Abstract

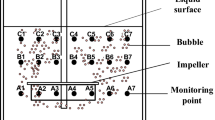

The gas–liquid flow behavior of the stirred flow field, the different positions of a single bubble, the initial velocity, the surface tension and the agglomeration of multiple bubbles were studied by CFD numerical simulation. The results show that the pressure distribution and velocity distribution inside the fluid during agitation indicate that the velocity difference between the liquid and the gas phase and the collision between the bubbles caused by the turbulent behavior of the liquid are the important conditions leading to the bubble breakage. Different initial bubble positions and initial bubble velocities have important effects on single bubble breakage. The surface tension is an important condition that affects the bubble breakage. When the surface tension coefficient is 0.7, the bubble will be stretched to the smallest degree; when the surface tension coefficient is 0.1, the bubble will be stretched to the largest degree and it will be easily broken into smaller bubbles. The multi-bubble results show the states and trajectories of coalescence between bubbles. The research results can provide data support for the engineering application of desulfurization process and theoretical guidance for the research of bubble breaking mechanism.

Similar content being viewed by others

References

G.L. Lane, M.P. Schwarz, G.M. Evans, Appl. Math. Model. 26 (2002) 223–235.

K.E. Morud, B.H. Hjertager, Chem. Eng. Sci. 51 (1996) 233–249.

H. Liu, M.Z. Xie, D.Q. Wang, Chin. J. Process Eng. 71 (2007) 34–38.

Y.Y. Zhao, L.F. Zhang, W. Chen, S.S. Cheng, Y. Ren, J. Iron Steel Res. Int. 29 (2022) 719–724.

J.M. Su, Z.H. Dou, T.A. Zhang, Y. Liu, J. Iron Steel Res. Int. 27 (2020) 1137–1144.

Y. Zhao, W. Chen, S. Cheng, L. Zhang, Int. J. Miner. Metall. Mater. 29 (2022) 758–766.

Y.J. Chen, J. Ding, P.F. Weng, X.Q. Yang, W.J. Wu, Chem. Eng. J. 386 (2020) 121826.

W. Abbassi, S. Besbes, H. Ben Aissia, J.Y. Champagne, J. Braz. Soc. Mech. Sci. Eng. 41 (2019) 272.

I. Chakraborty, G. Biswas, P.S. Ghoshdastidar, Int. J. Heat Mass Transf. 58 (2013) 240–259.

D.D. McClure, N. Aboudha, J.M. Kavanagh, D.F. Fletcher, G.W. Barton, Chem. Eng. J. 264 (2015) 291–301.

M. Cheng, J. Hua, J. Lou, Comput. Fluids 39 (2010) 260–270.

T. Shimogouchi, H. Naganawa, T. Nagano, B. Grambow, Y. Nagame, Anal. Sci. 35 (2019) 955–960.

J. Szekely, S. Asai, Metall. Trans. 5 (1974) 463–467.

C.W. Stewart, Int. J. Multiph. Flow 21 (1995) 1037–1046.

G. Bozano, M. Dente, Comput. Chem. Eng. 25 (2001) 571–576.

S.J. Zhang, C.J. Wu, J. Hydrodynam B 23 (2008) 681–686.

Z.Q. Cai, Experimental study on dynamic behavior of bubbles in Newtonian fluids, Beijing University of Chemical Technology, Beijing, China, 2011.

T.M. Li, S.Y. Jia, Chin. J. Chem. Eng. 46 (1995) 532–538.

J. Ramírez-Muñoz, A. Gama-Goicochea, E. Salinas-Rodríguez, Int. J. Multiph. Flow 37 (2011) 983–986.

T. Wang, H.X. Li, Y. Li, Journal of Xi’an Jiaotong University 47 (2013) No. 5, 1–6.

A. Smolianski, H. Haario, P. Luukka, Appl. Math. Model. 29 (2005) 615–632.

A. Tomiyama, G.P. Celata, S. Hosokawa, S. Yoshida, Int. J. Multiph. Flow 28 (2002) 1497–1519.

Z. Cai, Z. Gao, Y. Bao, G.M. Evans, E. Doroodchi, Ind. Eng. Chem. Res. 51 (2012) 1990–1996.

D. Ma, VOF numerical simulation of dynamic behavior of single-pore bubbles, Tianjin University, Tianjin, China, 2009.

J.H. Ji, Study on fluid flow characteristics based on hot metal pretreatment desulfurization, Northeastern University, Shen-yang, China, 2017.

Acknowledgements

This research was supported by the National Natural Science Foundation of China (51904069), the Fundamental Research Funds for the Central Universities (N2223026), and the Scientific Research Fund Project of Northeastern University at Qinhuangdao (XNY201808).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declared that they have no conflicts of interest to this work. We declare that we do not have any commercial or associative interest that represents a conflict of interest in connection with the work submitted.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lv, C., Chen, Xx., Ji, Zx. et al. Simulation of bubble breaking process in a jet mixing reactor for desulfurization of molten iron. J. Iron Steel Res. Int. 30, 1117–1127 (2023). https://doi.org/10.1007/s42243-023-00984-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-023-00984-8