Abstract

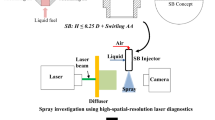

In this study, the effect of gellant concentration on spray characteristics was investigated in a pressure swirl injector. The cold-flow tests of simulant gel were carried out to identify the air core formation of non-Newtonian fluid within the injector. Morphological analysis of the spray shapes was performed with regards to the air core location. Results show that the spray patterns can be classified into four distinct shapes as reported earlier in the literature. However, the transiting border between spray patterns was somewhat unlike due to the different gellant type used in this study. By categorizing the breakup regimes with dimensionless numbers, critical curves dividing each breakup regions were proposed. Regarding the quantitative spray characteristics, whether the gellant concentration increased or the pressure drop decreased, the spray angle was reduced, while the breakup length was elongated. These facts were partly due to the increased momentum loss triggered by relatively high viscosity.

Similar content being viewed by others

References

Natan B, Rahimi S (2002) The status of gel propellants in year 2000. International journal of energetic materials and chemical propulsion, 5(1–6). https://doi.org/10.1615/IntJEnergeticMaterialsChemProp.v5.i1-6.200

Padwal MB, Natan B, Mishra DP (2021) Gel propellants. Prog Energy Combust Sci 83:100885. https://doi.org/10.1016/j.pecs.2020.100885

Ciezki HK, Kirchberger C, Stiefel A, Kröger P, Pinto PC, Ramsel J, Weiser V (2017) Overview on the German gel propulsion technology activities: Status 2017 and outlook. In: 7th European conference for aeronautics and space sciences, The Korean Society of Propulsion Engineers Spring conference (Vol. 253). https://doi.org/10.13009/EUCASS2017-253

Ciezki, HK, Hürttlen, J, Naumann, KW, Negri, M, Ramsel, J, Weiser, V. (2014) Overview of the German gel propulsion technology program. In: 50th AIAA/ASME/SAE/ASEE Joint Propulsion Conference (p. 3794). https://doi.org/10.2514/6.2014-3794

Green J, Rapp D, Roncace J (1991) Flow visualization of a rocket injector spray using gelled propellant simulants. In: 27th Joint Propulsion Conference (p. 2198). https://doi.org/10.2514/6.1991-2198

Yang LJ, Fu QF, Qu YY, Zhang W, Du ML, Xu BR (2012) Spray characteristics of gelled propellants in swirl injectors. Fuel 97:253–261. https://doi.org/10.1016/j.fuel.2012.02.036

Chen J, Li G, Zhang T (2018) Analysis of characteristics of swirling spray of the ammonium dinitramide (ADN)-based green monopropellant. Int J Aeronaut Space Sci 19(4):926–931. https://doi.org/10.1007/s42405-018-0085-4

Guan HS, Li GX, Zhang NY (2018) Experimental investigation of atomization characteristics of swirling spray by ADN gelled propellant. Acta Astronaut 144:119–125. https://doi.org/10.1016/j.actaastro.2017.12.015

Kang Z, Wang ZG, Li Q, Cheng P (2018) Review on pressure swirl injector in liquid rocket engine. Acta Astronaut 145:174–198. https://doi.org/10.1016/j.actaastro.2017.12.038

Hanon MM, Salman ND, Alazawi DA (2018) Relative deviation of mass flow rate in swirl injectors due to the engineering tolerances: experimental study. Int J Aeronaut Space Sci 19(3):645–650. https://doi.org/10.1007/s42405-018-0056-9

Rashad M, Yong H, Zekun Z (2016) Effect of geometric parameters on spray characteristics of pressure swirl atomizers. Int J Hydrogen Energy 41(35):15790–15799. https://doi.org/10.1016/j.ijhydene.2016.04.037

Suyari M, Lefebvre AH (1986) Film thickness measurements in a simplex swirl atomizer. J Propul Power 2(6):528–533. https://doi.org/10.2514/3.22937

Kutty PS, Narasimhan MV, Narayanaswamy K (1978) Design and prediction of discharge rate, cone angle and air core diameter of swirl chamber atomizers. In: Proceedings of the first international conference on liquid atomization and spray systems (p 93).

Kim S, Khil T, Kim D, Yoon Y (2008) Effect of geometric parameters on the liquid film thickness and air core formation in a swirl injector. Meas Sci Technol 20(1):015403. https://doi.org/10.1088/0957-0233/20/1/015403

Amini G (2016) Liquid flow in a simplex swirl nozzle. Int J Multiph Flow 79:225–235. https://doi.org/10.1016/j.ijmultiphaseflow.2015.09.004

Liu Z, Huang Y, Sun L (2017) Studies on air core size in a simplex pressure-swirl atomizer. Int J Hydrogen Energy 42(29):18649–18657. https://doi.org/10.1016/j.ijhydene.2017.04.188

Thompson JC, Rothstein JP (2007) The atomization of viscoelastic fluids in flat-fan and hollow-cone spray nozzles. J Nonnewton Fluid Mech 147(1–2):11–22. https://doi.org/10.1016/j.jnnfm.2007.06.004

Rahimi, S, Natan, B. (1998). Atomization characteristics of gel fuels. In: 34th AIAA/ASME/SAE/ASEE joint propulsion conference and exhibit (p 3830). https://doi.org/10.2514/6.1998-3830

Baek G, Kim S, Han J, Kim C (2011) Atomization characteristics of impinging jets of gel material containing nanoparticles. J Nonnewton Fluid Mech 166(21–22):1272–1285. https://doi.org/10.1016/j.jnnfm.2011.08.005

Han S, Koo J, Moon H (2020) Morphological classification of disintegration behavior of viscoelastic simulant gel propellant in coaxial streams. J Visualization 23(2):287–298. https://doi.org/10.1007/s12650-019-00619-9

Lefebvre AH, McDonell VG (2017) Atomization and sprays. CRC Press

Kim K, Kim S, Han S, Kim J, Moon H (2017) Surface tension change of simulant gel propellant according to the metal particle addition. J Korean Soc Propulsion Eng 21(3):34–40. https://doi.org/10.6108/KSPE.2017.21.3.034

Madlener K, Frey B, Ciezki HK (2009) Generalized reynolds number for non-newtonian fluids. Progress Prop Phys 1:237–250. https://doi.org/10.1051/eucass/200901237

Prakash RS, Gadgil H, Raghunandan BN (2014) Breakup processes of pressure swirl spray in gaseous cross-flow. Int J Multiph Flow 66:79–91. https://doi.org/10.1016/j.ijmultiphaseflow.2014.07.002

Saurabh A, Deshmukh D, Nath S, Agarwal DK, Kabiraj L (2020) Impingement Atomization of Carbopol Gels. In: AIAA Propulsion and Energy 2020 Forum (p 3973). https://doi.org/10.2514/6.2020-3973

Ohnesorge WV (1936) The formation of drops by nozzles and the breakup of liquid jets. Z Angew Math Mech 16:355–358. https://doi.org/10.26153/tsw/3391

Acknowledgements

This research was supported by National R&D Program through the National Research Foundation of Korea (NRF) funded by Ministry of Science and ICT (2020M3F6A1110342) and was supported by 2019 Korea Aerospace University Faculty Research grant.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

An earlier version of this paper was presented at APISAT 2021, Jeju, South Korea, in November 2021.

Rights and permissions

About this article

Cite this article

Cho, J., Lee, D., Kang, T.G. et al. Study on Spray Characteristics of Simulant Gel in Pressure Swirl Injector. Int. J. Aeronaut. Space Sci. 23, 794–803 (2022). https://doi.org/10.1007/s42405-022-00504-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42405-022-00504-0