Abstract

Strong and stable woven formations are a type of promising structure for regulating external forces in hybrid material systems with desired electro/thermomechanical properties. The strength of the knitted composite structures relies on the distribution of stress over a cohesive network of nanoribbons/fabrics, whose integrity is dependent upon an underlying mechanism of stabilization through friction that keeps the nanoribbons/fabrics in their place. Herein, we uncover a new molecular-level friction mechanism in interwoven composite structures, where the extreme pulling speed causes instant orbital overlap, which creates additional resisting interfacial shear strength that delays the collapse of the woven structure. Our theoretical analysis of atomic woven two-dimensional materials (e.g., graphene, MXene, black phosphorus, and layered double hydroxide) conducted through molecular dynamics simulations and density functional theory calculations help break up this force between the atomic interactions and a repulsive force residing within the forced orbital overlap at the edges of the sliding and the confining nanosheets. Our results depict the robustness of the epoxy-weave interface considering the presence of imperfections within the woven formation. The detailed dissection of the friction within the woven formations provides new insight into its crucial role in preserving the post-failure integrity of woven composites. This knowledge will help us understand the physical behavior of knots and weaves as reinforcements at the atomic scale and further realize the potential of nanofabrics for bottom-up ultimate design.

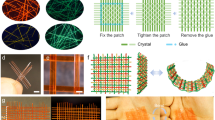

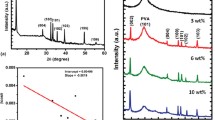

Graphical abstract

Similar content being viewed by others

Data availability

Data can be made available on request to the corresponding authors.

References

Tiwari SK et al (2020) Graphene research and their outputs: status and prospect. J Sci Adv Mater Devices 5(1):10–29

Yu W et al (2020) Progress in the functional modification of graphene/graphene oxide: a review. RSC Adv 10(26):15328–15345

Cai W et al (2010) Thermal transport in suspended and supported monolayer graphene grown by chemical vapor deposition. Nano Lett 10(5):1645–1651

Wei N et al (2019) Thermal rectification of graphene on substrates with inhomogeneous stiffness. Carbon 154:81–89

Balandin AA et al (2008) Superior thermal conductivity of single-layer graphene. Nano Lett 8(3):902–907

Gabris MA et al (2022) Chitosan magnetic graphene grafted polyaniline doped with cobalt oxide for removal of arsenic (V) from water. Environ Res 207:112209

Hosseini E et al (2021) Mechanical hydrolysis imparts self-destruction of water molecules under steric confinement. Phys Chem Chem Phys 23(10):5999–6008

Geim AK, Novoselov KS (2010) The rise of graphene. Nanoscience and technology: a collection of reviews from nature journals. World Scientific, pp 11–19

Yue Y et al (2018) Highly self-healable 3D microsupercapacitor with MXene–graphene composite aerogel. ACS Nano 12(5):4224–4232

Wang C et al (2021) Review of recent progress on graphene-based composite gas sensors. Ceram Int 47(12):16367–16384

Kim KS et al (2009) Large-scale pattern growth of graphene films for stretchable transparent electrodes. Nature 457(7230):706–710

Bunch JS et al (2008) Impermeable atomic membranes from graphene sheets. Nano Lett 8(8):2458–2462

Kaynan O et al (2023) Multifunctionality through embedding patterned nanostructures in high-performance composites. Adv Mater 35(32):2300948

Shi X et al (2021) Improvement of thermal conductivities and simulation model for glass fabrics reinforced epoxy laminated composites via introducing hetero-structured BNN-30@ BNNS fillers. J Mater Sci Technol 82:239–249

Cai X et al (2021) Matching micro-and nano-boron nitride hybrid fillers for high-thermal conductive composites. J Appl Polym Sci 138(24):50575

Hosseini E et al (2018) Mechanical and electromechanical properties of functionalized hexagonal boron nitride nanosheet: a density functional theory study. J Chem Phys 149(11):114701

Roudi MRR et al (2022) Review of boron nitride nanosheet-based composites for construction applications. ACS Appl Nano Mate 5(12):17356–17372

Wei N et al (2012) Knitted graphene-nanoribbon sheet: a mechanically robust structure. Nanoscale 4(3):785–791

Wei N et al (2021) A heat and force locating sensor with nanoscale precision: a knitted graphene sheet. Nanoscale 13(11):5826–5833

Reecht G et al (2015) Pulling and stretching a molecular wire to tune its conductance. J Phys Chem Lett 6(15):2987–2992

Fournier N et al (2011) Force-controlled lifting of molecular wires. Phys Rev B 84(3):035435

Hosseini E et al (2021) Robust cleaning mechanism permanently detaches hydrocarbon species from silicate surfaces by amphiphiles. Appl Surf Sci 558:149954

Zakertabrizi M et al (2021) Turning two waste streams into one solution for enhancing sustainability of the built environment. Resour Conserv Recycl 174:105778

Arzt E, Gorb S, Spolenak R (2003) From micro to nano contacts in biological attachment devices. Proc Natl Acad Sci 100(19):10603–10606

Gao H, Yao H (2004) Shape insensitive optimal adhesion of nanoscale fibrillar structures. Proc Natl Acad Sci 101(21):7851–7856

Yao H et al (2023) Optimal design of multilayer radar absorbing materials: a simulation-optimization approach. Adv Compos Hybrid Mater 6(1):43

Shkir M et al (2022) Density functional theory studies on a novel 1-ethyl-4-phenyl-1,5-benzodiazepin-2-thione molecule and its derivatives for opto-nonlinear applications. Eng Sci 19:319–329

Qin Z et al (2023) Mechanics of micropattern-guided formation of elastic surface instabilities on the polydimethylsiloxane bilayer. Adv Compos Hybrid Mater 6(5):160

Ibitoye AI et al (2022) Investigation of photoelectric properties, substrate effects and structural identification of layered rutile titanium oxide with χ3 of borophene using density functional theory. Eng Sci 20:364–376

Zhiguo M et al (2022) Co-simulation technology of mold flow and structure for injection molding reinforced thermoplastic composite (FRT) parts. Adv Compos Hybrid Mater 5(2):960–972

Jyoti R et al (2022) Density functional theory study of manganese doped armchair graphene nanoribbon for effective carbon dioxide gas sensing. ES Energy Environ 18:47–55

Wu N et al (2022) Dielectric properties and electromagnetic simulation of molybdenum disulfide and ferric oxide-modified Ti3C2TX MXene hetero-structure for potential microwave absorption. Adv Compos Hybrid Mater 5(2):1548–1556

Rahimian-Koloor SMR, Shokrieh MM (2023) Investigating the effect of the curing-induced residual stress on the mechanical behavior of carbon nanotube/epoxy nanocomposites by molecular dynamics simulation. Eng Sci 22:817

Sinclair RC, Suter JL, Coveney PV (2018) Graphene–graphene interactions: friction, superlubricity, and exfoliation. Adv Mater 30(13):1705791

Hod O et al (2018) Structural superlubricity and ultralow friction across the length scales. Nature 563(7732):485–492

Dietzel D et al (2017) Limitations of structural superlubricity: chemical bonds versus contact size. ACS Nano 11(8):7642–7647

Gao X et al (2021) Superlubric polycrystalline graphene interfaces. Nat Commun 12(1):5694

Zheng X et al (2016) Robust ultra-low-friction state of graphene via moiré superlattice confinement. Nat Commun 7(1):1–7

Vazirisereshk MR et al (2019) Origin of nanoscale friction contrast between supported graphene, MoS2, and a graphene/MoS2 heterostructure. Nano Lett 19(8):5496–5505

Hosseini E et al (2020) Orbital overlapping through induction bonding overcomes the intrinsic delamination of 3D-printed cementitious binders. ACS Nano 14(8):9466–9477

Cho D-H et al (2013) Effect of surface morphology on friction of graphene on various substrates. Nanoscale 5(7):3063–3069

Berman D et al (2015) Nanoscale friction properties of graphene and graphene oxide. Diam Relat Mater 54:91–96

Li H et al (2020) Nonmonotonic interfacial friction with normal force in two-dimensional crystals. Phys Rev B 102(8):085427

Guo Y, Guo W, Chen C (2007) Modifying atomic-scale friction between two graphene sheets: a molecular-force-field study. Phys Rev B 76(15):155429

Song Y et al (2022) Velocity dependence of Moiré friction. Nano Lett 22(23):9529–9536

Hosseini E et al (2019) Graphene oxide in ceramic-based layered structure: nanosheet optimization. Constr Build Mater 224:266–275

Sun H (1998) COMPASS: an ab initio force-field optimized for condensed-phase applications overview with details on alkane and benzene compounds. J Phys Chem B 102(38):7338–7364

Zhang T et al (2020) Parameterization of a COMPASS force field for single layer blue phosphorene. Nanotechnology 31(14):145702

Chen W-H et al (2017) Mechanical property assessment of black phosphorene nanotube using molecular dynamics simulation. Comput Mater Sci 133:35–44

Chen SJ et al (2017) Reinforcing mechanism of graphene at atomic level: friction, crack surface adhesion and 2D geometry. Carbon 114:557–565

Arshadi F et al (2021) The effect of D-spacing on the ion selectivity performance of MXene membrane. J Membr Sci 639:119752

Rappé AK et al (1992) UFF, a full periodic table force field for molecular mechanics and molecular dynamics simulations. J Am Chem Soc 114(25):10024–10035

Ding L et al (2018) MXene molecular sieving membranes for highly efficient gas separation. Nat Commun 9(1):1–7

Ding L et al (2020) Effective ion sieving with Ti3C2Tx MXene membranes for production of drinking water from seawater. Nature Sustainability 3(4):296–302

Abdollahzadeh M et al (2021) Low humid transport of anions in layered double hydroxides membranes using polydopamine coating. J Membr Sci 624:118974

Heinz H et al (2013) Thermodynamically consistent force fields for the assembly of inorganic, organic, and biological nanostructures: the INTERFACE force field. Langmuir 29(6):1754–1765

Lin T-J, Heinz H (2016) Accurate force field parameters and pH resolved surface models for hydroxyapatite to understand structure, mechanics, hydration, and biological interfaces. J Phys Chem C 120(9):4975–4992

Zhang L, Ji W, Liew K (2018) Mechanical properties of diamond nanothread reinforced polymer composites. Carbon 132:232–240

Ji W-M, Zhang L-W, Liew K (2021) Understanding interfacial interaction characteristics of carbon nitride reinforced epoxy composites from atomistic insights. Carbon 171:45–54

Basquiroto de Souza F et al (2021) Controlled growth and ordering of poorly-crystalline calcium-silicate-hydrate nanosheets. Commun Mater 2(1):1–11

Rad AS et al (2015) Lewis acid-base surface interaction of some boron compounds with N-doped graphene; first principles study. Curr Appl Phys 15(10):1271–1277

Abdollahzadeh M et al (2022) Designing Angstrom-scale asymmetric MOF-on-MOF cavities for high monovalent ion selectivity. Adv Mater 34(9):2107878

Viani L, Curutchet C, Mennucci B (2013) Spatial and electronic correlations in the PE545 light-harvesting complex. J Phys Chem Lett 4(3):372–377

Mennucci B (2013) Modeling environment effects on spectroscopies through QM/classical models. Phys Chem Chem Phys 15(18):6583–6594

Wang X, Lu C, Yang M (2020) The impact of electron correlation on describing QM/MM interactions in the attendant molecular dynamics simulations of CO in myoglobin. Sci Rep 10(1):1–12

Wang J-N et al (2021) Accelerated computation of free energy profile at ab initio quantum mechanical/molecular mechanics accuracy via a semiempirical reference potential. 4. Adaptive QM/MM. J Chem Theory Comput 17(3):1318–1325

Hohenberg P, Kohn W (1964) Inhomogeneous electron gas. Phys Rev 136(3B):B864

Kohn W, Sham LJ (1965) Self-consistent equations including exchange and correlation effects. Phys Rev 140(4A):A1133

Roothaan CCJ (1951) New Developments in molecular orbital theory. Rev Mod Phys 23(2):69–89

Perdew JP, Burke K, Ernzerhof M (1996) Generalized gradient approximation made simple. Phys Rev Lett 77(18):3865–3868

Aramfard M et al (2022) Aqueous dispersion of carbon nanomaterials with cellulose nanocrystals: an investigation of molecular interactions. Small 18(37):2202216

Abraham J et al (2017) Tunable sieving of ions using graphene oxide membranes. Nat Nanotechnol 12(6):546–550

Lei Y-J et al (2020) Tailoring MXene-based materials for sodium-ion storage: synthesis, mechanisms, and applications. Electrochem Energy Rev 3(4):766–792

Tang J et al (2021) Interlayer space engineering of MXenes for electrochemical energy storage applications. Chem Eur J 27(6):1921–1940

Pan D et al (2017) Simulations of twisted bilayer orthorhombic black phosphorus. Phys Rev B 96(4):041411

Shulenburger L et al (2015) The nature of the interlayer interaction in bulk and few-layer phosphorus. Nano Lett 15(12):8170–8175

Liu Y et al (2014) Molecular sieving through interlayer galleries. J Mater Chem 2(5):1235–1238

Li Z et al (2023) Boron nitride whiskers and nano alumina synergistically enhancing the vertical thermal conductivity of epoxy-cellulose aerogel nanocomposites. Adv Compos Hybrid Mater 6(6):224

Li X et al (2023) Electrophoretically deposited “rigid-flexible” hybrid graphene oxide-polyethyleneimine on carbon fibers for synergistically reinforced epoxy nanocomposites. Adv Compos Hybrid Mater 6(4):152

Zhao M et al (2023) Stepwise assembling manganese dioxide nanosheets and metal-organic frameworks on carbon fiber for deriving desirable mechanical properties and flame retardancy of epoxy composites. Adv Compos Hybrid Mater 6(4):150

Sun Y et al (2022) Effects of stitch yarns on interlaminar shear behavior of three-dimensional stitched carbon fiber epoxy composites at room temperature and high temperature. Adv Compos Hybrid Mater 5(3):1951–1965

Ye X-Y et al (2023) Sustainable wearable infrared shielding bamboo fiber fabrics loaded with antimony doped tin oxide/silver binary nanoparticles. Adv Compos Hybrid Mater 6(3):106

Wang W et al (2023) Lead-free and wearing comfort 3D composite fiber-needled fabric for highly efficient X-ray shielding. Adv Compos Hybrid Mater 6(2):76

Funding

This work was supported by the National Science Foundation, Civil, Mechanical and Manufacturing Innovation (CMMI), Advanced Manufacturing, under Grants #1930277 and #2134465.

Author information

Authors and Affiliations

Contributions

Mohammad Zakertabrizi and Ehsan Hossieni devised the idea, simulations, original analysis, and writing—original draft. Hamed Fallahi contributed to the simulations and data curing. Terry Creasy and Kenan Song aided in developing and transforming the original idea into models. Ali Tabei, Kyungjun Lee, and Amir Razmjou contributed to the data analysis and revisions to the manuscript. Dorrin Jarrahbashi and Amir Asadi led the project and supervised the models, analysis, and writing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zakertabrizi, M., Hosseini, E., Fallahi, H. et al. Dissecting atomic interweaving friction reveals the orbital overlap repulsion and its role in the integrity of woven nanofabrics in composites. Adv Compos Hybrid Mater 7, 86 (2024). https://doi.org/10.1007/s42114-024-00897-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42114-024-00897-4