Abstract

Solid-liquid fluidized beds of binary mixtures are widely used in many industries. Particle segregation may occur as particles can differ in size, density, or shape. Extensive studies have been conducted in the past to understand the effects of particlesize and density on the mixing and segregation, but the effect of particle shape has not been well addressed. Therefore, in the present work, CFD-DEM approach is employed to perform a numerical analysis of the effect of particle shape on the particle mixing and segregation phenomenon in liquid fluidization system. Different particle shapes from oblate to prolate are produced by varying aspect ratio of ellipsoids from 0.25 to 3, and eight binary mixtures of spheres and ellipsoids are examined. The results show that when oblate or prolate particles are added to spheres, the segregation takes place. The segregation degree increases with particle aspect ratio diverging from 1.0 and also liquid superficial velocity. The relationship of mixing index with aspect ratio under different liquid velocities is established, and a detailed explanation is given. It is revealed that increasing the projected area and hence the drag force results in the separation of ellipsoidal particles from spheres.

Similar content being viewed by others

References

Epstein N., Leclair B. P., Pruden B. B. Liquid fluidization of binary particle mixtures-I: Overall bed expansion [J]. Chemical Engineering Science, 1981, 36(11): 1803–1809.

Sahoo A., Roy G. K. Mixing characteristic of homogeneous binary mixture of regular particles in a gas–solid fluidized bed [J]. Powder Technology, 2005, 159(3): 150–154.

Upadhyay R. K., Roy S. Investigation of hydrodynamics of binary fluidized beds via radioactive particle tracking and dual-source densitometry [J]. The Canadian Journal of Chemical Engineering, 2010, 88(4): 601–610.

Lewis E. W., Bowerman E. W. Fluidization of solid particles in liquids [J]. Chemical Engineering Progress, 1952, 48: 603–611.

Richardson J. F., Zaki W. N. Sedimentation and fluidization: Part I [J]. Transactions of the Institution of Chemical Engineers, 1954, 32: 35–53.

Wen C. Y., Yu Y. H. Mechanics of fluidization [J]. Chemical Engineering Progress Symposium Series, 1966, 62: 100–111.

Epstein N., LeClair B. P. Liquid fluidization of binary particle mixtures-II. Bed inversion [J]. Chemical Engineering Science, 1985, 40(8): 1517–1526.

Moritomi H., Iwase T., Chiba T. A comprehensive interpretation of solid layer inversion in liquid fluidised beds [J]. Chemical Engineering Science, 1982, 37(12): 1751–1757.

Patwardhan V. S., Tien C. Sedimentation and liquid fluidization of solid particles of different sizes and densities [J]. Chemical Engineering Science, 1985, 40(7): 1051–1060.

Masliyah J. H. Hindered settling in a multi-species particle system [J]. Chemical Engineering Science, 1979, 34(9): 1166–1168.

Moritomi H., Yamagishi T., Chiba T. Prediction of complete mixing of liquid-fluidized binary solid particles [J]. Chemical Engineering Science, 1986, 41(2): 297–305.

Gibilaro L. G., Di Felice R., Waldram S. P. et al. A predictive model for the equilibrium composition and inversion of binary-solid liquid fluidized beds [J]. Chemical Engineering Science, 1986, 41(2): 379–387.

Vivacqua V., Vashisth S., Hébrard G. et al. Characterization of fluidized bed layer inversion in a 191-mm-diameter column using both experimental and CPFD approaches [J]. Chemical Engineering Science, 2012, 80: 419–428.

Escudié R., Epstein N., Grace J. R. et al. Effect of particle shape on liquid-fluidized beds of binary (and ternary) solids mixtures: Segregation vs. mixing [J]. Chemical Engineering Science, 2006, 61(5): 1528–1539.

Maiti S. B., Let S., Bar N. et al. Non-spherical solid-non-Newtonian liquid fluidization and ANN modelling: Minimum fluidization velocity [J]. Chemical Engineering Science, 2018, 176: 233–241.

Boyce C., Ozel A., Rice N. et al. Effective particle diameters for simulating fluidization of non-spherical particles: CFD-DEM models vs. MRI measurements [J]. AIChE Journal, 2017, 63(7): 2555–2568.

Oschmann T., Hold J., Kruggel-Emden H. Numerical investigation of mixing and orientation of non-spherical particles in a model type fluidized bed [J]. Powder Technology, 2014, 258: 304–323.

Vollmari K., Oschmann T., Kruggel-Emden H. Mixing quality in mono-and bidisperse systems under the influence of particle shape: A numerical and experimental study [J]. Powder Technology, 2017, 308: 101–113.

Barghi S., Briens C. L., Bergougnou M. A. Mixing and segregation of binary mixtures of particles in liquid–solid fluidized beds [J]. Powder Technology, 2003, 131(2–3): 223–233.

Tripathy A., Bagchi S., Biswal S. K. et al. Study of particle hydrodynamics and misplacement in liquid–solid fluidized bed separator [J]. Chemical Engineering Research and Design, 2017, 117: 520–532.

Ehsani M., Movahedirad S., Shahhosseini S. The effect of particle properties on the heat transfer characteristics of a liquid-solid fluidized bed heat exchanger [J]. International Journal of Thermal Sciences, 2016, 102: 111–121.

Sen M., Barrasso D., Singh R. et al. A multiscale hybrid CFD-DEM-PBM description of a fluid-bed granulation process [J]. Processes, 2014, 2(1): 89–111.

Zhu H. P., Zhou Z. Y., Yang R. Y. et al. Discrete particle simulation of particulate systems: A review of major applications and findings [J]. Chemical Engineering Science, 2008, 63(23): 5728–5770.

Zhu H. P., Zhou Z. Y., Yang R. Y. et al. Discrete particle simulation of particulate systems: Theoretical developments [J]. Chemical Engineering Science, 2007, 62(13): 3378–3396.

Abbaszadeh Molaei E., Yu A. B., Zhou Z. Y. Particle scale modelling of mixing of ellipsoids and spheres in gas-fluidized beds by a modified drag correlation [J]. Powder Technology, 2019, 343: 619–628.

Gan J., Zhou Z., Yu A. CFD-DEM modeling of gas fluidization of fine ellipsoidal particles [J]. AIChE Journal, 2016, 62(1): 62–77.

Cundall P. A., Strack O. D. L. A discrete numerical model for granular assemblies [J]. Géotechnique, 1979, 29(1): 47–65.

Gidaspow D. Multiphase flow and fluidization: Continuum and kinetic theory descriptions [M]. New York, USA: Academic Press, 1994.

Launder B. E., Spalding D. B. The numerical computation of turbulent flows [J]. Computer Methods in Applied Mechanics and Engineering, 1974, 3(2): 269–289.

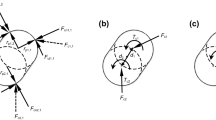

Zheng Q. J., Zhou Z. Y., Yu A. B. Contact forces between viscoelastic ellipsoidal particles [J]. Powder Technology, 2013, 248: 25–33.

Di Renzo A., Di Maio F. P. Homogeneous and bubbling fluidization regimes in DEM-CFD simulations: Hydrodynamic stability of gas and liquid fluidized beds [J]. Chemical Engineering Science, 2007, 62(1): 116–130.

Abbaszadeh Molaei E., Yu A. B., Zhou Z. Y. Investigation of causes of layer inversion and prediction of inversion velocity in liquid fluidizations of binary particle mixtures [J]. Powder Technology, 2019, 342: 418–432.

Rong L. W., Dong K. J., Yu A. B. Lattice-Boltzmann simulation of fluid flow through packed beds of spheres: Effect of particle size distribution [J]. Chemical Engineering Science, 2014, 116: 508–523.

Hölzer A., Sommerfeld M. New simple correlation formula for the drag coefficient of non-spherical particles [J]. Powder Technology, 2008, 184(3): 361–365.

Heiss J. F., Coull J. The effect of orientation and shape on the settling velocity of non-isometric particles in a viscous medium [J]. Chemical Engineering Process, 1952, 48: 133–140.

Rodrigue D., Chhabra R., De Kee D. Drag on non-spherical particles in non-newtonian fluids [J]. The Canadian Journal of Chemical Engineering, 1994, 72(4): 588–593.

Rong L., Zhou Z. Y., Yu A. B. Lattice–Boltzmann simulation of fluid flow through packed beds of uniform ellipsoids [J]. Powder Technology, 2015, 285: 146–156.

Feng Y. Q., Xu B. H., Zhang S. J. et al. Discrete particle simulation of gas fluidization of particle mixtures [J]. AIChE Journal, 2004, 50(8): 1713–1728.

Zhang Z. P., Liu L. F., Yuan Y. D. et al. A simulation study of the effects of dynamic variables on the packing of spheres [J]. Powder Technology, 2001, 116(1): 23–32.

Acknowledgement

Funding from the Australian Research Council Industrial Transformation Research Hubs Scheme (Grant No. IH140100035) is gratefully acknowledged. This research was undertaken with the assistance of resources from the National Computational Infrastructure (NCI), which is supported by the Australian Government.

Author information

Authors and Affiliations

Corresponding author

Additional information

Biography: Esmaeil Abbaszadeh Molaei (1987-), Male, Ph. D.

Rights and permissions

About this article

Cite this article

Molaei, E.A., Yu, A. & Zhou, Z. CFD-DEM modelling of mixing and segregation of binary mixtures of ellipsoidal particles in liquid fluidizations. J Hydrodyn 31, 1190–1203 (2019). https://doi.org/10.1007/s42241-019-0019-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42241-019-0019-z