Abstract

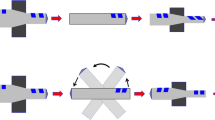

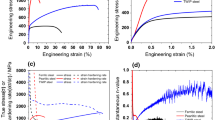

The effect of drawing speed on temperature rise and microstructure distribution in twinning-induced plasticity (TWIP) steel during wire drawing has been investigated to improve drawability for wire rod applications. Although wire drawing process is performed at room temperature, heat is generated due to the plastic deformation and friction at the wire–die interface. The steel wires subjected to the low drawing speed (LD) of 0.5 m/min and the high drawing speed (HD) of 5.0 m/min were analyzed using the numerical simulation and electron backscatter diffraction techniques. Interestingly, the specimens subjected to the HD had a higher drawability by about 18% compared to the LD, which is totally different from the general behavior of plain carbon pearlitic steels. The LD wire had uniform temperature distribution along the radial direction during wire drawing. In contrast, the HD wire had a temperature gradient along the radial direction due to the higher frictional effect at surface: the minimum temperature of 58 °C at center area and the maximum temperature of 143 °C at surface area. The higher stacking fault energy of HD wire at the surface area due to the high temperature rise retarded twinning rate, resulting in the prevention of fast exhaustion in ductility in comparison with the LD wires since the earlier depletion of twins at surface area is known as the main reason for the fracture of TWIP steel during wire drawing. Consequently, HD process delayed the fracture strain of wire and increased the uniformity of microstructure and mechanical properties along the radial direction.

Similar content being viewed by others

References

Y. Namimura, M. Fujita, N. Ibaraki, Y. Oki, Kobe Steel Eng. Rep. 54 (2004) 16–20.

J.K. Hwang, I.C. Yi, I.H. Son, J.Y. Yoo, B. Kim, A. Zargaran, N.J. Kim, Mater. Sci. Eng. A 644 (2015) 41–52.

Y.S. Chun, J. Lee, C.M. Bae, K.T. Prak, C.S. Lee, Scripta Mater. 67 (2012) 681–684.

K.H. So, J.S. Kim, Y.S. Chun, K.T. Park, Y.K. Lee, C.S. Lee, ISIJ Int. 49 (2009) 1952–1959.

O. Bouaziz, S. Allain, C.P. Scott, P. Cugy, D. Barbier, Curr. Opin. Solid State Mater. Sci. 15 (2011) 141–168.

O. Grassel, L. Kruger, G. Frommeyer, L.W. Meyer, Int. J. Plast. 16 (2000) 1391–1409.

D. Barbier, N. Gey, S. Allain, N. Bozzolo, M. Humbert, Mater. Sci. Eng. A 500 (2009) 196–206.

Y.N. Dastur, W.C. Leslie, Metall. Trans. A 12 (1981) 749–759.

O. Bouaziz, N. Guelton, Mater. Sci. Eng. A 319–321 (2001) 246–249.

J.E. Jin, Y.K. Lee, Mater. Sci. Eng. A 527 (2009) 157–161.

H. Idrissi, K. Renard, D. Schryvers, P.J. Jacques, Scripta Mater. 63 (2010) 961–964.

E.I. Galindo-Nava, P.E.J. Rivera-Diaz-del-Castillo, Acta Mater. 128 (2017) 120–134.

B.C. De Cooman, Y. Estrin, S.K. Kim, Acta Mater. 142 (2018) 283–362.

O.A. Zambrano, J. Mater. Sci. 53 (2018) 14003–14062.

J.K. Hwang, J. Mater. Sci. 54 (2019) 8743–8759.

R.N. Wright, Wire technology: process engineering and metallurgy, Butterworth-Heinemann, Elsevier, USA, 2011.

S. Curtze, V.T. Kuokkala, A. Oikari, J. Talonen, H. Hannien, Acta Mater. 59 (2011) 1068–1076.

S. Allain, J.P. Chateau, O. Bouaziz, S. Migot, N. Guelton, Mater. Sci. Eng. A 387–389 (2004) 158–162.

A. Saeed-Akbari, J. Imlau, U. Prahl, W. Bleck, Metall. Mater. Trans. A 40 (2009) 3076–3090.

S. Curtze, V.T. Kuokkala, Acta Mater. 58 (2010) 5129–5141.

J.K. Hwang, Mater. Sci. Eng. A 711 (2018) 156–164.

T. Lee, M. Koyama, K. Tsuzaki, Y.H. Lee, C.S. Lee, Mater. Lett. 75 (2012) 169–171.

H.M. Baek, S.K. Hwang, H.S. Joo, Y.T. Im, I.H. Son, C.M. Bae, Mater. Des. 62 (2014) 137–148.

U. Chakkingal, A.B. Suriadi, P.F. Thomson, Mater. Sci. Eng. A 266 (1999) 241–249.

A.G. Atkins, R.M. Caddell, Int. J. Mech. Sci. 10 (1968) 15–28.

R.K. Chin, P.S. Stelf, Int. J. Mach. Tools Manuf. 35 (1995) 1087–1098.

M.T.P. Aguilar, E.C.S. Correa, R.F. Silva, P.R. Cetlin, J. Mater. Process. Technol. 125–126 (2002) 323–325.

H.S. Lin, Y.C. Hsu, C.C. Keh, J. Mater. Process. Technol. 201 (2008) 128–132.

J.K. Hwang, I.H. Son, J.Y. Yoo, A. Zargaran, N.J. Kim, Met. Mater. Int. 21 (2015) 815–822.

H. Nagashima, K. Yoshida, J. AMME 70 (2015) 29–35.

J.K. Hwang, Mater. Sci. Eng. A 737 (2018) 188–197.

A. Haddi, A. Imad, G. Vega, Mater. Des. 32 (2011) 4310–4315.

A. El-Domiaty, S.Z. Kassab, J. Mater. Process. Technol. 83 (1998) 72–83.

G. Vega, A. Haddi, A. Imad, Int. J. Mater. Form 2 (2009) 229–232.

M. Suliga, R. Kruzel, T. Garstka, J. Gazdowicz, Metalurgija 54 (2015) 161–164.

J.W. Pilarczyk, J. Markowski, H. Dyja, B. Golis, Wire J. Int. 37 (2004) 118–123.

C.S. Cetinarslan, A. Guzey, Mater. Technol. 47 (2013) 245–252.

S.K. Lee, D.C. Ko, B.M. Kim, Mater. Des. 30 (2009) 2919–2927.

I. Nemec, B. Golis, J.W. Pilarczyk, R. Budzik, W. Waszkielewicz, Wire J. Int. 40 (2007) 63–68.

A. Dumay, J.P. Chateau, S. Allain, S. Migot, O. Bouaziz, Mater. Sci. Eng. A 483–484 (2008) 184–187.

M. Ghasri-Khouzani, J.R. McDermid, Mater. Sci. Eng. A 621 (2015) 118–127.

J.K. Hwang, Appl. Therm. Eng. 142 (2018) 311–320.

J.E. Jin, Y.K. Lee, Acta Mater. 60 (2012) 1680–1688.

S.K. Lee, S.B. Lee, B.M. Kim, J. Mater. Process. Technol. 210 (2010) 776–783.

A.A. Saleh, E.V. Pereloma, A.A. Gazder, Mater. Sci. Eng. A 528 (2011) 4537–4549.

O.A. Zambrano, J. Valdes, Y. Aguilar, J.J. Coronado, S.A. Rodriguez, R.E. Loge, Mater. Sci. Eng. A 689 (2017) 269–285.

A.J. Schwartz, M. Kumar, B.L. Adams, D.P. Field, Electron backscatter diffraction in materials science, 2nd ed., Springer, Boston, USA, 2009.

R. Badji, T. Chauveau, B. Bacroix, Mater. Sci. Eng. A 575 (2013) 94–103.

J. Park, M. Kang, S.S. Sohn, S.H. Kim, K.S. Kim, N.J. Kim, S. Lee, Mater. Sci. Eng. A 684 (2017) 54–63.

Z.W. Wang, Y.B. Wang, X.Z. Liao, Y.H. Zhao, E.J. Lavemia, Y.T. Zhu, Z. Horita, T.G. Langdon, Scripta Mater. 60 (2009) 52–55.

E.G. Astafurova, M.S. Tukeeva, G.G. Maier, E.V. Melnikov, H.J. Maier, Mater. Sci. Eng. A 604 (2014) 166–175.

E. Bayraktar, F.A. Khalid, C. Levaillant, J. Mater. Process. Technol. 147 (2004) 145–154.

H.K. Yang, Z.J. Zhang, F.Y. Dong, Q.Q. Duan, Z.F. Zhang, Mater. Sci. Eng. A 607 (2014) 551–558.

F.C. Liu, Z.N. Yang, C.L. Zheng, F.C. Zhang, Scripta Mater. 66 (2012) 431–434.

Y.F. Shen, N. Jia, R.D.K. Misra, L. Zuo, Acta Mater. 103 (2016) 229–242.

G.H. Hasani, R. Mahmudi, A. Karimi-Taheri, Int. J. Mater. Form 3 (2010) 59–64.

C. Moon, N. Kim, J. Mech. Sci. Technol. 26 (2012) 2903–2911.

R.W. Neu, Materials Performance and Characterization 2 (2013) 244–284.

E. Felder, C. Levrau, M. Mantel, N.G. Truong Dinh, Wear 286–287 (2012) 27–34.

K.G. Chin, C.Y. Kang, S.Y. Shin, S. Hong, S. Lee, H.S. Kim, K. Kim, N.J. Kim, Mater. Sci. Eng. A 528 (2011) 2922–2928.

K. Renard, P.J. Jacques, Mater. Sci. Eng. A 542 (2012) 8–14.

S.K. Lee, D.W. Kim, M.S. Jeong, B.M. Kim, Mater. Des. 34 (2012) 363–371.

H.K. Yang, Y.Z. Tian, Z.J. Zhang, C.L. Yang, P. Zhang, Z.F. Zhang, Metall. Mater. Trans. A 48 (2017) 4458–4462.

H.Y. Yu, S.M. Lee, J.H. Nam, S.J. Lee, D. Fabregue, M.H. Park, N. Tsuji, Y.K. Lee, Acta Mater. 131 (2017) 435–444.

M. Koyama, Y. Shimomura, A. Chiba, E. Akiyama, K. Tsuzaki, Scripta Mater. 141 (2017) 20–23.

Acknowledgements

This research was supported by National Research Foundation of Korea (NRF-2018R1D1A1B07050103).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hwang, Jk. Effect of drawing speed on microstructure distribution and drawability in twinning-induced plasticity steel during wire drawing. J. Iron Steel Res. Int. 27, 577–587 (2020). https://doi.org/10.1007/s42243-019-00328-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-019-00328-5