Abstract

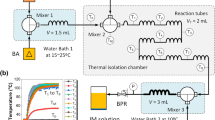

The Pinnick oxidation, due to its tolerance for sensitive functional groups, is widely used in the process of oxidizing α,β-unsaturated aldehydes to corresponding carboxylic acids. The reaction reagents typically include sodium chlorite, buffer salts, and a scavenger. However, the controllability of Pinnick oxidation in the batch reaction process is poor due to the inherent limitations of the reactor’s performance. This leads to potential safety risks and necessitates the reaction to proceed slowly under conditions of low temperature and low concentration. In this work, we introduced a new continuous micro-reaction process to intensify the Pinnick oxidation. The water-soluble crotonic acid was selected as a typical object of study. Through the study of reaction parameters and the construction of a micro-reaction system, efficient continuous process was achieved under high-temperature and high-pressure conditions for the first time. Compared to the batch process, the reaction benefited from the superheated condition resulting in a significant acceleration of the reaction rate, efficient gas–liquid interphase mass transfer allowing for effective utilization of the generated chlorine dioxide, and the inherent safety of the microreactor enabling an increase in reaction concentration. In addition, the buffer salts used in the Pinnick oxidation has been successfully replaced by hydrochloric acid and applied to the continuous flow. This work shows the tremendous potential of microreactors in utilizing harsh reaction conditions to achieve process intensification.

Graphical abstract

Article Highlights

-

A superheated micro-reaction process was introduced into the Pinnick oxidation to achieve efficient and safe preparation of crotonic acid.

-

Efficient gas–liquid interphase mass transfer in microreactor realized effective utilization of the by-product chlorine dioxide.

-

The great replacement of phosphate buffer salts with hydrochloric acid was achieved in continuous flow.

Similar content being viewed by others

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Krapcho AP (2006) Org Prep Proced Int 38:177–216. https://doi.org/10.1080/00304940609355988

Bal BS, Childers WE, Pinnick HW (1981) Tetrahedron 37:2091–2096. https://doi.org/10.1016/S0040-4020(01)97963-3

Lindgren BO, Nilsson T (1973) Acta Chem Scand 27:888–890. https://doi.org/10.3891/acta.chem.scand.27-0888

Mannam S, Sekar G (2008) Tetrahedron Lett 49:1083–1086. https://doi.org/10.1016/j.tetlet.2007.11.198

Kon Y, Imao D, Nakashima T, Sato K (2009) Chem Lett 38:430–431. https://doi.org/10.1246/cl.2009.430

Mahmood A, Robinson GE, Powell L (1999) Org Process Res Dev 3:363–364. https://doi.org/10.1021/op990021h

Hunsen M (2005) Synthesis 2005:2487–2490. https://doi.org/10.1055/s-2005-872085

Bowden K, Heilbron IM, Jones ERH, Weedon BCL (1946) J Chem Soc (Resumed): 39–45. https://doi.org/10.1039/JR9460000039

Travis BR, Sivakumar M, Hollist GO, Borhan B (2003) Org Lett 5:1031–1034. https://doi.org/10.1021/ol0340078

Baumeister T, Kitzler H, Obermaier K, Zikeli S, Röder T (2015) Org Process Res Dev 19:1576–1579. https://doi.org/10.1021/acs.oprd.5b00173

Liu K-J, Fu Y-L, Xie L-Y, Wu C, He W-B, Peng S, Wang Z, Bao W-H, Cao Z, Xu X, He W-M (2018) ACS Sustain Chem Eng 6:4916–4921. https://doi.org/10.1021/acssuschemeng.7b04400

Dai PF, Qu JP, Kang YB (2019) Org Lett 21:1393–1396. https://doi.org/10.1021/acs.orglett.9b00101

Tanaka S, Kon Y, Uesaka Y, Morioka R, Tamura M, Sato K (2016) Chem Lett 45:188–190. https://doi.org/10.1246/cl.151024

Fedevich OE, Levush SS, Fedevich EV, Kit YV (2003) Russ J Org Chem 39:29–32. https://doi.org/10.1023/A:1023482226774

Vanoye L, Abdelaal M, Grundhauser K, Guicheret B, Fongarland P, De Bellefon C, Favre-Reguillon A (2019) Org Lett 21:10134–10138. https://doi.org/10.1021/acs.orglett.9b04193

Vanoye L, Favre-Réguillon A (2022) Org Process Res Dev 26:335–346. https://doi.org/10.1021/acs.oprd.1c00399

Lehtinen C, Brunow G (2000) Org Process Res Dev 4:544–549. https://doi.org/10.1021/op000045k

Murakami K, Toma T, Fukuyama T, Yokoshima S (2020) Angew Chem Int Ed 59:6253–6257. https://doi.org/10.1002/anie.201916611

Ishihara J, Hagihara K, Chiba H, Ito K, Yanagisawa Y, Totani K (2000) Tadano K-i. Tetrahedron Lett 41:1771–1774. https://doi.org/10.1016/S0040-4039(00)00013-7

Kuramochi K, Nagata S, Itaya H (1999) Takao K-i, Kobayashi S. Tetrahedron Lett 40:7371–7374. https://doi.org/10.1016/S0040-4039(99)01512-9

Miyashita M, Sasaki M, Hattori I, Sakai M, Tanino K (2004) Science 305:495–499. https://doi.org/10.1126/science.1098851

Nicolaou KC, Edmonds DJ, Li A, Tria GS (2007) Angew Chem Int Ed 46:3942–3945. https://doi.org/10.1002/anie.200700586

Magauer T, Martin HJ, Mulzer J (2009) Angew Chem Int Ed 48:6032–6036. https://doi.org/10.1002/anie.200900522

Hussein AA, Al-Hadedi AAM, Mahrath AJ, Moustafa GAI, Almalki FA, Alqahtani A, Shityakov S, Algazally ME (2020) R Soc Open Sci 7:191568. https://doi.org/10.1098/rsos.191568

Dalcanale E, Montanari F (1986) J Org Chem 51:567–569. https://doi.org/10.1021/jo00354a037

Raach A, Reiser O (2000) J Prakt Chem 342:605–608. https://doi.org/10.1002/1521-3897(200006)342:6%3c605::Aid-prac605%3e3.3.Co;2-9

Hessel V, Kralisch D, Kockmann N, Noel T, Wang Q (2013) Chemsuschem 6:746–789. https://doi.org/10.1002/cssc.201200766

Hessel V, Cortese B, De Croon M (2011) Chem Eng Sci 66:1426–1448. https://doi.org/10.1016/j.ces.2010.08.018

Jensen KF, Reizman BJ, Newman SG (2014) Lab Chip 14:3206–3212. https://doi.org/10.1039/c4lc00330f

Jensen KF (2017) AIChE J 63:858–869. https://doi.org/10.1002/aic.15642

Nagao I, Ishizaka T, Kawanami H (2016) Green Chem 18:3494–3498. https://doi.org/10.1039/c6gc01195k

Razzaq T, Kappe CO (2010) Chem Asian J 5:1274–1289. https://doi.org/10.1002/asia.201000010

Shang M, Noël T, Su Y, Hessel V (2016) Ind Eng Chem Res 55:2669–2676. https://doi.org/10.1021/acs.iecr.5b04813

Huang J-P, Sang F-N, Luo G-S, Xu J-H (2017) Chem Eng Sci 173:507–513. https://doi.org/10.1016/j.ces.2017.08.020

Huang J, Geng Y, Wang Y, Xu J (2019) Ind Eng Chem Res 58:16389–16394. https://doi.org/10.1021/acs.iecr.9b02438

Phung Hai TA, Samoylov AA, Rajput BS, Burkart MD (2022) ACS Omega 7:15350–15358. https://doi.org/10.1021/acsomega.1c06823

Jin RY, Hu SQ, Zhang YH, Bo T (2008) Chin Chem Lett 19:1375–1378. https://doi.org/10.1016/j.cclet.2008.09.001

Boucher MM, Furigay MH, Quach PK, Brindle CS (2017) Org Process Res Dev 21:1394–1403. https://doi.org/10.1021/acs.oprd.7b00231

Acknowledgements

The authors gratefully acknowledge the support of the National Natural Science Foundation of

The supplementary China (22108264, 22378376) for this work.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding authors state that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Huang, J., Li, Y., Zhou, Y. et al. Efficient pinnick oxidation by a superheated micro-reaction process. J Flow Chem (2024). https://doi.org/10.1007/s41981-024-00324-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41981-024-00324-1