Abstract

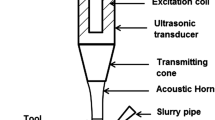

Ultrasonic machining is one of the hybrid machining processes which is gaining importance in the manufacturing of hard to cut materials particularly aerospace alloys. The success of ultrasonic machining will depend on the applied vibration parameters, viz. amplitude and frequency. In ultrasonic machining setup, the vibrations from the transducer are amplified and concentrated at desired location by the horn. The increment in amplitude reduces the tool work contact ratio (TWCR) and vice versa. Surface roughness, cutting forces, cutting temperatures and tool wear are affected by TWCR. Higher amplitude will reduce the TWCR and enhances the machining performance. Hence, proper design of the horn will enhance the amplification and therefore the machining efficiency. In this work, the influence of horn diameter ratio, horn profile, and length variation within the horn on deformation, amplification and effective stress are studied. Titanium is chosen as horn material. Horns of single exponential, double exponential and mixed horn profiles are studied through modeling and simulation using Finite Element Analysis (FEA). The tool end diameter of the horns is varied from 10 to 20 mm in steps of 2.5 mm for all the horn profiles. Further, double exponential and mixed horns are modeled and analyzed with three length variations in each case. All these are subjected to longitudinal vibrations along the axial direction with same amplitude and frequency. The analysis revealed that horns with lower diameter ratio are yielding high amplification. In addition, horns with double exponential profile with 5050 length variation and 10-mm tool end diameter, mixed horn with 2575 length variation and 10-mm tool end diameter are proved as best designs. The high amplification of horns at lower tool end diameters is attributed to their reduced strength because of reduced cross section. The stress concentration because of abrupt change in the cross section in case of double exponential and mixed horns also contributed to increase in effective stress.

Similar content being viewed by others

References

Amin SG, Youssef HA (1995) Computer-aided design of acoustic horns for ultrasonic machining using finite-element analysis. J Mater Process Technol 55:254–260

Brehl DE, Dow TA (2008) Review of vibration-assisted machining. Precis Eng 32(3):153–172. https://doi.org/10.1016/j.precisioneng.2007.08.003

Chandan GK, Sahoo CK (2021) Numerical analysis on a selection of horn material for the design of cylindrical horn in ultrasonic machining. In: Pandey KM, Misra RD, Patowari PK, Dixit US (eds) Recent advances in mechanical engineering. Singapore Singapore, Singapore, pp 127–136

Chhabra AD, Vinod Kumar R, Vundavilli PR, Surekha B (2016) Design and analysis of higher order exponential horn profiles for ultrasonic machining. J Manuf Sci Prod 16(1):13–19. https://doi.org/10.1515/jmsp-2015-0012

Chu NH, Ngo QH, Nguyen VD (2018) A step-by-step design of vibratory apparatus for ultrasonic-assisted drilling. Int J Adv Eng Res Appl 4 139–148

Halim NFHA, Ascroft H, Barnes S (2017) Analysis of Tool wear, cutting force, surface roughness and machining temperature during finishing operation of Ultrasonic Assisted Milling (UAM) of Carbon Fibre Reinforced Plastic (CFRP). Proc Eng 184:185–191. https://doi.org/10.1016/j.proeng.2017.04.084

He T, Ye XQ, Zhao Y (2015) Optimization design for ultrasonic horn with large amplitude based on genetic algorithm. J Vibroeng 17(3):1157–1168

Jagadish, & Ray, A. (2018) Design and performance analysis of ultrasonic horn with a longitudinally changing rectangular cross section for USM using finite element analysis. J Braz Soc Mech Sci Eng 40(7):1–11. https://doi.org/10.1007/s40430-018-1281-7

Kaul S, Joshi T, Gope PC (2018) Design and analysis of sonotrode for ultrasonic eye-punching process. Int J Mech Eng Technol 9(9):1276–1283

Kumar Patel L, Kumar Singh A, Sharma V, Kala P (2020) Analysis of a hybrid ultrasonic horn profile using finite element analysis. Mater Today Proc 41:772–779. https://doi.org/10.1016/j.matpr.2020.08.465

Lian H, Guo Z, Huang Z, Tang Y, Song J (2013) Experimental research of Al6061 on ultrasonic vibration assisted micro-milling. Procedia CIRP 6:561–564. https://doi.org/10.1016/j.procir.2013.03.056

Llanos I, Campa Á, Iturbe A, Arrazola PJ, Zelaieta O (2018) Experimental analysis of cutting force reduction during ultrasonic assisted turning of Ti6Al4V. Procedia-CIRP 77(Hpc):86–89. https://doi.org/10.1016/j.procir.2018.08.227

Moghaddas MA, Short MA, Wiley NR, Yi AY, Graff KF (2018) Performance of an ultrasonic-assisted drilling module. Int J Adv Manuf Technol 94(9–12):3019–3028. https://doi.org/10.1007/s00170-017-0495-7

Nath C, Rahman M (2008) Effect of machining parameters in ultrasonic vibration cutting. Int J Mach Tools Manuf 48(9):965–974. https://doi.org/10.1016/j.ijmachtools.2008.01.013

Nestler A, Schubert A (2014) Surface properties in ultrasonic vibration assisted turning of particle reinforced aluminium matrix composites. Proc CIRP 13:125–130. https://doi.org/10.1016/j.procir.2014.04.022

Nguyen HT, Nguyen HD, Uan JY, Wang DA (2014) A nonrational B-spline profiled horn with high displacement amplification for ultrasonic welding. Ultrasonics 54(8):2063–2071. https://doi.org/10.1016/j.ultras.2014.07.003

Roopa Rani M, Prakasan K, Rudramoorthy R (2015) Studies on thermo-elastic heating of horns used in ultrasonic plastic welding. Ultrasonics 55(1):123–132. https://doi.org/10.1016/j.ultras.2014.07.005

Roy S, Jagadish (2017) Design of a circular hollow ultrasonic horn for USM using finite element analysis. Int J Adv Manuf Technol 93(1–4):319–328. https://doi.org/10.1007/s00170-016-8985-6

Satpathy MP, Sahoo SK, Datta S (2016) Acoustic horn design and effects of process parameters on properties of dissimilar ultrasonic welding aluminum to brass. Mater Manuf Processes 31(3):283–290. https://doi.org/10.1080/10426914.2015.1048465

Shahid MB, Jung JY, Park DS (2020) Finite element analysis coupled artificial neural network approach to design the longitudinal-torsional mode ultrasonic welding horn. Int J Adv Manuf Technol 107(5–6):2731–2743. https://doi.org/10.1007/s00170-020-05200-5

Shakeeb Z, Sarraf A (2019) Design and analysis of ultrasonic horns operating in multiple vibration modes. J Inf Eng Appl 2(2):28–32. https://doi.org/10.7176/jiea/9-3-02

Singh DP, Mishra S, Porwal RK (2019) Modal analysis of ultrasonic horn using finite element method. Mater Today Proc 18:3617–3623. https://doi.org/10.1016/j.matpr.2019.07.293

Stănăşel I, Buidoş T, Blaga F (2014) Design and fem simulation of ultrasonic welding horn. Nonconventional Technologies Review/Revista de Tehnologii Neconventionale 18(1):51–55. Retrieved from http://www.ultrasonicresonators.org/misc/references/articles/Stanasel__'Design_and_FEM_Simulation_of_Ultrasonic_Welding_Horn'.pdf. Accessed 05 Feb 2020

Sui H, Zhang L, Wang S, Gu Z (2021) Theoretical and experimental investigation into the machining performance in axial ultrasonic vibration-assisted cutting of Ti6Al4V. Int J Adv Manuf Technol 116(1–2):449–472. https://doi.org/10.1007/s00170-021-07447-y

Tadvi M, Prajapati J, Pandey A, Shah J (2015) Design and development of sonotrode for ultrasonic drilling. In: ASME International Mechanical Engineering Congress and Exposition, Proceedings (IMECE), 2B-2015 (August 2016). https://doi.org/10.1115/IMECE2015-53023

Verma, G. C., & Pandey, P. M. (2019). Machining forces in ultrasonic-vibration assisted end milling. Ultrasonics, 94(June 2017), 350–363. https://doi.org/10.1016/j.ultras.2018.07.004

Vivekananda K, Arka GN, Sahoo SK (2014) Design and analysis of ultrasonic vibratory tool (UVT) using FEM, and experimental study on Ultrasonic Vibration-assisted turning (UAT). Procedia Engineering 97:1178–1186. https://doi.org/10.1016/j.proeng.2014.12.396

Wang DA, Nguyen HD (2014) A planar Bézier profiled horn for reducing penetration force in ultrasonic cutting. Ultrasonics 54(1):375–384. https://doi.org/10.1016/j.ultras.2013.05.002

Wang P, Wang D (2020) Evaluation of different tool geometries in the finite element simulation of ultrasonic-assisted drilling of Ti6A14V. J Braz Soc Mech Sci Eng 42(4):1–14. https://doi.org/10.1007/s40430-020-2266-x

Wei L, Wang D (2019) Comparative study on drilling effect between conventional drilling and ultrasonic-assisted drilling of Ti-6Al-4V/Al2024-T351 laminated material. Int J Adv Manuf Technol 103(1–4):141–152. https://doi.org/10.1007/s00170-019-03507-6

Xiang D, Shi Z, Feng H, Wu B, Zhang Z, Chen Y, Zhao B (2019) Finite element analysis of ultrasonic assisted milling of SiCp/Al composites. Int J Adv Manuf Technol 105(7–8):3477–3488. https://doi.org/10.1007/s00170-019-04542-z

Youssef HA, El-Hofy H (2008) Machining technology: Machine tools and operations. In: Machining technology: machine tools and operations. https://doi.org/10.5860/choice.46-0911

Zhao JT, Ning LP, Jiang ZM, Li YL (2021) Design and finite element analysis of longitudinal vibrating stepped ultrasonic horn. J Phys Conf Ser 2029(1):012056. https://doi.org/10.1088/1742-6596/2029/1/012056

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kartheek, G., Krishna, P.V. Design and analysis of different horn profiles using FEM for vibration assisted machining. Multiscale and Multidiscip. Model. Exp. and Des. 5, 135–155 (2022). https://doi.org/10.1007/s41939-021-00108-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41939-021-00108-3