Abstract

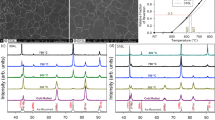

AISI 310S stable austenitic stainless steel was subjected to 90% cryorolling and then annealed at 800 °C for 2–60 min. The effect of annealing time on the microstructure and mechanical properties was studied by optical microscopy, scanning electron microscopy, transmission electron microscopy, microhardness and tensile test. The results show that the grain size of AISI 310S stainless steel is refined to the nanometer level after 90% cryorolling, and the grain size is approximately 20 nm. With the increase in annealing time, the degree of grain recrystallization occurs more fully and completely, as the grain begins to grow and then tends to stabilize. The strength and hardness of the annealed specimens decrease with increasing annealing time, while elongation tends to increase. When the annealing time is 10 min, the yield strength increases by about 2 times compared to that of the original austenite (unrolled), and the elongation is also above 20%, which is the best preparation process for ultra-fine grain austenitic stainless steel under this experimental condition. As the annealing time treatment increases, the fracture morphology changes from mixed quasi-cleavage and ductile fracture (after cryorolling) to ductile fracture (after annealing).

Similar content being viewed by others

References

R. Singh, S.D. Yadav, B.K. Sahoo, S.G. Chowdhury, A. Kumar, Def. Sci. J. 71 (2021) 383–389.

S. Chattopadhyay, G. Anand, S.G. Chowdhury, I. Manna, Mater. Sci. Eng. A 734 (2018) 139–148.

Y.Z. Zhang, J.J. Wang, N.R. Tao, J. Mater. Sci. Technol. 36 (2020) 65–69.

Z.J. Zheng, Y. Gao, J.W. Liu, M. Zhu, Mater. Sci. Eng. A 639 (2015) 615–625.

B.R. Kumar, B. Mahato, S. Sharma, J.K. Sahu, Metall. Mater. Trans. A 40 (2009) 3226–3224.

M. Wang, H.Z. Guo, Hot Working Technology 37 (2008) No. 20, 24–26+30.

Y. Xiong, J.B. Wang, L.F. Chen, Y. Lu, F.Z. Ren, L.F. Zhang, J.L. Ma, Trans. Mater. Heat Treat. 37 (2016) No. 4, 101–107.

Y.F. Shen, X.M. Zhao, X. Sun, Y.D. Wang, L. Zuo, Scripta Mater. (2014) https://doi.org/10.1016/j.scriptamat.2014.05.001.

A. Shokohfar, S.M. Abbasi, A. Yazdani, B. Rabiee, Defect Diffus. Forum 312–315 (2011) 51–55.

G. Niu, H.B. Wu, Mater. Sci. Eng. A 772 (2020) 138669.

H.A. Rezai, M. Shaban Ghazani, B. Eghbali, Mater. Sci. Eng. A 736 (2018) 364–374.

J.L. Lv, Z.Q. Wang, Mater. Lett. 282 (2021) 128708.

A. Amininejad, R. Jamaati, S.J. Hosseinipour, Trans. Ind. Inst. Metals 74 (2021) 1799–1807.

J.X. Zhang, Y.M. He, Y.H. Wang, Y.F. Wang, T.S. Wang, Materialia 8 (2019) 10045.

B. Roy, R. Kumar, J. Das, Mater. Sci. Eng. A 631 (2015) 241–247.

J.T. Shi, L.G. Hou, J.R. Zuo, L.Z. Zhuang, J.S. Zhang, Int. J. Miner. Metall. Mater. 24 (2017) 638–645.

Y. Xiong, T.T. He, H.P. Li, Y. Lu, F.Z. Ren, A.A Volinsky, Mater. Sci. Eng. A 703 (2017) 68–75.

T. Zhou, Y. Xiong, Y. Yue, Y. Lu, Y.N. Chen, T.T. He, F.Z. Ren, H. Singh, J. Kömi, M. Huttula, W. Cao, Mater. Sci. Eng. A 766 (2019) 138352.

Z.D. Li, Y.Z. Wu, Z.B. Xie, C. Kong, H. Yu, Materials 14 (2021) 4025.

A. Dhal, S.K. Panigrahi, M.S. Shunmugam, J. Alloy. Compd. 726 (2017) 1205–1219.

H.C. Ding, Y.J. Zhao, Y.M. Su, X. Wang, Q.H. Nan, C. Chou, Y.J. Feng, Heat Treat. of Met. 46 (2021) No. 6, 70–76.

D. Chatterjee, Metallogr. Microstruct. Anal. 9 (2020) https://doi.org/10.1007/s13632-020-00677-8.

D. Liu, D.X. Liu, X.H. Zhang, C.S. Liu, N. Ao, Mater. Sci. Eng. A. 726 (2018) 69–81.

Z.X. Huang, C.S. Wu, Electroplating theory, China Agricultural Machinery Press, Beijing, China, 1982.

Y. Xiong, T.T. He, J.B. Wang, Y. Lu, L.Y. Chen, F.Z. Ren, Y.L. Liu, A.A. Volinsky, Mater. Des. 88 (2015) 398–405.

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant Nos. U1804146, 52111530068 and 51905153), the Science and Technology Innovation Team of Henan University of Science and Technology (Grant No. 2015XTD006) and the Foreign Experts Introduction Project of Henan Province (Grant No. HNGD2020009).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lian, Xk., Li, Y., Xiong, Y. et al. Effect of annealing time on microstructure and mechanical properties of cryorolled AISI 310S stainless steel. J. Iron Steel Res. Int. 30, 548–556 (2023). https://doi.org/10.1007/s42243-022-00870-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-022-00870-9