Abstract

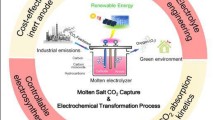

Electrochemical CO2 reduction technology could solve the CO2-induced climate warming by electrochemically converting atmospheric CO2 back into fuel, essentially recycling it and building a low carbon emission economy. However, the electrochemical CO2 reduction reaction (CO2RR) poses a significant challenge due to the highly stable and linear CO2 molecules, in addition to a proton-coupled multi-electron transfer process. Thus, highly active catalysts, placed on activity bolstering materials, and permeable electrodes are crucial for CO2RR. Single-atom catalysts (SACs) have recently garnered increasing interest in the electrocatalysis community due to their potentially high mass efficiency and cost benefits (every atom is an active center, resulting in nearly 100% utilization) and adjustable selectivity (higher uniformity of the active sites compared to nanoparticles). However, preserving the accessibility and activity of the SACs inside the electrode poses major materials development and electrode design challenges. A conventional layered structure SAC electrode typically consists of a gas diffusion layer (GDL), a microporous layer (MPL) and a SAC catalyst layer (SACCL), fabricated by using a powder bonding process. However, this process usually encounters issues such as delamination and instability of SACs due to the weak binder-catalyst-support interface. Conversely, the free-standing SAC electrode design has the potential to overcome these issues by eliminating the GDL, MPL, and need of a binder, in contrast to the powder bonding process. This work first reviews the latest developments in experimental and modeling studies of powdered SAC electrode by the traditional powder bonding process. Next, it examines the development towards the free-standing SAC electrode for high-performance electrochemical reduction of CO2. The synthesis-structure-fabrication-performance relationships of SAC-based materials and associated electrodes are analyzed. Furthermore, the article presents future challenges and perspectives for high-performance SAC electrodes for CO2RR.

Graphical Abstract

Similar content being viewed by others

1 Introduction

In the context of climate change, CO2 pollution is global, and electrochemical CO2 reduction technology offers a promising route for sustainable energy economy and low or zero carbon emissions. Significant technical progress has been made in recent years, demonstrating the commercial feasibility of the technology [1,2,3,4,5]. However, their large-scale application for the production of fuels has been seriously hindered by the lack of efficient and inexpensive electrocatalysts [6]. In just a decade, a new class of catalysts—the single-atom catalysts (SACs)—have seen an increasing interest in the electrocatalysis community due to the potentially high mass efficiency and cost benefits (every atom is an active center, thus nearly 100% utilization) and the higher uniformity of the active sites based on single atoms compared to nanoparticles. SAC possesses a well-defined and specific atomic structure that can offer high selectivity toward the adsorption/desorption of certain intermediates during the electrochemical reduction of CO2 [6,7,8,9,10]. Similar to molecular catalysts, SAC builds a conceptual bridge between heterogeneous and homogeneous catalysis and offers an opportunity to design and understand heterogeneous catalysis from a molecular perspective [11, 12]. The superior performance of SAC has been demonstrated for iron, cobalt and nickel atoms isolated as single atoms on nitrogen-doped carbons for oxygen reduction, hydrogen evolution and CO2 reduction reaction [13,14,15]. Concerning the development of the controlled synthesis design of SACs, significant progress has been made specifically in the development of strategies to achieve ultra-high metal loadings and to precisely control the atomically dispersed species [16, 17]. Table 1 shows recently developed SACs with their synthesis methods and the primary product of CO2 reduction with their stability. Recently, some research work has shown a greater focus on scalable routes to accelerate commercialization [18, 19]. Tool development for the characterization of SACs has led to state-of-the-art techniques such as aberration-corrected transmission electron microscopy imaging and X-ray absorption fine structure analysis [20, 21], which enable the verification and visualization of the presence of the single-atom as well as the local coordination environment. In addition, the difficulty in experimentally verifying the structures has also generated computational methods mainly based on density functional theory to support hypotheses for the observed reactivity.

While attention has been devoted so far to synthesis design, atomic-level structural and functional studies, little is understood about the relation between the SACs and the macroscopic setting (electrode structure and morphology) [7,8,9, 22, 23]. Electrodes in the system play a crucial role since CO2RR occurs on the gas-liquid-solid triple-phase boundaries on the surface of an electrode where the CO2 gas, the proton from the aqueous electrolyte solution and the solid catalyst may coexist. Therefore, it is critical to achieving high performance by controlling the structure and morphology of the electrode for high CO2 mass transfer, boosting high electronic and H+ conductivity and enabling large active surface area of the atomically dispersed species by architecture engineering designs. A conventional layered structure SAC electrode typically consists of a gas diffusion layer (GDL), a microporous layer (MPL) and a SAC catalyst layer (CL) [24]. The SAC layered structure electrode is usually fabricated by the powder bonding process which increases potential failures of delamination and instability of catalysts due to the weak binder-catalyst-support interface [25]. For example, most attempts to produce SACs have used powder or particle-like carbon supports; hence, polymer binders, such as Nafion, were employed to incorporate them into the catalyst layer. The binder and inactive support particles will, inevitably, cover a fraction of the catalysts’ active sites, rendering them inactive. The free-standing electrode design has the potential to overcome these issues, which is one of the motivations for writing this review paper. Here we define the free-standing electrodes as electrodes with an independent, separate component that can be detached from the assembly and still retains its structural integrity and mechanical strength. Therefore, the free-standing electrodes do not need additional GDLs and MPLs, which increase electrode performance and stability by avoiding additional interfaces, reducing the interface resistance and time-consuming fabrication processes. The free-standing electrode design will increase the overall efficiency by simply exposing more catalytic active sites, facilitating mass transport, charge transfer and electrical conductivity due to the interconnectedness of the structure, and enhancing mechanical stability due to the absence of a weak binder-catalyst-support interface. The challenge, however, is to devise free-standing designs that can efficiently maintain structural integrity and electrical continuity of the electrodes. Currently, the development of free-standing SACs electrodes is still in the early stages for electrochemical reduction of CO2 [26,27,28,29]. Preserving the accessibility and activity of the SACs inside the electrode remains the major materials development and electrode design challenges for the overall device performance improvement. The techniques considered for the development of free-standing SAC electrodes should generate high form factor nano-sized materials with very good control of morphology, continuous porous structure and high utilization, thus opening a path for producing and investigating free-standing electrodes designs. A successful technology should provide a technically simple, scalable and continuous process toward large-scale production of electrodes using SAC, not only for electrochemical CO2 reduction applications but also for a wide range of electrochemical energy storage and conversion applications—a technical gap also recognized by Mitchell et al. [8]. Figure 1 shows the specific activity of different-sized particles and catalytic performance of various electrodes for CO2 reduction.

This work reviews the most recent work in the areas of using SACs and their associated electrodes for electrochemical CO2 reduction applications, namely (1) approaches and strategies to the areas of design, synthesis and structure characterization of SACs; (2) powdered SAC electrode for electrochemical reduction of CO2, which includes the fabrication and structure characterization, structure-property relationship and DFT studies of electrochemical reduction of CO2; (3) electrode architecture engineering of the free-standing SAC electrode to improve the exposure of the active metal moieties and the mass transfer performance of the electrode. Specifically, this section provides a comprehensive review and analysis of the free-standing SAC synthesis method, support production, electrode chemistry, fabrication and manufacturing process.

2 Design, Synthesis and Structure Characterization of SACs

Many nanostructured catalysts have been used for the electrochemical reduction of CO2. Their size, shape, surface morphology and surface area play essential roles in catalytic activity, product selectivity and stability [59,60,61,62,63,64]. Studies show that the active sites of these nanostructured materials ultimately dominate the catalytic performance [64,65,66,67]. When the size of the nanostructured catalysts further reduces to the atomic level and disperses on the support surface, it must have a large surface area because of the full catalyst atom utilization, and each atom can act as an active site; hence their catalytic activity and selectivity could dramatically increase [68,69,70]. Many studies have focused on the development of SACs for the electrolysis of CO2 in the last decade. Among these, metal catalysts such as Fe, Mn, Ni, Co, Cu, Zn, Ag, Pd and Sn atoms dispersed on carbon support or embedded on metal foil/foam have widely been studied as SACs for electroreduction of CO2 [49, 71,72,73,74,75]. However, stabilizing the single atom on the substrate surface still remains a challenge because of the formation of atom clusters or nanoclusters by aggregation while further decreasing the size of nanoparticles [21, 76]. The metal single atoms are stabilized by different approaches to obtain active SACs, e.g., pyrolysis of well-mixed metal salts, nitrogen sources and carbon sources at high temperature, deriving metal-organic framework and anchoring metal ions on the defective carbon frame such as graphene [77]. Therefore, different methods have been used for the synthesis of SACs, including physical deposition, electrodeposition, chemical vapor deposition, mechanical ball-milling, photochemical reduction and thermal treatment [20, 78,79,80].

Transition metal-based nanostructured catalysts, such as Fe, Ni, Co and Cu, have been widely studied for the electrochemical reduction of CO2 due to their abundance and low cost [81,82,83]. Recent development has focused on transition metal-based SACs development as they are found to be highly efficient electrocatalysts for CO2 reduction [70, 77, 84]. Nitrogen-coordinated metal SACs have gained the most attention due to their stable M–N–C bond, and great effort has been employed in the development of such effective nitrogen-coordinated metal SACs [75, 84, 85]. Figure 2 shows various schemes of the synthesis of various metal SACs supported on the carbon matrix. Many useful strategies, including various types of heteroatoms or defects on carbon substrates, such as pyridine-type N, pyrrole-type N, edge and vacancy defects have been reported as useful anchor sites to stabilize metal single atoms [86,87,88,89,90,91]. The structure and nature of the carbon matrix play a crucial role in constructing the electronic structure of metal centers, leading to tunable catalytic activity. The fabrication of MNxCy usually requires a high-temperature treatment process of complex metal and nitrogen precursors as well as carbon-containing precursors such as metal-organic frameworks, functional carbon particles, carbon nanotubes and graphene. A zeolite imidazole framework (ZIF-8) is commonly used as a self-template to synthesize the MNxCy catalyst with homogeneous dispersion of M atoms in the carbon matrix [87, 92,93,94,95]. For example, Fig. 2A shows the synthesis of C-ZnxNiy ZIF-8, which is a coordinately unsaturated Ni-N site embedded within porous carbon. The Zn and Ni precursor solutions were mixed with 2-methyl imidazole (2-MeIm) to form ZnxNiy ZIF-8, followed by pyrolyzed at 900 to 1 000 °C under Ar to obtain the C-ZnxNiy ZIF-8. A wet impregnation process followed by pyrolysis was used to fabricate In SAC in a N-doped carbon matrix (In-SAs/NC) as shown in Fig. 2B. A mixture of a solution containing 2-MeIm, Zn(NO3)2 and In(acac)3 was used to prepare the In(acac)3@ZIF-8, which was heated at 950 °C for 3 h in an inert environment to form the In-SAs/NC. The ZIF-8 precursor was used to encapsulate and prevent the aggregation of In ions, which also provides the platform to form Inδ+-N4 atomic interface sites. Figure 2C describes the formation of a F-N-C SAC catalyst with a uniform dispersion of Fe atoms into the carbon phase. The process involves the synthesis of Fe-doped ZnO and growing ZIF-8 crystal simultaneously, followed by pyrolysis at a high temperature in an inert environment. The heat treatment sublimes the ZnO, and Zn acts as spacers to disperse Fe during the pyrolysis process, creating Fe-N-C. The scheme of Fig. 2D illustrates the synthetic process for this Ni SAC catalyst. Activated carbon blacks were homogeneously dispersed in water, followed by the addition of Ni2+ solution and stirred overnight. Subsequently, it was mixed with a certain amount of urea as the N source and annealed at 800 °C in Ar. The activated carbon black has a high adsorption capacity to metal ions due to its large surface area and the presence of defects as well as O-containing functional groups on the surface. Figure 2E shows the synthesis steps of the Ni SAC growing on CNTs. Typically, commercial MWCNTs containing Ni particles were homogeneously dispersed in water and coated with a layer of resorcinol, melamine and formaldehyde. Subsequently, the obtained dried powder was heated at 800 °C for 2 h in an Ar environment.

The synthesis of different SACs is illustrated schematically as follows: A The synthesis of C-ZnxNiy ZIF-8 is shown. Reproduced with permission from Ref. [86]. Copyright 2018, Royal Society of Chemistry. B The synthesis of In-SAs/NC is demonstrated. Reproduced with permission from Ref. [50]. Copyright 2020, Wiley-VCH. C Fe/Co-N-C is illustrated as another SAC. Reproduced with permission from Ref. [87]. Copyright 2018, American Chemical Society. D Ni-NCB is shown as a representative SAC. Reproduced with permission from Ref. [41]. Copyright 2019, Cell Press Publishing group. E NC-CNTs is also included in the schematic illustration. Reproduced with permission from Ref. [106]. Copyright 2020, Wiley-VCH

Structure, morphology, surface area, material density and active sites play critical roles in electrochemical properties. However, the single atoms (SAs) are isolated atoms and their electrochemical properties rely on the distribution throughout the support surface and also on the structure of that support material. Therefore, it is significantly important with the identification of isolated single atoms and confirmation of their distribution. Determining the structure and properties of SACs and identifying their active sites require many sophisticated characterization tools, such as aberration-corrected high-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM), scanning tunneling microscopy (STM), X-ray absorption spectroscopy (XAS), X-ray absorption near-edge spectroscopy (XANES) and X-ray absorption fine structure spectroscopy (XAFS). Moreover, X-ray photoelectron spectroscopy (XPS) and infrared spectroscopy (IR) are also used to support these sophisticated techniques to characterize SACs. Moreover, the density functional theory (DFT) calculation provides deep insight into the active sites and understanding of the reaction mechanisms. Direct imaging SACs on the support surface using both bright filed high-resolution transmission electron microscopy (HR-TEM) and HAADF-STEM modes can be used to verify the formation of isolated atoms [96]. For instance, Pan et al. synthesized Fe-SACs using the Fe-doped ZIF precursor for the electrochemical reduction of CO2 and identified the isolated catalytic site of Fe-N4 using HAADF-STEM (Fig. 3A) [87]. The Fe-N4 sites were found to be homogeneously dispersed and embedded throughout the carbon matrix located at the edge sites. Similarly, HAADF-STEM analysis revealed the absence of Cu nanoparticles and the presence of Cu single atoms in a CuN4−x-Cx SAC. The bright spots observed throughout the carbon matrix in Fig. 3C provide evidence for the formation of Cu single atoms [80]. In another study, the formation of Ni SAC on CNTs, developed by Liu and his coworkers for electrochemical reduction of CO2, was also initially identified through HAADF-STEM analysis which revealed homogeneously dispersed Ni single atoms with a mean size of 0.2 nm on CNTs (Fig. 3E) [97]. The presence of Ga atoms on Ga SACs was also confirmed by using aberration-corrected HAADF-STEM, which obtained an atomic phase image and highlighted the bright dots corresponding to single-dispersed gallium atoms on the catalyst (Fig. 3G) [71]. The uniform dispersion of Pd and Co atoms on the 2,6-DCP-CTF support at high concentrations in Pd-Co bimetallic SACs was demonstrated through aberration-corrected STEM analysis, which also revealed numerous neighboring dual-dots (Fig. 3I) [72]. Additionally, the presence of a large number of atomically dispersed Mn species in the Mn-NO/CNs catalyst was confirmed through aberration-corrected HAADF-STEM imaging, which displayed numerous isolated bright spots (Fig. 3K) [73]. The local atomic structure and coordination environment of the SACs can be determined by using the XAFS tool as its spectrum is very sensitive to the electronic structure and thereby has been widely used in both ex situ and in situ atomic structure and coordination environment analysis [28]. To determine the electronic and chemical structure of central metal SACs and quantify electron vacancy, XANES is utilized by analyzing the energy shift and peak intensity of the main X-ray absorption edge [98]. As demonstrated in Fig. 3B, the Fe K-edge XANES spectra verify the bonds of the Fe–SAC, revealing that the oxidation state of Fe-N-C is between + 2 and + 3, which is comparable to FeO and Fe2O3 standards. The local coordination number further can be determined by analyzing the L-edge XANES. The presence of a splitting peak at 708 eV indicates the octahedral structure of FeO6 and the absence of splitting peak suggests possible FeN4 coordination (Fig. 3B). The coordination structure of the Cu SAC was determined through XANES spectra analysis (Fig. 3D), which displayed similar spectra to Cu-N4, indicating a coordination number of four for the developed Cu SAC [80]. The Ni K-edge XANES spectra of the Ni SAC embedded on CNTs are presented in Fig. 3F, showing a similarity to that of Ni-TAPc, indicating that Ni has a + 2 oxidation state and D4h symmetry structure. Figure 3H displays the XANES spectra of Ga K-edge, which provides information about the oxidation state and coordination environment of the gallium atoms. The inset magnified image in Fig. 3H highlights that the adsorption edge of Ga elements in SACs is close to Ga2O3 with a + 3 valence state, pointing out that the oxidation state of the gallium atoms in the SACs is around + 3 [71]. Figure 3J shows the Pd K-edge XANES spectra of Pd1-Co1/CTF, along with corresponding references. The adsorption intensity of Pd in dual-atom Pd1-Co1 was higher than that of Pd foil and similar to that of PdO, demonstrating an average valence state of Pd close to Pd2+. The absorption edge position of Co in Pd1-Co1/CTF was located between CoO and Co3O4, suggesting that the valence state of Co species ranged between Co2+ and Co3+ [72]. XAFS analysis was conducted on Mn-NO/CNs to obtain insights into its coordination environment. The Mn K-edge XANES diagram of Mn-NO/CNs showed a distinct difference from the oxide diagrams of MnxOy and Mn foil (Fig. 3L), suggesting that the valence state of Mn in Mn-NO/CNs was greater than zero [73]. Operando XAFS can be used to investigate the dynamic structure of the SACs during the electrochemical reaction and provides a deep understanding of the reaction and working mechanism of active centers [99]. For example, Liu et al. synthesized Ni SAC for CO2 reduction and performed in situ XAFS during the electrochemical reaction [15]. The CO2-saturated KHCO3 solution shows 0.4 eV higher energy for Ni K-edge of low-valent Ni SACs (A-Ni-NG) compared to Ar-saturated KHCO3 solution at the open-circuit voltage and it went down to lower energy during the CO2 electrolysis, indicating the recovery of low-oxidation-state of Ni sites. However, the main peak in FT-EXAFS for Ni-N became longer during CO2 reduction at the applied potentials of − 0.7 V (vs. RHE), suggesting the larger and distorted Ni–N bond while adsorbing CO2 on Ni SA sites. According to their operando XAFS and theoretical calculations, the Ni (I) atomic center is monovalent with a d9 electronic configuration and determined as active sites for the activation of CO2 molecule and electrochemical reduction.

Characterization of various metal SACs. Fe-N4-C SAC: A HAADF-STEM image and B X-ray absorption near-edge spectroscopy (XANES) at the Fe K-edge. Reproduced with permission from Ref. [87]. Copyright 2018, American Chemical Society. Cu SAC: C HAADF-STEM image and D XANES spectra at Cu K-edge for as-synthesized Cu SACs. Reproduced with permission from Ref. [80]. Copyright 2022, Wiley-VCH. Ni-CNT-CC SAC: E HAADF-STEM imaging (with a scale bar of 5 nm) and F XANES at the Ni K-edge. The inset in (F) displays a Fourier transform of the EXAFS spectra. Reproduced with permission from Ref. [97]. Copyright 2020, Wiley-VCH. Ga-N3S-PC: G Atomic phase image and H Ga K-edge XANES spectra (the inset shows the absorption edges for Ga species). Reproduced with permission from Ref. [71]. Copyright 2023, Wiley-VCH. Pd1-Co1/CTF: I AC-STEM image and J Pd K-edge XANES spectra. Reproduced with permission from Ref. [72]. Copyright 2023, American Chemical Society. Mn-NO/CNs: K HAADF-STEM and L Mn K-edge XANES spectra. Reproduced with permission from Ref. [73]. Copyright 2022, Royal Society of Chemistry

3 Powder-Based SAC Electrode for Electrochemical Reduction of CO2

Various materials have been explored as electrodes for CO2 reduction, e.g., metals, oxides, alloys, metal complexes and carbon-based materials. Their nanostructured materials exhibit higher catalytic performance as they have a large surface area and more active sites. Recently, SACs have drawn wide attention to CO2 electrolysis and exhibited excellent electrocatalytic performances due to their maximum atomic utilization and having a special electronic structure. Most of these catalysts are in powder form and need to bind to support surfaces to make working electrodes [10, 15, 100]. Various polymer binders, such as nafion, polyvinylidene fluoride, styrene butadiene rubber, sodium carboxymethyl cellulose and others, have been used as binders to attach catalyst powders onto the electrode support surface.

3.1 Fabrication and Structure Characterization of Powder-Based SAC Electrode

Recently, many transition metal-based SACs have been explored as electrocatalysts for CO2 reduction [70, 77, 84]. Among these developed SACs, nitrogen-anchored metal atom sites (e.g., Fe, Co, Ni etc.) have been found as outstanding catalysts. Various effective methods have been employed for the preparation of these highly efficient SACs-based electrodes. For example, ZIF-8 is commonly used as a self-template to synthesize the F-N-C catalyst with homogeneous dispersion of Fe atoms in the carbon matrix [87, 92,93,94,95]. The synthesis process needs the Fe-doped ZnO preparation and growing ZIF-8 crystal simultaneously. Then pyrolysis occurred at a high temperature in the Ar environment, where ZnO sublimed and created Fe-N-C. In another work, Gu et al. have synthesized Fe-SAC with dispersed single-atom Fe sites in ZIF-8 through the pyrolysis of Fe-doped Zn-ZIF-8 at 900 °C under the N2 environment [92]. The prepared Fe-SAC was porous with an electrochemical double-layer surface area of 554 m2 g−1 and a Brunauer-Emmett-Teller surface area of 772 m2 g−1. Its porosity was determined by employing high-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM), as shown in Fig. 4A. The corresponding energy-dispersive X-ray spectroscopy (EDS) and EDS mapping showed the presence of Fe and homogeneous distributions of Fe and N atoms in the carbon matrix, respectively (Fig. 4B, C and E). The aberration-corrected HAADF-STEM image shows the bright spots with the size of ~ 0.2 nm and is uniformly dispersed in the carbon phase corresponding to Fe and Zn sites (Fig. 4D). As seen in Fig. 4F, the binding and edge energies are close to Fe2O3 and Fe3+-tetraphenylporphyrin-Cl (Fe3+TPPCl) determined by the Fe K-edge X-ray absorption near-edge structure spectrum, suggesting that the Fe ion was in the + 3 oxidation state in the synthesized Fe3+-N-C. Thus, Fe3+ was oxidized to Fe3+ during the pyrolysis and protons, or residual oxygens might be the oxidants that oxidized the carbon backbone of the ZIF-8 precursor. The k space and R space Fe K-edge extended X-ray absorption (EXAFS) fine structure confirmed the atomic dispersion of Fe sites in Fe3+-N-C, and the fitting of the spectrum suggested that the Fe center obtains a planar Fe-X4 (X = N or C) structure (Fig. 4, G and H). Nitrogen-coordinated Fe sites as Fe-N4 moieties in carbon-containing bulk- and edge-hosted coordination were also fabricated by using a similar synthesis approach reported by Shao’s group [95]. In their work, the atomic structure of Fe single atoms and their homogeneous dispersion were determined by using STEM-HAADF. X-ray absorption spectroscopic studies revealed that each Fe atom was coordinated with four N atoms, and the catalyst reserved its original shape. X-ray diffraction patterns revealed that it is partially graphitized carbon, and no metallic phases are observed. Moreover, Raman spectroscopy showed a disordered structure of the carbon phase for the synthesized Fe-N-C catalyst, which is similar to the N-C catalyst [87]. ZIF was also used as a precursor with other carbon materials, such as porous carbon, carbon nanotubes, graphene and graphene oxide, to synthesize Fe-N-C catalysts for CO2 reduction [93, 95, 101,102,103]. Wei and his coworkers developed Fe-N/P-C SAC supported on activated carbon black, showing that the Fe atom coordinated with both N and P atoms acted as an active site and uniformly dispersed throughout the carbon substrate [102]. Their synthesis steps involved a two-stage pyrolysis process at 400 and 800 °C in forming Fe–P and Fe–N coordination bonds supported by XRD, X-ray photoelectron spectrometry (XPS), HAADF-STEM and inductive coupled plasma mass spectrometry (ICP-MS) studies. Creating Fe–N and Fe–P bonds together as FeN3P moiety in the Fe single-atom catalyst could alter the electronic structure of the Fe atom, which may boost the catalytic activity for CO2 reduction. A different approach has been used by Chen et al. to synthesize porous carbon nanospheres containing high-density Fe-N-C active sites [105]. SiO2 was used as a template for developing carbon shells and acted as a microreactor to prevent the aggregation of Fe atoms during the formation of Fe-N-C in the pyrolysis step. Multi-walled carbon nanotubes (MWCNTs) combined with ZIFs were used to prepare Fe-N-C catalyst, where MWCNT could create mesoporosity and increase electrical conductivity for higher mass transport and reduce the overpotential for the reduction of CO2 to CO [95]. ZIF and MWCNTs were mixed with Zn and Fe precursors in methanol, and the obtained ZIF-Fe-CNT was pyrolyzed at 900 °C under the Ar. TEM analysis revealed that the networks of MWCNTs in ZIF-Fe-CNT covered by Fe-N-C and carboxylates on the MWCNTs induce site-specific nucleation. Pan et al. have used commercial MWCNTs to fabricate FeN4 sites anchored on CNT and graphene nanoribbon networks (Fe-N/CNT@GNR) as an effective electrocatalyst for CO2 reduction [103]. CNT was oxidized by H2O2 and KMnO4 mixture followed by pyrolysis at 900 °C in the presence of urea to obtain the atomically dispersed FeN4 moiety Fe-N/CNT@GNR. The Fe residues present in the commercial MWCNTs served as Fe sources to grow isolated FeN4 sites, the chemical unzipping incurred by oxidizing the CNT creates graphene nanoribbon (GNR) layers attached to the outer shell-wall of the CNTs and subsequent N doping by the thermal pyrolysis leads to the generation of FeN4 sites containing Fe-N/CNT@GNR. In the developed structure, the CNTs act as a fibrous backbone to anchor the GNRs, suppress their aggregation and thus reticulate a hierarchically mesoporous structure with a large electrochemical surface area. The monodispersed FeN4 centers supported on the CNT and GNR basal plane and edge sites in the mesoporous CNT@GNR architecture act as active and selective centers to enhance CO2 activation and suppress hydrogen evolution reaction. Graphene has also been taken into consideration to deposit SAC due to its unique electronic and physical properties. The FeN5 SAC was successfully synthesized through the pyrolysis of hemin and melamine molecules on N-doped graphene [93]. The aggregation of Fe atoms on graphene is suppressed due to the formation of cross-linking of hemin and melamine at high temperatures, resulting in the homogeneous dispersion of FeN5 sites. Moreover, melamine introduces the N-dopant into graphene because it is the main source of N, which is able to anchor the Fe atom to form a unique FeN5 active site. Furthermore, graphene increases the electrical conductivity, provides a high specific surface area with hierarchical porosity. A facile approach to synthesis Fe-SAC was demonstrated for Fe metal foam by the adsorption graphene oxide (GO) based on the dangling bond trapping method [101]. The Fe-SAC was synthesized by injection GO dispersion slurry into the Fe foam and then drying at room temperature under Ar. Subsequently, the Fe-GO was ultrasonicated in ethanol to separate the adsorbed layers to yield Fe SAs/GO. The oxygen-containing group on the GO surface is strongly attached with Fe atoms of Fe foam due to the charge transfer between Fe and O atoms, resulting in Feδ+ (0 < δ < 3) species, which could be an efficient electrocatalyst for CO2 reduction. HAADF-STEM, EDS elemental mapping and XANES analysis confirmed the uniform dispersion of Fe atoms rather than Fe nanoparticles or clusters on the surface of GO.

Structural characterization of Fe-SAC using various techniques. A HAADF-STEM image. B and C Corresponding EDS mappings of Fe and N in the red square region, respectively. D Aberration-corrected HAADF-STEM image. E EDS spectrum of the region enclosed by the red square. F Fe K-edge XANES spectra of Fe3+-N-C (black), Fe2O3 (blue), Fe3+TPPCl (green), FeO (pink) and Fe foil (orange); inset shows the enlargement of the main edges. G the k space Fe K-edge EXAFS spectra. H the R space Fe K-edge EXAFS spectra. The experimental data are shown in black, while the fitting curves are shown in red. Reproduced with permission from Ref. [92]. Copyright 2019, Science Publishing Group

Ni nanostructured materials are more highly active for hydrogen evolution reactions than the electrochemical reduction of CO2 due to the strong CO adsorption [32]. However, its electrochemical properties can significantly be turned into CO2 reduction application once modified into single atoms, such as the nitrogen-stabilized nickel single-atom matrix (Ni-N). The atomically dispersed Ni-N centers have unique properties compared to corresponding nanostructured and bulk materials. Various Ni-based single-atom catalysts have been successfully developed for electrochemical reduction of CO2, typically for CO generation, as they exhibit high faradaic efficiencies [97, 105]. For example, a Ni SAC with coordinatively unsaturated Ni-N active sites fabricated by pyrolyzing Ni-substituted ZIF-8 exhibited Faradaic efficiencies of 92.0%-98.0% for the electrochemical reduction of over a wide potential range [86]. The high-resolution HAADF-STEM image (Fig. 5A) shows the atomic dispersion of nickel species and no existence of Ni nanoparticles in C-ZnNi4 ZIF-8. The binding energies of the Ni 2p3/2 peak of the pyrolyzed products are found to be ~ 855.0 eV, which is greater than that of metallic Ni and lower than that of Ni2+ in NiPc (Fig. 5B), suggesting that the valence of Ni of pyrolyzed samples is between 0 and + 2. Figure 5C and D displays the Ni K-edge XANES and EXAFS of the synthesized C-ZnxNiy ZIF-8 and standard Ni foil and NiPc. The Ni absorption edge and main transition energies of C-ZnNi4 ZIF-8 and other studied materials are between those of Ni foil and NiPc, indicating an intermediate valence state of Ni. Fourier transformed EXAFS analysis also revealed the presence of Ni–N bonds in the pyrolysis products, indicating that the Ni atoms are atomically dispersed in the samples. The coordination numbers of the Ni atom of the synthesized materials fitted from EXAFS analysis revealed the coordinatively unsaturated state of the Ni species. The 2-MeIm was carbonized and most of the Zn was sublimed during pyrolysis, resulting in coordinated Ni with N atoms anchored into the carbon matrix and thus forming a homogenously dispersed and coordinatively unsaturated Ni SAC. Another simple and scalable method was used to synthesize Ni SACs supported on commercial carbon black as the efficient electrocatalyst for CO2 reduction [41]. The aberration-corrected HAADF-STEM image shows the homogeneously dispersed bright spot of the Ni atom on the entire carbon particles (Fig. 5E). Ni 2p XPS spectra of the synthesized Ni SAC catalysts are displayed in Fig. 5F, demonstrating that the binding energy of Ni 2p3/2 of the Ni single atom dispersed on carbon black is higher than the Ni0, indicating its positive oxidation state. XANES and EXAFS analysis indicated further that the oxidation state of Ni species in synthesized Ni SACs was higher than Ni foil and lower than NiO (Fig. 5G and H). Fan et al. have designed a scalable strategy to grow Ni SACs on CNT by in situ thermal diffusions with NiN3 moiety from the Ni nanoparticle in CNT [106]. Their developed Ni SAC exhibited a high FE, superb turnover frequencies and a large mass activity for the conversion of CO2 to CO. High-resolution HAADF-STEM shows the isolated Ni atoms as bright spots, indicating the formation of Ni single atoms on the wall of MWCNT (Fig. 5I). Figure 5J displays the XPS of the developed Ni SAC-CNT, showing the presence of N atom and its deconvolution of the high-resolution 1s XPS peak indicating four N configurations including pyridinic, pyrrolic, graphitic and oxidized N. However, there was no Ni XPS peak appeared, which could be the low concentration of Ni on the surface. The EXAFS of Ni K-edge determined the electronic structure of the synthesized Ni SAC-CNT and its chemical configuration (Fig. 5K and L). The Ni edge positions of Ni SAC-CNTs are consistent with those of Ni metal and NiO, suggesting that the average oxidation state of Ni is 0 to 2. A Ni-Ni pair and a Ni-N interaction was identified at 2.15 Å (1 Å = 1 × 10−10 m) and 1.40 Å, respectively. After fitting the EXAFS curves, the coordination number of Ni was found to be between two and three, confirming the formation of Ni single atoms after the treatments.

Characterization of various samples. For C-ZnNi4 ZIF-8: a high-magnification HAADF-STEM image (A), Ni 2p high-resolution XPS spectra (B), XANES spectra (C) and Fourier transformed EXAFS spectra of the Ni K-edge and corresponding reference samples (D). The solid line represents experimental data, while the dotted line represents fitting curves. Reproduced with permission from Ref. [86]. Copyright 2018, Royal Society of Chemistry. For Ni-NCB: an aberration-corrected HAADF-STEM image (E) with a scale bar of 2 nm, Ni 2p high-resolution XPS spectra (F), Ni K-edge XANES spectra (G) and Ni K-edge Fourier transformed EXAFS spectra in R space (H). Reproduced with permission from Ref. [41]. Copyright 2019, Cell Press Publishing group. For NC-CNTs: a high-resolution HAADF-STEM image (I), N 1s high-resolution XPS spectra (J), Ni K-edge XANES spectra (K) and Ni K-edge Fourier transformed EXAFS spectra in the R space of NC-CNTs (Ni) and CNTs in comparison to Ni metal foil (L). An inset is also included, showing the k2-weighted EXAFS in k space. Reproduced with permission from Ref. [106]. Copyright 2020, Wiley-VCH

Among various metal SACs (e.g., Fe-NC, Co-NC and Ni-NC), Zn SAC (Zn-NC) has also been studied for CO2 electrolysis. However, the number of Zn SACs developed in the literature is much less compared to other transition metal SACs. It is difficult to incorporate Zn atoms into the carbon matrix because Zn has a low boiling point (1 180 K) and easily evaporates during pyrolysis [105]. Therefore, various metal-doped Zn precursors are commonly used as templates to fabricate uniformly dispersed metal atoms in porous carbon structures. As Zn has fully occupied 3d10 configuration, the possibility of charge transfer might be low, resulting in the low catalytic activity of the developed Zn SAC. However, some studies still focused on the development of Zn SAC for the electrochemical reduction of CO2 and showed a significant improvement. For example, Daasbjerg and his coworkers developed N-containing low-valance Zn-based SACs (Znδ+-NC) using ZN-containing precursors by pyrolyzing at high temperatures under the nitrogen environment [36]. Figure 6A shows an aberration-corrected HAADF-STEM image of the developed Zn SAC with a homogeneous distribution of bright spots with through-plane pores, indicating the formation of Zn atoms throughout the carbon matrix. XPS was employed to study the chemical composition and oxidation states of the Zn using ZnII tetraphenylporphine (ZnTPP), showing the binding energy of Zn 2p3/2 in Znδ+-NC is 1 021.6 eV, which is lower than that of ZnTPP, indicating a low-valence Zn (< + 2) (Fig. 6B). A distinct Zn LMM peak was appeared at 990.0 eV of Znδ+-NC in Zn Auger LMM kinetic energy spectra (Fig. 6C), which is located between ZnTPP (987.8 eV) and Zn metal (992.0 eV), suggesting that the states of Zn higher than 0 and lower than + 2. Figure 6D shows the Zn K-edge spectrum taken from XANES with ZnTPP, ZnO and Zn foil serving as references to determine the electronic structure of the Znδ+-NC (Fig. 6D). The adsorption edge position of Znδ+-NC is comparatively low than that of ZnTPP but also found to be far away from that of Zn foil. The D4h symmetry fingerprint peak of Zn-N4 appears at 9 661.8 eV (which is similar to the ZnTPP spectrum) but disappears in Znδ+-NC, indicating a non-centrosymmetric Zn-N configuration. The DFT calculations suggest that Znδ+-NC has partially unsaturated Zn-N3 and Zn-N3-V sites, which favors the COOH* intermediate formation. The developed Zn SACs exhibit Faradaic efficiency (99%) for CO production at the overpotential of 310 mV from CO2 electrolysis. Zhu et al. have developed Zn single atom (coexistence with Co) on N-doped carbon as an efficient electrocatalyst for CO2 reduction with Faradaic efficiency of 93% for CO [107]. They have found that electronic interaction between Zn and Co atoms facilitated COOH* formation to boost CO generation during the electrolysis of CO2. Hao et al. have shown that the curvature of Zn-Nx sites can increase the electron density of the Zn 3d orbital, which can improve the catalytic performance for CO2 reduction [108].

Characterization of Zn SAC and Co SAC. Aberration-corrected HAADF-STEM image (A), XPS Zn 2p spectra (B), Zn Auger LMM kinetic energy Spectra (C) and Zn K-edge XANES with an enlarged near-edge pattern in the inset (D). Reproduced with permission from Ref. [36]. Copyright 2021, Wiley-VCH. Co K-edge XANES spectra (E), Fourier transformed k3-weighted χ(k) function of the EXAFS spectra for Co1-N4, Co1-N4−x-Cx, CoO, Co3O4 and Co foil (F). EXAFS spectra for Co1-N4 with an atomic structure shown in the inset, where gray, yellow and green spheres represent C, N and Co atoms, respectively (G). WT of the Co K-edge for Co1-N4−xCx and Co1-N4 (H). Reproduced with permission from Ref. [109]. Copyright 2019, Elsevier

Various Co SACs have been explored for HER and studies show that Co SACs dispersed on N-doped graphene exhibited higher catalytic activity than those dispersed on graphene for HER [14]. Recent studies also explored Co SACs for electrochemical reduction of CO2 [35, 109]. Pan et al. synthesized atomically dispersed Co sites anchored on polymer-derived hollow N-doped porous carbon spheres as electrocatalysts for CO2 reduction, which shows almost 100% FE for CO generation at − 0.73 V [35]. Another work adopted MOF assisting with pyrolysis at a high temperature to synthesize Co SACs with N4 and N4/C coordinated on N-doped carbon for CO2 reduction [109]. The coordination of the Co with N and N/C plays an important role in the CO2 reduction activity, such as Co1-N4 that exhibited higher performance than the Co1-N4/C. Figure 6E compares the XANES spectra at the Co K-edge of various Co SACs dispersed on N-doped carbon. The synthesized Co1-N4 showed a higher energy absorption threshold value than that of Co foil and it was found to be in between CoO and Co3O4, suggesting the oxidation states of Co is + 2 or + 3. The higher energy absorption threshold value of Co1-N4−x-Cx was much closer to Co1-N4, indicating a similar valance state of Co in both compounds. As shown in Fig. 6F, the main peak of Co1-N4 and Co1-N4−x-Cx of the Fourier transformed k3-weighted χ(k) function of the EXAFS spectra appeared at 1.35 Å and no Co-Co path at 2.16 Å was observed, ascribing to the Co-N/Co-C coordination peak and confirming the formation of the single atoms with homogenous dispersion. The EXAFS fitting further shows that the coordination number of Co is four in both Co1-N4 and Co1-N4−x-Cx (Fig. 6G). The radial distance and k space resolution of both Co-coordinated compounds were determined by EXAFS wavelet transform (WT). The WT contour was maximum at 4.3 Å−1 for Co1-N4 and 4.0 Å−1 for Co1-N4−x-Cx, confirming the presence of the Co–N–C bond (Fig. 6H). The higher contour maximum of 0.3 Å−1 at Co1-N4 suggests the existence of a shorter Co-C path. The XAFS studies suggest that Co-N coordination turned into Co-C coordination for Co1-N4−x-Cx under the high pyrolysis temperature. The variation of the coordination state of Co with N and N/C of the Co SACs influences their catalytic activity during the electrolysis of CO2.

3.2 Electrochemical Reduction of CO2 on Powder-Based SAC Electrode and Structure-Property Relationship

CO2 is a fully oxidized inert molecule and thermodynamically very stable. The electrochemical conversion of CO2 into other molecules is a complicated process, which involves multiple electrons and proton transfer processes [110,111,112]. Carbon monoxide (CO), formic acid (HCOOH), acetic acid (CH3COOH), methanol (CH3OH), ethanol (CH3CH2OH), methane (CH4) and ethylene (C2H4) are the common products of CO2 reduction. The formation of these molecules involves two- to twelve-electron reaction pathways and requires high energy to activate CO2. The selectivity of the products from the CO2 reduction reaction primarily depends on the nature of the catalysts, applied electrode potential and properties of the electrolyte [113,114,115]. Various metal and carbon-based nanostructured catalysts have been evaluated for CO2 reduction over the past few decades and the search for efficient catalysts for CO2 conversion at low overpotential with high selectivity and stability is ongoing. SACs are embedded into a support matrix having unsaturated coordination configurations that allow the binding of reaction intermediates and facilitate catalytic reactions. The structure of the SAC, in terms of oxidation states and coordination numbers, plays a crucial role in catalytic activity. Table 2 summarizes the electrocatalytic performance of recently reported SACs in the literature for CO2 reduction to value-added products. For example, Fe-SAC (Fe3+-N-C), developed by Hu and coworkers, showed excellent catalytic performance for the conversion of CO2 to CO in both H-cell and gas diffusion electrode (GDE) cells [92]. Figure 7A and B shows the Faradaic efficiencies (FE) and CO current density for this catalyst, respectively. CO was detected at an overpotential of 80 mV and the FE was exhibited higher than 80% at the applied potential between − 0.2 and − 0.5 V (vs. RHE). The synthesized catalyst generated 20 mA cm−2 for CO at − 0.47 V (vs. RHE) in an H-cell, whereas 94 mA cm−2 current for CO at − 0.45 V (vs. RHE) with FE higher than 90% while it was conducted in GDE using 0.5 M (1 M = 1 mol L−1) KHCO3. The lower current density for CO in the H-cell indicated the limited mass transport of CO2 during the electrolysis. The performance of CO2 reduction of Fe-SAC depends on the state of the Fe atom in the carbon matrix. Figure 7C and D shows the operando XAS characterization of the Fe-SACs at different applied potentials for the electrochemical reduction of CO2 in a CO2-saturated 0.5 M KHCO3 solution [92]. The Fe3+-N-C and Fe2+-N-C loaded glassy carbon electrodes were tested at open-circuit potential and the potential between − 0.1 and − 0.6 V vs. RHE. Fe K-edge spectra were recorded at all these potentials as well as their dry samples and compared with Fe3+TPPCl, Fe2O3, Fe foil and FeO. The activity of Fe3+-N-C was satisfied at − 0.5 V versus RHE; however, the catalyst became unstable, further increasing the cathode potentials. The Fe K-edge shift remains the same for dry samples and at − 0.4 V, which is similar to Fe K-edge of Fe3+TPPCl, suggesting that the oxidation state of Fe atom in Fe3+-N-C did not change during the reduction of CO2. However, the Fe K-edge moved to lower energies while further increasing the cathode potential to − 0.5 V and higher, which is close to that of FeO, indicating the Fe3+ ion of Fe3+-N-C reduced to Fe2+ during the CO2 electroreduction. The spectroscopic data suggest that Fe3+-N-C and Fe2+-N-C comprise pyrrolic N ligands and pyridinic N ligands, respectively. The pyridinic N ligands may stabilize Fe2+ compared to Fe3+, whereas the pyrrolic N ligands have the opposite effect. Hence, the oxidation state of the Fe atom and its coordination bond play vital roles in the electrocatalysis of CO2.

Product analysis and Operando XAS Characterization of CO2 reduction at the Fe-SAC. A Faradaic efficiency of CO (solid lines) and H2 (dashed lines). B Partial current density of CO and H2 in an H-cell and on a GDE. Operando XAS characterization of Fe-SAC at different electrode potentials, including Fe K-edge XANES spectra (left column) and the first derivative of the spectra (right column). C Fe3+-N-C and D Fe2+-N-C as a dry powder (black) and loaded on glassy carbon electrodes at various applied potentials versus RHE. Reproduced with permission from Ref. [92]. Copyright 2019, Science Publishing Group

SACs often contain mixed structures and coordination numbers due to the lack of a precise synthesis method, which highly hinders a proper exploration of the CO2 reduction reaction mechanism, and suppresses the development of high-performance catalysts for CO2 reduction. Liu et al. have synthesized Ni SAC with a precise structure and well-defined Ni-N4 site supported on CNT by linking Ni-TAPc to CNT through C-C coupling for the electrochemical reduction of CO2 [97]. Their developed Ni SAC exhibited excellent performance with a CO2-to-CO Faradaic efficiency of 99% and in situ spectroscopy studies revealed that Ni+ in the Ni SAC was very active for CO2 activation. As shown in Fig. 8A, the Faradaic efficiency is over 90% at all the applied potentials, indicating that the developed Ni SAC is highly stable for CO2 reduction. The transformation of the electronic state Ni atom in Ni SAC was investigated by using operando XAS during the CO2 reduction process. Figure 8B and C describes the Ni K-edge XANES spectra at various cathodic potentials in Ar-saturated and CO2-saturated KHCO3 solutions, respectively. The Ni K-edge of Ni SAC shifted to lower energy of 0.3 eV when potential is increased in the Ar-saturated solution (Fig. 8B inset), indicating the reduction of N2+ to Ni+. However, there is no Ni K-edge shift observed in CO2-saturated solution (Fig. 8C inset) under a similar cathodic bias, suggesting that the Ni center in Ni SAC maintained a + 2 oxidation state and remained stable during the CO2 conversion process. Based on the operando XAS results, in the CO2 environment, the in situ formed Ni+ center would activate CO2 by donating its lone pair electrons. Pan et al. have reported on Co SAC, atomically dispersed Co sites anchored on hollow N-doped porous carbon spheres with abundant coordination N sites (Co-N5/HNPCSs), which exhibited excellent performance for the reduction of CO2 to CO with FE of over 90% over a wide potential range (from − 0.75 to − 0.88 V vs. RHE) [35]. The current density for CO2 reduction of the synthesized Co-N5/HNPCSs was 15.5 times higher compared to the pure CoPc as shown in Fig. 8D, indicating that the Co-N5 active site plays a crucial role in the excellent catalytic activity. In CO2 electroreduction, reaction pathways depend on the metal catalytic sites, leading to a deference in FE. For example, M-N5 sites (M = Fe, Ni, Cu, Co) are dispersed on the same HNPCSs support to probe the effect of metal active sites on electrocatalytic activity. Figure 8E displays the FE of CO from CO2 reduction, showing that Co-N5/HNPCSs possessed higher FE compared to Fe-N5/HNPCSs, Ni-N5/HNPCSs and Cu-N5/HNPCSs catalysts, indicating the vital role of Co sites in CO2 reduction activity. The electronic structure of the metal sites also plays an important role in the selective reduction of CO2. As seen in Fig. 8F, the Co K-edge XANES peaks, recorded at potential from − 0.66 to − 0.79 V during CO2 electrolysis, appeared at higher energy than that of the ex situ state, suggesting a higher oxidation state of Co. However, Co K-edge has significantly shifted when 0.88 V is applied and FE of CO is also decreased at this potential, suggesting that the electronic structure of metal sites is also important for the electrochemical reduction of CO2. Shang et al. have designed In SAC with Inδ+-N4 atomic interface moieties on MOFs derived N-doped carbon matrix (In-SAC/NC), which served as a highly efficient electrocatalyst for electrochemical reduction of CO2 to formate [50]. Figure 8G compares the FE and turnover frequency (TOF) for HCOO− production at various potentials of In-SAC/NC, In-NP/NC and NC. The In-SAC/NC attained FEHCOOH− over 85% in the potential between − 0.65 and − 0.95 V (vs. RHE) and exhibited over 12 500 h−1 TOF at − 0.95 V, suggesting superb catalytic activity of In-SAs/NC owing to the exclusive Inδ+-N4 atomic active sites. In situ XAFS was performed at the different potential of In-SAC/NC to evaluate its chemical and atomic structure during CO2 reduction. The In K-edge peak of In-SAs/NC appeared to have higher energy in the CO2-saturated 0.5 M KHCO3 solution (Fig. 8H), indicating a higher oxidation state of the In sites, suggesting the formation of CO2δ− species due to a charge transfer from low-valent Inδ+ to CO2 molecule. However, the In K-edge shifted back to lower energy during CO2 reduction at − 0.65 V, indicating the high activation ability of Inδ+-N4 sites for CO2 electroreduction. As seen in Fig. 8I, the main peak of FT-EXAFS was shifted to a lower bond length of around 0.02 Å at − 0.65 V and EXAFS fitting showed that the In–N bond length was much shorter when no potential was applied, suggesting that the shorter bond length of Inδ+–N4 sites plays a critical role for high catalytic activity and selectivity for CO2 reduction.

A Current density and CO FE (symbol) at various applied electrode potentials on Ni SAC. Ni K-edge XANES spectra of Ni-CNT-CC in 0.5 M KHCO3 aqueous solution under B Ar (1 atm, 1 atm = 101 325 Pa) and C CO2 (1 atm) atmospheres, recorded at different applied potentials; inset shows enlarged Ni K-edge XANES. The OCP is ~ 0.57 V versus RHE. The CO2 line in (C) was obtained 5 min after switching Ar to CO2 at 0.2 V versus RHE. Reproduced with permission from Ref. [97]. Copyright 2020, Wiley-VCH. D LSV curves of different Co catalysts in CO2 saturated 0.5 M KHCO3 solution. FECO and \({\mathrm{FE}}_{{\mathrm{H}}_{2}}\) of E M-N5/HNPCSs (M = Co, Fe, Ni, Cu). F XANES of Co-N5/HNPCSs catalyst under ex situ and in situ conditions (inset shows the magnified image). Reproduced with permission from Ref. [35]. Copyright 2018, American Chemical Society. G FEs and TOF of HCOO− at different potentials of In SAC, In nanoparticles and N-doped carbon catalysts. (H) XANES and (I) FT-EXAFS of In-SAs/NC with and without applied voltage. Reproduced with permission from Ref. [50]. Copyright 2020, Wiley-VCH

Using a straightforward one-step synthesis method, Dong et al. covalently integrated Mn-N2O2 sites into carbon nanosheets to develop a low MN-content single-atom catalyst (SAC), referred to as Mn-NO/CNs [73]. They found that the Mn-NO/CN catalyst showed impressive electrocatalytic performance for the CO2 reduction reaction. In Fig. 9A, it is demonstrated that the current density in the CO2-saturated electrolyte was significantly higher for the Mn-NO/CN catalyst than for the Mn-metal containing Mn-NO/CN catalyst, but not for the Ar-saturated electrolyte. They also measured the CO2 reduction performance of the Mn-NO/CN catalysts Mn-NO/CNs-900 and Mn-NO/CNs-1100 and observed that the current density in the CO2 atmosphere was higher than that in the Ar atmosphere, indicating their CO2 reduction activity. Figure 9B shows that the MN-containing SAC released only CO as the CO2 reduction product, demonstrating superior CO2 reduction performance compared to the NO/CN catalyst. At a cathode potential of − 0.46 V (V vs. RHE), the maximum faradaic efficiency (FE) of CO reached 96.0%. Figure 9C reveals that the Tafel slope of Mn-NO/CNs was lower than those of the NO/CNs, Mn-NO/CNs-900 and Mn-NO/CNs-1100 catalysts. The Tafel slope of the Mn-NO/CN catalyst was closer to the theoretical value of 59 mV dec−1 for the rate-limiting step, indicating faster kinetics for the transfer of the first electron to adsorbed CO2 species at Mn-NO/CN. Li et al. synthesized a Ni SAC with a hierarchical hollow structure (Ni/HH) that showed a larger current density in CO2-saturated electrolytes than in Ar-saturated ones (Fig. 9D) [88]. Ni/HH achieved a maximum FECO of 97.9%, higher than other Ni SACs (Fig. 9E). In situ ATR-SEIRAS measurements indicated that Ni/HH facilitated the formation of the rate-determining intermediate *COOH (Fig. 9F). The special hierarchical porous structure of Ni/HH increased the number and accessibility of active sites, facilitated mass and charge transfer for enhanced kinetics and enhanced overall CO2 reduction reaction performance. Zhang et al. discovered that downsizing the active center of gallium (Ga) to the atomic level results in SACs with unique properties [71]. Ga SACs with P, S atomic coordination environment showed higher CO formation ability than traditional gallium oxide (Fig. 9G). The Ga-N3S-PC structure achieved a CO Faradaic efficiency of 92% at − 0.3 V versus RHE, which was better than the Ga-N4 structure (Fig. 9H). By modulating the coordination environment through polymer-coating, they could improve CO formation and restrict the HER side reaction. Through in situ FTIR test, AIMD and DFT calculation, they explored the catalytic intermediate of SAC and constructed the probable structure model of the best Ga-N3SPC catalyst (Fig. 9I). The Ga-N3S-PC structure is flexible, and the Ga–S and Ga–P bonds are constantly reconfigured and adjusted during the catalytic process, reducing the adsorption activation energy of *COOH species, thus promoting the formation of CO products.

Electrocatalystic activity of Mn-NO/CN and NO/CN for CO2 reduction: A LSV curve, B FE of CO and C Tafel slopes. Reproduced with permission from Ref. [72]. Copyright 2022, Royal Society of Chemistry. CO2 reduction activity of Ni SACs: D FE of CO, E proposed reaction pathway to CO on the Ni-N4 active site, and F in situ ATR-SEIRAS spectra at various applied potentials (purple, blue, gray, silver, red lines represent Ni, N, C, O and H atoms, respectively). Reproduced with permission from Ref. [88]. Copyright 2023, Royal Society of Chemistry. CO2 reduction performance of Ga SACs: G LSV curves, H FE of CO, and I in situ FTIR spectra during CO2 electrolysis. Reproduced with permission from Ref. [71]. Copyright 2023, Wiley-VCH

3.3 DFT Studies of Electrochemical Reduction of CO2 on Powder-Based SAC Electrode

Metal SACs are dispersed on various carbon supports, such as graphene, carbon nanotubes and porous carbon. These carbon supports possess high electrical conductivity and large surface area, which facilitates high active catalyst loading and uniform distribution metal atoms (Co, Ni, Fe, Zn and Cu) usually bind weakly to the carbon atoms of the carbon substrate, which can be easily aggregated or separated from the substrate during the electrochemical reaction. Therefore, metal atoms need to chemically bond to the substrate to be stable. The stabilization of metal atoms is often achieved via binding with the defect sites or forming coordination bonds with the heteroatoms on the carbon substrate, such as N, O, P and S. The geometric and electronic structures of the metal active sites depend on the nature of the coordination atoms and coordination numbers. For example, interactions between the metal atom and CO2 molecule and reaction intermediates can vary by the strong or weak coordination bond of the metal atom with the heteroatom on the carbon substrate. Decreasing the coordination number can increase the interaction between CO2 and metal atoms [34, 158]. Density functional theory (DFT) calculation can provide an understanding of the role of active sites, coordination bonds and coordination numbers for high catalytic performance. Fe-based SACs have widely been studied for CO2 electroreduction. Various synthesis approaches were been used to develop these catalysts and N-doped carbon surfaces were mainly chosen to disperse Fe atoms, where N forms coordination bonds with Fe as Fe–N4 and Fe–N3 [85, 87, 93, 102,103,104]. The coordination numbers and electronic structures of these active sites play vital roles in catalytic performance. Zhang et al. have reported on Fe-SACs/N-graphene for electrochemical reduction of CO2, where Fe single atoms were homogeneously dispersed on N-doped graphene support and Fe-N4 and Fe-N5 played as the active sites for CO2 reduction [93]. According to the experimental results, the Fe-N5 active site containing Fe-SACs/N-graphene achieved the highest CO FE of 97.0% at − 0.46 V (vs. RHE), whereas the Fe-N4 active site containing Fe-SACs/N-graphene exhibited ~ 55% CO FE. DFT calculation suggested that Fe-N5 has the lowest free energy pathway for CO2 to CO reduction compared to Fe-N4. The main step is CO2 → *COOH at the FeN5 and *CO desorption at the FeN4 catalyst for CO production. The free energy change for CO2 → *COOH is 0.77 eV over Fe-N5, whereas Fe-N4 has a much higher free energy change for the key step (1.35 eV for *CO → CO+ *), therefore Fe-N5 catalysts possessed excellent catalytic performance for the CO2 to CO conversion. Li et al. have successfully fabricated a Fe-N/P-C catalyst that contains FeN4P moiety, which plays the main role in CO2 reduction to CO [102]. The Fe atom was coordinated with N and P atoms forming Fe-N3/P as active sites, which were highly dispersed on the activated carbon. The Fe-N/P-C catalyst exhibited excellent catalytic activity at 0.34 V (vs. RHE) with CO FE of 98% and maintained over 90% CO FE in the potential window between − 0.40 to − 0.70 V in an H-type cell. Moreover, it showed outstanding long-term electrochemical stability, remaining > 96% FE of CO at − 0.45 V after 24 h electrolysis. The high performance of the Fe-N/P-C catalyst for CO2 reduction was evaluated by the DFT calculations as shown in Fig. 10. The DFT studies revealed that the incorporation of P into the Fe-N-C catalyst reduced the energy barrier for forming COOH*, which is one of the key steps for CO2 reduction [45, 159]. It has proven by calculating energy barriers and reaction pathways for the conversion of CO2 to CO using Fe-N4-C, Fe-N3/P-C, Fe-N4/P-C and Fe-N4/Vac-P-C configurations. The free energies for the protonation of the CO2 to *COOH step for Fe-N4-C, Fe-N3/P-C, Fe-N4/P-C and Fe-N4-Vac-P-C are 0.63, 0.63, 0.48 and 0.62 eV, respectively, suggesting that the potential-limiting step is the formation of *COOH during the CO2 reduction reaction process and Fe-N4/P-C exhibited lower free energy of formation of *COOH compared to other three single-Fe-atom configurations (Fig. 10A). Furthermore, the CO2 adsorption energies were calculated to be − 0.17, − 0.20, − 0.20 and − 0.17 eV for Fe-N4-C, Fe-N3/P-C, Fe-N4/P-C and Fe-N4-Vac-P-C, respectively, suggesting that the formation of *COOH is limited by the low adsorption energy of CO2. Desorption of *CO from the catalyst surface can also influence the CO2 reduction reaction process. The energy barriers of the *CO → CO step were calculated to be 1.09, 1.05, 0.81 and 0.96 eV over Fe-N4-C, Fe-N3/P-C, Fe-N4/P-C and Fe-N4-Vac-P-C, respectively, suggesting that the Fe-N4/P-C configuration obtains the lowest energy barrier. The adsorption energy of CO was also determined to be − 1.68 eV, − 1.61, − 1.39 and − 1.55 eV for Fe-N4-C, Fe-N3/P-C, Fe-N4/P-C and Fe-N4-Vac-P-C, respectively, suggesting that it is unfavorable for desorption of the *CO intermediate on the catalyst surface. As HER is the primary competitive reaction during CO2 electrolysis in an aqueous solution, the Gibbs free energy barrier of hydrogen adsorption is also estimated for each configuration as shown in Fig. 10B. The energy barrier was calculated to be 0.24 eV for Fe-N4/P-C, 0.27 eV for Fe-N4-C, 0.48 eV for Fe-N3/P-C and 0.37 eV for Fe-N4-Vac-P-C, indicating that the HER is largely limited on the Fe-N3/P-C and Fe-N4-Vac-P-C configurations. Figure 10C-E shows the differential charge density upon *COOH, *CO and *H intermediates adsorption on the Fe-N4-C configuration, respectively. Similarly, Fig. 10F-H displays differential charge density for the same intermediates on the Fe-N3/P-C configuration. It is seen that the Fe center of P-tuned single-Fe-atom catalysts has more localized electrons and fewer electrons can be transferred to the P and N atoms, suggesting a lower oxidation state of Fe, which is in good agreement with the ex situ XANES results. Bader charge analysis further confirmed that Fe atom Fe-N3/P-C catalyst obtains a lower oxidation state upon *COOH, *CO and *H intermediate adsorption, which consequently provides more electrons to increase CO2 activation and CO desorption, revealing that the Fe tuning with P and N boosts the catalytic performance of the CO2 reduction. Another Fe-SAC containing Fe-N4 moieties dispersed on defective graphite layers developed by Qin et al. has exhibited a very low overpotential of 90 mV and a high FE of 93.5% at − 0.5 V (vs. RHE) for CO generation [85]. Their DFT calculations suggest that if Fe centers of bulk and edge Fe-N4 sites are poisoned by *CO, they do not act as active sites for CO generation from CO2. However, high catalytic activity for CO2 reduction comes from the synergistic interactions between the defective graphitic layer and the Fe-N4 moiety, which supports a balanced *COOH and *CO binding strength, mitigating the *CO poisoning and facilitating the low overpotential. Chen et al. have developed Fe-SACs catalyst consisting of Fe-N4 sites and Fe clusters supported on porous carbon (Fe-N-PC) for efficient CO2 reduction to CO with FE of ∼90% and a partial CO current density of 11.44 mA cm−2 at − 0.49 V (vs. RHE) [104]. The DFT studies suggest that *COOH and *CO are the important intermediates of CO2 reduction and the CO desorption step is easier and free energy change for HER was low on the Fe-N-PC catalysts surface. The Fe-SAC composed of CNT and GNR decorated by Fe-N4 moieties exhibited an excellent CO2 reduction performance with CO FE of 96% at the overpotential of 0.650 V [103]. DFT calculation suggests that the Fe-N4 sites dispersed on CNT/GNR networks have a high capability of CO2 activation and HER suppression in an aqueous solution. The CO2 reduction reaction pathway involves the formation of *COOH and *CO intermediates including a two-step proton-coupled electron transfer process, where Fe-N4 moiety works as an adsorption site for intermediates [160,161,162]. Moreover, the Fe-N4 site has a low free energy barrier for the formation of *COOH and shows weak adsorption for CO, enabling low onset potential for CO2 to CO conversion.

DFT calculation evaluating catalytic activity. A Gibbs free energy profiles for electroreduction of CO2 to CO on single-Fe-atom structures with different coordination environments. B Gibbs free energy profiles for hydrogen adsorption on the single-Fe-atom structures with different coordination environments. Differential charge densities of Fe-N4-C (C, D and E) and Fe-N3/P-C (F, G and H) after the adsorption of *COOH, *CO and *H intermediates near the Fe atom. Yellow and cyan isosurfaces represent electron accumulation and depletion, respectively, which shows an isosurface value of 0.001 5 e Å−3. Reproduced with permission from Ref. [102]. Copyright 2022, American Chemical Society

Ni SACs containing various active sites, including Ni-N4, Ni-N3 and Ni-N2 supported on different carbon surfaces have been used as effective catalysts for electrochemical reduction of CO2. The electrocatalytic activity for CO2 reduction varies on the surface structures and formation of the different intermediates and free energy changes on the active sites. Fan et al. have synthesized Ni SACs supported on the CNT with homogeneously distributed Ni-N3 moiety, which exhibited an improved CO2 reduction activity compared to Ni nanoparticles [106]. According to their XANES and XPS analysis, Ni-N has a coordination number of 2.5 ± 0.2 and the Ni atom is coordinated with both pyridinic N [Ni@N3(pyridinic)] and pyrrolic N [Ni@N(pyrrolic)], as shown in Fig. 11A. DFT calculation indicated that the Ni@N(pyrrolic) site plays a vital role in high catalytic activity for CO2 to CO conversion (Fig. 11B). The free energy changes for the formation of *COOH intermediate are − 0.2 eV at Ni@N(pyridinic), 0.29 eV at Ni(111) and 1.09 eV at Ni@N(pyrrolic). The second intermediate *CO formation is exothermic at all the catalyst surfaces. The CO desorption step is highly endothermic at Ni@N(pyridinic) and Ni(111); however, the same step is exothermic with free energy changes of 0.03 eV at Ni@N(pyrrolic), suggesting that Ni@N(pyridinic) and Ni(111) sites can easily be poisoned by *CO. The free energy changes for the formation of *COOH and desorption of CO were also estimated on Ni-N4 sites, showing that free energy change for CO desorption is similar to Ni@N(pyrrolic) site and *COOH formation requires 1.54 eV on the Ni-N4 site, which is much higher than that of the Ni@N(pyrrolic) site, indicating that the Ni@N(pyrrolic) site is better than the Ni-N4 site for CO2 reduction activity [15, 89]. The Ni@N3 site in both pyridinic and pyrrolic obtained more negative ΔG(*COOH) than ΔG(*H), indicating that CO2 reduction can be dominant on the Ni@N3 site, as shown in Fig. 11C. However, the ΔG(*H) is more negative than ΔG(*COOH) on Ni(111), suggesting that HER is more favorable than CO2 reduction on Ni(111) site (Fig. 11C). Bao group has developed coordinatively unsaturated Ni-N sites supported on porous carbon for CO2 reduction with CO FE of 92.0%-98.0% at the potential between − 0.53 and − 1.03 V (vs. RHE) [86]. The free energy changes of *COOH on coordinatively unsaturated Ni-N sites are much lower than those on Ni-N4, implying that the enhanced CO2 reduction activity could originate from the coordinatively unsaturated Ni-N sites. Ni atoms dispersed on the graphene layer have also been studied for CO2 reduction, showing that free energy change for *COOH is more negative than *H and CO desorption is low, indicating the high catalytic activity for CO2 reduction of the Ni-C site [32]. The Co-N5 site anchored in N-doped porous carbon spheres has shown excellent CO2 reduction activity with CO FE over 90% at a wide range of potential of − 0.57 to − 0.88 V (vs. RHE) [35]. DFT calculations suggest that the Co-N5 site can simultaneously activate CO2 molecule, form *COOH intermediate and desorb CO easily.

A Schematic representation of Ni@N3(pyrrolic) and Ni@N3(pyridinic) models for CO2 reduction reaction. Gray, brown and blue balls represent Ni, C and N atoms, respectively. B Free energy diagram illustrating the electrochemical reduction of CO2 to CO. C Comparison of ΔG(*H) and ΔG(*COOH). Reproduced with permission from Ref. [106]. Copyright 2020, Wiley-VCH. D Schematic showing the key practical difference between ZnN/CNO and ZnN/GR in terms of thickness of the EDL (0.3 and 0.9 nm). E The potential-dependent standard formation Gibbs free energy of COOH* and H* for ZnN/GR (above) and ZnN/CNO (below). F Reaction free energy diagrams of HER and CO2 reduction reaction pathway for ZnN/GR (above) and ZnN/CNO (below) on URHE = −0.48 V. G The projected crystal orbital Hamilton population (pCOHP) analysis for Zn−H (orange) and Zn−C (green) bonds in ZnN-H and ZnN-COOH, respectively, on ZnN/CNO at URHE = 0 V. H The excess electron number in the unit cell for ZnN/CNO and ZnN/GR under URHE = − 0.5 V. I Proposed reaction pathways for complete CO2 reduction reaction on ZnN/CNO. Reproduced with permission from Ref. [108]. Copyright 2021, Elsevier

Zn-based SACs have emerged as one of the most competitive CO2 reduction catalysts [36, 39, 53, 108]. The Zn can form a coordination bond with N as Zn–N4 active site supported on the carbon substrate. Xu’s group has synthesized carbon-supported N-anchored Zn SAC for CO2 to CO conversion with FE up to 95% at − 0.43 V (vs. RHE) [39]. The formation of *COOH and *CO intermediates has a low free energy barrier on the Zn-N4 site compared to N4-C and ZN-C sites. Moreover, desorption of CO on the Zn-N4 active site has more negative free energy than the other two active sites, indicating a high CO selectivity for the Zn-N4 site. The surface curviness of the carbon substrate of the Zn SACs may also play important role in catalytic activity for CO2 reduction. For example, Hao et al. have developed Zn SAC, where Zn-N4 sites were homogeneously dispersed on N-doped carbon onions (Zn SACs/N-CNO), as the catalyst for electrochemical reduction of CO2, obtaining a CO FE ~ 97% at − 0.47 V (vs. RHE) and over 100 h durability without losing activity [108]. The effects of curviness of carbon substrates were studied by DFT calculations, as shown in Fig. 11D–I. The electrochemical double-layer (EDL) charge of the flat and curved surface decorated by Zn single atoms was estimated by the Gouy-Chapman-Sterm model, which found that the curved surface catalyst (Zn SACs/N-CNO) exhibited lower EDL charge than the flat surface catalyst (Zn SACs/N-graphene) (Fig. 11D) [163]. However, HER dominates over the CO2 reduction reaction at high overpotentials due to the mass transport limitation of CO2; therefore, the thickness of EDL could not be one of the important factors for high catalytic activity. The free energy at different potentials on both surfaces is calculated using the hydrogen electron model proposed by Norskov et al. displayed in Fig. 11E for CO generation from CO2 and HER in the aqueous solution [164, 165]. The relative kinetics (\({v}_{\mathrm{HER}/\mathrm{CO}}\)), calculated by using the microkinetic model, was 0.07 for Zn SACs/N-graphene and 3.5 × 10−6 for Zn SACs/N-CNO, suggesting a higher CO selectivity at Zn SACs/N-graphene [166]. Further, free energy for H* and COOH* intermediates was determined, observing that the free energy for both intermediates is similar at the surface of Zn SACs/N-graphene at all the applied potentials. However, free energy is found to be lower at higher electrode potentials at Zn SACs/N-CNO for COOH* compared to H*, implying that CO2 reduction reaction is dominant at highly curved surface catalysts. Therefore, the product selectivity of CO2 electrolysis in aqueous media is largely dependent on the relative affinity to COOH* and H* at the surface of the catalyst. Figure 11F displays the potential-dependent free energy changes of different intermediates on both catalysts’ surfaces for CO and HER pathways. The free energy changes for COOH* were smaller than H* at both flat and curved surfaces, indicating that both surfaces tend to have high CO selectivity. However, the difference in the free energy changes between COOH* and H* (ΔG(*COOH)−ΔG(*H)) was found to be low at the Zn SACs/N-CNO compared to the Zn SACs/N-graphene, proving a low free energy pathway of CO at Zn SACs/N-CNO, which resulted in a higher FE for CO. Therefore, low value of ΔG(*COOH)−ΔG(*H) than the smaller EDL charge could be the primary factor of having higher CO selectivity. The origin of lower (ΔG(*COOH) − ΔG(*H)) was clarified by the crystal orbital Hamilton population (COHP) analysis along with the charge analysis, shown in Fig. 11G and F, respectively. The orbitals for both ZN-COOH and Zn-H on the Fermi level have negative COHP values, which indicates having the bonding orbitals in both catalysts (Fig. 11G). Once experiments are performed at different cathode potentials, which means additional charges are applied to the systems; therefore, adsorption of both COOH* and H* will be strengthened. However, when EDL charge is lowered at a fixed potential, correspondingly, a larger amount of charge is injected into COOH* rather than H*, as shown in Fig. 11H. Therefore, COOH* receives more charges than H* while decreasing EDL charge, causing the stronger adsorption of COOH*, making it a major intermediate of CO2 reduction reaction and resulting in high selectivity of CO. According to the aforementioned DFT calculations, the proposed reaction pathways on Zn SACs/N-CNO for the complete CO2 reduction reaction are shown in Fig. 11F. Therefore, the curvature effect is the key effect of Zn SACs/N-CNO to provide enhanced CO2 reduction activity. Above results suggest that Zn-N4 sites dispersing on the carbon substrate with a highly curved surface than the flat surface may possess a low EDL charge, but shows a strong COOH* absorption, resulting in the high conversion of CO2 to CO.

4 Free-Standing Electrode Architecture for Electrochemical Reduction of CO2

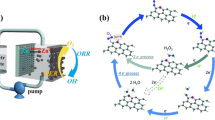

Many nanostructured materials have been explored for the electrochemical reduction of CO2, e.g., metal nanoparticles, nanorods, nanoneedles, nanocubes and carbon-based nanostructured materials [44, 137, 167,168,169,170]. Molecular catalysts, such as metal-porphyrin and metal-pyridine complexes have also been widely studied as catalysts for CO2 reduction [171,172,– 173]. Both types of catalysts are usually in a powder form and thereby need to be attached to a support surface to use these catalysts as working electrodes. Nafion or polyvinylidene difluoride (PVDF) is commonly used as a binder material for most powdered materials. Unfortunately, the binder may block the potential active sites, lower the accessibility to the pores and decrease the electrical conductivity of the catalysts [144, 174,175,176]. Thus, the design of binder-free electrocatalysts is necessary to achieve high catalytic performance and many efforts have been focused on the development of free/self-standing electrodes. A free-standing electrode is an electrode having an independent and separate component that can be detached from the assembly but still retains its structural integrity and mechanical strength. Free-standing electrode architectures can be developed through the formation of nanostructured materials on flat surfaces, assembly of them into hierarchical structures and grafting molecular catalysts on the electrode surface through chemical bonding. Recently, several free-standing single-atom catalysts (FSSACs), such as Ni single-atom catalysts decorated on carbon membrane and carbon paper, Co single-atom catalysts on carbon nanofiber, Cu, Mn, Fe and Sn single-atom catalysts-doped polyanilines, Cu single-atom catalysts decorated on carbon nanofibers, have been developed as effective electrocatalysts for CO2 reduction [44, 46, 48, 49, 177].

4.1 Fabrication and Structure Characterization of Free-Standing SAC Electrode (FSSACE)