Abstract

Purpose

In order to solve the problem of ice accumulation on the surface of wind turbine blades, a two-dimensional stress analysis model, numerical simulation and experiment for ultrasonic de-icing were completed in this paper.

Methods

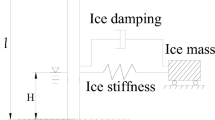

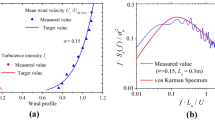

2-D stress analysis was used to illustrate the stress distribution of ice-covered structures under ultrasonic excitation. The stress analysis model shows that the maximum stress appears the edge of ice. The dispersion curves for substructure with ice were calculated to determine the suitable excitation frequency range and guided wave modes.

Results

When the shear stresses generated are greater than the adhesive stress of the ice layer on the structure, the ice layer will break and fall off. The shear stresses generated by transducers at different installation distance between the two sandwich transducers were calculated to determine the installation distance and excitation frequency of transducers. The numerical simulation results and experimental results show that the ultrasonic guided waves de-icing is feasible.

Conclusions

The simulation results are in good agreement with the experimental results and provide a good reference for experiments. The icing at the edge of plate will crack and de-bond first, and the icing at the sticking position of transducers crack and shed off lastly.

Similar content being viewed by others

Data availability

All relevant data are within the paper.

References

Shi Z, Kang Z, Xie Q, Tian Y, Zhao Y, Zhang J (2020) Ultrasonic deicing efficiency prediction and validation for a flat deicing system. Appl Sci 10(19):6640

Daniliuk V, Xu Y, Liu R, He T, Wang X (2020) Ultrasonic de-icing of wind turbine blades: performance comparison of perspective transducers. Renew Energy 145:2005–2018

Tan H, Li L, Panke J (2010) Ultrasonic de-icing theory and method for wind turbine blades. Proc CSEE 30(35):112–117

Gao L, Liu Y, Ma L, Hu H (2019) A hybrid strategy combining minimized leading-edge electric-heating and superhydro-/ice-phobic surface coating for wind turbine icing mitigation. Renew Energy 140:943–956

Xu K, Hu J, Jiang X, Meng W, Lan B, Shu L (2018) Anti-icing performance of hydrophobic silicone-acrylate resin coatings on wind blades. Coatings 8(4):151

Wang Z (2017) Recent progress on ultrasonic de-icing technique used for wind power generation, high-voltage transmission line and aircraft. Energy Build 140:42–49

Hannat R, Morency F (2014) Numerical validation of conjugate heat transfer method for anti-/de-icing piccolo system. J Aircr 51(1):104–116

Zanon A, De Gennaro M (2022) Design of the thermoelectric ice protection system for a tiltrotor application. J Aircr 59(5):1–14

Reid T, Baruzzi GS, Habashi WG (2012) Fensap-ice: unsteady conjugate heat transfer simulation of electrothermal de-icing. J Aircr 49(4):1101–1109

Pommier-Budinger V, Budinger M, Rouset P, Dezitter F, Huet F, Wetterwald M, Bonaccurso E (2018) Electromechanical resonant ice protection systems: initiation of fractures with piezoelectric actuators. AIAA J 56(11):4400–4411

Ramamurthy S, Keith TG, De Witt KJ, Putt JC, Mailing CA, Leffel KL (1992) Numerical modeling of an advanced pneumatic impulse ice protection system for aircraft. J Aircr 29(6):1057–1063

Martin CA, Putt JC (1992) Advanced pneumatic impulse ice protection system (piip) for aircraft. J Aircr 29(4):714–716

Wang Y, Xu Y, Huang Q (2017) Progress on ultrasonic guided waves de-icing techniques in improving aviation energy efficiency. Renew Sustain Energy Rev 79:638–645

Kandagal S, Venkatraman K (2005) Piezo-actuated vibratory deicing of a flat plate. In: 46th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, p 2115

Pommier-Budinger V, Budinger M, Rouset P, Dezitter F, Huet F, Wetterwald M, Bonaccurso E (2018) Electromechanical resonant ice protection systems: initiation of fractures with piezoelectric actuators. AIAA J 56(11):4400–4411

Zhu Y, Palacios J, Rose J, Smith E (2008) De-icing of multi-layer composite plates using ultrasonic guided waves. In: 49th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, 16th AIAA/ASME/AHS Adaptive Structures Conference, 10th AIAA Non-Deterministic Approaches Conference, 9th AIAA Gossamer Spacecraft Forum, 4th AIAA Multidisciplinary Design Optimization Specialists Conference, p 1862

Ramanathan S, Varadan VV, Varadan VK (2000) Deicing of helicopter blades using piezoelectric actuators. In: Smart structures and materials 2000: Smart Electronics and MEMS, vol. 3990, pp 281–292 . SPIE

Palacios JL, Smith EC, Gao H, Rose JL (2006) Ultrasonic shear wave anti-icing system for helicopter rotor blades. In: Annual Forum Proceedings-American Helicopter Society, vol. 62, p 1492. AMERICAN HELICOPTER SOCIETY, INC

Yin C, Zhang Z, Wang Z, Guo H (2016) Numerical simulation and experimental validation of ultrasonic de-icing system for wind turbine blade. Appl Acoust 114:19–26

Li L, Tan H, Lu X, Liu S (2012) Ultrasonic propagation theory in multi-layer composite structure and its application to blade de-icing of wind turbine. In: Zhongguo Dianji Gongcheng Xuebao(Proceedings of the Chinese Society of Electrical Engineering), vol. 32, pp 125–132. Chinese Society for Electrical Engineering

Wang Y, Xu Y, Lei Y (2018) An effect assessment and prediction method of ultrasonic de-icing for composite wind turbine blades. Renew Energy 118:1015–1023

Venna SV, Lin Y-J (2006) Mechatronic development of self-actuating in-flight deicing structures. IEEE/ASME Trans Mechatron 11(5):585–592

Palacios J, Smith E, Rose J, Royer R (2011) Instantaneous de-icing of freezer ice via ultrasonic actuation. AIAA J 49(6):1158–1167

Venna SV, Lin Y-J, Botura G (2007) Piezoelectric transducer actuated leading edge de-icing with simultaneous shear and impulse forces. J Aircr 44(2):509–515

Habibi H, Cheng L, Zheng H, Kappatos V, Selcuk C, Gan T-H (2015) A dual de-icing system for wind turbine blades combining high-power ultrasonic guided waves and low-frequency forced vibrations. Renew Energy 83:859–870

Venna SV, Lin Y (2003) Optimal placement of pzt transducers for passive vibration control of planar composite structures. In: ASME International Mechanical Engineering Congress and Exposition 37076:281–287

Mäder T, Nestler M, Kranz B, Drossel W-G (2018) Studies on sheet-metal compounds with piezoceramic modules for icing detection and de-icing. Adv Eng Mater 20(12):1800589

Budinger M, Pommier-Budinger V, Napias G, Silva A (2016) Ultrasonic ice protection systems: analytical and numerical models for architecture tradeoff. J Aircr 53(3):680–690

Palacios J, Smith E, Rose J, Royer R (2011) Ultrasonic de-icing of wind-tunnel impact icing. J Aircr 48(3):1020–1027

DiPlacido N, Soltis J, Palacios J (2016) Enhancement of ultrasonic de-icing via tone burst excitation. J Aircr 53(6):1821–1829

Crawley EF, De Luis J (1987) Use of piezoelectric actuators as elements of intelligent structures. AIAA J 25(10):1373–1385

Santoni-Bottai G, Giurgiutiu V (2010) Shear lag solution for structurally attached active sensors. In: Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems 2010, vol. 7647, pp 838–847. SPIE

Giurgiutiu V, Bottai-Santoni G (2009) Extension of the shear-lag solution for structurally attached ultrasonic active sensors. AIAA J 47(8):1980–1983

Bai T, Zhu C, Miao B, Li K, Zhu C (2015) Vibration de-icing method with piezoelectric actuators. J Vibroeng 17(1):61–73

Giurgiutiu V (2007) Structural health monitoring: with piezoelectric wafer active sensors. Elsevier

Rose JL (1999) Ultrasonic waves in solid media. Cambridge University Press

Tan H, Xu G, Tao T, Zhang S, Luo A (2016) Investigation on the ultrasonic propagation mechanism and its application on air-source heat pump defrosting. Appl Therm Eng 107:479–492

Wang Z, Xu Y, Gu Y (2015) A light lithium niobate transducer design and ultrasonic de-icing research for aircraft wing. Energy 87:173–181

Gao W, Zhang D, Zhang E (2020) Defect detection in the dead zone of magnetostrictive sensor for pipe monitoring. IEEE Sens J 21(3):3420–3428

Acknowledgements

This work was supported by the Shenzhen Science and Technology Plan Project (Grant No.: JSGG20220831093601003). The authors would like to acknowledge the support of Peng Cheng Laboratory.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xu, P., Zhang, D., Gao, W. et al. Stress Model Analysis and Effectiveness of an Ultrasonic Guided Wave De-icing Technique. J. Vib. Eng. Technol. 12, 5747–5757 (2024). https://doi.org/10.1007/s42417-023-01215-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42417-023-01215-w