Abstract

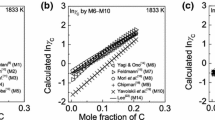

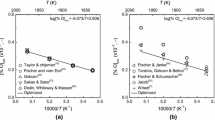

In order to further verify the accuracy and feasibility of the calculated mass action concentrations \(N_{i}\) of Al and Fe by the developed atom and molecule coexistence theory (AMCT) model, i.e., AMCT–\(N_{i}\) model, for representing activities \(a_{{{\text{R, }}i}}^{{}}\) of Al and Fe in Fe–Al binary melts reported in the first part of the serial studies, the molar mixing thermodynamic functions of Fe–Al binary melts over a temperature range from 1823 to 1973 K have been calculated based on \(N_{i}\) of Al and Fe as well as the effect of temperature on activity coefficients \(\gamma_{i}^{{}}\) of Al and Fe as \({{\partial \ln \gamma_{i} } \mathord{\left/ {\vphantom {{\partial \ln \gamma_{i} } {\partial T}}} \right. \kern-0pt} {\partial T}} = {{\partial \ln \left( {{{N_{i} } \mathord{\left/ {\vphantom {{N_{i} } {x_{i} }}} \right. \kern-0pt} {x_{i} }}} \right)} \mathord{\left/ {\vphantom {{\partial \ln \left( {{{N_{i} } \mathord{\left/ {\vphantom {{N_{i} } {x_{i} }}} \right. \kern-0pt} {x_{i} }}} \right)} {\partial T}}} \right. \kern-0pt} {\partial T}}\) by the developed AMCT–\(N_{i}\) model, where T is absolute temperature and xi is the mole fraction of element i or compound i in metallic melts. The reported molar mixing thermodynamic functions of Fe–Al binary melts as well as the reported excess molar mixing thermodynamic functions of Fe–Al binary melts relative to ideal solution as a basis from the available literatures have been critically assessed and applied as criteria to verify the developed AMCT–\(N_{i}\) model. The effect of changing temperature on \(\gamma_{i}^{{}}\) of Al and Fe, i.e., activity coefficient gradients \({{\partial \ln \gamma_{\text{Al}}^{{}} } \mathord{\left/ {\vphantom {{\partial \ln \gamma_{\text{Al}}^{{}} } {\partial T}}} \right. \kern-0pt} {\partial T}}\) and \({{\partial \ln \gamma_{\text{Fe}}^{{}} } \mathord{\left/ {\vphantom {{\partial \ln \gamma_{\text{Fe}}^{{}} } {\partial T}}} \right. \kern-0pt} {\partial T}}\), which are two indispensable parameters to calculate the molar mixing thermodynamic functions of Fe–Al binary melts, can be accurately obtained by the developed AMCT–\(N_{i}\) model and expressed by the cubic polynomial functions. Not only the partial molar mixing thermodynamic functions of Al and Fe in Fe–Al binary melts but also the integral molar mixing thermodynamic functions of Fe–Al binary melts can be accurately calculated by the developed AMCT–\(N_{i}\) model. Furthermore, the excess partial and integral molar mixing thermodynamic functions of Fe–Al binary melts relative to ideal solution as a basis can also be precisely calculated by the developed AMCT–\(N_{i}\) model.

Similar content being viewed by others

References

B. Sundman, I. Ohnuma, N. Dupin, U.R. Kattner, S.G. Fries, Acta Mater. 57 (2009) 2896–2908.

A.T. Phan, M.K. Paek, Y.B. Kang, Acta Mater. 79 (2014) 1–15.

M.K. Paek, J.J. Pak, Y.B. Kang, Metall. Mater. Trans. B 46 (2015) 2224–2233.

M.K. Paek, K.H. Do, Y.B. Kang, I.H. Jung, J.J. Pak, Metall. Mater. Trans. B 47 (2016) 2837–2847.

H. Lukas, S.G. Fries, B. Sundman, Computational thermodynamics: the Calphad method, Cambridge University Press, New York, USA, 2007.

W. Zheng, S. He, M. Selleby, Y. He, L. Li, X.G. Lu, J. Ågren, Calphad 58 (2017) 34–49.

R.P. Goel, H.H. Kellogg, J. Larrain, Metall. Trans. B 11 (1980) 107–117.

B. Björkman, Calphad 9 (1985) 271–282.

B. Sundman, J. Phase Equilib. 12 (1991) 127–140.

M. Selleby, B. Sundman, Calphad 20 (1996) 381–392.

B. Sundman, Calphad 15 (1991) 109–119.

A.D. Pelton, S.A. Degterov, G. Eriksson, C. Robelin, Y. Dessureault, Metall. Mater. Trans. B 31 (2000) 651–659.

A.D. Pelton, P. Chartrand, Metall. Mater. Trans. A 32 (2001) 1355–1360.

P. Chartrand, A.D. Pelton, Metall. Mater. Trans. A 32 (2001) 1397–1407.

S.A. Degterov, E. Jak, P.C. Hayes, A.D. Pelton, Metall. Mater. Trans. B 32 (2001) 643–657.

O. Akinlade, R.N. Singh, F. Sommer, J. Alloy. Compd. 299 (2000) 163–168.

J. Zhang, Computational thermodynamics of metallurgical melts and solutions, Metallurgical Industry Press, Beijing, China, 2007.

X.M. Yang, J.S. Jiao, R.C. Ding, C.B. Shi, H.J. Guo, ISIJ Int. 49 (2009) 1828–1837.

C.B. Shi, X.M. Yang, J.S. Jiao, C. Li, H.J. Guo, ISIJ Int. 50 (2010) 1362–1372.

X.M. Yang, C.B. Shi, M. Zhang, G.M. Chai, F. Wang, Metall. Mater. Trans. B 42 (2011) 1150–1180.

X.M. Yang, M. Zhang, C.B. Shi, G.M. Chai, J. Zhang, Metall. Mater. Trans. B 43 (2012) 241–266.

X.M. Yang, J.P. Duan, C.B. Shi, M. Zhang, Y.L. Zhang, J.C. Wang, Metall. Mater. Trans. B 42 (2011) 738–770.

X.M. Yang, C.B. Shi, M. Zhang, J.P. Duan, J. Zhang, Metall. Mater. Trans. B 42 (2011) 951–977.

X.M. Yang, C.B. Shi, M. Zhang, J. Zhang, Steel Res. Int. 83 (2012) 244–258.

X.M. Yang, M. Zhang, J.L. Zhang, P.C. Li, J.Y. Li, J. Zhang, Steel Res. Int. 85 (2014) 347–375.

J.Y. Li, M. Zhang, M. Guo, X.M. Yang, Metall. Mater. Trans. B 45 (2014) 1666–1682.

X.M. Yang, J.Y. Li, M. Zhang, G.M. Chai, J. Zhang, Metall. Mater. Trans. B 45 (2014) 2118–2137.

X.M. Yang, M. Zhang, G.M. Chai, J.Y. Li, Q. Liang, J. Zhang, Ironmak. Steelmak. 43 (2016) 663–687.

X.M. Yang, J.Y. Li, G.M. Chai, D.P. Duan, J. Zhang, Metall. Mater. Trans. B 47 (2016) 2279–2301.

X.M. Yang, J.Y. Li, G.M. Chai, D.P. Duan, J. Zhang, Metall. Mater. Trans. B 47 (2016) 2302–2329.

X.M. Yang, J.Y. Li, G.M. Chai, D.P. Duan, J. Zhang, Ironmak. Steelmak. 44 (2017) 437–454.

X.M. Yang, J.Y. Li, M. Zhang, G.M. Chai, D.P. Duan, J. Zhang, Ironmak. Steelmak. 45 (2018) 25–43.

X.M. Yang J.Y. Li, M. Zhang, F.J. Yan, D.P. Duan, J. Zhang, Metals 8 (2018) 1083

X.M. Yang, M. Zhang, P.C. Li, J.Y. Li, J.L. Zhang, J. Zhang, Metall. Mater. Trans. B 43 (2012) 1358–1387.

X.M. Yang, M. Zhang, P.C. Li, J.Y. Li, J. Zhang, Steel Res. Int. 84 (2013) 784–811.

X.M. Yang, J.Y. Li, P.C. Li, M. Zhang, J. Zhang, Steel Res. Int. 85 (2014) 164–206.

X.M. Yang, P.C. Li, J.Y. Li, M. Zhang, J.L. Zhang, J. Zhang, Steel Res. Int. 85 (2014) 426–460.

X.M. Yang, J.Y. Li, M.F. Wei, J. Zhang, Metall. Mater. Trans. B 47 (2016) 174–206.

X.M. Yang, J.Y. Li, D.P. Duan, F.J. Yan, J. Zhang, J. Iron Steel Res. Int. 25 (2018) 37–56.

X.M. Yang, J.Y. Li, F.J. Yan, D.P. Duan, J. Zhang, J. Iron Steel Res. Int. 25 (2018) 181–199.

X.M. Yang, J.Y. Li, F.J. Yan, D.P. Duan, J. Zhang, High Temp. Mater. Proc. 37 (2018) 815–848.

F. Sommer, Z. Metallkde 73 (1982) 72–76.

F. Sommer, Z. Metallkde 73 (1982) 77–86.

K. Wasai, K. Mukai, J. Jpn. Inst. Met. 45 (1981) 593–602.

K. Wasai, K. Mukai, J. Jpn. Inst. Met. 46 (1982) 266–274.

J.H. Hildebrand, E.D. Eastman, J. Am. Chem. Soc. 37 (1915) 2452–2459.

A.S. Jordan, Metall. Trans. 1 (1970) 239–249.

Z. Moser, E. Kawecka, F. Sommer, B. Predel, Metall. Trans. B 13 (1982) 71–76.

C.A. Eckert, J.S. Smith, R.B. Irwin, K.R. Cox, AIChE J. 28 (1982) 325–333.

C.A. Eckert, R.B. Irwin, J.S. Smith, Metall. Trans. B 14 (1983) 451–458.

S. Wasiur-Rahman, M. Medraj, Intermetallics 17 (2009) 847-864.

A.D. Pelton, Y.B. Kang, Int. J. Mater. Res. 98 (2007) 907–917.

J.Y. Zhang, Metallurgical physicochemistry, Metallurgical Industry Press, Beijing, China, 2004.

X.H. Huang, Principles of ironmaking and steelmaking, 3rd ed., Metallurgical Industry Press, Beijing, China, 2005.

N.S. Jacobson, G.M. Mehrotra, Metall. Trans. B 24 (1993) 481–486.

J. Chipman, T.P. Floridis, Acta Metall. 3 (1955) 456–459.

F. Wooley, J.F. Elliott, Trans. Met. Soc. AIME 239 (1967) 1872–1883.

A. Coskun, J.F. Elliott, Trans. Met. Soc. AIME 242 (1968) 253–255.

H. Mitani, H. Nagai, J. Jpn. Inst. Met. 32 (1968) 752–755.

G.R. Belton, R.J. Fruehan, Trans. Met. Soc. AIME 245 (1969) 113–117.

R.J. Fruehan, Metall. Trans. 1 (1970) 3403–3410.

E. Ichise, T. Yamauchi, T. Mori, Tetsu-to-Hagané 63 (1977) 417–424.

P.D. Desai, J. Phys. Chem. Ref. Data 16 (1987) 109–124.

S.V. Radcliffe, B.L. Averbach, M. Cohen, Acta Metall. 9 (1961) 169–176.

J. Eldridge, K.L. Komarek, Trans. Met. Soc. AIME 230 (1964) 226–233.

M.W. Chase Jr., C.A. Davies, J.R. Downey Jr., D.J. Frurip, R.A. McDonald, A.N. Syverud, eds., JANAF thermochemical tables, American Institute for Physics, New York, USA, 1986.

O. Kubaschewski, Iron-binary phase diagrams, Springer-Verlag Berlin Heidelberg, New York, USA, 1982.

T.B. Massalski, J.L. Murray, L.H. Bennett, H. Baker, eds., Binary alloy phase diagrams, ASM, Metals Park, OH, USA, 1986.

ASM International, ASM handbook volume 3-alloy phase diagrams, The Materials Information Company, USA, 1992.

S.K. Wei, Thermodynamics of metallurgical processes, Science Press, Beijing, China, 2010.

S.K. Wei, Application of activity into metallurgical physicochemistry, China Industry Press, Beijing, China, 1964.

Acknowledgements

This work is supported by the Beijing Natural Science Foundation (Grant No. 2182069) and the National Natural Science Foundation of China (Grant No. 51174186).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, Xm., Li, Jy., Yan, Fj. et al. Critical assessment of mixing thermodynamic functions of Fe–Al binary melts based on atom–molecule coexistence theory. J. Iron Steel Res. Int. 27, 266–281 (2020). https://doi.org/10.1007/s42243-019-00301-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-019-00301-2