Abstract

The seismic data acquisition system from analog to digital data converter has been integrated to develop acquisition device. Contrary to the digitizers currently in use, seismic data acquisition using PC/104, or industrial personal computer, turned out to be able to produce a less expensive digitizer (analog to digital converter) proven able to overcome issues of portability, efficiency, and durability. PC/104 used in this study was Arbor production with the EmCORE n-511 serial number within operating system, and the programming languages are DOS 6.02 and C, respectively. This research resulted in a design of a prototyping device based on PC/104 and created a program to record seismic data. The program was compiled in the Microsoft Windows XP operating system environment using Borland C 5.02 software. The input range of the data acquisition system that has been tested is ± 10 V. The performance test results show a resolution of ± 0.915 mV, a linearity of 0.2% full-scale reading, instrument work noise is ± 1.2 mV with a maximum frequency distortion of 2%. The instrument performs well at a rate of 10 Hz to 5000 Hz, but the software has a limited capacity of only 1000 Hz. From the results of a comparative test with Digitizer Güralp Type CGM-DM16R8, the value of the RMS error is 4.64%.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Passive seismic is a broad term incorporating various techniques and methodologies, which all exploit some part of the seismic signal that naturally exists or occurs in the Earth’s subsurface. This signal may differ significantly in the form and/or the provenance (e.g., earthquakes, ambient seismic noise, etc.), as well as the frequency content and, subsequently, the part of the subspace on which it may carry useful information that is recorded using a microprocessor: a computer processor that incorporates the functions of a central processing unit on a single integrated circuit. Nowadays, the applications of electronic engineering have developed in a broader direction such as this microprocessor [1,2,3]. This device prototype of seismic acquisition apparatus based on PC/104 is not only competitive production but also has a simple user interface design and supports the maximizing of program application. Lots of researchers, especially in the geophysical devices sector use single-chip microprocessor “SCM” digital signal processing (DSP), PC computers and other embedded microprocessors as a perfect solution on their work. MCS has many advantages such as good performance, high reliability, small dimensions, and low power consumption [4,5,6]. The bus-based PC architecture design provides the flexibility to reconfigure the instrument to meet the technical requirements fitted to user needs [7].

One type of electronic device that uses a microprocessor as the core of the system is an industrial PC or often called PC/104. PC/104 is a standard embedded computer controlled by the PC/104 Consortium and can also be defined as a computer bus [8, 9]. The seismic data acquisition system usually has an analog to digital data converter (ADC) that is integrated in it. Some systems like this are connected to computers via external ports (such as, LPT, COM, or USB ports) and some others via PC system buses, e.g., PCI and ISA buses.

The advantage of the interface using external ports is that they are portable, while the disadvantage is its maximum data rate is limited to only 115 Kbps. In addition, the design of portable computers on the current market does not support activities in the field with conditions that can be so extreme that computers are susceptible to damage. The advantage of interface using a bus system is that the data rate can reach up to 8.33 Mbps but has disadvantages of not being portable and having difficulty carrying PC computers to the field. The current digitizer products which are all portable, efficient, and durable are too expensive on the market today. A data acquisition instrument that uses an industrial PC (PC/104) has been designed with a 16-bit ADC module.

2 Materials and methods

2.1 Hardware designing

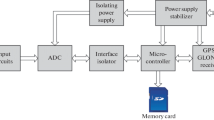

The seismic data acquisition system simply consists of several main parts, namely sensor parts, ADC, processor, storage media, time base clock and power supply. The block diagram of the seismic data acquisition system is shown in Fig. 1. PC/104 used in this study was Arbor production with the EmCORE n-511 serial number. Arbor was chosen because it has a pretty good performance and provides a fairly complete interface slot [10].

The operating system used is DOS 6.2. PC/104 Arbor EmCORE n-511 uses the AMD Geode GX1 300 MHz with 64 Mbytes SDRAM memory internal and provides several types of interface slots, including ISA slots, PCI slots, Ethernet interfaces, two USB ports, two serial ports, one parallel port, storage media port, and a slot for solid state flash memory (disk on chip). The hard drive used is the Toshiba brand MP0402H series. Installation of the operating system and other softwares used floppy media.

Power converter device FCDB-1272 is used to produce 12 volt DC voltage and 5 volt from battery as PC/104 voltage source. The ADC component used is Diamond MM-48-AT (Fig. 2). The Diamond MM-48-AT provides 16 input channels, 16-bit resolution, and a sampling rate of up to 200 kHz for one channel operation and 5000 Hz on multiple channel usage [11, 12]. This module has the auto-calibration and FIFO algorithm features inside with 2 Mbytes internal memory. In this design, the timer system uses an internal ADC clock generator with a choice of clock frequency of 10 MHz or 100 kHz. The ADC DMM-48-AT clock generator uses an 82C54 chip [11, 12].

2.2 Software design

The operating system and the programming language are DOS 6.02 and C, respectively. The program was compiled in the Microsoft Windows XP operating system environment using Borland C 5.02 software. The software engine was constructed in C language (“Appendix 1–3” in Electronic supplementary material) for inputting design of seismic sensor that records like the other commercial devices but is faster, cheaper, and more capable.

The interface program is divided into two parts, the main routine and the interrupt service routine. The main routine includes the ADC module initialization, ADC module settings, acquisition settings, output files, and all other realization, while the interrupt service routine includes reading digital input/output (DIO) and recording it in a buffer file. The software work flow diagram is shown in Fig. 3.

One of the additional features possessed by Diamond MM-48-AT is that it can do auto-calibration. The auto-calibration function is to reduce the offset data and error-gain results values from the data seismic recorded. From this instrument, it is expected that the resulting output file matches the input of the PITSA software. PITSA supports several input file formats including GSE, ISAM and ASCII and MSEED for newer versions of PITSA software. In this study, the selected file format is ASCII because it is easier to apply and can be read by all computers. To be able to be read by the PITSA software, the output file must contain the header file in the form of: data acquisition start time, sampling rate value, amount of data, channel code, and station code. The input format for the PITSA software is explained in PITSA [13].

3 Results and discussion

3.1 Prototyping

The main purpose of this research is to maximize PC/104 in recording data. PC/104 is a computer that has an integrated design and additional devices (modules) which is arranged to the needs of users in a stacked structure [14, 15]. The illustration of PC/104 assembly is shown in Fig. 4. Before assembling the tool, the aluminum boards were made to put PC/104 and a DC voltage converter device. Tool assembly begins with PC/104 Arbor installation on the board; then, the PC/104 pin in the ADC module was installed on the PC/104 socket on the motherboard. Installation of ADC modules is stacked. The connector cable is used to connect the hard drive with the integrated drive electronics (IDE) slot on the motherboard.

In the final stage of assembly devices, the assembled board is placed on a plastic box for final finishing of prototyping process. The inside of the box acrylic board is installed as a place to put the board, battery, and charger connector. The LCD screen is placed at the top of the box by bolt. The installation of the system components in the box and the seismic data acquisition toll that has been established is shown in Fig. 5.

3.2 Tools parameter measurement

To understand the quality and capabilities of the acquisition system, a test is conducted to analyze the main components of this system, namely, the ADC device. This test includes linearity test, tool noise test, frequency distortion test, and click time test [16]. Figure 6 presents the linearity of data record with a voltmeter. The percentage of error is averaged by the moving average method and then compared with the estimated maximum error of the tool set by the ADC DMM-48-AT (Fig. 7). From the calculation results, it is known that the value of measurement accuracy using a data acquisition tool is still within the range of resolution set by the manufacturer of the Diamond MM-48-AT ADC (± 3 LSB = ± 0.915 mV). The results of working noise testing on the data acquisition system in the time zone are shown in Fig. 8 with the maximum amplitude of the device noise signal is ± 1.2 mV.

The noise amplitude exceeds the noise signal tolerance set by Diamond Ind. It is possible that this noise was originated from an unstable current source sensor and a replacement of sensor connecting cable [1]. These sources are still included in the device; moreover, that noise can be referred to as the acquisition system noise shown in Fig. 9. The noise signal has a frequency component that is almost evenly distributed along the tool response bandwidth. Therefore, frequency distortion test is intended to determine the frequency error recorded by the device. From the calculation results, it is known that the frequency distortion value of the data acquisition tool after the average run is 2% [11, 12, 17].

From the result of the click time test obtained at the 10 kHz sampling rate frequency, there occurs a deviation of the duration of time recorded (the recording time occurred). This indicates the presence of samples lost or not recorded during the acquisition process. Deviations may be caused by a processor that is too heavy because it has to process interruptions at high speed [5, 18,19,20]. Although the tests that have been carried out did not use high accuracy or calibrated equipment, they provide consistent results and prove that the tools that have been made are reliable and have a certain quality data acquisition device. Table 1 shows the test result of time stamp sampling using Canal 1 in this research. The recorded data rate ranged from 10 to 3000 Hz within linearity from 600 to 180.000 measurement data which mean every single data that recorded were real-time function with the sampling rate within error function of this system is 0%.

4 Application test

4.1 Data acquisition using digitizer PC/104

This time, the experiment used a 3-channel Mark L4C sensor. Furthermore, the recorded data were transferred to another computer to go through the processing stage with the PITSA program. Furthermore, the recorded data were transferred to another computer to go through the processing stage with the PITSA. Figures 10, 11 and 12 show the PITSA software window that is opening digital seismic signal data to emphasize that seismic data were well-recorded using this device which is similar to common interpreted software. Experiments that have been carried out show the files produced by a data compatible acquisition system program for PITSA software [11, 12]. From the numbers presented above, we can see that the data acquisition system works as expected, the device gives a reading error less than the specified threshold and produces a slight frequency distortion. Acquisition system devices that have been made are feasible to be used as seismic data acquisition devices. The dynamic range is an important performance of the seismograph, which is directly related to the quality of the final seismic signal and ultimately affects the data processing results [21, 22]. Experiments that have been performed showing the files generated by the instrument that have been created are suitable for PITSA software (Fig. 12).

4.2 PC/104 digitizer performance test match with CMG-DM16R8 Güralp digitizer device

This experiment was conducted to compare the signals recorded using a device made with the Güralp CMG-DM16R8 digitizer as a reference seismometer. Two sensors used are identical, namely Mark L4C 1D, assuming the waves received by the two sensors are the same.

From the test results obtained, the difference in reading values from the Güralp CMG-DM16R8 and PC/104 ranges from − 4 to 8 mV. The deviation value is quite far when compared with the results of the working noise test equipment which only ranges from ± 1 mV; this is probably due to differences in the location of sensor 1 and sensor 2. From the difference in reading results between these two devices, the RMS error reading value is 4.64% [6, 23,24,25]. The signal from the data recording uses the PC/104 digitizer and the Guralp digitizer along with the difference shown in Fig. 13. On the other hand, the spectrum generated from the two digitizers is shown in Fig. 14. From the results of the FFT, it can be seen that the two spectra are not much different. To record low-amplitude passive seismic signals, a combination of a low natural-frequency highly sensitive geophone with a low noise-floor acquisition system is essential to record low-amplitude passive seismic signals. To avoid wind noise, the sensor should be well coupled to the surface and ideally buried [26, 27]. The test results obtained from the specifications of data acquisition devices made are as follows:

-

a.

Input range: ± 10 Volt

-

b.

Sampling rate (each channel): 10–1000 Hz

-

c.

Resolution: ± 0.915 mV

-

d.

Linearity: 0.2% full scale

-

e.

Work noise: ± 1.2 mV

-

f.

Maximum frequency distortion: 2%.

5 Conclusion

From the research, a 16-channel seismic data acquisition system has been successfully designed and created using PC/104 and an ADC Diamond MM-48-AT module. Dmm_dos.exe software has been successfully designed to access the data acquisition system with the PITSA program compatible output files. The software was created using C language on DOS 6.02 environment with the Borland compiler version 5.02. Compared to the reference digitizer (CMG-DM16R8 type Güralp product), the data acquisition system test has shown good results, where the RMS value of the reading error was 4.64%.

References

Bowden G (1995) Mark L4C geophone design constants. NLC ME Note No. 1–94 Rev 2

Bullen KE, Bolt BB (1985) An introduction to the theory of seismology, 4th edn. Cambridge University Press, Cambridge

Howell RF (1989) Seismic instrumentation. In: The encyclopedia of solid earth geophysics, James DE (ed) New York

Avery H (2005) The development of a low-cost strong motion seismograph. Dissertation, Civil Engineering, University Canterbury, Christchurch

Mattos LS (2003) The evbot ii an enhanced evolutionary robotics platform equipped with integrated sensing for control. Thesis, Faculty of Electrical and Computer Engineering, University North Carolina, Raleigh

Shaver JA (2006) PC/104 control environment development and use for testing the dynamic accuracy of the micro-strain 3 dm-Gx1 sensor. Thesis, Department of Electrical and Computer Engineering, Naval Postgraduate School, California

Asch G (2009) Seismic recording systems. In: Bormann P (ed) New manual of seismological observatory practice (NMSOP). Deutsches Geo Forschungs Zentrum (GFZ), Potsdam, pp 1–20

Elder K, Starlt JE, Wager GT, Dice J (2018) Cableless seismic acquisition with hierarchical communication protocol. US Grant US010107926B1

Roberts KA (2018) Design and testing of an additively manufactured cubesat structural bus. Thesis of Department of Astronautical Engineering, Graduate School of Engineering and Management, Air Force Institute of Technology, Air University, USA

Austerlitz H (2003) Data acquisition techniques using PCs. Academic Press, Oxford

Diamond Systems Corporation (2004) DIAMOND-MM-48-AT auto calibrating 16-bit analog I/O PC/104 module with relays and optocouplers user manual. Ver 1.01

Diamond Systems Corporation (2007) Universal driver documentation. http://docs.diamondsistems.com/dscud/manual_Main_Page.html

Scherbaum F (1996) Of poles and zeros, fundamentals of digital seismology. Kluwer Academic Publishers, Dordrecht

Doebelin EO (1983) Sistem Pengukuran: Aplikasi dan Perancangan, Ed.3, Jilid 1, Terjemahan, Bab 3 hal 34–181, Erlangga, Jakarta, Indonesia (in Indonesian Language)

Kumar S, Sharma BK, Sharma P, Shamshi MA (2003) 24 bit seismic processor for analyzing extra large dynamic range signals for early warnings. J Sci Ind Res 68(372):372–378

Ball S (2001) Analog interfacing to embedded microprocessors real world design. Newness, Boston

Teng Y, Zhang L, Wang Y, Liu X, Ma Y (2002) Technique development of PC104 embedded module and its application in the geophysical instrument design. Acta Seismol Sinica 4(15):439–446

Lehrbaum R (1997) Real-time software for PC/104 systems. www.ampro.com/tmp/rtsw.pdf, AmiPro Computers, Inc

Pandey VK, Kumar S, Sharma BK, Shamshi MA (2007) Performance characteristics of indigenously developed 24-bit seismic data recorder for earthquake seismology. J Sci Ind Res 66:741–747

Shannon CE (1949) Communication in the presence of noise. Proc IRE 37(1):10–21

Gao P, Li Z, Li F, Li H, Yang Z, Zhou W (2018) Design of distributed three component seismic data acquisition system based on LoRawireless communication technology. In: Proceedings of the 37th Chinese control conference, Wuhan, China, 25–27 July

Friskel MR, Edmunson JE, Edward GWIII (2018) The disruptive technology that is additive construction: system development lessons learned for terrestrial and planetary applications. American Institute of Aeronautics and Astronautics. https://ntrs.nasa.gov/search.jsp?R=20180006817 2018-12-13T04:21:38 + 00:00Z

Güralp Sistems Limited (2006) CMG-DM16R8 broadband digitizer operator’s guide. http://www.guralp.com/documents/MAN-D16-0001.pdf

Scherbaum F, Johnson J (1992) PITSA, programmable interactive toolbox for seismological analysis. IASPEI, Software Library, vol 5

Swanson P (2001) Seismic event data acquisition and processing: distribution and coordination across PC-based networks. In: Proceedings of the 5th international symposium on rock-bursts and seismicity in mines, Johannesburg, South Africa, 17–19 Sept 2001

Dean T, Shem A, Al-Hasani M (2018) Methods for reducing unwanted noise (and increasing signal) in passive seismic surveys. In: AEGC 2018, Sydney, Australia

Polychronopoulou K, Lois A, Martakis N, Chevrot S, Sylvander M, Diaz J, Villaseňor A, Calassou S, Collin M, Masini E, Bitri A, Stehly L (2018) Broad-band, short-period or geophone nodes? Quality assessment of passive seismic signals acquired during the Maupasacq experiment. First Break 36(4):71–75

Acknowledgements

The authors deeply appreciate to The Institute for Research and Technology Development of Geological Disaster (BPPTKG) of Yogyakarta, Indonesia, for supporting this research.

Author information

Authors and Affiliations

Contributions

Lutfian R Daryono: Data curation, Writing- Original draft preparation, Visualization, Investigation. Arief Rahmadi: Coding Software C+, Investigation, Draft preparation, Device Prototyping. Imam Suyanto: Supervision, Validation. Wiwit Suryanto: Writing- Reviewing and Editing, Supervision. A great achievement to maximizing the gap between equipment limit and technology in the developing country, as a supervisor I am conducted writing-reviewing and editing, really appreciated this work.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical statement

This research was carried out in efforts to tackle the gap between technology and electronic device instruments. It was conducted on a laboratory scale to compare real seismograph data. The participants of this study came from the members of the Institute for Geological Disaster Technology Research and Development (BPPTKG) Yogyakarta, Indonesia.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Daryono, L.R., Rahmadi, A., Suyanto, I. et al. Design and implementation of seismic data acquisition system using PC/104. SN Appl. Sci. 1, 1182 (2019). https://doi.org/10.1007/s42452-019-1038-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-019-1038-7