Abstract

This study presents new measured slug liquid holdup data for liquid viscosity ranging from 200 to 800 mPa s. The experiments were conducted using two different large pipe diameters (0.08 and 0.1 m) and pipe inclination angles of 0°, 30°, 60° and 90° from horizontal. To our best knowledge, most of the existing experimental data were limited to either vertical or horizontal flow and mostly performed using small pipe diameters. Based on the measured data, a new unified empirical correlation is developed to predict slug liquid holdup for viscous two-phase flow in horizontal, vertical and inclined pipes. The proposed correlation is simple and fully consistent with the trends of published experimental data. This study also investigates in details the performance of the existing liquid holdup correlations using different flow conditions. The investigation reveals several discrepancies associated with these correlations. Based on statistical analysis, the proposed correlation performs best as compared to the existing correlations using both the present measured data and data from three independent sources.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Two-phase flow is a common occurrence in oil and gas production and transportation. The most common flow regime, in the pipelines, is the slug flow, which is described by alternating liquid slugs and gas intervals. Many theoretical and experimental studies for predicting flow regimes, liquid holdup and pressure drop in two-phase slug flow are available in the literature. Most of these studies were dealing with low viscosity two-phase slug flow. However, new challenges have appeared for the petroleum and chemical industries where high viscosity liquid and gas flows are increasingly occupied. Liquid viscosities were found to significantly affect flow behaviors, such as flow regimes, liquid holdup and hence, the pressure drop. The slug liquid holdup is the liquid fraction in the slug body and is required for the closure of most two-phase slug flow mechanistic models. The prediction of slug liquid holdup has been studied widely; however, it has not been solved yet, especially for inclined pipe and high viscosity systems.

Several theoretical and experimental studies investigated the prediction of the slug liquid holdup. A survey of these studies revealed that the slug liquid holdup (HLS) is a function of several flow parameters, namely, superficial gas velocity (Vsg), mixture superficial velocity (Vm), liquid density (ρL), angle of inclination from horizontal (θ), superficial liquid velocity (Vsl), liquid viscosity (µL), surface tension (σL) and pipe diameter (d). Observations of Al-Ruhaimani et al. [5], Al-Safran et al. [8], Andreussi and Bendiksen [9], Baba et al. [10], Baba et al. [11], Brito et al. [15], Farsetti et al. [18], Gokcal [20], Gregory et al. [22], Kora et al. [23], Nadler and Mewes [25], Nuland [26], Pan [28], Wang et al. [31], Wen et al. [32], Zhao et al. [34], Zhao et al. [35] showed a clear inverse relationship between HLS and both Vsg and Vm. The HLS decreases with the increase of Vsg, due to sweeping out the liquid phase from the pipe resulting in more of the gas phase occupying the pipe cross sectional area. On the other hand, there is a slight increase in HLS with the increase of Vsl, due to an increase in the input of liquid content in the pipe. It seems that the effect of Vsg on HLS is stronger than the effect of Vsl, hence the overall effect of Vm (sum of Vsg and Vsl) is that as the Vm increases the HLS decreases.

Wen et al. [32] investigated the effect of liquid medium, in terms of liquid density and the proportion of heavy components, on the liquid holdup. The authors observed that the HLS is proportional to high content of heavy components and inversely related to ρL. The inverse relationship between HLS and ρL is also confirmed by the mechanistic model of Barnea and Brauner [12].

Nuland et al. [27] and Gomez et al. [21] observed a slight decrease in HLS as the angle θ increases. Gomez et al. [21] concluded that HLS is maximum at horizontal flow conditions, decreasing as the upward inclination increases, and it is minimum for upward vertical flow. The mechanistic models of Abdul-Majeed and Al-Mashat [3] and Brauner and Ullmann [14] confirmed the decreasing of HLS with increasing of θ from horizontal. Al-Ruhaimani et al. [5] compared their vertical data with Kora et al. [23] horizontal data and observed a decrease in HLS with increasing of θ and a decreasing effect of θ on HLS with increasing of Vm.

The effect of σL on HLS was studied by Nadler and Mewes [25], Pereyra et al. [29] and Brito et al. [15] using data of air/water and air/oil with a moderate liquid viscosity (µL up to 120 mPa s). These studies revealed that σL has a significant effect on HLS for low superficial gas velocity (less than 0.5 m/s). Above this value of Vsg, a decreasing effect of σL was observed and the effect of µL becomes the dominant, resulting in larger values of HLS for air/oil data as compared to air/water data. The effect of σL can be explained in terms of gas bubble rise velocity. As the surface tension increases, the bubble rise velocity increases resulting in bubble accumulation, which promotes bubble loss rate and increase liquid holdup.

Regarding the effect of pipe diameter, the observations of Wen et al. [32] and Andreussi and Bendksen [9] and the mechanistic models of Barnea and Brauner [12] and Abdul-Majeed and Al-Mashat [3] indicated a slight increase of HLS with increasing of pipe diameter. Godbole et al. [19] stated that the reason, for this effect, is due to higher bubble rise velocity in larger pipe diameter.

Several experimental studies have been conducted to investigate the effect of µL on HLS in vertical and horizontal two-phase flow [5, 8, 10, 11, 15, 20, 23, 25, 26, 28, 31, 34, 35]. All these studies showed that for medium to high liquid viscosity, HLS increases as µL increases. The liquid level in the pipe cross section increases when liquid viscosity increases owing to the increase in shear around the pipe wall and resistance to flow, which leads to an increase of HLS. A number of researchers [17, 24, 33] observed a dual effect of liquid viscosity on gas holdup (1-HLS). They found that for low liquid viscosity (up to 3 mPa s.), the gas holdup increases with the increase of liquid viscosity, whereas, above 3 mPa s., the gas holdup decreases with increasing of liquid viscosity. This behavior can be explained by the increase in bubble coalescence due to large drag forces in two-phase flow with liquid viscosity greater than 3 mPa s. For low liquid viscosity, drag forces are not large enough to cause bubbles coalescence, instead these forces could contribute to a more uniform distribution of bubbles resulting in higher gas holdup (lower liquid holdup).

The objective of the present study is to investigate the effect of µL on HLS in vertical, horizontal and inclined viscous two-phase flow. At the beginning, the behavior of the existing slug liquid holdup correlations, that accounting for liquid viscosity, is compared with the trends of the published experimental data and also tested against variation of the flow parameters. The correlations included are those of Gomez et al. [21], Abdul-Majeed [2], Kora et al. [23], Al-Safran et al. [8] and Al-Ruhaimani et al. [5]. Other correlations, namely, Abdul-Majeed and Al-Mashat [3], Brauner and Ullmann [14], Al-Safran [7] and Wang et al. [31] are not included due to their complexity. An experimental study is then conducted to provide a new data set of slug liquid holdup data for viscous two-phase flow covered liquid viscosity ranging from 200 to 800 mPa s. A new unified semi-empirical correlation is proposed to predict HLS for viscous two-phase flow in horizontal, vertical and inclined pipes. Finally, the proposed and the existing correlations are tested against the present experimental data and also against data from three different sources. The following section describes and tests the existing correlations against variation of mixture superficial velocity and liquid viscosity, while keeping other parameter constants (pipe diameter = 0.04 m, liquid density = 850 kg/m3, gas density = 2 kg/m3, gas viscosity = 0.02 mPa s).

1.1 Gomez et al. correlation

Gomez et al. [21] proposed the following correlation for predicting horizontal to vertical upward flow, as a function of the slug Reynolds number (NReSL)

where θ is the inclination angle from horizontal in degrees. Figure 1 shows the results of Eq. (1) against liquid viscosity for Vm = 1.5 m/s and θ= 0. The performance of Eq. (1) with the variation of Vm and µL is given in Fig. 2. As noted, Eq. (1) shows the expected trend of increasing HLS with increasing of µL and decreasing of Vm. However, this correlation tends to yield HLS close to unity for µL greater than 100 mPa s, indicating an overestimation of slug liquid holdup for viscous two-phase horizontal flow. Figure 2 shows that there is a decreasing effect of Vm on HLS with increasing of µL. Analysis of Eqs. (1) and (2) indicates a decrease in HLS with increasing of d, which mismatches with the experimental data of Wen et al. [32], Abdul-Majeed [1] and Andreussi and Bendksen [9].

Liquid viscosity effect on slug liquid holdup predicted by Gomez et al. [21]

Performance of Gomez et al. [21] correlation using different liquid viscosities

1.2 Abdul-Majeed correlation

Abdul-Majeed [2] developed a correlation to predict HLS for horizontal and slightly inclined flow:

Performance of Eq. (3) with variation of µL for horizontal flow at Vm = 1.5 m/s is shown in Fig. 3. As noted, HLS increases with the increase of µL, however for high liquid viscosity, this effect becomes less significant. Figure 4 illustrates the effect of both the µL and Vm using Abdul-Majeed [2] correlation. As shown, this correlation does not well account for effect µL on HLS. This implies that Eq. (4) needs a revision to reveal the actual effect of µL. Analysis of Eq. (5) indicates that HLS decreases with increasing of θ which matches with the experimental data of Nuland et al. [27], Gomez et al. [21] and Al-Ruhaimani et al. [5].

Liquid viscosity effect on horizontal slug liquid holdup predicted by Abdul-Majeed [2]

Performance of Abdul-Majeed [2] correlation using different liquid viscosities

1.3 Kora et al. correlation

Based on experimental data, Kora et al. [23] observed a direct relationship between HLS and µL (180–587 mPa s). They proposed the following correlations for prediction HLS as a function of two dimensionless groups representing Wallis Froude number (NFr) and viscosity number (Nµ):

where

The performance of Kora et al. correlation (2011) presented in Fig. 5, shows an inverse relationship between slug liquid holdup and liquid viscosity. This disagrees with the experimental studies and most of the published correlations. To explain this unexpected behavior, the term \(N_{Fr } N_{\mu }^{0.2}\) is simplified as:

Liquid viscosity effect on slug liquid holdup predicted by Kora et al. [23]

Equations (6) and (7) can be expressed as:

Several comments can be drawn from Eqs. (12) and (13). First, the predicted slug liquid holdup increases with decreasing of liquid viscosity, which opposes with the experimental liquid holdup data of Nuland [26], Gokcal [20], Pan [28], Al-Ruhaimani et al. [5] and Baba et al. [10]. Second, the predicted slug liquid holdup is proportional to liquid density (the net effect of ρL and Δρ, for ρL ≫ ρg), whereas the experimental study of Wen et al. [32] showed an opposite relationship. Also, the mechanistic model of Barnea and Brauner [12] indicated that as the liquid density increases, the slug liquid holdup decreases. Third, the effect of pipe diameter on slug liquid holdup is significant as compared to the effect of liquid viscosity, as shown in Fig. 6. The results of Kora et al. [23] correlation against mixture velocity and liquid viscosity are shown in Fig. 7. As noted, the slug liquid holdup decreases with the increase of both mixture velocity and liquid viscosity. Figure 7 shows a high effect of liquid viscosity for Vm greater than 2 m/s. The effect becomes less significant for Vm values less than 2 m/s.

Effect of pipe diameter on liquid holdup predicted by Kora et al. [23]

Performance of Kora et al. [23] correlation using different liquid viscosities

1.4 Al-Safran et al. correlation

Based on Kora et al. [23] experimental data, Al-Safran et al. [8] developed a better fitting formula using the same term suggested by Kora et al. [23], that is \(N_{Fr } N_{\mu }^{0.2}\). Their correlation is expressed as:

where

Figure 8 shows the unexpected trend of decreasing slug liquid holdup with increasing of liquid viscosity. The prediction of Eq. (14) versus mixture velocity for different liquid viscosities is shown in Fig. 9. As noted, Al-Safran et al. [8] correlation shows the same behavior predicted by Kora et al. [23]. Detailed calculations of slug liquid holdup indicate that both correlations yield approximately the same results. For completeness and simplification, Eq. (15) can be rewritten as:

Liquid viscosity effect on slug liquid holdup predicted by Al-Safran et al. [8]

Performance of Al-Safran et al. [8] correlation using different liquid viscosities

Analysis of Eq. (16) reveals the same above three comments associated with Kora et al. correlation (2011).

1.5 Al-Ruhaimani et al. correlation

Based on experimental study of viscous (127–558.7 mPa s) upward two-phase vertical flow, Al-Ruhaimani et al. [5] developed the following correlation for predicting slug liquid holdup:

where NFr is defined in Eq. (9) and Nf is the inverse viscosity number given by:

Equation (17) can be simplified to:

Equation (19) reveals that the slug liquid holdup increases with increasing of liquid viscosity and decreasing of mixture velocity (see Figs. 10, 11). This agrees with the published horizontal experimental studies [8, 20, 23]. Also, Al-Ruhaimani et al. [5] correlation reveals the correct inverse relationship between slug liquid holdup and liquid density; however, it indicates an increase in liquid holdup with decreasing of pipe diameter which is not in agreement with observations of Wen et al. [32] and Andreussi and Bendksen [9]. Also the mechanistic models of Barnea and Brauner [12] and Abdul-Majeed and Al-Mashat [3] indicated an increase of slug liquid holdup with increasing of pipe diameter. Another worthy note is that Al-Ruhaimani et al. [5] predicts a very narrow range of liquid holdup and always yields slug liquid holdup greater than 0.912. Detailed results show that the first term on the right hand side of Eq. (19) predicts very little effect on liquid holdup, for example, for µL = 100 mPa s, the term is only 0.0054 and it becomes 0.012 for µL = 500 mPa s. Figure 11 shows the results of Eq. (19) against mixture velocity for different liquid viscosities. As noted, the effect of liquid viscosity is significant for low mixture velocity (less than 2 m/s). For greater values of Vm, the effect is less significant. This behavior is exactly the opposite of that shown by both Kora et al. [23] and Al-Safran et al. [8] correlations.

Liquid viscosity effect on slug liquid holdup predicted by Al-Ruhaimani et al. [5]

Performance of Al-Ruhaimani et al. [5] correlation using different liquid viscosities

2 New correlations

From the above analysis, it is clear that there is a need for a new correlation that can be simple, accurate, consistent in units and consistent with observations trends. To achieve this goal, we try to correlate the slug liquid holdup with the function \(N_{Fr} / N_{\mu }^{0.2}\), which can be written as:

It is expected that the slug liquid holdup will be inversely related to the above suggested function. As already mentioned, the effect of each of the flow parameters included in this function is justified by the trends of the observations, as described earlier. The final form of the new correlation is obtained based on new measured slug liquid holdup data created from experiments conducted in two large pipe sizes. The total number of the measured data is 180, distributed as: 60 points for horizontal flow with 0.08 m and 0.1 m pipe diameters, 60 points for the inclined flow of 30 and 60 degree angles from horizontal and 60 points for vertical flow with 0.08 m and 0.1 m pipe diameters. The liquid viscosity range covered by the measured data is (200- 800) mPa s. The experimental setup is explained in the following sections.

2.1 Test fluids

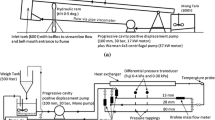

Air and lubricant oil are used as test fluids. The physical properties of lubricating oil at 25 °C are: API gravity = 25.7°; density = 900 kg/m3; surface tension = 31 mN/m. Gas properties are: density = 1.3 kg/m3; viscosity = 0.02 mPa s. Two factory calibrated flow meters were used to measure the oil and gas flow rates, with accuracy of ± 0.05% of the scale reading. The oil viscosity is measured using rheometer at different temperature values. Fitting technique is used to correlate the results and the following empirical equation is obtained (see Fig. 12)

where Tc is the temperature in °C and µL in Pa s. Oil viscosities of 199, 402, 499, 601 and 802 mPa s were used during measuring liquid holdup. These viscosities were measured at temperatures of 41.6, 30, 26.5, 23.4 and 18.7 °C respectively. This viscosity variation is achieved by heating/cooling system that controls the oil temperature during circulation in the tank. Prior to starting experiments, a circulation process is done by a circulation heater, connected to the storage tank, to achieve a uniform oil viscosity. The experimental heating system is presented in Fig. 13. The oil temperature in the oil tank is increased by the circulation heater, where the desired oil temperature is entered into the heater control panel. On average, the period required to reach each desired oil temperature, is about 3 h. The range of the temperature of the circulation heater is (0–50) °C. The lubricant oil circulates through a pipe connecting the heater and the oil storage tank until the temperature reaches the desired value. For the liquid viscosity range covered, the corresponding range of the densities of the lubricant oil is from 884.7 to 908.3 kg/m3 and the corresponding range for the lubricant oil-air surface tension is from 29.8 to 31.7 mN/m. The change in the lubricant oil density is less than 3% and the change in surface tension is less than 6%, so that an effect on the slug characteristics due to the change in oil density and surface tension is negligible in comparison to the changes in liquid viscosity.

To make sure that the lubricant oil obeys Newton’s law, the flow behavior of three lubricant oil samples (200, 500 and 800 mPa s) were investigated over a wide range of shear rates at 25 °C. The measurement tests were conducted under the controlled rate (CR) mode of the rheometer, and the values of shear stress and shear rate were obtained. The results are presented in Fig. 14, from which it can be seen that measured shear stress and shear rate of these samples are collated by a linear line, indicating the oil used in this study with viscosity up to 800 mPa s is a Newtonian fluid.

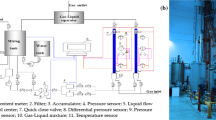

2.2 Test section

Experiments were conducted using two different polycarbonate pipe diameters (0.08 and 0.1 m), each with 18 m length. The testing pipe is connected to a return steel pipe with the same diameter and length. An inclinable boom is connected to the test section to move it up to any inclination angle from 0° to 90° from horizontal. The lubricant oil is stored in a tank of 2 m3 capacity and feeds using cavity pump of 16 m3/h maximum capacity. Compressed air is supplied from a screw compressor with a maximum capacity of 400 m3/h, and with a maximum discharge pressure of 7 barg. Five temperature detectors were used to measure the temperature, three of them located at the test section and two detectors placed in the oil and gas flow lines. The pressure is measured using four pressure transducers, two are placed in the test section, the other two are located on the flow lines of oil and gas. Quick closing valve system was used to trap and determine the slug liquid holdup. Five closing valves are installed in the test section; two of them are dedicated for dynamic calibration of capacitance sensors. Four capacitance sensors (two-wire type) were used to track the development of slug flow in the test section. In addition to the capacitance sensors, there is a laser sensor installed in the test section to detect the front of the slug and then activate the closing valves. The test platform is shown in Fig. 15. The calibrations of the closing valves and capacitance sensors and uncertainty analysis [16] are given in “Appendix”.

2.3 Test matrix

Table 1 shows a description of the fluid and flow parameters covered by the measured data. To our best knowledge, this study is one of the very few studies that present viscous measured liquid holdup data for inclined two-phase flow using large pipe diameters. Most of the existing experimental data were limited to either vertical or horizontal flow and mostly performed using small pipe diameters. The ranges of the investigated superficial gas and liquid velocities are (0.2–1.85) m/s and (0.05–0.25) m/s for vertical flow, (0.6–3.9) m/s and (0.07–0.39) m/s for inclined flow of 30° from horizontal, (0.6–2.8) m/s and (0.1–0.32) m/s for inclined flow of 60° from horizontal, (0.1–2.4) m/s and (0.1–0.3) m/s for horizontal flow. The upper limits of superficial liquid velocities are determined by the liquid pumping limitation, whereas, the upper limits of superficial gas velocities are controlled to avoid transition from slug flow to another flow pattern. Figures 16, 17 and 18 show comparisons of the measured vertical and inclined data against the flow pattern map proposed by Abdul-Majeed [1]. As can be seen, all the data points are falling within the slug flow. Figure 19 compares the horizontal measured data with Beggs and Brill [13] flow pattern map. As shown, some data points are not predicted well by this flow map and this could be attributed to viscosity and diameter effects. The uncertainties of fluid and flow properties were calculated using Taylor propagation equations as described in detail by Al-Safran [6] and Al-Ruhaimani [4]. For VSL, VSg, ρL, and µL the certainties are 0.5%, 1.9%, 1% and 1% respectively.

Measured vertical data superimposed on Abdul-Majeed [1] flow pattern map, using 0.08 m pipe size

Measured 30° inclined data superimposed on Abdul-Majeed [1] flow pattern, using 0.08 m pipe size

Measured 60° inclined data superimposed on Abdul-Majeed [1] flow pattern, using 0.08 m pipe size

Measured horizontal data superimposed on Beggs and Brill [13] flow pattern map, using 0.08 m pipe size

2.4 Correlations development

The measured vertical data are shown in Fig. 20. As noted, the slug liquid holdup is slightly higher for pipe diameter of 0.1 m as compared to pipe diameter of 0.08 m. This observation agrees with the finding of Wen et al. [32]. It seems that, as the pipe diameter increases in viscous two-phase flow, the bubble rise velocity increases, resulting in reduction of the gas residence time and then reducing the gas void fraction (i.e., increasing of liquid holdup). Figure 21 presents the vertical measured liquid holdup vs. liquid viscosity. The slug liquid holdup increases as the liquid viscosity increases. The scatter is due to the effect of mixture velocity, which varies for vertical flow from 0.45 to 2.0 m/s (as described in Table 1).

Figure 22 shows the measured slug liquid holdup versus NFr/N 0.2µ for vertical data. The proposed correlation that can best fit the vertical measured data is:

Figure 23 displays the measured horizontal data for both pipe diameters 0.08 m and 0.1 m. As can be seen, the slug liquid holdup value increases slightly with increasing of pipe diameter for the same mixture velocity. The measured horizontal slug liquid holdup data are plotted against NFr/N 0.2µ as shown in Fig. 24. These data can be represented by the following correlation:

The same procedure is used for inclined data. Figures 25 and 26 show the liquid holdup values for pipe angles of 30° and 60° respectively.

The proposed correlation for 30° inclined data is:

For inclined data of 60° from horizontal, the following correlation is suggested:

To develop a unified correlation that can be used for all ranges of the inclination angle, Eqs. (22) through (25) are combined into one correlation as suggested below:

where NFr N −0.2µ can be calculated from Eq. (20) and θ is the angle of inclination from the horizontal in degree.

The results of the new correlation presented in Fig. 27, indicates an increase in liquid holdup with increasing of liquid viscosity. This is in agreement with the present and previous observations. The performance of the proposed correlation against mixture velocity for different liquid viscosities is illustrated in Fig. 28. As shown, the proposed correlation predicts high effect of liquid viscosity for high mixture velocity.

For comparison purpose, the predictions of all correlations are tested using different flow conditions. Figures 29 and 30 show the predictions for high viscosity with Vm = 1.5 and 3 m/s respectively. The other flow parameters are kept constant with the following values: ρL= 850 kg/m3, d = 0.04 m, ρg= 2 kg/m3, µg= 0.02 mPa s. For both Vm values Gomez et al. [21] yields the highest liquid holdup values close to unity. For Vm = 1.5 m/s, Abdul-Majeed [2] and Al-Ruhaimani et al. [5] correlations give the same trend and approximately the same results for medium liquid viscosity (µL = 20–200 mPa s). Correlations of Kora et al. [23] and Al-Safran et al. [8] give very close values. For Vm = 1.5 m/s, all the existing correlations yield liquid holdup greater than 0.9, whereas the proposed correlation shows that the predicted holdup can be as low as 0.83 for µL = 20 mPa s. It is important to remark that for both mixture velocities, the proposed correlation and those of Kora et al. [23] and Al-Safran et al. [8] predict significant effect of liquid viscosity change, but in opposite trend. That is, the proposed correlation shows an increase in liquid holdup while the correlations of Kora et al. [23] and Al-Safran et al. [8] show a decrease in liquid holdup with increasing of liquid viscosity. For both Vm values, the predictions of Gomez et al. [21], Abdul-Majeed [2] and Al-Ruhaimani et al. [5] correlations do not vary significantly. Figure 31 illustrates the prediction with the variation of pipe diameter. Gomez et al. [21] and Al-Ruhaimani et al. [5] correlations predict very slight decrease in holdup with the increase of pipe diameter, which disagrees with the observations of the present study and those of Wen et al. [32]. Abdul-Majeed [2] correlation predicts constant values since it does not account to pipe diameter. The correlations of Kora et al. [23] and Al-Safran et al. [8] predict very high effect of pipe diameter on liquid holdup, which does not show by any experimental study. The proposed correlation predicts a reasonable increase in holdup with increasing of pipe diameter.

3 Evaluation and validation

3.1 Evaluation

The proposed and the existing correlations are evaluated using the present measured data. Four statistical parameters are selected for evaluation, namely: average relative error (ɛ1), absolute average relative error (ɛ2), average actual error (ɛ3) and absolute average actual error (ɛ4). Refer to Al-Ruhaimani [4] for a detailed description or equations of these parameters. The results for horizontal, vertical and inclined data are listed in Tables 2, 3 and 4 respectively. As shown, the new correlation yields the best performance among all correlations. For vertical flow, Al-Ruhaimani et al. [5] correlation is determined as the second best method. For horizontal flow, Al-Ruhaimani et al. [5] and Abdul-Majeed [2] correlations give better results as compared to Gomez et al. [21], Kora et al. [23] and Al-Safran et al. [8] correlations. For inclined data, Al-Ruhaimani et al. [5] is again the second best correlation followed by Al-Safran et al. [8] correlation. The worse performance for vertical and inclined flows is shown by Abdul-Majeed [2] and Gomez et al. [21] correlations. It is important to remark that the results of Abdul-Majeed [2] and Gomez et al. [21] correlations can be improved significantly by eliminating the correction factor used by these authors for the effect of inclination angle. For example, for the present vertical data, when using θ = 0 (instead of 90°) in these two correlations, the four statistical parameters become 0.483, 1.242, 0.463, 1.161 for Abdul-Majeed [2] correlation and 6.15, 6.15, 5.736, 5.736 for Gomez et al. [21] correlation (see Table 3 for comparison). The same observation is noticed for present inclined data. Following the approach of Shi et al. [30] for performance evaluation, the measured and predicted liquid holdup for all correlations are plotted in Figs. 32, 33 and 34, for horizontal, vertical and inclined data respectively. As indicated, for horizontal and inclined data, the predictions of the proposed correlation fall within the ± 3% range. For vertical flow, the prediction of the present correlation falls within the ± 1% error range. The existing correlations show predictions with higher error ranges compared to the proposed, as described above and demonstrated in Tables 2, 3 and 4.

3.2 Validation

The newly proposed correlation is also tested against independent, measured data collected from three different sources. These data are those of Nuland [26] for horizontal slug flow (89 data points), Kora et al. [23] for horizontal slug flow (144 data points) and Al-Ruhaimani et al. [5] for vertical slug flow (68 data points). Before starting validation process, we would like to compare Nuland [26] data with Kora et al. [23] data, since they are both for viscous horizontal slug flow. Figure 35 shows a comparison of these two data sets. The present horizontal data points are also shown in this figure. It is noted that for approximately the same values of mixture velocity and liquid viscosity, the three data sets show different measured liquid holdup values. On average, Nuland [26] data are 40% lower than the data of Kora et al. [23] and the present horizontal data. We also compare Nuland [26] data with Gregory et al. [22] horizontal data and observe that Nuland data are 30% lower than those of Gregory et al. [22]. It is expected that this large difference is due to using different liquid holdup measurement instruments. Table 5 summarizes the validation measured data.

3.2.1 Al-Ruhaimani et al. [5] vertical measured data (68 data points)

The statistical parameters of the correlations using, Al-Ruhaimani et al. [5] data, are presented in Table 6. The cross plot of the measured versus predicted liquid holdup is illustrated in Fig. 36. As expected Al-Ruhaimani et al. [5] correlation gives the best results since it was developed using this data set. The proposed correlation yields excellent results and very closes to Al-Ruhaimani et al. [5]. The correlations of Abdul-Majeed [2] and Gomez et al. [21] are totally unsatisfactory for vertical measured data due to using the correction factor for the effect of inclination angle (as stated previously).

Measured versus predicted liquid holdup for Al-Ruhaimani et al. [5] vertical data set

3.2.2 Nuland [26] horizontal data (89 data points)

Table 7 lists the statistical results of the correlations using the horizontal data of Nuland [26]. Figure 37 presents a comparison between measured and predicted liquid holdup data. Recalling the conclusion, mentioned above, that Nuland [26] data are always low as compared to other data sets, it is expected that all correlations over predict Nuland [26] data as shown in Fig. 37 and Table 7. The best performance is shown by the proposed correlation followed by Abdul-Majeed [2] correlation. Gomez et al. [21] correlation over predicts all the 89 data points.

Measured versus predicted liquid holdup for Nuland [26] horizontal data set

3.2.3 Kora et al. [23] horizontal data (144 data points)

Kora et al. [23] dataset consists of 144 data points covering liquid viscosities of 586, 378, 257 and 181 mPa s. Based on fitting techniques, Kora et al. [23] and Al-Safran et al. [8] used these data to develop their empirical correlations. Since these two correlations predict a decrease in liquid holdup with increasing of liquid viscosity, as stated above (see Figs. 5, 8). Therefore, it is important to analyze this data set to see the behavior of liquid holdup with liquid viscosity change. Figure 38 displays the data of Kora et al. [23]. As noted and expected there is an overlap in liquid holdup measurements. The HLS values for viscosity of 586 mPa s are greater than those for viscosity of 378 mPa s. However, the highest measured HLS values are associated with the lowest liquid viscosity of 181 mPa s. This behavior of measured data explains why Kora et al. [23] and Al-Safran et al. [8] show discrepancies in holdup prediction with variation of liquid viscosity.

Kora et al. [23] measured slug liquid holdup data

Table 8 shows the performance of all correlations. Figure 39 shows a cross plot of measured versus predicted liquid holdup data. Kora et al. [23] and Al-Safran et al. [8] correlations have an advantage over other correlations due to the bias they have towards this data set, from which they were developed. Al-Safran et al. [8], as expected, gives the best results. The proposed correlation is shown to be the second best correlation as it yields better results than the rest correlations, including Kora et al. [23] correlation.

Measured versus predicted liquid holdup for Kora et al. [23] horizontal data set

3.2.4 All measured validation data (301 data points)

Table 9 presents the statistical parameters of correlations for the entire measured data used for validation. This data set consists of Nuland [26], Kora et al. [23] and Al-Ruhaimani et al. [5] measured data. As can be seen, the proposed correlation shows the best performance for the entire validation data and clearly outperforms all the other correlations. The correlations of Kora et al. [23], Al-Safran et al. [8] and Al-Ruhaimani et al. [5] give approximately the same results.

4 Conclusions

A new measured liquid holdup dataset is presented that covering a wide range of liquid viscosity (200–800 mPa s) and pipe inclination angles (0°, 30°, 60° and 90° from horizontal). The experiments were conducted using two large pipe diameters (0.08 and 0.1 m). Analysis of data indicates that the slug liquid holdup increases as liquid viscosity increases. Comparison of the inclined data with vertical and/or horizontal data reveals a slight decreasing in slug liquid holdup with the increase of inclination angle from horizontal. A predictive analysis of the existing slug liquid holdup correlations against the published observations was conducted and three main conclusions were revealed, namely, none of these correlations is fully consistent with the trends of experimental data; none of them accounts for all of the important flow parameters; and they predict different minimum slug liquid holdup (ranging from 0.34 to 0.912). A new unified correlation is proposed to predict liquid holdup in horizontal, vertical and inclined viscous slug flow. The new correlation is simple and totally agrees with observations. The proposed correlation clearly outperforms the existing correlations using the current measured data and data from three independent sources.

Abbreviations

- A, C:

-

Constants

- d:

-

Pipe diameter (m)

- g:

-

Acceleration gravity (m/s2)

- N:

-

Dimensionless number

- H:

-

Slug liquid holdup

- Nf :

-

Inverse viscosity number

- NRe :

-

Reynolds number

- T:

-

Temperature (°C)

- V:

-

Velocity (m/s)

- ɛ :

-

Residual error

- ɸ :

-

Correlation independent parameter

- σ :

-

Surface tension (N/m)

- µ :

-

Viscosity (kg/m s) (Pa s)

- ρ :

-

Density (kg/m3)

- Δρ :

-

Density difference (kg/m3)

- θ:

-

Inclination angle from horizontal (°)

- Fr:

-

Froude number

- g:

-

Gas phase

- L:

-

Liquid phase

- m:

-

Mixture phase

- s:

-

Superficial

- LS:

-

Liquid slug

- µ:

-

Viscosity

- C:

-

Celsius

References

Abdul-Majeed GH (1997) A comprehensive mechanistic model for vertical and inclined two-phase flow. Ph.D. Dissertation, The University of Baghdad, Iraq. https://doi.org/10.13140/RG.2.2.14313.60008

Abdul-Majeed GH (2000) Liquid slug holdup in horizontal and slightly inclined two-phase slug flow. J Petrol Sci Eng 27:27–32. https://doi.org/10.1016/S0920-4105(99)00056-X

Abdul-Majeed GH, Al-Mashat AM (2000) A mechanistic model for vertical and inclined two-phase slug flow. J Petrol Sci Eng 27:59–67. https://doi.org/10.1016/S0920-4105(00)00047-4

Al-Ruhaimani F (2015) Experimental analysis and theoretical modeling of high liquid viscosity two-phase upward vertical pipe flow. Ph.D. Dissertation, The University of Tulsa, Tulsa, OK

Al-Ruhaimani F, Pereyra E, Sarica C, Al-Safran E, Torres C (2017) Prediction slug-liquid holdup for high-viscosity oils in upward gas/liquid vertical-pipe low. SPE Prod Oper 3:1–19 (SPE-187957)

Al-Safran E (2003) An experimental and theoretical investigation of slug flow characteristics in the valley of a Hilly-Terrain pipeline. Ph.D. Dissertation, The University of Tulsa, Tulsa, OK

Al-Safran E (2009) Prediction of slug liquid holdup in two-phase horizontal pipes. ASME J Energy Res Technol 131:1–8

Al-Safran E, Kora C, Sarica C (2015) Prediction of slug liquid holdup in high viscosity liquid and gas two-phase flow in horizontal pipes. J Petrol Sci Eng 133:566–575. https://doi.org/10.1016/j.petrol.2015.06.032

Andreussi P, Bendiksen K (1989) An investigation of void fraction in liquid slugs for horizontal and inclined gas–liquid flow. Int J Multiphase Flow 15(6):937–939

Baba YD, Aliyu AM, Archibong A-E, Almabrok AA, Igbafe AI (2017) Study of high viscous multi-phase flow in a horizontal pipe. Heat Mass Transf. https://doi.org/10.1007/s00231-017-2158-5

Baba YD, Aliyu M, Aliyu Archibong E, Archibong Mukhtar Abdulkadir, Lao Liyun, Yeung Hoi (2018) Slug length for high viscosity oil-gas flow in horizontal pipes: experiments and prediction. J Petrol Sci Eng 165:397–411. https://doi.org/10.1016/j.petrol.2018.02.003

Barnea D, Brauner N (1985) Holdup of the liquid slug in two-phase intermittent flow. Int J Multiphase Flow 11:43–49

Beggs DH, Brill JP (1973) A study of two-phase flow in inclined pipes. J Pet Technol 25(5):607–617

Brauner N, Ullmann A (2004) Modelling of gas entrainment from Taylor bubbles. Part A: slug flow. Int J Multiphase Flow 30:239–272. https://doi.org/10.1016/j.ijmultiphaseflow.2003.11.007

Brito R, Pereyra E, Sarica C (2013) Effect of medium oil viscosity on two-phase oil-gas flow behavior in horizontal pipes. In: At offshore technology conference, p 285

Dieck RH (2007) Measurement uncertainty: methods and application, 4th edn. ISA, Durham

Eissa SH, Schügerl K (1975) Holdup and backmixing investigations in cocurrent and countercurrent bubble columns. Chem Eng Sci 30:1251–1256

Farsetti S, Farisè S, Poesio P (2014) Experimental Investigation of High Viscosity Oil-Air intermittent Flow. Exp Thermal Fluid Sci 57:285–292. https://doi.org/10.1016/j.expthermflusci.2013.12.004

Godbole SP, Honath MF, Shah YT (1982) Holdup structure in highly viscous newtonian and non-Newtonian liquids in bubble columns. Chem Eng Commun 16:119–134

Gokcal B (2008) An experimental and theoretical investigation of slug flow for high oil viscosity in horizontal pipes. Ph.D. Dissertation, University of Tulsa, Tulsa, OK

Gomez L, Shoham O, Taitel Y (2000) Prediction of slug liquid holdup: horizontal to upward vertical flow. Int J Multiphase Flow 26:517–521

Gregory G, Nicholson M, Aziz K (1978) Correlation of the liquid volume fraction in the slug for horizontal gas–liquid slug flow. Int J Multiphase Flow 4:33–39

Kora C, Sarica C, Zhang H-Q, Al-Sarkhi A, Al-Safran E (2011) Effects of high oil viscosity on slug liquid holdup in horizontal pipes. In: SPE 146954, Presented in Canadian unconventional resources conference, Calgary, Alberta, Canada, 15–17 November

Kuncová G, Zahradník J (1995) Gas holdup and bubble frequency in a bubble column reactor containing viscous saccharose solutions. Chem Eng Process 34:25–34

Nadler M, Mewes D (1995) Effects of the liquid viscosity on the phase distributions in horizontal gas–liquid slug flow. Int J Multiphase Flow 21(2):253–266. https://doi.org/10.1016/0301-9322(94)00067-T

Nuland S (1999) Bubble fraction in slugs in two-phase flow with high viscosity liquid. In: Paper presented in the international symposium on two-phase flow modeling and experimentation, Pisa, Italy

Nuland S, Malvik IM, Valle A, Hende P (1997) Gas fractions in slugs in dense-gas two-phase flow from horizontal to 60 degrees of inclination. In: The 1997 ASME fluids engineering division summer

Pan J (2010) Gas entrainment in two-phase gas-liquid slug flow. Ph.D. Dissertation, Imperial College London

Pereyra E, Arismendi R, Gomez L, Mohan R, Shoham O, Kouba G (2012) State of the art of experimental studies and predictive methods for slug liquid holdup. ASME J Energy Res Technol 134:1–9

Shi H, Holmes JA, Durlofsky LJ, Aziz K, Diaz LR, Alkaya B, Oddie G (2005) Drift-flux modeling of two-phase flow in wellbores. SPE J 10:24–34. https://doi.org/10.2118/84228-PA

Wang S, Zhang H-Q, Sarica C, Pereyra E (2014) A mechanistic slug-liquid holdup model for different oil viscosities and pipe-inclination angles. SPEPO J 6:1–7

Wen Y, Wu Z, Wang J, Wu J, Yin Q, Luo W (2017) Experimental study of liquid holdup of liquid-gas two-phase flow in horizontal and inclined pipes. Int J Heat Technol 35:713–720. https://doi.org/10.18280/ijht.350404

Wu B, Firouzi M, Mitchell T, Ruffor TE, Leonardi C, Towler B (2017) A critical review of flow maps for gas-liquid flows in vertical pipes and annuli. Chem Eng J 326:350–377. https://doi.org/10.1016/j.cej.2017.05.135

Zhao Y, Yeung H, Zorgani EE, Archibong AE, Lao L (2013) High viscosity effects on characteristics of oil and gas two-phase flow in horizontal pipes. Chem Eng Sci 95:343–352. https://doi.org/10.1016/j.ces.2013.03.004

Zhao Y, Lao L, Yeung H (2015) Investigation and prediction of slug flow characteristics in highly viscous liquid and gas flows in horizontal pipes. Chem Eng Res Design 102:124–137. https://doi.org/10.1016/j.cherd.2015.06.002

Acknowledgements

The authors will like to thank the support received for this project from the Iraqi South Oil Company.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Appendix

Appendix

The calibration of closing valves and capacitance sensors applied to the present measured data is approximately similar to that used by Al-Safran [6] and Al-Ruhaimani et al. [5] with slight differences due to using large pipe diameters compared to 0.0508 m ID used in these studies. The following sections describe the calibrations for vertical slug flow. Similar procedures were conducted for horizontal and inclined slug flows.

1.1 Quick closing valves calibration

The requirement of this calibration depends on the accuracy of volume measurements (trap section volume, Vt and vessel volume, Vv). Any possible error in these measurements can lead to a difference between actual liquid holdup and that determined by quick closing valves. Since the volume measurements were repeated several times with quite accuracy, very slight differences were found between the determined and actual liquid holdup. The closing valve calibration of the present measured data was shown in Fig. 40 and could be expressed by:

The certainty of estimated Vv/Vt, calculated holdup and estimated Vt were calculated according to Al-Ruhaimani et al. [5] procedure. The overall calibration uncertainty of closing valves was found to be 0.0204.

1.2 Capacitance sensor static calibration

The static calibration of the capacitance sensor was conducted to define a relationship between the voltage reading of the capacitance sensor and the liquid holdup calculated from this reading voltage, under stratified conditions. The results, of one of the used sensors, were plotted in Fig. 41, with a relation of straight line curve fitting. Table 10 shows the coefficients of the straight lines of the three sensors, in addition to the uncertainties of static calibration of sensors (calculated using the procedure of Al-Ruhaimani et al. [5].

1.3 Capacitance sensor dynamic calibration

As mentioned in the test section, two quick closing valves are used for dynamic calibration of the capacitance sensors. This calibration was conducted to define a relationship between the dynamic calibrated liquid holdup and the static calibrated liquid holdup. The need for conducting dynamic calibration to the capacitance sensors is due to the fact that static calibration was performed under stratified flow conditions. Al-Safran [6] showed that one capacitance sensor should be dynamically calibrated and this calibration can be applied to all other capacitance sensors. Figure 42 illustrates the dynamic calibration of capacitance sensors. Table 11 presents the dynamic calibration curve fitting coefficients and uncertainties.

Rights and permissions

About this article

Cite this article

Abdul-Majeed, G.H., Al-Mashat, A.M. A unified correlation for predicting slug liquid holdup in viscous two-phase flow for pipe inclination from horizontal to vertical. SN Appl. Sci. 1, 71 (2019). https://doi.org/10.1007/s42452-018-0081-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-018-0081-0