 2030 [82, 84], which has given rise to other countries importing plastic waste, especially in Southeast Asia. Although countries such as Malaysia, Indonesia and Thailand are importing a much larger share of plastic wastes since China’s ban, none of these countries have the waste management capacity of China [84].

5.2 Malaysian plastic imports

In order to produce recycled products, Malaysia has been importing wastes from other countries; this is necessary because of the low domestic recycling rates [85]. Unlike China, the import of plastic wastes into Malaysia (2006–10 data) is much lower than export rates [24]. However, this trend has changed since the announcement of the ban of import of plastic wastes by the Chinese government, with import of plastic waste rising since 2017 (Fig. 5). While Britain, the USA, Australia and Japan are the top exporters of plastic wastes, Malaysia is a top importer: a total of 105 thousand tonnes of plastic wastes was imported in 2017, a 68 percent increase from 2016 (Fig. 5) [86–88]. Since 2017, Malaysia has been the world’s largest plastic waste importer, including illegal imports, where plastic wastes are declared using commodity codes which do not require permits [89]. The problem has been exacerbated by the lack of plastic waste recycling facilities [86]. Plastic wastes that are imported illegally are often contaminated and are of lower grades, which are often burned illegally, resulting in the release of toxic substances [90].

Imports of plastic wastes by Malaysia from 2016 to 2018 [87]

The Malaysian Government has now introduced several policies to address this problem, including the issuance of plastic waste import permits and the close monitoring of permit holders. In July 2018, the issuance of permits required for the import of plastic wastes were suspended, while the 62 current permit holders in Malaysia have been monitored closely as of June 2019 [91, 62]. Up to 148 illegal plastic recycling plants (i.e. plants that do not hold a permit) have been shut down in 2019 [93, 94]. In October 2018, NSWMD have enforced 18 terms for the import of plastic wastes, which mandates waste recycling plants to categorise plastic wastes, keep clear records of appropriate documents and pay levies for the imports of plastic wastes [95].

The problem of plastic waste imports has also been addressed globally through the Basel Convention. This Convention is an international treaty aimed at reducing the transboundary movement of hazardous wastes, primarily from developed to developing countries [96]. In 2019, parties from 187 countries amended the Basel Convention and included plastic wastes in the legally binding framework, ensuring a transparent global trade of plastic wastes [97]. This amendment will assist in the restriction of plastic waste imports into Malaysia, whereby plastic trade will be supported by a “Prior Informed Consent” (PIC) procedure to prevent the dumping of waste plastics to developing countries [94, 97].

6 The way forward

6.1 Mainstreaming plastic alternatives

As well as reducing the amount of plastic going into landfill, an important complementary approach is to mainstream plastic alternatives; e.g. the use of biodegradable plastics has been suggested by the government [25]. However, despite the promotion of such alternatives and existence of legal frameworks for the management of plastic waste in Malaysia, several challenges remain. The public and many organisations including food and beverage businesses are still unaware of biodegradable alternatives, and despite the government’s strong motivation, the ratio of plastic manufacturing to recycling or biodeagradable plastics remains low.

Biodegradable alternatives derived from materials such as sugarcane, starch and polylactic acid (PLA) each have different characteristics. For instance, sugarcane is 100 per cent biodegradable and compostable, while starch products are formulated with PLA, which require specific conditions to degrade, making them harder to degrade. Unlike traditional plastic materials, biodegradable plastics are polymers produced from natural resources such as plants, animals as well as microorganisms. If subjected to sufficient humidity and oxygen levels, these polymers will be broken down by microorganisms that are usually found in landfills [24]. However, in spite of their degradable properties, certain single-use plastic alternatives, specifically biodegradable plastics, will not perish from the environment, but instead disintegrate into microplastics [98, 99]. In addition, falsely advertising non-biodegradable and non-recyclable polystyrene food containers with certified biodegradable logos further complicates the process for business owners that have a genuine intent to switch to biodegradable alternatives.

A key challenge for businesses is associated with both the cost and demonstrating benefits of using plastic alternatives. Business owners that are ready to use biodegradable packaging are required to charge more to consumers to minimise liability, but consumers may not be satisfied with bearing the cost. In addition, manufacturers are reluctant to produce alternative packaging due to the immature market and production costs therefore are high when not being produced in high volumes. Manufacturers need to work together with businesses to educate and promote biodegradable alternatives, and work towards mass production to reduce costs.

6.2 Model of plastic waste management based on circular economy

Malaysia needs a step change in how it addresses and manages plastic waste. Currently, most manufacturers using recycled plastics will firstly opt for imported plastic as raw materials, because of guaranteed supply, lower price, large volumes and homogeneous resins. The second choice for raw materials is local industrial rejects (factory grade) plastic. Municipal (post-consumer) plastic waste is usually the last choice for most plastic recyclers in Malaysia because of high level of impurities, higher buy-back cost, inconsistent quality and higher loss. Weak and fragile supply chain is the largest challenge faced by current and past local plastic recyclers; business sustainability is highly dependent on market buying price. The demand side of management is very challenging, as plastic recyclers have to offer very competitive price on recycled plastic resins [100] because of inherent challenges such as buyers’ perception, limited application, smaller market segments and competition from China. Local plastic manufacturers often don’t give due priority to recycled plastic resins as environmental concern is not a priority and profit outweighs environment. Moreover, the plastic recycling business in Malaysia (and globally) is highly affected by oil price. When oil price plunges, plastic manufacturers will prefer to buy virgin plastic resin as its price difference with recycled plastic resin is very small. Therefore, most post-consumer plastics in Malaysia end up in landfill or is illegally dumped or burnt, due to weak support and enforcement.

Based on the concept of the circular economy and the integrated solid waste management hierarchy, a plastic waste management model is proposed (Fig. 6). This could serve as a sustainable option complying with the ‘New Plastics Economy’, which is an initiative spearheaded by the Ellen MacArthur Foundation with support from the UN Environmental Programme (The Ellen MacArthur [101]).

We identify nine recommendations for Malaysia and discuss key elements of these recommendations in the subsequent text:

-

1.

A comprehensive evaluation of current recycling and waste disposal activities including data on rates and methods of recycling of different types of plastics and the key industry players across Malaysia.

-

2.

Ban on single-use plastics and microbeads.

-

4.

Promote, educate and enforce the recycling of waste plastics.

-

5.

Establishment of standards for plastic labelling and production.

-

6.

Support plastics recycling supply chain which standardises the collection, distribution and production of recycled plastics.

-

7.

Promote biodegradable alternatives along with the collection, processing and composting of plastics wastes.

-

8.

Support a circular economy approach which reduces waste—extension of plastic product longevity and the redistribution of products (i.e. sharing economy).

-

9.

Incinerate and conversion to biogas of petroleum-based plastics in the short term.

The model emphasises the recovery of fossil-fuel plastic waste via recycling processes into raw materials and the development of plastic alternatives. Moh and Manaf [22] argued that plastics have high potential for waste recovery due to their widespread use and thoughtless disposal into landfills in Malaysia. Plastic recycling can be encouraged by establishing a standard for plastic production, primarily for the plastic packaging industry. While, adopting a Circular Economy approach will require changes from society, industry and government which in some cases can be quite radical. For example, George [46] suggested that standardising plastic production by industry would ensure that all plastics are of the same colour or are produced from similar monomers, which would greatly benefit the plastic recycling process. Consumers will be required to be educated in order to understand the importance of recycling from the perspective of waste separation to paying higher prices for recycled products [102].

The plastic waste management model encompasses the significance of the development of renewable and compostable plastic alternatives, and the establishment of a closed-loop supply chain of the existing fossil-fuel derived plastics. The former conforms to the initiatives from the government on developing renewable and compostable (biodegradable) plastic alternatives to slowly replace the fossil-fuel plastics [25]. In Malaysia, most of the plastic recycling companies will opt for imported recycled plastics compared to local recycled plastics due to lower prices, large volume, homogeneous and guaranteed supply. The local industrial plastic rejects (factory grade) are their second preferred choice. Weak and fragile supply chains and a lack of a well-functioning market for recycled plastics is the largest challenge faced by the local plastic recyclers [102]. Therefore, in order to boost the recycling industries and market competitiveness, the establishment of a systematic closed-loop supply chain as outlined in the plastic waste management model requires a collaborative effort from all sectors from waste collection, sorting and recycling, to manufacturing and post-consumer, with the enforcement of legislation in place [24].

In addition to implementing a complete ban on single-use plastics with the Roadmap, MESTECC should consider how to deal with microbeads (one type of primary microplastic). Xanthos and Walker [103] indicated that microbeads have received far less attention when it comes to minimising the impact of plastic wastes on the environment compared with plastic bags. In countries such as the Netherlands, Canada and the USA, legislation has been passed to control the use of microbeads, which includes the prohibition of manufacturing, imports and sales [103]. Drawing on experiences from these countries, MESTECC may implement the prohibition of microbeads, primarily in pharmaceuticals and personal care products (PPCPs).

The Malaysian government also needs stronger enforcement of its legislation and further efforts to promote environmental awareness and public engagement. Lack of enforcement has also hindered the success bans on plastic in other countries [104,105,106]. If implemented efficiently, bans and levies on single-use plastics, primarily plastic bags, have shown positive results in Denmark, Portugal and England, with a reduction in the use of plastic bags of more than 50 per cent [103,104,109]. Education campaigns will most likely aid in the reduction of plastic pollution [103], primarily those that result from plastic bags and microbeads. In locations such as Aruba (Venezuela) and India, the wide acceptance and endorsement of the plastic bag bans were made possible by the active promotion of education programmes [8]. The government can also encourage the use of cloth or jute bags to reduce the overall consumption of single-use plastic bags in Malaysia. The encouragement of the use of reusable cloth bags in countries such as Thailand, Egypt, Kenya and China has successfully reduced the consumption of up to 4.4 million plastic bags [8]. Other measured targeted at local municipalities and industry may include landfill taxes and incentives for municipalities to promote recycling [102].

From the perspective of household wastes, Malaysia needs to implement stricter waste separation at source by drawing upon lessons from policy implementations in Japan, Taiwan and Germany (i.e. Table 1). Legislation in Malaysia is often unclear, and enforcement of waste separation varies between municipalities and states. Residents are often uninformed about obligations and opportunities for recycling, this indicates a lack of governance in the waste management sector. Housing developers and housing management committees could be integrated into the governance structure to improve this situation. Also, there should be proper signage in every housing area, showing the importance and proper methods of waste separation and recycling. Concurrently, housing management organisations can provide appropriate bins for waste disposal and impose non-compliance penalties. On the other hand, incentives (e.g. vouchers) can be provided to those who heed waste recycling rules.

The promotion of alternatives to petroleum-based plastics is also critical; and biodegradable alternatives have recommended by the government [24, 25, 110, 111]. However, in many cases these alternatives will not break down in landfill, require very specific conditions for decomposition and/or create microplastics which are detrimental to the environment. If the biodegradable plastic is compostable (e.g. labelled as renewable and compostable plastics in Fig. 6), it can easily be grouped together with food waste or organic waste and sent to composting facilities. Compost can serve as a green alternative to chemical fertiliser. Therefore, in addition to the recycling system for plastic waste, establishment of an effective organic waste management system able to treat compostable plastic simultaneously, is an important part of the waste management system. This requires substantial and long-term collaborative efforts between government, industry and community sectors.

From a Circular Economy perspective, keeping resources in a closed-loop system should be considered a first priority. The role of incineration is questionable in a Circular Economy, although it can simultaneously address the problems of energy demand, waste management and GHG emissions (Pan et al., 2015). However, incineration is not applicable for many of the plastic types, especially polyvinyl chloride (PVC, resin code 3) and polystyrene (PS, resin code 6), as these plastic types emit hazardous gases during incineration [112]. A recent study in Malaysia has found that the energy from non-recycled plastics is equivalent to more than 4 million barrels of oil per year [113]. If incineration is used to treat plastic waste, PVC and PS will have to be separated out appropriately either via automatic sorting plant such as material recycling facility, or manual sorting which requires manpower and can be costly. There also needs to be a flue gas treatment system in place. The government needs to focus efforts on plastic waste recovery (i.e. recycling), while also working on reducing the environmental impact of existing incineration plants.

Finally, a Circular Economy promotes a systemic approach to green economic development which is transformative, and characterised by new business models, innovative approaches to product design, distribution and refurbishment/remanufacturing products [101]. The principles of Circular Economy are more far reaching than just zero-waste and recycling. It promotes the three principles: (1) design out waste and pollution, (2) keep products and materials in use, and (3) regenerating natural systems [101]. A Circular Economy approach will need to provide the right economic incentives, technological advancements and changes to the labour force which will involve many stakeholders [102]. Such an approach will require that the costs be shared fairly among all parties involved in the product life cycle [102].

7 Conclusion

Improper landfilling and plastic waste management systems have resulted in many environmental and human health problems in Malaysia, with the country now having an unwanted reputation as a major contributor to the marine plastics problem. Malaysia needs to aim for a closed-loop plastic waste recycling system based on a circular economy approach where plastics never end up as waste. This needs to be supported by financial investments for establishing a green supply chain and developing a consistent waste management model which includes standardising plastic production and recycling processes. In addition, stronger enforcement of legislation, stricter waste separation at source and environmental educational programmes are required. There is also potential for renewable and compostable biodegradable plastics, which can be treated along with food and organic waste, as a clean alternative worth investigating and investing in to gradually replace conventional plastics. Uptake barriers include the low cost of solid waste management, whereby landfill is the favoured option. Mainstreaming of plastic alternatives and recycled plastics faces a number of challenges, including competing with the low cost and higher quality fossil-fuel-derived resins, lack of proper segregation from other wastes, and dealing with associated contamination. Plastics alternatives will always be an important part of the solution as not all plastics can be recycled or are economical to recycle. Finally, it is critical that Malaysia regulates the import of plastic waste, ensuring that its waste management system can recycle these plastics without causing environmental and human health risks. Currently, the volumes of material being produced are such that waste management systems cannot cope, so a package of efforts are needed. Critical to underpin these changes are increased awareness and commitment, with government and other stakeholders working together to change mindsets.

Notes

The Malaysia Plans are commonly prepared by the economic planning unit (EPU) of the Prime Minister's Department and the Finance Ministry of Malaysia with the approval of Cabinet and represents one of the most important overarching national policy documents. They provide a five-year development plan for the nation, outlining where the national budget will be allocated for all economic sectors in Malaysia.

References

Ivleva NP, Wiesheu AC, Niessner R (2017) Microplastic in aquatic ecosystems. Angew Chem Int Ed 56(7):1720–1739

Li J, Liu H, Chen JP (2018) Microplastics in freshwater systems: A review on occurrence, environmental effects, and methods for microplastics detection. Water Res 137:362–374

Beckman E (2018) The world of plastics, in numbers. The Conversation, viewed 3 July 2019, https://theconversation.com/the-world-of-plastics-in-numbers-100291

Gourmelon G (2015) Global Plastic Production Rises. Recycling Lags, Worldwatch Institute

Sivan A (2011) New perspectives in plastic biodegradation. Curr Opin Biotechnol 22(3):422–426

Geyer R, Jambeck JR, Law KL (2017) Production, use, and fate of all plastics ever made. Science advances 3(7):e1700782

Plastics Europe (2015) Plastics - the Facts, PlasticsEurope, viewed 25 January 2020, https://www.plasticseurope.org/application/files/5515/1689/9220/2014plastics_the_facts_PubFeb2015.pdf

UNEP (2018) Single-use Plastics. A Roadmap for Sustainability, United Nations Environment Programme (UNEP)

Kaza S, Yao L, Bhada-Tata P, Van Woerden F (2018) What a waste 2.0: a global snapshot of solid waste management to 2050. The World Bank

Drzyzga O, Prieto A (2019) Plastic waste management, a matter for the ‘community.’ Microb Biotechnol 12(1):66

Ragaert K, Delva L, Van Geem K (2017) Mechanical and chemical recycling of solid plastic waste. Waste Manage 69:24–58

Chu LM (2008) Landfills. Encyclopedia of Ecology. Elsevier Science Publishers, pp 2099–2103

Hoornweg D, Bhada-Tata P (2012) What a waste: a global review of solid waste management. Urban development series; knowledge papers no. 15. World Bank, Washington

European Commission (2017) Raw materials, viewed 10 July 2019, http://ec.europa.eu/environment/green-growth/raw-materials/index_en.htm

Sander K, Jepsen D, Schilling S, Tebert C (2004) Definition of waste recovery and disposal operations, Okopol, viewed 10 July 2019, http://ec.europa.eu/environment/waste/studies/pdf/r_d_part_a.pdf

Thompson RC, Moore CJ, Vom Saal FS, Swan SH (2009) Plastics, the environment and human health: current consensus and future trends. Philosophical Trans Royal Soc B: BiolSci 364(1526):2153–2166

Lavers JL, Bond AL, Hutton I (2014) Plastic ingestion by Flesh-footed Shearwaters (Puffinus carneipes): Implications for fledgling body condition and the accumulation of plastic-derived chemicals. Environ Pollut 187:124–129

Schuyler Q, Hardesty BD, Wilcox C, Townsend K (2014) Global analysis of anthropogenic debris ingestion by sea turtles. Conserv Biol 28(1):129–139

Williams R, Ashe E, O’Hara PD (2011) Marine mammals and debris in coastal waters of British Columbia. Canada Marine pollution bulletin 62(6):1303–1316

Derraik JG (2002) The pollution of the marine environment by plastic debris: a review. Mar Pollut Bull 44(9):842–852

Lechner AM, Gomes RL, Rodrigues L, Ashfold MJ, Bannir S, Phin E, Raymond CM, Zieritz A, Wah K, Moug P, Billa L, Sagala S, Cheshmehzangi A, Lourdes K, Azhar B, Sanusi R, Ives D, Tang Y, Tan DT, Ka F, Chan S, Kumar T, Aliya N, Sabarudin B, Metcalfe SE, Gulsrud NM, Schuerch M, Campos-arceiz A, Macklin MG, Gibbins C (2020) Challenges and considerations of applying nature-based solutions in low- and middle-income countries in Southeast and East. Asia 2:331–351. https://doi.org/10.2166/bgs.2020.014

Moh YC, Manaf LA (2014) Overview of household solid waste recycling policy status and challenges in Malaysia. Resour Conserv Recycl 82:50–61

Cros A, Fatan NA, White A, Teoh SJ, Tan S, Handayani C, Huang C, Peterson N, Li RV, Siry HY, Fitriana R (2014) The Coral Triangle Atlas: an integrated online spatial database system for improving coral reef management. PloS one 9(6):e96332

GESB (2011) A Study on Plastic Management in Peninsular Malaysia. Golden Ecosystem SDN. BHD; Malaysia, National Solid Waste Management Department Ministry Of Housing And Local Government, Selangor, viewed 25 January 2021, https://jpspn.kpkt.gov.my/resources/index/user_1/Sumber_Rujukan/kajian/JPSPN%20Plastic%20Study%20-%20Final%20Report%20GESB%20-%20Softcopy%20English%20Ed2.pdf

MESTECC (2018) Malaysia’s Roadmap towards Zero Single-Use Plastics 2018–2030. Ministry of Energy, Science, Technology, Environment and Climate Change (MESTECC), viewed 25 January 2021, https://www.mestecc.gov.my/web/wp-content/uploads/2019/03/Malaysia-Roadmap-Towards-Zero-Single-Use-Plastics-2018-20302.pdf

NSWMD (2015) Pengurusan Sisa Pepejal dan Pembersihan Awam [Solid Waste Management and Public Cleansing], National Solid Waste Management Department (NSWMD), viewed 25 January 2021, https://jpspn.kpkt.gov.my/index.php/pages/view/106

Zainu ZA, Songip AR (2017) Policies, challenges and strategies for municipal waste management in Malaysia. J Sci Technol Innov Policy 3(1)

Castillo AL and Otoma S, (2013) Status of solid waste management in the Philippines. In Proceedings of the Annual Conference of Japan Society of Material Cycles and Waste Management The 24th Annual Conference of Japan Society of Material Cycles and Waste Management (p. 677). Japan Society of Material Cycles and Waste Management

Khair H, Rachman I, Matsumoto T (2019) Analyzing household waste generation and its composition to expand the solid waste bank program in Indonesia: a case study of Medan City. J Mater Cycles Waste Manage 21(4):1027–1037

Wahab DA, Abidin A, Azhari CH (2007) Recycling trends in the plastics manufacturing and recycling companies in Malaysia. J Appl Sci 7(7):1030–1035

Jambeck JR, Geyer R, Wilcox C, Siegler TR, Perryman M, Andrady A, Narayan R, Law KL (2015) Plastic waste inputs from land into the ocean. Science 347(6223):768–771

Moh Y, Manaf LA (2017) Solid waste management transformation and future challenges of source separation and recycling practice in Malaysia. Resour Conserv Recycl 116:1–14

American Chemistry Council (2016) Plastics and Sustainability: A Valuation of Environmental Benefits, Costs and Opportunities for Continuous Improvement, viewed 25 January 2021, https://www.plasticpackagingfacts.org/wp-content/uploads/2016/08/ACC-report_July-2016_v4.pdf

UNEP (2014) Valuing Plastic: The Business Case for Measuring. Managing and Disclosing Plastic Use in the Consumer Goods Industry, United Nations Environment Programme (UNEP)

Ahsan A, Ismail N, Rahman MM, Imteaz M, Rahman A, Mohammad N, Salleh MA (2013) Municipal solid waste recycling in Malaysia: present scenario and future prospects. Fresenius Environ Bull 22(12a):3654–3664

Khamis SS, Purwanto H, Rozhan AN, Rahman MA, Salleh HM (2019) Characterization of Municipal Solid Waste in Malaysia for Energy Recovery. IOP Conference Series: Earth and Environmental Science. IOP Publishing. pp. 012003

Khan S, Alvarez LCM, Wei Y (2018) Sustainable management of municipal solid waste under changing climate: A case study of Karachi. Pakistan Asian Journal of Environmental Biotechnology 2(1):23–32

Renou S, Givaudan J, Poulain S, Dirassouyan F, Moulin P (2008) Landfill leachate treatment: Review and opportunity. J Hazard Mater 150(3):468–493

Blettler MC, Abrial E, Khan FR, Sivri N, Espinola LA (2018) Freshwater plastic pollution: recognizing research biases and identifying knowledge gaps. Water res 143:416–424

Wang J, Tan Z, Peng J, Qiu Q, Li M (2016) The behaviors of microplastics in the marine environment. Marine Environ Res 113:7–17

Al-Salem S, Lettieri P, Baeyens J (2009) Recycling and recovery routes of plastic solid waste (PSW): a review. Waste Manage 29(10):2625–2643

Abas MA, Wee S (2014) Municipal solid waste management in Malaysia: An insight towards sustainability. Available at SSRN 2714755

Mwanza BG, Mbohwa C (2017) Drivers to sustainable plastic solid waste recycling: a review. Procedia Manufacturing 8:649–656

Kamaruddin MA, Yusoff MS, Rui LM, Isa AM, Zawawi MH, Alrozi R (2017) An overview of municipal solid waste management and landfill leachate treatment: Malaysia and Asian perspectives. Environ Sci Pollut Res 24:26988–27020. https://doi.org/10.1007/s11356-017-0303-9

Jereme IA, Siwar C, MahmudulAlam M (2019) Waste recycling in Malaysia: transition from developing to developed country. J Chem Inf Model 53:1689–1699

George S (2018) Why can’t all plastic waste be recycled. The Conversation. https://theconversation.com/why-cant-all-plastic-waste-be-recycled-100857

Garcia JM, Robertson ML (2017) The future of plastics recycling. Science 358(6365):870–872

Lea WR (1996) Plastic incineration versus recycling: a comparison of energy and landfill cost savings. J Hazard Mater 47(1–3):295–302

Gradus RH, Nillesen PH, Dijkgraaf E, Van Koppen RJ (2017) A cost-effectiveness analysis for incineration or recycling of Dutch household plastic waste. Ecol Econ 135:22–28

Morris J (2005) Comparative LCAs for curbside recycling versus either landfilling or incineration with energy recovery (12 pp). Int J Life Cycle Assess 10(4):273–284

Royte E (2019) Is burning plastic waste a good idea?, National Geographic, viewed 9 July 2019, https://www.nationalgeographic.com/environment/2019/03/should-we-burn-plastic-waste/

Arena U, Mastellone ML, Perugini F (2003) Life cycle assessment of a plastic packaging recycling system. Int J Life Cycle Assessm 8(2):92

Hopewell J, Dvorak R, Kosior E (2009) Plastics recycling: challenges and opportunities. Philosophical Transactions of the Royal Society B: Biological Sciences 364(1526):2115–2126

World Economic Forum (2016) The New Plastics Economy: Rethinking the future of plastics, viewed 25 January 2021, http://www3.weforum.org/docs/WEF_The_New_Plastics_Economy.pdf

Barnes DK, Galgani F, Thompson RC, Barlaz M (2009) Accumulation and fragmentation of plastic debris in global environments. Philosophical Transactions of the Royal Society B: Biological Sciences 364(1526):1985–1998

Sarijan S, Azman S, Said MIM, Andu Y, Zon NF (2018) Microplastics in sediment from Skudai and Tebrau river, Malaysia: a preliminary study. In: MATEC Web of Conferences, 250, p 06012. EDP Sciences

Ibrahim YS, Rathnam R, Anuar ST, Khalik WMAWM (2017) Isolation and characterisation of microplastic abundance in Lates calcarifer from Setiu Wetlands, Malaysia (Pemisahandan Pencirian Plastik-Mikro di dalam Lates calcarifer dari Tanah Bencah Setiu, Malaysia). Malaysian J Anal Sci 21(5):1054–1064

ENF (2020) Plastic Recycling Plants In Malaysia. ENF Recyling. https://www.enfrecycling.com/directory/plastic-plant/Malaysia

MPMA (2019) Plastics and the Environment Recycling Handbook. Malaysian Plastics Recyclers Association (MPRA), viewed 25 January 2021, http://mpma.org.my/v4/wpcontent/uploads/2019/06/Recycling-BookExxonMobil.pdf

Government of Malaysia (2007) Act 672. In: Solid waste and public cleansing management act 2007, viewed 25 January 2021, http://www.agc.gov.my/agcportal/uploads/files/Publications/LOM/EN/Act%20672.pdf#:~:text=AND%20PUBLIC%20CLEANSING-,MANAGEMENT%20ACT%202007,and%20for%20matters%20incidental%20thereto

Government of Malaysia (2006) Local Government Act 1976, Third Reprint, viewed 25 January 2021, http://www.doa.gov.my/index/resources/info_doa/akta171_kerajaan_tempatan_1976.pdf

Hassan MN, Rahman RA, Chong TL, Zakaria Z, Awang M (2000) Waste recycling in Malaysia: problems and prospects. Waste Manage Res 18(4):320–328

Afroz R, Rahman A, Masud MM, Akhtar R (2017) The knowledge, awareness, attitude and motivational analysis of plastic waste and household perspective in Malaysia. Environ Sci Pollut Res 24(3):2304–2315

Asmuni S, Hussin NB, Khalili JM, Zain ZM (2015) Public participation and effectiveness of the no plastic bag day program in Malaysia. Procedia-Soc Behavior Sci 168:328–340

Zen IS, Ahamad R, Omar W (2013) No plastic bag campaign day in Malaysia and the policy implication. Environ Dev Sustain 15(5):1259–1269

Kamaruddin R, Yusuf MM (2012) Selangor Government’s “No plastic Bag Day” Campaign: motivation and acceptance level. Procedia-Social and Behavioral Sciences 42:205–211

Nair V (2018) Ban on plastic straws in KL, Putrajaya and Labuan from Jan 1, 2019, Star Media, 20 September, viewed 23 July, https://www.thestar.com.my/news/nation/2018/09/20/ban-on-plastic-straws-in-kl-putrajaya-and-labuan-next-year-to-protect-environment/

Rajendra E (2019) Ban on plastic straws in Selangor eateries from July 1, Star Media, 18 May, viewed 23 July 2019, https://www.thestar.com.my/metro/metro-news/2019/05/18/ban-on-plastic-straws-in-selangor-eateries-from-july-1/

Rajendra E, Izzati F, Manimaran K (2019) Plastic straws still freely available, Star Metro, 2 July, pp.4, viewed 15 July 2019, http://katu.kpkt.gov.my/uploads/keratan/file_1562110479.pdf

Malay Mail (2019) Plastic straw ban effective 2020, ministry clarifies, Malay Mail, 22 September, viewed 23 July 2019, https://www.malaymail.com/news/malaysia/2018/09/22/plastic-straw-ban-effective-2020-ministry-clarifies/1675334

Wong EL (2019) Plastic straw ban not working, New Straits Times, 9 July, pp.66, viewed 15 July 2019, http://katu.kpkt.gov.my/uploads/keratan/file_1562645605.pdf

MHLG (2006) The Study on National Waste Minimisation in Malaysia: Final Report, Ministry of Housing and Local Government Malaysia (MHLG), viewed 25 January 2021, https://jpspn.kpkt.gov.my/resources/index/user_1/Sumber_Rujukan/kajian/PSP/Supporting_Report_1/SupportingReport1_V1.pdf

Government of Malaysia (2001) Eighth Malaysia Plan, viewed 25 January 2021, https://www.pmo.gov.my/dokumenattached/RMK/RM8.pdf

Budhiarta I, Siwar C, Basri H (2012) Current status of municipal solid waste generation in Malaysia. Int J Adv Sci Eng Inform Technol 2(2):16–21

Government of Malaysia (2015) Eleventh Malaysia Plan, viewed 25 January 2021, https://www.pmo.gov.my/dokumenattached/speech/files/RMK11_Speech.pdf

Sim LL (2019) Waste separation rules to cover three sectors from August, Star Media, 31 July, viewed 31 July 2019, https://www.thestar.com.my/news/nation/2019/07/31/waste-separation-rules-to-cover-three-sectors-from-august

Malik NKA, Abdullah SH, Manaf LA (2015) Community participation on solid waste segregation through recycling programmes in Putrajaya. Proced Environ Sci 30:10–14

Government of Malaysia (2010) Tenth Malaysia Plan, 25 January 2021, https://www.pmo.gov.my/dokumenattached/RMK/RMK10_Eds.pdf

Lim J (2018) Waste-to-energy plant in Kepong, yes or no, Star Media, 25 August, viewed 26 July 2019, https://www.thestar.com.my/metro/focus/2018/08/25/problem-of-waste-disposal-still-burning-ministry-needs-to-find-effective-alternative-to-incinerators/

Aziz A (2019) First WTE incinerator to begin operation by June, The Malaysian Reserve, 18 March, viewed 25 July 2019, https://themalaysianreserve.com/2019/03/18/first-wte-incinerator-to-begin-operation-by-june/

Yoshida A, Terazono A, Aramaki T, Hanaki K (2005) Secondary materials transfer from Japan to China: destination analysis. J Mater Cycles Waste Manage 7(1):8–15

Brooks AL, Wang S, Jambeck JR (2018) The Chinese import ban and its impact on global plastic waste trade. Sci adv 4(6):eaat0131

Velis CA (2014) Global recycling markets-plastic waste: A story for one player–China. Int Solid Waste Assoc—Glob Waste Manag Task Force, pp 1–66

Parker L, Elliott K (2018) Plastic Recycling Is Broken. Here’s How to Fix It, National Geographic. https://news.nationalgeographic.com/2018/06/china-plastic-recycling-ban-solutions-science-environment/

Isa MH, Asaari FA, Ramli NA, Ahmad S, Siew TS (2005) Solid waste collection and recycling in Nibong Tebal, Penang, Malaysia: a case study. Waste Manage Res 23(6):565–570

Harrabin R, Edgington T (2019) Recycling: Where is the plastic waste mountain?

Sun N, Phoonphongphiphat A (2018) China’s scrap plastic ban saddles neighbors with piles of problems. Nikkei Asian Review, 26 June, viewed 17 July 2019, https://asia.nikkei.com/Spotlight/Asia-Insight/China-s-scrap-plastic-ban-saddles-neighbors-with-piles-of-problems

Star Media (2019) Malaysia to send back some plastic scrap to source, Star Media, 22 May, viewed 17 July 2019, https://www.thestar.com.my/business/business-news/2019/05/22/malaysiato-send-back-some-plastic-scrap-to-source/

Wong EK, Jasmin AF (2019) Plastic: an undegradable problem. Khazanah Research Institute, Kuala Lumpur, viewed 25 January 2021, http://www.krinstitute.org/assets/contentMS/img/template/editor/Views_Plastic%20An%20Undegradable%20Problem.pdf

Timbuong J, Tang A (2019) CAP: Ban all plastic waste imports, Star Media, 29 May, viewed 18 July 2019, https://www.thestar.com.my/news/nation/2019/05/29/cap-ban-all-plasticwaste-imports/

New Straits Times (2019) 62 Malaysian companies hold permits to import plastic waste, New Straits Times, 8 June, viewed 15 July 2019, https://www.nst.com.my/news/nation/2019/06/494782/62-malaysian-companies-hold-permits-import-plastic-waste

Star Media (2019) Dept says 62 M’sian companies have approved permits to import plastic waste, Star Media, 8 June, viewed 16 July 2019, https://www.thestar.com.my/news/nation/2019/06/08/dept-says-62-msian-companies-have-approved-permits-to-import-plastic-waste/

Azizi NA (2019) War on illegal plastic waste intensifies, New Straits Times, 25 February, viewed 19 July 2019, https://www.nst.com.my/news/nation/2019/02/463544/war-illegal-plastic-waste-intensifies

Star Media (2019) Basel Convention amendment helps Malaysia restrict plastic waste imports better, says Yeo, Star Media, 17 May, viewed 19 July 2019, https://www.thestar.com.my/news/nation/2019/05/17/basel-convention-amendment-helps-malaysia-restrict-plastic-waste-imports-better-says-yeo/

NSWMD (2018) Syarat-syarat pengimportan sisa plastik H. S. Code 3915, viewed 25 January 2021, https://jpspn.kpkt.gov.my/resources/index/user_1/Pelesenan/Pengimportan_Sisa_Plastik/Syarat-Syarat_Baharu_Pengimportan_Sisa_Plastik.pdf

Basel Convention (2011) Convention Overview, viewed 19 July 2019, http://www.basel.int/TheConvention/Overview/tabid/1271/Default.aspx

Basel Convention (2019) Overview: Plastic waste, Marine Plastics Litter and Microplastics, viewed 19 July 2019, http://www.basel.int/Implementation/Plasticwastes/Overview/tabid/6068/Default.aspx. Accessed 15 July 2019

Choong MY (2011) Going green with biodegradable products, Star Media, 25 October, viewed 18 July 2019, https://www.thestar.com.my/lifestyle/features/2011/10/25/going-green-withbiodegradable-products/

Thomlinson I (2019). When biodegradable plastic is not biodegradable, The Conversation, viewed 31 July 2019, https://theconversation.com/when-biodegradable-plastic-is-notbiodegradable-116368

Kirchherr J, Piscicelli L, Bour R, Kostense-Smit E, Muller J, Huibrechtse-Truijens A, Hekkert M (2018) Barriers to the Circular Economy: Evidence From the European Union (EU). Ecol Econ 150:264–272

The Ellen MacArthur Foundation (2017) New Plastics Economy. In: A circular economy for plastic in which it never becomes waste, vol 2020. The Ellen MacArthur Foundation, viewed 25 January 2021, https://www.ellenmacarthurfoundation.org/assets/downloads/New-Plastics-Economy_Catalysing-Action_13-1-17.pdf

MPMA, MPRA (2019) An Advanced Plastics Recycling Industry for Malaysia. Malaysian Plastics Manufacturers Association (MPMA) and the Malaysian Plastics Recyclers Association (MPRA), viewed 25 January 2021, https://mpma.org.my/v4/wp-content/uploads/2019/09/White-Paper-FINALR.pdf

Xanthos D, Walker TR (2017) International policies to reduce plastic marine pollution from single-use plastics (plastic bags and microbeads): a review. Mar Pollut Bull 118(1–2):17–26

Chitotombe JW, Gukurume S (2014) The plastic bag ‘ban’controversy in Zimbabwe: An analysis of policy issues and local responses. International Journal of Development and Sustainability 3(5):1000–1012

Dikgang J, Visser M (2012) Behavioural response to plastic bag legislation in Botswana. South African J Econom 80(1):123–133

The New Humanitarian (2011) Plastics proliferate despite ban, The New Humanitarian, 2 March, viewed 31 July 2019,. http://www.thenewhumanitarian.org/report/92072/bangladesh-plastics-proliferate-despite-ban

Green Budget Europe (2014) Fact sheet: Tax on plastic bags, viewed 25 January 2021, https://green-budget.eu/fact-sheet-tax-on-plastic-bags/

Martinho G, Balaia N, Pires A (2017) The Portuguese plastic carrier bag tax: The effects on consumers’ behavior. Waste Manage 61:3–12

Smithers R (2016) England’s plastic bag usage drops 85% since 5p charge introduced, The Guardian, 30 July, viewed 1 August 2019, https://www.theguardian.com/environment/2016/jul/30/england-plastic-bag-usage-drops-85-per-cent-since-5p-charged-introduced

Berita Harian (2018) Guna straw biodegradasi ganti bahan plastic [Use biodegradable straws to replace plastic products], Berita Harian, 23 September, pp.15, viewed 18 July 2019, http://katu.kpkt.gov.my/uploads/keratan/file_1537778015.pdf

New Straits Times (2018) Biodegradable plastic may be the solution, New Straits Times, 22 July, pp. 13, viewed 18 July 2019, http://katu.kpkt.gov.my/uploads/keratan/file_1532338518.pdf

Verma R, Vinoda K, Papireddy M, Gowda A (2016) Toxic pollutants from plastic waste-a review. Proced Environm Sci 35:701–708

Sharuddin SDA, Abnisa F, Daud WMAW, Aroua MK (2017) Energy recovery from pyrolysis of plastic waste: Study on non-recycled plastics (NRP) data as the real measure of plastic waste. Energy Convers Manage 148:925–934

Badgie D, Samah MAA, Manaf LA, Muda AB (2012) Assessment of Municipal Solid Waste Composition in Malaysia: Management, Practice, and Challenges. Polish J Environ Stud 21(3):539–547

Periathamby A, Hamid FS (2007) Khidzir K (2009) Evolution of solid waste management in Malaysia: impacts and implications of the solid waste bill. J Mater Cycles Waste Manage 11(2):96–103

The Danish Government (2015) Denmark without waste II-a waste prevention strategy, viewed 25 January 2021, https://eng.mst.dk/media/164923/denmark-without-wastewasteprevention.pdf

Nelles M, Gruenes J, Morscheck G (2016) Waste management in Germany–development to a sustainable circular economy. Procedia Environmental Sciences 35(6):14

Ministry of the Environment Government of Japan (2001) Waste Management and Public Cleansing Law, viewed 25 January 2021, https://www.env.go.jp/en/recycle/basel_conv/files/Waste_Management_and_Public_Cleansing.pdf

Government Offices of Sweden (2000) The Swedish Environmental Code, viewed 25 January 2021, https://www.government.se/contentassets/be5e4d4ebdb4499f8d6365720ae68724/theswedish-environmental-code-ds-200061

Brigham K (2018) How San Francisco sends less trash to the landfill than any other major U.S. city, Consumer News and Business Channel (CNBC), viewed 25 January 2021, https://www.cnbc.com/2018/07/13/how-san-francisco-became-a-global-leader-in-waste-management.html

Acknowledgements

The authors would like to acknowledge Jaron Keng from OWD Consultancy for his assistance.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Chen, H.L., Nath, T.K., Chong, S. et al. The plastic waste problem in Malaysia: management, recycling and disposal of local and global plastic waste. SN Appl. Sci. 3, 437 (2021). https://doi.org/10.1007/s42452-021-04234-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-021-04234-y