Abstract

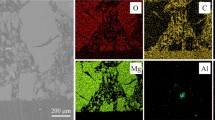

To understand the mechanism of the interfacial reaction between high-Mn and high-Al steel and MgO refractory, a series of laboratory experiments as well as thermodynamic calculations were performed. The effects of Mn and Al contents in the steel and the reaction time on the interfacial reaction were investigated. It was observed that the erosion of the MgO refractory is caused by the reaction of Al and Mn in the steel with MgO in the refractory, which would lead to the formation of (Mn, Mg)O·Al2O3 spinel and (Mn, Mg)O solid solution. The formation mechanism of the spinel and solid solution is as follows. The Al in the steel firstly reacts with MgO in the refractory to generate MgO·Al2O3 spinel, and then, the spinel reacts with Mn in the steel to form (Mn, Mg)O·Al2O3 spinel. Finally, the MnO in the spinel reacts with the MgO in the inner refractory to form (Mn, Mg)O solid solution. In addition, only (Mn, Mg)O·Al2O3 spinel is present in the interfacial reaction layer of the refractory when the Al content in the steel is sufficient.

Similar content being viewed by others

References

Y. Hino, S. Zhang, ISIJ Int. 54 (2014) 2221–2229.

S. Behera, R. Sarkar, Prot. Met. Phys. Chem. Surf. 52 (2016) 467–474.

Z. Liu, J. Yu, X. Wang, P. Ma, W. Gu, J. Wen, S. Wei, X. Zhang, Z. Yan, T. Wen, L. Yuan, B. Ma, Ceram. Int. 48 (2022) 14117–14126.

Q. Chen, Y. Li, T. Zhu, Y. Xu, Y. Li, X. Wang, Ceram. Int. 48 (2022) 2500–2509.

R.W. Limes, JOM 18 (1966) 865–869.

R.H. Herron, C.R. Beechan, R.C. Padfield, Amer. Ceram. Soc. Bull. 46 (1967) 1163–1168.

M. Guo, S. Parada, P.T. Jones, J. Van Dyck, E. Boydens, D. Durinck, B. Blanpain, P. Wollants, Ceram. Int. 33 (2007) 1007–1018.

M. Boher, J. Lehmann, H. Soulard, M. Kandel, M.C. Kaerlé, C. Gatellier, Key Eng. Mater. 132–136 (1997) 1854–1857.

C. Liu, F. Huang, X. Wang, Metall. Mater. Trans. B 47 (2016) 999–1009.

C. Liu, F. Huang, J. Suo, X. Wang, Metall. Mater. Trans. B 47 (2016) 989–998.

V. Brabie, Steel Res. 68 (1997) 54–60.

A. Salomon, M. Dopita, M. Emmel, S. Dudczig, C.G. Aneziris, D. Rafaja, J. Eur. Ceram. Soc. 35 (2015) 795–802.

L. Kong, Z. Deng, M. Zhu, Metall. Mater. Trans. B 49 (2018) 1444–1452.

L. Kong, Z. Deng, M. Zhu, ISIJ Int. 57 (2017) 1537–1545.

Z. Deng, M. Zhu, ISIJ Int. 53 (2013) 450–458.

F.P. Calderon, N. Sano, Y. Matsushita, Metall. Trans. 2 (1971) 3325–3332.

K. Beskow, L. Jonsson, D. Sichen, N.N. Viswanathan, Metall. Mater. Trans. B 32 (2001) 319–328.

M.A. Van Ende, M. Guo, P.T. Jones, B. Blanpain, P. Wollants, Ceram. Int. 35 (2009) 2203–2212.

A. Romero-Serrano, A.D. Pelton, ISIJ Int. 39 (1999) 399–408.

P. von Schweinichen, Z. Chen, D. Senk, A. Lob, Metall. Mater. Trans. A 44 (2013) 5416–5423.

W. Wang, L. Xue, T. Zhang, L. Zhou, H. Liu, H. Xiao, Q. Sun, Ceram. Int. 46 (2020) 17561–17568.

L. Fu, Y. Zou, A. Huang, H. Gu, H. Ni, J. Am. Ceram. Soc. 102 (2019) 3705–3714.

Y. Zou, A. Huang, L. Fu, H. Gu, Ceram. Int. 44 (2018) 12965–12972.

L. Zhang, L. Cheng, Y. Ren, J. Zhang, Ceram. Int. 46 (2020) 15674–15685.

A. Huang, Y. Wang, H. Gu, Y. Zou, Ceram. Int. 44 (2018) 22146–22153.

Acknowledgements

The authors appreciate the support of the National Natural Science Foundation of China (Grant Nos. 52274337 and 52174317).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kong, Lz., Zu, L., Yang, J. et al. Reaction behavior of MgO refractory with high-Mn and high-Al steel. J. Iron Steel Res. Int. (2023). https://doi.org/10.1007/s42243-023-01124-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42243-023-01124-y