Abstract

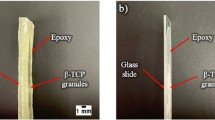

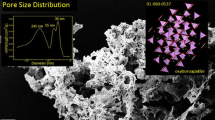

This study aims to understand the influence of pore size on the compositional, morphological, and functional group characteristics of dicalcium phosphate dihydrate (DCPD)-coated porous β-tricalcium phosphate (β-TCP) granules. This study produced 300–600 μm granular sizes of porous β-TCP granules with various pore diameters. This was achieved by combining dry powders of DCPD and calcium carbonate (CaCO3) [Ca/P ratio: 1.5] with varied quantities of 10%, 20%, 30%, and 40% of sodium chloride (NaCl) powders to obtain mixtures composed of weight percentages (wt%) ratios of 90:10, 80:20, 70:30, and 60:40, respectively. Post-sintering, the porous β-TCP granules fabricated were soaked in an acidic calcium phosphate solution for 30 min to coat the surfaces with DCPD crystals formation via a dissolution-precipitation reaction. Subsequently, the specimens were examined with scanning electron microscopy (SEM), X-ray diffraction (XRD), and Fourier-transform infrared (FTIR). The morphological observations demonstrated that increasing NaCl powder up to 40% with a mixture of CaCO3 and DCPD enhanced the β-TCP granules' pore size. Furthermore, The formation of DCPD on and inside the porous β-TCP granules has been accelerated due to the presence of large pores. Conversely, dissolution-precipitation reactions were incomplete on granules with 2.8, 4.9, and 6.91 μm pore sizes. The major XRD peaks of the DCPD and β-TCP phases with 2.8, 4.9, and 6.91 μm pores were also slightly shifted to the right, while granules with 7.53 μm pores demonstrated DCPD and β-TCP peaks aligned with pure β-TCP and DCPD phases. This study's findings are expected to offer insight into the role of pore size in influencing the dissolution-precipitation process that affects the morphological, compositional, and functional group characteristics of DCPD-coated β-TCP granules.

Similar content being viewed by others

References

Ishikawa, K., Miyamoto, Y., Tsuchiya, A., Hayashi, K., Tsuru, K., Ohe, G.: Physical and histological comparison of hydroxyapatite, carbonate apatite, and β-tricalcium phosphate bone substitutes. Materials 11(10), 1993 (2018). https://doi.org/10.3390/ma11101993. (Basel, Switzerland)

Zaidi, N.Z., Ridzwan, N.R., Mohammed, A.M., Shariff, K.A.: Effect of soaking time on the compositional and morphological changes of DCPD-coated β-TCP bioceramic. Key Eng. Mater. 908, 135–140 (2022). https://doi.org/10.4028/P-I0P5C7

Lee, D.S., Pai, Y., Chang, S., Kim, D.H.: Microstructure, physical properties, and bone regeneration effect of the nano-sized β-tricalcium phosphate granules. Mater. Sci. Eng. C Mater. Biol. Appl. 58, l971-976 (2016). https://doi.org/10.1016/j.msec.2015.09.047

Shariff, K.A., Tsuru, K., Ishikawa, K.: Fabrication of dicalcium phosphate dihydrate-coated β-TCP granules and evaluation of their osteoconductivity using experimental rats. Mater. Sci. Eng. C Mater. Biol. Appl. 75, 1411–1419 (2017). https://doi.org/10.1016/j.msec.2017.03.004

Khatiblou, F.: Histologic and histometric evaluation of bovine cancellous bone and beta-tricalcium phosphate 45 months after grafting in maxillary sinus. J. Oral Implantol. 37(6), 727–733 (2011). https://doi.org/10.1563/AAID-JOI-D-10-00093

Loh, Q.L., Choong, C.: Three-dimensional scaffolds for tissue engineering applications: role of porosity and pore size. Tissue Eng. Part B Rev. 19(6), 485–502 (2013). https://doi.org/10.1089/ten.TEB.2012.0437

Zhang, Y.S., Zhu, C., Xia, Y.: Inverse opal scaffolds and their biomedical applications. Adv. Mater. 29(33), (2017). https://doi.org/10.1002/adma.201701115. (Deerfield Beach, Fla.)

Zhang, H., Zhang, H., Xiong, Y., Dong, L., Li, X.: Development of hierarchical porous bioceramic scaffolds with controlled micro/nano surface topography for accelerating bone regeneration. Mater. Sci. Eng. C Mater. Biol. Appl. 130, 112437 (2021). https://doi.org/10.1016/J.MSEC.2021.112437

Mohammed Mohammed, A.H., Shariff, K.A., Wahjuningrum, D.A., Bakar, M.H., Mohamad, H.: A comprehensive review of the effects of porosity and macro- and micropore formations in porous β-TCP scaffolds on cell responses. J. Aust. Ceram. Soc. 59, 865–879 (2023). https://doi.org/10.1007/S41779-023-00880-0

Chen, Z., Yan, X., Yin, S., Liu, L., Liu, X., Zhao, G., Ma, W., Qi, W., Ren, Z., Liao, H., Liu, M., Cai, D., Fang, H.: Influence of the pore size and porosity of selective laser melted Ti6Al4V ELI porous scaffold on cell proliferation, osteogenesis and bone ingrowth. Mater. Sci. Eng. C Mater. Biol. Appl. 106, 110289 (2020). https://doi.org/10.1016/j.msec.2019.110289

Bohner, M., Baroud, G., Bernstein, A., Döbelin, N., Galea, L., Hesse, B., Heuberger, R., Meille, S., Michel, P., Rechenberg, B.V., Sagué, J.L., Seeherman, H.J.: Characterisation and distribution of mechanically competent mineralised tissue in micropores of β-tricalcium phosphate bone substitutes. Mater. Today 20, 106–115 (2017). https://doi.org/10.1016/J.MATTOD.2017.02.002

Li, X., Wang, M., Deng, Y., Chen, X., Xiao, Y., Zhang, X.: Fabrication and properties of Ca-P bioceramic spherical granules with interconnected porous structure. ACS Biomater. Sci. Eng. 3(8), 1557–1566 (2017). https://doi.org/10.1021/acsbiomaterials.7b00232

Mohammed, A.M., Shariff, K.A., Abu Bakar, M.H., Mohamad, H.: Recent methods in fabricating porous β-tricalcium phosphate scaffolds: A mini review. Mater. Today: Proc. (2022). https://doi.org/10.1016/J.MATPR.2022.06.498

Li, X., Zhang, H., Shen, Y., Xiong, Y., Dong, L., Zheng, J., Zhao, S.: Fabrication of porous β-TCP/58S bioglass scaffolds via top-down DLP printing with high solid loading ceramic-resin slurry. Mater. Chem. Phys. 267, 124587 (2021). https://doi.org/10.1016/J.MATCHEMPHYS.2021.124587

Tan, Q., Li, S., Ren, J., Chen, C.: Fabrication of porous scaffolds with a controllable microstructure and mechanical properties by porogen fusion technique. Int. J. Mol. Sci. 12(2), 890–904 (2011). https://doi.org/10.3390/ijms12020890

Mekala, N.K., Baadhe, R.R., Parcha, S.R., Yalavarthy, P.D.: Physical and degradation properties of PLGA scaffolds fabricated by salt fusion technique. J. Biomed. Res. 27(4), 318–325 (2013). https://doi.org/10.7555/JBR.27.20130001

Ruiz-Aguilar, C., Olivares-Pinto, U., Alfonso, I.: Novel β-TCP scaffold production using NaCl as a porogen for bone tissue applications. Ceram. Int. 47, 2244–2254 (2021). https://doi.org/10.1016/J.CERAMINT.2020.09.064

Zhou, Z., Liu, X., Liu, Q.: A Comparative Study of Preparation of Porous Poly-L-lactide Scaffolds Using NaHCO3 and NaCl as Porogen Materials. J. Macromol. Sci. B 47, 667–674 (2008). https://doi.org/10.1080/00222340802118804

Park, M., Lee, G., Ryu, K.H., Lim, W.: Improvement of bone formation in rats with calvarial defects by modulating the pore size of tricalcium phosphate scaffolds. Biotechnol. Bioprocess Eng. 24, 885–892 (2019). https://doi.org/10.1007/S12257-019-0248-6/METRICS

Shariff, K.A., Abu Bakar, M.H., Cahyanto, A.: Behavior of osteoclast cells response on dicalcium phosphate dihydrate layer-coated β-tricalcium phosphate granular. Mater. Sci. Forum 1010, 549–554 (2020). https://doi.org/10.4028/www.scientific.net/MSF.1010.549

Fukuda, N., Ishikawa, K., Akita, K., Kamada, K., Kurio, N., Mori, Y., Miyamoto, Y.: Effects of acidic calcium phosphate concentration on setting reaction and tissue response to β-tricalcium phosphate granular cement. J. Biomed. Mater. Res. B Appl. Biomater. 108(1), 22–29 (2020). https://doi.org/10.1002/jbm.b.34361

Fukuda, N., Tsuru, K., Mori, Y., Ishikawa, K.: Fabrication of self-setting β-tricalcium phosphate granular cement. J. Biomed. Mater. Res. B Appl. Biomater. 106(2), 800–807 (2018). https://doi.org/10.1002/jbm.b.33891

Wu, Y., Tahmasebi, P., Lin, C., Zahid, M.A., Dong, C., Golab, A.N., Ren, L.: A comprehensive study on geometric, topological and fractal characterisations of pore systems in low-permeability reservoirs based on SEM, MICP, NMR, and X-ray CT experiments. Mar. Pet. Geol. 103, 12–28 (2019). https://doi.org/10.1016/J.MARPETGEO.2019.02.003

Whitbread, I.K.: Fabric description of archaeological ceramics. 200–216 (2016). https://doi.org/10.1093/OXFORDHB/9780199681532.013.13

Sánchez Fortoul, C.G.: Maya Ceramic Technology and Ceramic Socio-economy: A multifaceted analysis of Late Postclassic ceramic production and distribution in Northern Yucatán, México, Maya Ceramic Technology and Ceramic Socio-Economy: A Multifaceted Analysis of Late Postclassic Ceramic Production and Distribution in Northern Yucatán, México. 248 (2018)

Fukuda, N., Tsuru, K., Mori, Y., Ishikawa, K.: Effect of citric acid on setting reaction and tissue response to β-TCP granular cement. Biomed. Mater. 12(1), 015027 (2017). https://doi.org/10.1088/1748-605X/aa5aea. (Bristol, England)

Siqueira, L., Passador, F.R., Costa, M.M., Lobo, A.D., Sousa, E.M.: Influence of the addition of β-TCP on the morphology, thermal properties and cell viability of poly (lactic acid) fibers obtained by electrospinning. Mater. Sci. Eng. C Mater. Biol. Appl. 52, 135–43 (2015). https://doi.org/10.1016/J.MSEC.2015.03.055

Shariff, K.A., Tsuru, K., Ishikawa, K.: Regulation of DCPD formation on β-TCP granular surface by exposing different concentration of acidic calcium phosphate solution. Key Eng. Mater. 696, 27–31 (2016). https://doi.org/10.4028/WWW.SCIENTIFIC.NET/KEM.696.27

Wei, L.J., Shariff, K.A., Momin, S.A., et al.: Self-setting β-tricalcium phosphate granular cement at physiological body condition: effect of citric acid concentration as an inhibitor. J. Aust. Ceram. Soc. 57, 687–696 (2021). https://doi.org/10.1007/s41779-021-00575-4

Ślósarczyk, A., Paluszkiewicz, C., Gawlicki, M., Paszkiewicz, Z.: The FTIR spectroscopy and QXRD studies of calcium phosphate based materials produced from the powder precursors with different Ca/P ratios. Ceram. Int. 23, 297–304 (1997). https://doi.org/10.1016/S0272-8842(96)00016-8

Zhu, W.J., Kamali, A.R.: Green preparation of nanostructured β-MoO3/hexagonal-shaped MoS2/graphene with enhanced lithium-ion storage performance. J. Alloy. Compd. 932, 167724 (2023). https://doi.org/10.1016/J.JALLCOM.2022.167724

Mohamad Zaidi, N.Z., Mohammed, A.H.M., Sujon, M.K., et al.: Behavioural responses of bone-like cells on dense and porous dicalcium phosphate dihydrate-coated β-tricalcium phosphate granules. J. Aust. Ceram. Soc. 59, 1423–1431 (2023). https://doi.org/10.1007/s41779-023-00925-4

Boanini, E., Silingardi, F., Gazzano, M., Bigi, A.: Synthesis and hydrolysis of brushite (DCPD): the role of ionic substitution. Cryst. Growth Des. 21, 1689–1697 (2021). https://doi.org/10.1021/ACS.CGD.0C01569

Hayashi, K., Ishikawa, K.: Honeycomb scaffolds capable of ectopic osteogenesis: Histological evaluation of osteoinduction mechanism. Nano Select. 3, 60–77 (2022). https://doi.org/10.1002/NANO.202000283

Ishikawa, K.: Bone substitute fabrication based on dissolution-precipitation reactions. Materials 3, 1138–1155 (2010). https://doi.org/10.3390/MA3021138

Abbasi, N., Hamlet, S.M., Love, R.M., Nguyen, N.: Porous scaffolds for bone regeneration. J. Sci.: Adv. Mater. Devices 5, 1–9 (2020). https://doi.org/10.1016/J.JSAMD.2020.01.007

Putri, T.S., Hayashi, K., Ishikawa, K.: Bone regeneration using β-tricalcium phosphate (β-TCP) block with interconnected pores made by setting reaction of β-TCP granules. J. Biomed. Mater. Res. Part A 108(3), 625–632 (2020). https://doi.org/10.1002/jbm.a.36842

Kozelskaya, A.I., Kulkova, S.E., Fedotkin, A.Y., Bolbasov, E.N., Zhukov, Y.M., Stīpniece, L., Bakulin, A.V., Useinov, A., Shesterikov, E.V., Locs, J., Tverdokhlebov, S.I.: Radio frequency magnetron sputtering of Sr- and Mg-substituted β-tricalcium phosphate: Analysis of the physicochemical properties and deposition rate of coatings. Appl. Surf. Sci. 509, 144763 (2020). https://doi.org/10.1016/J.APSUSC.2019.144763

Kweh, S.W., Khor, K.A., Cheang, P.: High temperature in-situ XRD of plasma sprayed HA coatings. Biomaterials 23(2), 381–387 (2002). https://doi.org/10.1016/s0142-9612(01)00116-8

Hamdan Alkhraisat, M., Moseke, C., Blanco, L., Barralet, J.E., Lopez-Carbacos, E., Gbureck, U.: Strontium modified biocements with zero order release kinetics. Biomaterials 29(35), 4691–4697 (2008). https://doi.org/10.1016/J.BIOMATERIALS.2008.08.026

Cullity, B.D.: Elements of X-ray diffraction, 2nd edition, Addison-Wesley Publishing Co. Reading MA. 100–105, 277–279 (1978)

Tripathi, G., Ishikawa, K.: Fabrication and in vitro dissolution evaluation of low-crystalline β-TCP blocks through aqueous solution mediated phase conversion. Mater. Sci. Eng. C Mater. Biol. Appl. 101, 228–231 (2019). https://doi.org/10.1016/j.msec.2019.03.106

Kunio, I., Tsuru, K., Pham, T., Maruta, M., Matsuya, S.: Fully-interconnected pore forming calcium phosphate cement. Key Eng. Mater. 493–494, 832–835 (2011). https://doi.org/10.4028/www.scientific.net/KEM.493-494.832

Acknowledgements

This work was supported by a Universiti Sains Malaysia, Special Short-Term Grant with Project no: 304/PBAHAN/6315702, and Mustansiriyah University for sponsoring the first author to study in Malaysia.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mohammed Mohammed, A.H., Shariff, K.A., Bakar, M.H.A. et al. Pore size influence in fabricating DCPD-Coated Porous β-TCP granules: compositional, morphological, and functional group perspective. J Aust Ceram Soc (2024). https://doi.org/10.1007/s41779-024-01029-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41779-024-01029-3