Abstract

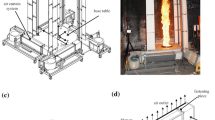

A fire whirl is a kind of spinning flow accompanied by chemical changes. It has a combustion-enhancing effect, increasing the fire’s heat release rate and may induce catastrophic consequences. However, the combustion characteristics of a fire whirl at dynamic pressure are still unknown. This experiment was conducted in a sizeable low-pressure chamber with dimensions of 3.0 m × 2.0 m × 2.0 m, in which a small-sized fire whirl was generated using a square vertical slot with variable slit width. The ambient pressure was reduced to the target pressure by the low-pressure chamber, and a dynamically pressurized environment was created by controlling the air inlet rate. This experiment investigates characteristic parameters such as combustion rate, heat radiation flux, and flame height of the fire whirl. The experimental results show that the flame height of the fire whirl with pressure changes as a result of the first increase and then maintains the same; the fire whirl has a pronounced combustion enhancement effect, and the combustion rate is about 3.5 times that of the ordinary pool fire; four walls open slit fire whirl combustion there is a “critical width,” the closer the width, the higher the mass combustion rate, the more stable the flow field, the more the ratio between the burning rate and the characteristic length of the oil basin, the more the ratio between the dimensionless number and the Grashof number is close to a linear relationship. The heat radiation flux increases with increasing pressure, and there is a linear relationship between \({\left({Q}_{r}^{\prime\prime}/{P}^{2}\right)}^{^{1}/_{4}}\) and \(\mathrm{P}^{^{-2}/_{3}}\), where \({Q^{\prime\prime}_r}\) is the flame radiation and P is the pressure.

Similar content being viewed by others

References

Tohidi A, Gollner M, Xiao H (2018) Fire whirls. Annu Rev Fluid Mech 50:187–213. https://doi.org/10.1146/annurev-fluid-122316-045209

Emmons H, Ying S (1967) The fire whirl 11(1):475–488. https://doi.org/10.1016/s0082-0784(67)80172-3

Satoh K, Yang K (1997) Simulations of swirling fires controlled by channeled self-generated entrainment flows. Fire Saf Sci 5:201–212. https://doi.org/10.3801/IAFSS.FSS.5-201

Liu C, Huang Q, Zheng K, Qin J, Zhou D, Wang J (2020) Impact of lithium salts on the combustion characteristics of electrolyte under diverse pressures. Energies 13(20):5373. https://doi.org/10.3390/en13205373

Chuah K, Kuwana K, Saito K (2009) Modeling a fire whirl generated over a 5-cm-diameter methanol pool fire. Combust Flame 156(9):1828–1833. https://doi.org/10.1016/j.combustflame.2009.06.010

Chuah K, Kuwana K, Saito K, Williams F (2011) Inclined fire whirls. Proc Combust Inst 33(2):2417–2424. https://doi.org/10.1016/j.proci.2010.05.102

Hayashi Y, Kuwana K, Dobashi R (2011) Influence of vortex structure on fire whirl behavior. Fire Safety Science 10:671–679. https://doi.org/10.3801/IAFSS.FSS.10-671

Hartl K, Smits A (2022) The interaction of double burner fire whirls. Combust Flame 235:111679. https://doi.org/10.1016/j.combustflame.2021.111679

Yan Y, Fang X, Cheung S, Yan P, Tu J (2021) Characterisation and analysis on the instantaneous development and dynamic vortex cores of fire whirls in a fixed-frame facility. Int J Heat Mass Transf 175:121355. https://doi.org/10.1016/j.ijheatmasstransfer.2021.121355

Li S, Yao Q, Law C (2019) The bottom boundary-layer structure of fire whirls. Proc Combust Inst. https://doi.org/10.1016/j.proci.05.009

Yu H, Guo S, Peng M, Li Q, Ruan J, Wan W, Chen C (2013) Study on the influence of air-inlet width on fire whirls combustion characteristic. Procedia Engineering 62:813–820. https://doi.org/10.1016/j.proeng.2013.08.130

Sun P, Zhang X, Ding C, Huang X (2021) Effect of reduced pressure on the burning dynamics of fire whirls. Fire Saf J 125:103419. https://doi.org/10.1016/j.firesaf.2021.103419

Zukoski E (1985) Visible structure of buoyant diffusion flames. Symp Combust 20(1):361–366. https://doi.org/10.1016/S0082-0784(85)80522-1

Parente R, Pereira J, Pereira J (2019) On the influence of circulation on fire whirl height. Fire Saf J 106:146–154. https://doi.org/10.1016/j.firesaf.2019.03.010

Ma Q, Liu Q, Zhang H, Tian R, Ye J, Yang R (2017) Experimental study of the mass burning rate in n-heptane pool fire under dynamic pressure. Appl Therm Eng 113:1004–1010. https://doi.org/10.1016/j.applthermaleng.2016.11.108

Wei Y, Zhang J, Nadjai A, Beji T, Delichatsios M (2011) A global soot model developed for fires: validation in laminar flames and application in turbulent pool fires. Fire Saf J 46(7):371–387. https://doi.org/10.1016/j.firesaf.2011.06.004

Lautenberger C, Ris J, Dembsey N, Barnett J, Baum H (2005) A simplified model for soot formation and oxidation in cfd simulation of non-premixed hydrocarbon flames. Fire Saf J 40(2):141–176

Delichatsios M (1994) A phenomenological model for smoke-point and soot formation in laminar flames. Combust Sci Technol 100(1–6):283–298. https://doi.org/10.1080/00102209408935457

Most J, Mandin P, Chen J, Joulain P, Durox D, Fernande-Pello A (1996) Influence of gravity and pressure on pool fire-type diffusion flames. In Symp (Int) Combust 26(1):1311–1317. https://doi.org/10.1016/S0082-0784(96)80349-3

Huang Q, Lu S, Liu X, Zheng K, Xu D, Liu C (2021) Experimental thermal hazard investigation on carbonate electrolytes using a cone calorimeter. Case Stud Therm Eng. https://doi.org/10.1016/j.csite.2021.100912

Liu C, Zheng K, Zhou Y, Zhu K, Huang Q (2021) Experimental thermal hazard investigation of pressure and EC/PC/EMC mass ratio on electrolyte. Energies 14(9):2511. https://doi.org/10.3390/en14092511

Xu D, Huang G, Guo L, Chen Y, Ding C, Liu C (2022) Enhancement of catalytic combustion and thermolysis for treating polyethylene plastic waste. Adv Compos Mater 5(1):113–129. https://doi.org/10.1007/s42114-021-00317-x

Huang Q, Glazier S, Louli A, McArthur M, Liu C, Schrooten J, Dahn J (2020) Effects of graphite heat-treatment temperature on single-crystal Li[Ni5Mn3Co2]O2/graphite pouch cells. J Electrochem Soc 167(8). https://doi.org/10.1149/1945-7111/ab9381

Qin J, Liu C, Huang Q (2020) Simulation on fire emergency evacuation in special subway station based on Pathfinder. Case Stud Therm Eng 21

Wu N, Zhao B, Chen X, Hou C, Huang M, Alhadhrami A, Mersal G, Ibrahim M, Tian J (2022) Dielectric properties and electromagnetic simulation of molybdenum disulfide and ferric oxide-modified Ti3C2TX MXene hetero-structure for potential microwave absorption. Adv Compos Mater 5:1548–1556. https://doi.org/10.1007/s42114-022-00490-7

Chen Y, Lin J, Mersal G, Zuo J, Li J, Wang Q, Feng Y, Liu J, Liu Z, Wang B, Xu B, Guo Z (2022) “Several birds with one stone” strategy of pH/thermoresponsive flame-retardant/photothermal bactericidal oil-absorbing material for recovering complex spilled oil. J Mater Sci Technol 128:82–97. https://doi.org/10.1016/j.jmst.2022.05.002

Zhang D, Williams B, Santos V, Lofink B, Becher E, Partyka A, Peng X, Sun L (2020) Self-assembled intumescent flame retardant coatings: influence of pH on the flammability of cotton fabrics. Engi Sci 12:106–112. https://doi.org/10.30919/es8d1134

Zheng Z, Lin X, Yang M, He Z, Bao E, Zhang H, Tian Z (2020) Progress in the application of machine learning in combustion studies. ES Energ Environ 9:1–14. https://doi.org/10.30919/esee8c795

Liu C, Xu D, Weng J, Zhou S, Li W, Wan Y, Jiang S, Zhou D, Wang J, Huang Q (2020) Phase change materials application in battery thermal management system: a review. Materials 13(20):4622. https://doi.org/10.3390/ma13204622

Jing X, Li Y, Zhu J, Chang L, Maganti S, Naik N, Xu B, Murugadoss V, Huang M, Guo Z (2022) Improving thermal conductivity of polyethylene/polypropylene by styrene-ethylene-propylene-styrene wrapping hexagonal boron nitride at the phase interface. Adv Compos Hybrid Mater. https://doi.org/10.1007/s42114-022-00438-x

Huang Q, Chen H, Zheng K, Zhu K, Liu C (2021) Comparison of oxygen consumption calorimetry and thermochemistry theory on quantitative analysis of electrolyte combustion characteristics. Case Studies in Thermal Engineering. https://doi.org/10.1016/j.csite.2021.101085

Chu T, Gao Y, Yi L, Fan C, Yan L, Ding C, Liu C, Huang Q, Wang Z (2022) Highly fire-retardant optical wood enabled by transparent fireproof coatings. Adv Compos Hybrid Mater. https://doi.org/10.1007/s42114-022-00440-3

Yu Z, Yan Z, Zhang F, Wang J, Shao Q, Murugadoss V, Alhadhrami A, Mersal G, Ibrahim M, El-Bahy Z, Li Y, Huang M, Guo Z (2022) Waterborne acrylic resin co-modified by itaconic acid and γ-methacryloxypropyl triisopropoxidesilane for improved mechanical properties, thermal stability, and corrosion resistance. Prog Org Coat 168:106875. https://doi.org/10.1016/j.porgcoat.2022.106875

Huang Q, Yu S, Chen Y, Lu S, Lu Z, Liu C (2022) Study on the high temperature oxidation/nitridation behavior of Mg alloys AZ31, WE43 and ZE10. Case Stud Therm Eng. https://doi.org/10.1016/j.csite.2022.101759

Ouyang L, Huang W, Huang M, Qiu B (2022) Polyaniline improves granulation and stability of aerobic granular sludge. Adv Compos Hybrid Mater. https://doi.org/10.1007/s42114-022-00450-1

Gao S, Zhao X, Fu Q, Zhang T, Zhu J, Hou F, Ni J, Zhu C, Li T, Wang Y, Murugadoss V, Mersal G, Ibrahim M, El-Bahy Z, Huang M, Guo Z (2022) Highly transmitted silver nanowires-SWCNTs conductive flexible film by nested density structure and aluminum-doped zinc oxide capping layer for flexible amorphous silicon solar cells. J Mater Sci Technol 126:152–160. https://doi.org/10.1016/j.jmst.2022.03.012

Jing C, Zhang Y, Zheng J, Ge S, Lin J, Pan D, Naik N, Guo Z (2022) In-situ constructing visible light CdS/Cd-MOF photocatalyst with enhanced photodegradation of methylene blue. Particuology 69:111–122. https://doi.org/10.1016/j.partic.2021.11.013

Zhang Y, Zheng J, Nan J, Gai C, Shao Q, Murugadoss V, Maganti S, Naik N, Algadi H, Huang M, Xu B, Guo Z (2023) Influence of mass ratio and calcination temperature on physical and photoelectrochemical properties of ZnFe-layered double oxide/cobalt oxide heterojunction semiconductor for dye degradation applications. Particuology 74:141–155. https://doi.org/10.1016/j.partic.2022.05.010

Pan D, Yang G, Abo-Dief H, Dong J, Su F, Liu C, Li Y, Xu B, Murugadoss V, Naik N, El-Bahy S, El-Bahy Z, Huang M, Guo Z (2022) Vertically aligned silicon carbide nanowires/boron nitride cellulose aerogel networks enhanced thermal conductivity and electromagnetic absorbing of epoxy composites. Nano-Micro Lett 14:118. https://doi.org/10.1007/s40820-022-00863-z

He S, Huang Y, Chen G, Feng M, Dai H, Yuan B, Chen X (2019) Effect of heat treatment on hydrophobic silica aerogel. J Hazard Mater 362:294–302. https://doi.org/10.1016/j.jhazmat.2018.08.087

Meng X, Yang H, Lu Z, Liu Y (2022) Study on catalytic pyrolysis and combustion characteristics of waste cable sheath with crosslinked polyethylene. Adv Compos Hybrid Mater. https://doi.org/10.1007/s42114-022-00516-0

Weng J, He Y, Ouyang D, Yang X, Chen M, Cui S, Zhang G, Yuen R, Wang J (2021) Honeycomb-inspired design of a thermal management module and its mitigation effect on thermal runaway propagation. Appl Therm Eng 195:117147. https://doi.org/10.1016/j.applthermaleng.2021.117147

Shi G, He S, Chen G, Ruan C, Ma Y, Chen Q, Jin X, Liu X, He C, Du C, Dai H, Yang X (2022) Crayfish shell-based micro-mesoporous activated carbon: Insight into preparation and gaseous benzene adsorption mechanism. Chem Eng J 428:131148. https://doi.org/10.1016/j.cej.2021.131148

Ding C, Zhu N, Wang X, Alhadhrami A, Mahmoud M, Ibrahim M, Huang Q, Liu C, Huang M, Wang J (2022) Experimental study on the burning behaviors of 21700 lithium-ion batteries with high specific energy after different immersion duration. Adv Compos Hybrid Mater. https://doi.org/10.1007/s42114-022-00536-w

Weng J, Ouyang D, Liu Y, Chen M, Li Y, Huang X, Wang J (2021) Alleviation on battery thermal runaway propagation: Effects of oxygen level and dilution gas. J Power Sources 509:230340. https://doi.org/10.1016/j.jpowsour.2021.230340

He S, Chen G, Xiao H, Shi G, Ruan C, Ma Y, Dai H, Yuan B, Chen X, Yang X (2021) Facile preparation of N-doped activated carbon produced from rice husk for CO2 capture. J Colloid and Interf Sci 582:90–10. https://doi.org/10.1016/j.jcis.2020.08.021

Funding

This study has been sponsored by National Natural Science Foundation of China (No. 51906238 and No. 12202410), Anhui Province Outstanding Young Talents Support Program under No.gxyqZD2022058, and the Open Project Program of the State Key Laboratory of Fire Science (No. HZ2020-KF01). The authors extend their appreciation to the Deputyship for Research & Innovation, Ministry of Education in Saudi Arabia for funding this research work through the project number “IF_2020_NBU_307.” Also, this work was supported by the Science and Technology Plan Project Form of Anhui Province Housing and Urban–Rural Construction (No. 2020-SF06), the Project of Anhui Jianzhu University Talent Research Program and the Horizontal commission project (No. 2019QDZ21 and No. HYB20200068), Natural Science Foundation of Anhui Province (No. 2008085QE268), Research Project Supported by Shanxi Scholarship Council of China (No. 2022–139), Natural Science Foundation of Shanxi Province (No. 20210302123017), and Fund Program for the Scientific Activities of Selected Returned Overseas Professionals in Shanxi Province (No. 20220012). The authors gratefully acknowledge these supports.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ding, C., Yan, Z., Lan, Q. et al. Study on the effect of pressure on fire whirl combustion characteristics with different air-inlet widths. Adv Compos Hybrid Mater 5, 2642–2650 (2022). https://doi.org/10.1007/s42114-022-00553-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42114-022-00553-9