Abstract

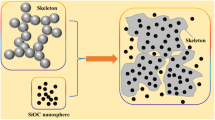

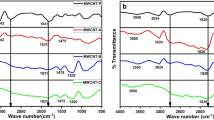

Diamond wire cutting polysilicon waste powder is a potential raw material for the preparation of α-Si3N4 fibers with its ultra-fine particle size and high reactivity. In this study, a new method for the preparation of α-Si3N4 fibers by additive-assisted nitridation was proposed, and the effects of type and content of additives, temperature and time on the nitridation of polysilicon waste powder were investigated in detail. The experimental results showed that compared to the samples without additive assistance, the samples containing 50 wt.% additive can obtain silicon nitride powders dominated by α-Si3N4 fibers after nitriding at 1250 °C for 8 h. Moreover, the growth of α-Si3N4 fibers obeys the VS mechanism. The decomposition of urea and melamine at low temperature produces a large number of pores, which in turn promotes the nitridation of polysilicon waste powder. The addition of α-Si3N4 acts as a diluent on the one hand, and provides nucleation conditions for the growth of α-Si3N4 fibers on the other.

Similar content being viewed by others

References

Cai, E., Tang, B., Fahrner, W.R., Zhou, L.: Characterization of the surfaces generated by diamond cutting of crystalline silicon. In: Ossenbrink, H., Jager-Waldau, A., Helm, P. (eds.) Proceedings of the 26th European International Conference on Photovoltaic Solar Energy, vol. 86, pp. 1884–1886. WIP - Renewable Energies, Munich, Germany (2011)

Chen, C.C.A., Chao, P.H.: Surface texture analysis of fixed and free abrasive machining of silicon substrates for solar cells. In: Liao, Y.S., Chen, C.C.A., Chao, C.L., Tso, P.L. (eds.) 13th International Symposium on Advances in Abrasive Technology/1st Cross-Strait Conference on Precision Machining, Advances in Abrasive Technology XIII, vol. 126, pp. 177–180, Taipei, TaiWan (2010)

Shi, Y.B., Ge, C.Z., Wang, M.M.: Design of an intelligent solar energy tracking system based on maximum power point tracking with light search perceptive technology. Power Syst. Technol. 38, 87–92 (2014)

Chen, I.W., Rosenflanz, A.: A tough SiAlON ceramic based on α-Si3N4 with a whisker-like microstructure. Nat. 389, 701–704 (1997)

Golla, B.R., Ko, J.W., Kim, J.M., Kim, H.D.: Effect of particle size and oxygen content of Si on processing, microstructure and thermal conductivity of sintered reaction bonded Si3N4. J. Alloy. Compd. 595, 60–66 (2014)

Cheng, H., Li, Y., Kroke, E., Herkenhoff, S.: In situ synthesis of Si2N2O/Si3N4 composite ceramics using polysilyloxycarbodiimide precursors. J. Eur. Ceram. Soc. 33, 2181–2189 (2013)

Chen, F., Shen, Q., Yan, F., Zhang, L.: Pressureless sintering of α-Si3N4 porous ceramics using a H3PO4 pore-forming agent. J. Am. Ceram. Soc. 90, 2379–2383 (2007)

Wu, Z., Zhang, Z., Yun, J., You, T.: Synthesis of α-Si3N4 crystallon by a solvothermal method at a low temperature of 180 °C. Phys. B Condens. Matter. 428, 10–13 (2013)

Hirao, K., Zhou, Y., Hyuga, H., Ohji, T., Kusano, D.: High thermal conductivity silicon nitride ceramics. J. Korean Ceram. Soc. 49, 380–384 (2012)

Yang, Q., Chen, Z., Yang, X.R., Zhou, D.T., Qian, X.X., Zhang, J.J., Zhang, D.: Facile synthesis of Si3N4 nanowires with enhanced photocatalytic application. Mater. Lett. 212, 41–44 (2018)

Lange, F.F.: Relation between strength, fracture Energy, and microstructure of hot-pressed Si3N4. J. Am. Ceram. Soc. 56, 518–522 (1973)

Lange, F.F.: Fracture toughness of Si3N4 as a function of the initial α-phase content. J. Am. Ceram. Soc. 62, 428–430 (1979)

Liu, X., Yi, X., Guo, R., Li, Q., Nomura, T.: Formation mechanisms of Si3N4 microstructures during silicon powder nitridation. Ceram. Int. 43, 16773–16779 (2017)

Chang, F.W., Liou, T.H., Tsai, F.M.: The nitridation kinetics of silicon powder compacts. Thermochim. Acta. 354, 71–80 (2000)

Messier, D.R., Wong, P.: Kinetics of nitridation of Si powder compacts. J. Am. Ceram. Soc. 56, 480–485 (1973)

Campos-Loriz, D., Riley, F.L.: The effect of silica on the nitridation of silicon. J. Mater. Sci. 11, 195–198 (1976)

Elias, D.P., Lindley, M.W.: Reaction sintered silicon nitride: Part 1 The influence of oxygen and water vapour contamination on strength and composition. J. Mater. Sci. 11, 1278–1287 (1976)

Rahaman, M.N., Moulson, A.J.: The removal of surface silica and its effect on the nitridation of high-purity silicon. J. Mater. Sci. 19, 189–194 (1984)

Barsoum, M., Kangutkar, P., Koczak, M.J.: Nitridation kinetics and thermodynamics of silicon powder compacts. J. Am. Ceram. Soc. 74, 1248–1253 (1991)

Omidi, Z., Bakhshi, S.R., Ghasemi, A.: Evaluation of processing parameters effects on the formation of Si3N4 wires synthesized by means of ball milling and nitridation route. Adv. Powder Technol. 25, 1667–1671 (2014)

Pavarajarn, V., Kimura, S.: Catalytic effects of metals on direct nitridation of silicon. J. Am. Ceram. Soc. 84, 1669–1674 (2001)

Chai, Z., Ding, J., Deng, C., Zhu, H., Li, G., Yu, C.: Ni-catalyzed synthesis of hexagonal plate-like alpha silicon nitride from nitridation of Si powder in molten salt media. Adv. Powder Technol. 27, 1637–1644 (2016)

Huang, J., Zhang, S., Huang, Z., Fang, M., Chen, K.: Co-catalyzed nitridation of silicon and in-situ growth of α-Si3N4 nanorods. Ceram. Int. 40, 11063–11070 (2014)

Hou, Y., Zhang, G.H., Chou, K.C.: Preparation of α-Si3N4 by direct nitridation using polysilicon waste by diamond wire cutting. Int. J. Appl. Ceram. Tec. 17, 84–93 (2020)

Tripp, W.C., Graham, H.C.: Oxidation of Si3N4 in the Range 1300 to 1500 °C. J. Am. Ceram. Soc. 59, 399–403 (1976)

Gu, Y., Lu, L., Zhang, H., Cao, Y., Li, F., Zhang, S.: Nitridation of silicon powders catalyzed by cobalt nanoparticles. J. Am. Ceram. Soc. 98, 1762–1768 (2015)

Lin, S.S.: Comparison of iron-alloy additives on nitridation of silicon. J. Am. Ceram. Soc. 61, 95–96 (1978)

Jennings, H.M.: On reactions between silicon and nitrogen. J. Mater. Sci. 18, 951–967 (1983)

Yin, L.W., Bando, Y., Zhu, Y.C., Li, Y.B.: Synthesis, structure, and photoluminescence of very thin and wide alpha silicon nitride (α-Si3N4) single-crystalline nanobelts. Appl. Phys. Lett. 83, 3584–3586 (2003)

Xu, Y., Cao, C., Du, H., Li, J., Zhu, H.: Synthesis and photoluminescence of belt-shaped Si3N4 whiskers. Mater. Lett. 61, 3855–3858 (2007)

Wang, F., Qin, X.F., Jin, G.Q., Wang, Y.Y., Guo, X.Y.: Synthesis and characterization of Si3N4 thin nanobelts via direct nitridation of Si powders. Physica E. 41, 120–123 (2008)

Zhang, Y.J., Wang, N.L., He, R.R., Liu, J., Zhang, X.Z., Zhu, J.: A simple method to synthesize Si3N4 and SiO2 nanowires from Si or Si/SiO2 mixture. J. Cryst. Growth. 233, 803–808 (2001)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (51734002).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hou, Y., Zhang, GH. & Lv, XW. Preparation of silicon nitride fibers by additive-assisted nitridation of polysilicon waste powder. J Aust Ceram Soc 60, 533–541 (2024). https://doi.org/10.1007/s41779-023-00967-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41779-023-00967-8