Abstract

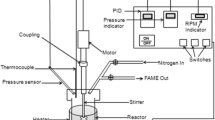

In India, a nation with a large population, the energy sector that meets both industrial and human demands is impacted by the depletion of fossil fuels. There is enormous growth in alternative biodiesel industrial sectors. These biodiesel industries require large quantity of water for refining crude biodiesel after the transesterification reaction of triglycerides from the natural non-edible feedstock. To save valuable water resources for future generations, this research work focused on development of areca husk resin instead of water to refine crude biodiesel obtained after transesterification reaction. Millettia pinnata fatty acid methyl esters (MFAME) synthesized from Millettia pinnata oil were collected and purified by areca husk resin (AHR) and commercial polystyrene-divinylbenzene sulfonic acid resin (CPSRH) in an ion-exchange column. Comparing the ion exchange capacity (IEC) of AHR with that of CPSRH, it is found that the IEC of AHR is 1.70 Meq/gm, while that of CPSRH is 1.90 Meq/gm. The prepared AHR was characterized by FTIR, SEM–EDS. MFAME eluted from an ion-exchange column with 30 cm height, and 1 cm diameter was filled with AHR and CPSRH resins. Based on that comparison, it was found that the flow rate was less than 40 drops/min, resulting in MFAME compliant with ASTM 6751D standards. In addition, the physicochemical properties of MFAME obtained through the developed resin were compared with conventional MFAME production methods, and it identified that the quality of MFAME obtained through the purification of the developed resin was excellent, with all properties within the permissible limits. Compared with the conventional MFAME purification method, the yield of MFAME obtained by the AHR method was higher (92%).

Graphical Abstract

Similar content being viewed by others

References

S. K. Tyagi, R. Kothari, and V. v. Tyagi, J. Biofuels (2019). https://doi.org/10.1080/17597269.2018.1532732

S.-Z. Li and C. Chan-Halbrendt, Appl. Energy, (2009), https://doi.org/10.1016/j.apenergy.2009.04.047

A. K. Agarwal, Prog. Energy Combust. Sci, (2007), https://doi.org/10.1016/j.pecs.2006.08.003

F. Ferella, G. Mazziotti Di Celso, I. de Michelis, V. Stanisci, and F. Vegliò’, Fuel, (2010), https://doi.org/10.1016/j.fuel.2009.01.025

L. Reijnders, Energy Policy, (2006), https://doi.org/10.1016/j.enpol.2004.09.001

F. Qiu, Y. Li, D. Yang, X. Li, and P. Sun, Appl. Energy, (2011), https://doi.org/10.1016/j.apenergy.2010.12.070

A. Dewangan, A. K. Yadav, and A. Mallick, Energy Sources, Part A: Recovery, Uti. Environ. Effects, (2018) https://doi.org/10.1080/15567036.2018.1502849

J. C. Yori, S. A. D’Ippolito, C. L. Pieck, and C. R. Vera, Energy Fuels, (2007), https://doi.org/10.1021/ef060362d

M. Berrios and R. L. Skelton, Chem. Eng. J, (2008), https://doi.org/10.1016/j.cej.2008.07.019

J. Saleh, A. Y. Tremblay, and M. A. Dubé, Fuel, (2010), https://doi.org/10.1016/j.fuel.2010.04.025

U. N. Annal, A. Natarajan, B. Gurunathan, V. Mani, and R. Sahadevan, Biofuels Bioenergy, (2022), https://doi.org/10.1016/B978-0-323-90040-9.00033-3

K. Sakura and A. Tsuge, Polym. J, (2014), https://doi.org/10.1038/pj.2013.57

H. P. de S. Costa, M. G. C. da Silva, and M. G. A. Vieira, J. Water Process Eng, (2021), https://doi.org/10.1016/j.jwpe.2021.101925

M. I. A. Abdel Maksoud, A. M. Elgarahy, C. Farrell, A. H. Al-Muhtaseb, D. W. Rooney, and A. I. Osman, Coord. Chem. Rev, (2020), https://doi.org/10.1016/j.ccr.2019.213096

V. K. Gupta, I. Ali, T. A. Saleh, M. N. Siddiqui, and S. Agarwal, Environ. Sci. Pollut. Res, (2013), https://doi.org/10.1007/s11356-012-0950-9

I. M. Atadashi, M. K. Aroua, A. R. A. Aziz, and N. M. N. Sulaiman, Appl. Energy (2011), https://doi.org/10.1016/j.apenergy.2011.05.029

M. K. Mondal, J Environ. Manage, (2009), https://doi.org/10.1016/j.jenvman.2009.05.025

N. Nasuha and B. H. Hameed, Chem. Eng. J. (2011), https://doi.org/10.1016/j.cej.2010.11.012

B. Xiao, X. F. Sun, and R. Sun, Polym. Degrad. Stab, (2001), https://doi.org/10.1016/S0141-3910(00)00133-6

V. Vinu and N. N. Binitha, Mater. Today Proc, (2020) , https://doi.org/10.1016/j.matpr.2020.01.210

D.R. Ramappa, Economics of areca nut cultivation in Karnataka, a case study of Shivamogga district. IOSR-JAVS 3, 50–59 (2013). https://doi.org/10.9790/2380-0315059

S. Sasmal, V. v. Goud, and K. Mohanty, Biomass Bioenergy. (2012), https://doi.org/10.1016/j.biombioe.2012.06.008

A. B. Fadhil and L. I. Saeed, Int. J. Green Energy. ( 2016), https://doi.org/10.1080/15435075.2014.896801

H. Muthu, V. SathyaSelvabala, T. K. Varathachary, D. Kirupha Selvaraj, J. Nandagopal, and S. Subramanian, Braz. J. Chem. Eng, (2010), https://doi.org/10.1590/S0104-66322010000400012

K. V. Yatish, H. S. Lalithamba, R. Suresh, and H. R. Harsha Hebbar, Renew Energy, 2018, https://doi.org/10.1016/j.renene.2018.01.124

R. B. Ashok, C. v. Srinivasa, and B. Basavaraju, Adv. Compos. Hybrid Mater, (2020), https://doi.org/10.1007/s42114-020-00169-x

S. Fisher, R. Kunin, Routine exchange capacity determinations of ion exchange resins. Anal Chem 27(7), 1191–1194 (1955). https://doi.org/10.1021/ac60103a052

A. Banagar, S. V. Chikkol, and B. Bennehalli, Materials Research Innovations, (2021), https://doi.org/10.1080/14328917.2020.1834747

R. B. Ashok, C. v. Srinivasa, and B. Basavaraju, Sci. Technol. Mater (2018), https://doi.org/10.1016/j.stmat.2018.05.004

X. Sha, X. Sheng, Y. Zhou, B. Wang, Y. Liu, and J. Bao, Appl. Organomet. Chem, (2019), https://doi.org/10.1002/aoc.5180

J. S. Oliveira, R. Montalvão, L. Daher, P. A. Z. Suarez, and J. C. Rubim, Talanta, (2006), https://doi.org/10.1016/j.talanta.2006.01.002

U. Rashid, F. Anwar, and G. Knothe, Biomass Bioenergy, (2011), https://doi.org/10.1016/j.biombioe.2011.06.043

T. Mehmood, Z. Shaheen, S. A. Malik, Q. Tabassam, F. Siddique, and L. Jabeen, Waste Biomass Valorization, (2016), https://doi.org/10.1007/s12649-015-9472-2

R.M. Silverstein, F.X. Webster, Spectrometric identification of organic compounds, 6th edn. (Wiley, New York, 1988)

P. Sorichetti, S. Romano, Water consumption in biodiesel production: optimization through measurement of electrical Properties. Environ Res J 6, 231–240 (2014)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chethan, S.G., Moinuddin Khan, M.H. & Sreepathi, L.K. Development of areca husk resin for purification of crude Millettia pinnata fatty acid methyl ester (biodiesel) and its comparative studies. emergent mater. 6, 231–243 (2023). https://doi.org/10.1007/s42247-023-00452-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42247-023-00452-9