Abstract

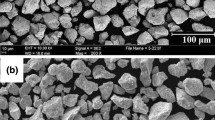

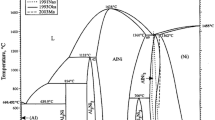

During the operation of a coke dry quenching system of coking plant, wear-proofing cover of the boiler was seriously eroded, and even the ceiling tube of the boiler was worn and torn. Thus, attentions were paid to the research, development and application of the wear-resistant coating spraying technique for wear-proofing cover of the coke dry quenching furnace. The Cr3C2–NiCr coatings for wear-proofing cover were fabricated via supersonic arc spraying process, and the residual coating of wear-proofing cover would be sampled for being analyzed after two years. The coating presents a dense microstructure with few pores and micro-cracks (the porosity is 4.65%). After thermal spraying of the wear-proofing cover, the hardness and the wear resistance of the surface are improved. The remaining coating is continuous and compact, with an average thickness of about 147 μm. Transverse micro-cracks parallel to the spreading direction of the coating surface are displayed on different areas of the coating, which demonstrates its serious erosion wear effect. The main chemical component of white zone is Fe–18Cr–Ni. The Cr level of light gray phase is about 77.57 wt.% and the O level is 22.43 wt.%. And the main chemical components of dark gray phase are C, O, Al, Si and Ca. X-ray diffraction patterns were adopted to implement phase analysis on the surface of coating sample, which indicated that the coating was composed of a large amount of Cr3O2 and a small amount of metal Cr.

Similar content being viewed by others

References

I.A. Sultanguzin, V.V. Bologova, A.M. Gyulmaliev, V.S. Glazov, R.B. Belov, Coke Chem. 59 (2016) 61–67.

X.Q. Meng, P.G. Ning, G.J. Xu, H.B. Cao, Sep. Purif. Technol. 175 (2017) 506–511.

Y.H. Gao, Z.Y. Liang, G.J. Zhu, N.Y. Deng, S.Q. Zhang, Adv. Mater. Res. 997 (2014) 550–553.

T.Q. Liang, X.F. Yang, Y.L. Wang, C.H. Zhao, Appl. Mech. Mater. 697 (2015) 90–94.

B.P. Ba, Y.J. Liu, Mech. Eng. 48 (2012) 152–153.

P. Du, B. Wu, J.W. Chen, Z.H. Li, H.Y. Xu, B.S. Xu, L.N. Zhang, Z.F. Yuan, Nonferr. Met. Sci. Eng. 6 (2015) 1–6.

B.S. Xu, Z.F. Yuan, Y. Wu, Colloids Surf. A 441 (2014) 217–225.

Y. Yang, K.Z. Li, Z.G. Zhao, G.X. Liu, Ceram. Int. 43 (2017) 1495–1503.

S.G. Liu, J.M. Wu, S.C. Zhang, S.J. Rong, Z.Z. Li, Wear 262 (2007) 555–561.

J.J. Tian, S.W. Yao, X.T. Luo, C.X. Li, C.J. Li, Acta Mater. 110 (2016) 19–30.

S. Matthews, M. Hyland, B. James, J. Therm. Spray Technol. 13 (2004) 526–536.

F. Otsubo, H. Era, K. Kishitake, T. Uchida, J. Therm. Spray Technol. 9 (2000) 499–504.

Z.Y. Zhang, X.C. Lu, J.B. Luo, Appl. Surf. Sci. 253 (2007) 4377–4385.

G. Bolelli, L. Lusvarghi, Tribol. Lett. 25 (2007) 43–54.

J.M. Hui, W.D. Ge, Fuel Chem. Ind. 40 (2009) No. 2, 27.

C.B. Huang, L.Z. Du, W.G. Zhang, J. Alloy. Compd. 479 (2009) 777–784.

Y.L. An, S.J Li, G.L. Hou, X.Q. Zhao, H.D. Zhou, J.M. Chen, Ceram. Int. 43 (2017) 5319–5328.

W. Deng, S.J. Li, X. Liu, X.Q. Zhao, Y.L. An, H.D. Zhou, J.M. Chen, Mater. Lett. 193 (2017) 199–202.

H.W. Zhang, X.H. Dong, S.G. Chen, Adv. Mech. Eng. 9 (2017) 1687814017694580.

T.Q. Liang, H.B. Guo, H. Peng, S.K. Gong, Chin. J. Aeronaut. 25 (2012) 796–803.

S.S. Li, T.Q. Liang, X.F. Yang, C.H. Zhao, Appl. Mech. Mater. 670–671 (2014) 554–559.

L. Lin, G.L. Li, H.D. Wang, J.J. Kang, Z.L. Xu, H.J. Wang, Appl. Surf. Sci. 356 (2015) 383–390.

Y.L. An, J. Chen, G.L. Hou, X.Q. Zhao, H.D. Zhou, J.M. Chen, F.Y. Yan, Tribol. Lett. 58 (2015) 34.

Acknowledgements

This research work was partially supported by the National Natural Science Foundation of China (Grant Nos. U1560101 and U1738101) and the National Key Research and Development Program of China (2016YFC0209302).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yuan, Zf., Xie, Ss., Yu, Xt. et al. Wear-resistant coating spraying technique for wear-proofing cover of coke dry quenching furnace. J. Iron Steel Res. Int. 26, 123–129 (2019). https://doi.org/10.1007/s42243-018-0201-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-018-0201-5