Abstract

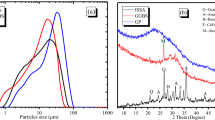

The reducing property of pellets prepared by ultrafine magnetite concentrate (UMC) and improving method were revealed. The results show that the reduction degree of UMC pellets is only about 56% compared with that of pellets prepared from ordinary iron ore concentrate with relatively coarse particle size, which is significantly lower than the general reduction degree of about 70%. When the composite binder composed of bentonite and organic binder was added, the reduction degree was significantly increased to 69.66%. The revealed mechanism shows that the reduced pellets with common bentonite have a concentric structure, the oxidation gap between the inner and outer layers is obvious, and the outer dense oxide layer hinders the oxidation and reduction of the inner layer. After adding the composite binder, the organic components significantly improved the internal porosity of the pellets and the aggregation degree of ultrafine iron ore concentrate particles in the granulation process, forming a porous structure. The non-uniform double-layer structure is eliminated, and the increased pores are conducive to the internal diffusion of CO, and finally the reduction degree of pellets is increased to the level equivalent to that of ordinary magnetite pellets.

Similar content being viewed by others

References

F. Chen, Y.F. Guo, T. Jiang, F.Q. Zheng, S. Wang, L.Z. Yang, J. Iron Steel Res. Int. 24 (2017) 266–272.

S.H. Zhang, B.Y. Wang, C.C. Lan, X.J. Liu, Q. Lv, Iron and Steel 55 (2020) No. 8, 19–26.

F.Q. Gu, Y.B. Zhang, G.H. Li, Q. Zhong, J. Luo, Z.J. Su, M.J. Rao, Z.W. Peng, T. Jiang. Ironmak. Steelmak. 47 (2020) 908–914.

S.L. De Moraes, J.R.B. De Lima, J.B.F. Neto, C. Fredericci, E.M. Saccoccio, Miner. Process. Extr. Metall. Rev 41 (2020) 247–254.

G.J. Wong, X.H. Fan, M. Gan, Z.Y. Ji, X.L. Chen, Z.Y. Tian, Z.Z. Wang, Powder Technol. 342 (2019) 873–879.

A.M. Nyembwe, R.D. Cromarty, A.M. Garbers-Craig, Powder Technol. 295 (2016) 7–15.

A. Abazarpoor, M. Halali, R. Hejazi, M. Saghaeian, V.S. Zadeh, Can. Metall. Quart. 59 (2020) 242–250.

Y.H. Luo, Basic research on oxidation pellets of magnet concentrate, Central South University, Changsha, China, 2011.

X.H. Fan, X.L. Yuan, T. Jiang, L.S. Yuan, G.H. Li, J.M. Zhuang, Q.R. Tang, X.F. Yang, Chin. J. Nonferrous Met. 16 (2006) 1965–1970.

V. de Morais Oliveira, A.L.A. Domingues, M.C. Bagatini, V.G. de Resende, ISIJ Int. 60 (2020) 2376–2384.

D.Q. Zhu, M.J. Xu, J. Pan, C.C. Yang, H.Y. Tian, J. Iron Steel Res. 29 (2017) 704–710.

S. Wang, Y.F. Guo, F.Q. Zheng, F. Chen, L.Z. Yang, Powder Technol. 376 (2020) 126–135.

X.H. Fan, M. Gan, T. Jiang, X.L. Chen, L.S. Yuan, in: TMS 2010 - 139th Annual Meeting and Exhibition - Supplemental Proceedings, vol. 1: Materials Processing and Properties, Seattle, USA, 2010, pp. 559–568.

Z.L. Xue, G.F. Zhou, H. Yang, Sinter. Pelletiz. 20 (1995) No. 5, 7–13.

O. Sivrikaya, A.I. Arol, Powder Technol. 210 (2011) 23–28.

M.H. Bai, H. Long, S.B. Ren, D. Liu, C.F. Zhao, ISIJ Int. 58 (2018) 1034–1041.

L.G. Xia, B.X. Su, X.Y. Li, J.L. Zhang, Z.X. Zhao, G.L. Qing, Sinter. Pelletiz. 39 (2014) No. 1, 21–24+39.

D.B. Guo, L.D. Zhu, S. Guo, B.H. Cui, S.P. Luo, M. Laghari, Z.H. Chen, C.F. Ma, Y. Zhou, J. Chen, B. Xiao, M. Hu, S.Y. Luo, Fuel Process. Technol. 148 (2016) 276–281.

J.J. Fan, W.P. Zhang, C.G. Liu, G.D. Zhao, Y.M. Xi, Iron and Steel 48 (2013) No. 12, 20–24.

S. Dwarapudi, T.U. Devi, S.M. Rao, M. Ranjan, ISIJ Int. 48 (2008) 768–776.

J.J. Fan, G.Z. Qiu, T. Jiang, Y.F. Guo, H.Z. Hao, Y.B. Yang, J. Cent. South Univ. 19 (2012) 2611–2619.

C.C. Yang, D.Q. Zhu, J. Pan, B.Z. Zhou, H. Xun, J. Iron Steel Res. Int. 23 (2016) 924–932.

A.B. Kotta, S.K. Karak, M. Kumar, Mater Sci Forum. 978 (2020) 525–531.

J.J. Fan, G.Z. Qiu, T. Jiang, Y.F. Guo, M.X. Cai, J. Iron Steel Res. Int. 18 (2011) No. 7, 1–7.

D.Q. Zhu, D. Chen, J. Pan, J. Iron Steel Res. Int. 16 (2009) No. S2, 345–349.

F. Zhang, D.Q. Zhu, J. Pan, Z.Q. Guo, M.J. Xu, J. Iron Steel Res. Int. 27 (2020) 770–781.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Grant Nos. 51974371 and 51804347).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Fan, Xh., Zhou, Za., Wang, S. et al. Mineralization characteristics of pellets prepared by ultrafine magnetite concentrate: influence on metallurgical property and improving method. J. Iron Steel Res. Int. 30, 446–455 (2023). https://doi.org/10.1007/s42243-022-00810-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-022-00810-7