Abstract

Background

Worm gear sets are used in many applications of the transmission field. These mechanisms have interesting advantages. Despite this, its modelization is still challenging. This is due to its complex geometry. The goal behind this is to have an accurate model that allows improvement of the design of worm gear sets.

Purpose

In this context, the paper presents a new mathematical model of a worm gear drive under rotational external excitations.

Methods

Dynamic model is defined by fourteen degrees of freedom describing all rotations and translations of worm gear set, AQ1 bearings, a motor and a receiver connected together. First, equations of motion are developed to describe the dynamic behavior. Lagrange formula is, thus, employed. Elastic deformations of meshed teeth are considered. The normal load associated with the meshing is established as function of the model degrees of freedom through the elastic deflection. Second, a numerical simulation is carried out. Newmark Beta method is used to solve equations.

Results

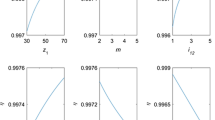

Numerical results are presented to discuss the model accuracy. The impact of the variation of friction coefficient and the stiffness of the worm gear is finally studied to discuss the consistency of the new formulation developed through this work.

Similar content being viewed by others

References

Litvin F, Gonzalez-Perez I, Yukishima K, Fuentes Aznar A, Hayasaka K (2007) Design, simulation of meshing, and contact stresses for an improved worm gear drive. Mech Mach Theory 42:940–959. https://doi.org/10.1016/j.mechmachtheory.2006.08.005

Falah AH, Elkholy AH (2006) Load and stress analysis of cylindrical worm gearing using tooth slicing method. Trans Can Soc Mech Eng 30:97–111

Sharif K, Evans H, Snidle RW (2006) Prediction of the wear pattern in worm gears. Wear 261:666–673. https://doi.org/10.1016/j.wear.2006.01.018

Kim SH, Shin MC, Byun JW, Kwang Hwan O, Chu CN (2012) Efficiency prediction of worm gear with plastic worm wheel. Int J Precis Eng Manuf 13(2):167–174. https://doi.org/10.1007/s12541-012-0021-7

Magyar B, Sauer B (2014) Calculation of the efficiency of worm gear drives. International Gear Conference, Lyon, 15–23. https://doi.org/10.1533/9781782421955.15

Paschold C, Sedlmair M, Lohner T, Stahl K (2020) Efficiency and heat balance calculation of worm gears. Forsch Im Ingenieurwesen 84(2):115–125. https://doi.org/10.1007/s10010-019-00390-1

Tamminana VK, Kahraman A, Vijayakar S (2006) A study of the relationship between the dynamic factors and the dynamic transmission error of Spur Gear Pairs. J Mech Des 129(1):75–84. https://doi.org/10.1115/1.2359470

Wang J, He G, Zhang J, Zhao Y, Yao Y (2017) Nonlinear dynamics analysis of the spur gear system for railway locomotive. Mech Syst Signal Process 100(85):41–55

Park CI (2020) Dynamic behavior of the spur gear system with time varying stiffness by gear positions in the backlash. J Mech Sci Technol 34(2):565–572. https://doi.org/10.1007/s12206-020-0104-9

Fakhfakh T, Walha L, Louati J, Haddar M (2006) Effect of manufacturing and assembly defects on two-stage gear system vibration. Int J Adv Manuf Technol 29:1008–1018. https://doi.org/10.1007/s00170-005-2602-4

Abboudi K, Walha L, Driss Y, Maatar M, Fakhfakh T, Haddar M (2011) Dynamic behavior of a two-stage gear train used in a fixed-speed wind turbine. Mech Mach Theory 46:1888–1900. https://doi.org/10.1016/j.mechmachtheory.2011.07.009

Chung MY, Shaw D (2007) Parametric study of dynamics of worm and worm-gear set under suddenly applied rotating angle. J Sound Vib 304(1):246–262. https://doi.org/10.1016/j.jsv.2007.02.022

Hammami C, Chakroun AE, Hammami A, De-Juan A, Chaari F, Fernandez A, Viadero F, Haddar M (2022) A parametric study to investigate the dynamic behavior of worm gear with plastic wheel. In: Modelling and simulation of complex systems for sustainable energy efficiency, Cham, vol 20, pp 152–159. https://doi.org/10.1007/978-3-030-85584-0_16

Stolyarchuk R (2007) Multibody modelling and dynamical analysis of the worm gear drive systems. In: Presented at the SIMS, Göteborg (Särö), 2007

Benabid Y, Mansouri S (2016) Dynamics study and diagnostics with vibration analysis from worm gear manufactured by reverse engineering techniques. J Vibroeng 18:4458–4471. https://doi.org/10.21595/jve.2016.17203

Fang H-S, Tsay CB (1996) Mathematical model and bearing contacts of the ZN-type worm gear set cut by oversize hob cutters. Mech Mach Theory 35:1689–1708

Chakroun AE, Hammami A, De-Juan A, Chaari F, Fernandez A, Viadero F, Haddar M (2021) Modal energetic analysis and dynamic response of worm gear drives with a new developed dynamic model. Comptes Rendus Mécanique 349(2):241–258. https://doi.org/10.5802/crmeca.80

Yeh T-J, Wu F-K (2009) Modeling and robust control of worm-gear driven systems. Simul Model Pract Theory 17(5):767–777. https://doi.org/10.1016/j.simpat.2009.01.002

Khabou MT, Bouchaala N, Chaari F, Fakhfakh T, Haddar M (2011) Study of a spur gear dynamic behavior in transient regime. Mech Syst Signal Process 25(8):3089–3101. https://doi.org/10.1016/j.ymssp.2011.04.018

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hammami, C., Chakroun, A.E., Hammami, A. et al. New Approach to Study the Dynamic Performance of Worm Gear Drive Model. J. Vib. Eng. Technol. 11, 1407–1415 (2023). https://doi.org/10.1007/s42417-022-00648-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42417-022-00648-z