Abstract

The role of oxygen adsorption in the formation of varistor characteristics in ZnO:Mn ceramics was investigated. The samples were made of the mixture of ZnO powder with MnSO4 aqueous solution, sintered in air for 3 h at 1100–1300 °C and furnace cooled. Mn content in the initial mixture was of 0.1 at.%. The density of prepared ceramics was of 5.37–5.41 g/cm3. XRD patterns indicated hexagonal wurtzite structure of obtained samples. The incorporation of manganese atoms in ZnO lattice as MnZn2+ centres was proven by EPR spectroscopy. Current–voltage (CV) characteristics of as-prepared samples and of the same ones kept in N2 flow, vacuum or oxygen atmosphere were compared. The increase of the sample conductivity and the decrease of CV characteristic nonlinearity after the exposure to nitrogen or vacuum were observed, whereas the action of oxygen resulted in the opposite effects. Obtained results testify that the adsorption of ambient oxygen contributes essentially to the formation of interface potential barriers in ZnO:Mn ceramics. The analysis of the available data has led to the conclusion that a thin layer of some Mn-related phase is formed at grain boundaries under sintering. This layer separates adjacent ZnO grains, which allows the diffusion of oxygen along grain boundaries and its adsorption on ZnO grain surface.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

ZnO-based ceramics are widely used as surge absorbers in electronic circuits due to excellent nonlinearity of their current–voltage (CV) characteristics and high energy absorption capability. These properties were proved to result from the formation of double back-to-back Schottky barriers at grain boundaries (GBs) under sintering ZnO powder with small amounts of other oxides (such as those of Bi, Co, Sb, Cr etc.) known as “varistor formers” [1]. However, the mechanism of barrier formation and the role of additives have not been reliably elucidated. It was supposed that the additives promoted the appearance of high-resistance layer at GBs [1,2,3,4,5,6,7] and it was experimentally shown that oxygen played the key role in this process. It was found that a thin layer of excess oxygen was present at the interfaces in ceramics sintered in air [1]. The annealing in vacuum resulted in the disappearance of this layer, which was accompanied by the reduction of barrier height and the increase of leakage current Lc, whereas the following annealing in air restored both the oxygen layer and the initial characteristics [1]. The main role of oxygen in the appearance of Schottky barriers at GBs was also stated in [5,6,7,8,9,10]. Two possibilities of oxygen participation in this process were considered:

-

Oxidation of near-surface grain region and the formation of high-resistance ZnO layer due to the interaction of oxygen with ZnO native defects during ceramics sintering [1, 6, 8, 9];

-

Oxygen adsorption during ceramics cooling from sintering temperature, which resulted in the capture of free electrons from ZnO grains by adsorbed oxygen atoms and the formation of negatively charged centres on the grain surface [5, 7].

The role of varistor formers was thought to consist in the production of oxygen due to the decomposition of additives under sintering [6, 7, 10], or in the promotion of oxygen diffusion along GBs [1].

It should be noted that oxidation process has to occur under sintering, whereas oxygen adsorption can take place at near-room temperature. At the same time, in vacuum or inert gas ambience, oxygen desorption from ZnO surface is observed in 300–450 K temperature range [11]. Thus, to separate the oxidation and adsorption processes and to elucidate the contribution of oxygen adsorption to the formation of interface barriers, the influence of ambient environment on CV characteristics of ZnO varistor ceramics at near-room temperatures should be investigated.

One of the important additives used for ZnO-based varistor preparation is manganese. It was found that the addition of Mn to other dopants caused the enhancement of CV characteristic nonlinearity [2, 5, 7, 12] and that ZnO ceramics doped solely with manganese also demonstrated nonlinear CV characteristics [6, 13,14,15]. The doping of ZnO ceramics with Mn was shown to result in essential increase of their resistivity, the greater Mn content the stronger this effect [6, 13,14,15]. At the same time, Mn is an isovalent impurity in ZnO matrix and, therefore, one might expect that it should have no influence on ZnO conductivity. In fact, ZnO single crystals doped with Mn under growth have the same conductivity that undoped ones [4]. The analysis of CV characteristics and a.c. impedance measurements testifies that ZnO:Mn ceramics, as well as multi-component ones, consist of low-resistance ZnO grains separated with high-resistance interface layers [4, 7, 8, 12, 13]. Both oxidation and adsorption processes were proposed to explain this effect.

In the present work, the influence of different environments on characteristics of ZnO:Mn ceramics has been investigated at 20–150 °C in order to clear up the contribution of ambient oxygen adsorption to the formation of interface Schottky barriers and the role of Mn doping in this process is discussed.

2 Experimental procedure

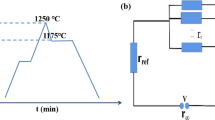

ZnO:Mn ceramics were prepared using the conventional solid-state sintering technology. The samples were formed of the mixture of ZnO powder (99.99% purity) with MnSO4 aqueous solution as rectangular plates by pressing at p = 500 kg/cm2, sintered in air for 3 h at 1100—1300 °C and furnace cooled. Mn content in the initial mixture was 0.1 at. %. This content was enough to obtain the essential increase of ZnO ceramics resistivity and noticeable nonlinearity of CV characteristics. Ceramic plates with average sizes of 10 × 5 × 1 mm3 and the density of 5.37–5.41 g/cm3 were obtained. The plates were cleft transversally in some parts with average sizes of 2 × 5 × 1 mm3, ohmic indium electrodes were melted on both cleft surfaces and CV characteristics of thus prepared samples were measured at room temperature before and after the procedure that had to lead to either oxygen desorption or adsorption. To carry out oxygen desorption the sample was kept in N2 flow or in vacuum 10–4 torr for several hours at 120–140 °C. For additional oxygen adsorption (as compared to the initial state) the sample was exposed to oxygen atmosphere at room temperature. In every case a number of the samples were used for the measurements. The effect of the certain environment (namely, the increase or the decrease of conductivity and CV characteristic nonlinearity) was the same for all investigated samples. Typical results are shown in the figures.

The structure properties of prepared ceramics were studied using X’ Pert Pro MPD X- ray diffractometer with CuKα wavelength (λ = 0.15418 nm). EPR spectra were measured using the upgraded Varian E-12 spectrometer (~ 9.5 GHz) with a sensitivity limit of about 1012 EPR centres.

3 Results and discussion

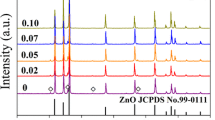

XRD patterns of obtained samples exhibit the characteristic diffraction reflexes of the hexagonal wurtzite structure corresponding to (100), (002), (101), (102), (110) and (103) planes (Fig. 1).

CV characteristics of ZnO:Mn ceramic sample in the initial state and after standing in N2 flow are shown in Fig. 2.

One can see that the influence of N2 flow leads to the rise of the sample conductivity and the reduction of CV characteristic nonlinearity. Similar changes in sample characteristics are observed after the exposure to vacuum (Fig. 3), whereas after keeping in oxygen atmosphere the opposite effects take place (Fig. 4).

Exposure of the sample to air after the influence of N2 flow, vacuum or oxygen atmosphere results in gradual restoration of the initial characteristics. Thus, obtained data show that adsorption/desorption of ambient oxygen influence essentially ZnO:Mn ceramics electrical properties. It has been also found that slow heating of the sample to 200–250 °C with subsequent fast cooling to room temperature results in some increase of its conductivity, which can be accounted for by partial oxygen thermal desorption.

It is known that ZnO crystal surface adsorbs oxygen from the ambient air [11]. Oxygen atoms capture crystal electrons, which results in the creation of negative surface charge and formation of depleted near-surface layer with reduced conductivity [11]. One might expect that the same process has to occur on the surface of grains in any polycrystalline ZnO structure as a result of oxygen diffusion along the GBs, and some intergranual barriers would be formed due to the appearance of double depletion layer at the interface. However, theoretical consideration of GB electronic structure in polycrystalline ZnO led to the inference that deep negatively charged electronic states responsible for non-ohmic varistor behaviour must not generated in undoped ZnO ceramics [16]. This inference is in accordance with experimental data reported in [4, 5, 17]. In fact, it was found that (1) a.c. impedance measurements demonstrated the absence of GB barriers in undoped ZnO ceramics [5]; (2) temperature dependence of undoped ZnO ceramics conductivity in 80–300 K range did not differ from that for undoped ZnO single crystals and was caused by the “freezing out” of free electrons on shallow donors Zni, whereas the intergranual barriers did not exhibit themselves [17]; besides, doping ZnO ceramics with Li resulted in considerable decrease of their conductivity, but CV characteristics of these samples did not show any nonlinearity [17]; (3) low interface resistance and linear CV curves were observed in ZnO/ZnO bicrystals, whereas ZnO:Mn/ZnO:Mn or ZnO:Bi/ZnO:Bi bicrystals demonstrated varistor characteristics [4]. Based on these data, one can conclude that oxygen adsorption on ZnO grain surface takes no place in undoped ZnO ceramics.

It should be noted, that nonlinearity of CV characteristics in undoped ZnO ceramics was reported in [18]. In this case, however, the samples were prepared of ZnO nanoparticles annealed in air for 2 h before pressing and sintering [19]. Observed effect was explained by the oxidation of zinc interstitials on nanoparticle surface under annealing [18]. In fact, such process has to cause the formation of a thin high-resistance layer on the surface of every nanoparticle which should result in the varistor behaviour of ceramics prepared by sintering of these nanoparticles. As for ZnO ceramics prepared by conventional technique, certain additives are required to form interface potential barriers.

As it was mentioned in Sect. 1, varistor formers were supposed either to act as oxygen generators due to their decomposition under sintering [7, 10] or to promote the diffusion of ambient oxygen along GBs and its following interaction with ZnO native defects [1]. It was found that some secondary phases related to these additives were usually formed at GBs in varistor ceramics under sintering and these species were believed to participate in the formation of the interface barriers [1, 2, 14, 20]. In ZnO:Mn ceramics, secondary phases related to Mn were detected in XRD and Raman scattering spectra only at NMn = 3–5 at.% [14, 20]. At the same time, considerable increase of resistivity and CV characteristic nonlinearity were already observed at NMn = 0.1 at.% [6, 10]. With the rise of sintering temperature Ts, however, the resistivity of ZnO:Mn samples decreases and at Ts = 1400 °C it becomes as low, as that of undoped ZnO ceramics [5, 13]. Similar effect was also observed in our experiments: the conductivity of the samples sintered at 1300 °C was essentially higher than that of the ones sintered at 1100 °C, and CV-characteristics of the formers are almost linear (Fig. 5).

So, one can think that some Mn-related phase layer undetectable by conventional equipment is formed at GBs. This layer separates adjacent ZnO grains, which allows oxygen diffusion along GBs and results in the appearance of negatively charged centres on ZnO grain surfaces due to oxygen adsorption. The rise of Ts should lead to the disappearance of separating layer due to the enhancement of Mn dissolution in ZnO matrix. This assumption is in accordance with EPR data obtained for the samples sintered at 1100 and 1300 °C.

EPR spectra of investigated samples display a series of hyperfine lines grouped into five sextets (Fig. 6). Such a pattern is unambiguously attributed to isolated Mn Zn2+ ions in ZnO lattice [21]. The intensity of the lines for the samples sintered at 1100 °C (Fig. 6, a) is found to be lower than that for the samples sintered at 1300 °C (Fig. 6, b). Besides, a weak broad band is present in the spectrum of ceramics sintered at 1100 °C which is absent in the spectrum of ceramics sintered at 1300 °C. A similar broad line was previously observed in EPR spectra of ZnO:Mn ceramics and was ascribed to the some Mn-related phase [22]. It was shown that the rise of sintering temperature favoured the incorporation of manganese atoms in zinc sites, which resulted in the increase of MnZn2+ centre concentration. It is the effect that is observed in our experiments. One can think that interface Mn-related phase can be the source of the additional Mn Zn 2+ centres.

Based on obtained results, one can conclude that the mechanism of the interface barrier formation in ZnO:Mn ceramics consists in ambient oxygen adsorption on ZnO grain surface, which becomes possible due to the presence of Mn-related layer separating ZnO grains. This process takes no place in undoped ZnO ceramics prepared by conventional technique or ZnO ceramics doped with homogeneously distributed impurity. Oxygen adsorption on ZnO grain surface occurs only when ZnO grains are separated one from the other by some additive-related layer appearing under sintering.

4 Conclusion

To elucidate the role of oxygen adsorption in the formation of GB potential barriers in ZnO:Mn ceramics, the influence of different environment on ceramics electrical characteristics was investigated. The samples with Mn content NMn = 0.1 at.% were prepared of the mixture of ZnO powder with MnSO4 aqueous solution, sintered in air for 3 h at 1100–1300 °C and furnace cooled. In the initial state, prepared ceramics were high-resistance and had nonlinear CV characteristics. After standing of the samples in N2 flow or vacuum, the decrease of their resistivity and the weakening of CV characteristic nonlinearity were observed, whereas after the standing of the samples in oxygen atmosphere the opposite effects took place. The initial characteristics restored after following standing of the samples in air. So, one can conclude that adsorption of ambient oxygen plays the main role in the formation of interface barriers. It has been supposed that this process becomes possible due to the formation of Mn-related layer that separates adjacent ZnO grains. The increase of sintering temperature leads to the dissolution of separating layer and, as a result, oxygen adsorption is absent.

Obtained results testify that the mechanism of interface barrier formation in standard doped ZnO ceramics consists in oxygen adsorption on the surface of ZnO grains separated by the layer of dopant-related phase.

References

Greuter F (1995) Electrically active interfaces in ZnO varistors. Solid State Ion 75:67–78

Eda K (1978) Conduction mechanism of non-ohmic zinc oxide ceramics. J Appl Phys 49:2964–2972

Vitsvanath NSM, Pandey Sh, Kumar D (2016) Effect of sintering temperature on electrical characteristics of ZnO-0.5mol% V2O5–2mol% MnO varistors. Adv Mater Sci Res 1:14–19

Ohashi N, Terada Y, Ohgaki T, Tsurumi T, Fukunaga O, Hanega H, Tanaka J (1999) Synthesis of ZnO bicrystals doped with Co or Mn and their electrical properties. Jpn J Appl Phys 38:5028–5032

Smith A, Baumard J-F, Abelard P (1989) AC impedance measurements and V-I characteristics for Co-, Mn-, or Bi-doped ZnO. J Appl Phys 65:5119–5125

Han J, Senos AMR, Mantas PQ (2002) Varistor behaviour in Mn-doped ZnO ceramics. J Eur Ceram Soc 22:1653–1660

He J, Lin J, Liu W, Feng K, Zhu Yu, Li Sh (2016) Electrical and dielectric properties of Mn-doped ZnO varistors. In: Proceedings of the IEEE conference on (CEIDP), Toronto, ON, Canada, 16–19 October 2016.

Al A, Bui A, Loubiere A (1991) Low frequency and low temperature behaviour of ZnO varistors by a.c. impedance measurements. J Appl Phys 69:4046–4052

Gupta TK (1990) Application of zinc oxide varistors. J Am Ceram Soc 73:1817–1840

Hembram K, Rao TN, Ramakrishna M, Srinivasa RS, Kulkarni AR (2018) A novel economic grain boundary ingineering ultra-high performance ZnO varistor with lesser dopants. J Eur Ceram Soc 38:5021–5029

Bonasewicz P, Littbarsky RS (1981) Adsorption phenomena. In: Kaldis E (ed) Current topics in material science, vol 7. North-Holland publishing Company, Amsterdam, pp 371–409

Hng HH, Chan PL (2002) Effects of MnO2 doping in V2O5 doped varistor system. Mat Chem Phys 75:61–66

Ronard-Haret JC (2004) Influence of the sintering temperature on the electrical and luminescence properties of Mn-doped ZnO. Sol StIonics 167:355–366

Boumezoued A, Guergouri K, Zaabat M, Recham D, Barille R (2018) Investigation of structural and electrical properties of manganese doped ZnO varistors prepared from nanopowders. J Nanosci Nanotechnol Appl 2:1–7

Shinde VR, Gujar TP, Lokhande CD, Mane RS, Han S-H (2006) Mn-doped and undoped ZnO films: a comparative structural, optical and electrical properties study. Mater Chem and Phys 96:326–330

Oba F, Nishitani SR, Adachi H, Tanaka I, Kohyama M, Tanaka S (2001) Ab initio study of symmetric tilt boundaries in ZnO. Phys Rev B 63:045410

Markevich IV, Kushnirenko VI, Rusavsky AV (2010) Influence of boric acid as a flux on the properties of ZnO ceramics. Radiat Meas 45:468–471

Ebrahimizadeh Abrishami M, Kompany A, Hosseini SM (2012) Varistor behaviour of Mn doped ZnO ceramics prepared from nanosized precursors. J Electroceram 29:125–132

Ebrahimizadeh Abrishami M, Hosseini SM, Attaran Kakhki E, Kompany A, Ghasemifard M (2010) Synthesis and structure of pure and Mn-doped zinc oxide nanopowders. Int J Nanosci 9:19–28

Phan T-L (2011) Structural, optical and magnetic properties of polycrystalline Zn1–xMnx ceramics. Solid State Commu 151:24–28

Altshuler SA, Kozyrev BM (1972) Electron paramagnetic resonance of compounds of the elements of the intermediate groups. Nauka, Moscow (in Russian)

Phan T-L, Vinsent R, Chems D (2007) Electron spin resonance and Raman studies of Mn-doped ZnO ceramics. J Appl Phys 101:09H103

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interests regarding the publication of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nosenko, V., Korsunska, N., Vorona, I. et al. The mechanism of formation of interface barriers in ZnO:Mn ceramics. SN Appl. Sci. 2, 979 (2020). https://doi.org/10.1007/s42452-020-2754-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-020-2754-8