Abstract

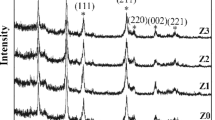

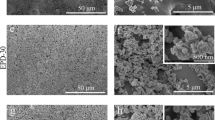

Surface modification of dental implants is an important key process in the fabrication of these medical materials. In this paper, a novel method of aluminum-doped titanium oxide (TiO2: Al) thin films as a functional coating for resistance to adhesion bacteria in dental implantology by RF magnetron plasma sputtering technique is presented. The ratios of doping were (0, 2, 4, 6) % weight concentration. The characteristics of produced films have been studied by X-ray diffraction (XRD) for structural properties, atomic force microscopy (AFM) for surface morphology, and antibacterial tests. The results showed that the phase of TiO2 was anatase type and the crystal phase was tetragonal and the crystalline size increased from 21 to 26.27 nm with increasing of Al concentration; the image of AFM showed the roughness increased from 0.95 to 1.46 nm with increasing Al concentration except for Al (6%) concentration. The antimicrobial results showed good efficacy of the prepared thin films in resisting bacterial growth and the zone of bacterial growth inhibition reach 21 mm.

Similar content being viewed by others

References

Wang, M., Tang T.: Surface treatment strategies to combat implant-related infection from the beginning. J. Orthop. Transl. 17, 42–54 (2019)

Mandrake, P., Mussing, F., Ravioli, P., Carissa, S.: Surface treatments and functional coatings for biocompatibility improvement and bacterial adhesion reduction in dental implantology. Coatings 6, 1–23 (2016)

Tang, T., Qin, L.: Translational study of orthopedic biomaterials and devices. J. Orthop. Transl. 17, 42–54 (2019)

Chen, M., Yang, L., Zhang, L., Han, Y., Lu, Z., Qin, G.: Effect of nano/micro-Ag compound particles on the bio-corrosion, antibacterial properties and cell biocompatibility of Ti-Ag alloys. Mater. Sci. Eng. C Mater. Biol. Appl. 75, 906–917 (2017)

Chen, M., Zhang, E., Zhang, L.: Microstructure, mechanical properties, bio-corrosion properties and antibacterial properties of Ti-Ag sintered alloys. Mater. Sci. Eng. C Mater. Biol. Appl. 62, 350–360 (2016)

Sun, D., Xu, D., Yang, C., Chen, J., Shahzad, M.B., Sun, Z.: Inhibition of Staphylococcus aureus biofilm by a copper-bearing 317L-Cu stainless steel and its corrosion resistance. Mater. Sci. Eng. C Mater. Biol. Appl. 69, 744–750 (2016)

BakhsheshiRad, H.R., Hamzah, E., Low, H.T., Kasiri, M., Farahany, S., Akbari, E.: Fabrication of biodegradable Zn-Al-Mg alloy: mechanical properties, corrosion behavior, cytotoxicity, and antibacterial activities. Mater. Sci. Eng. C Mater. Biol. Appl. 73, 215–219 (2017)

Karahaliloglu, Z., Kilicay, E., Denkbas, E.B.: Antibacterial chitosan/silk sericin 3D porous scaffolds as a wound dressing material. Artif. Cells Nanomed. Biotechnol. 45, 1–14 (2017)

Raphel, J., Holodniy, M., Goodman, S.B., Heilshorn, S.C.: Multifunctional coatings to simultaneously promote osseointegration and prevent infection of orthopedic implants. Biomaterials 84, 301–311 (2016)

Peng, Z., Ni, J., Zheng, K., Shen, Y., Wang, X., He, G.: Dual effects and mechanism of TiO2 nanotube arrays in reducing bacterial colonization and enhancing C3H10T1/2 cell adhesion. Int. J. Nanomed. 8, 3093 (2013)

Zhang, L., Liao, X., Fok, A., Ning, C., Ng, P., Wang, Y.: Effect of crystalline phase changes in titania (TiO2) nanotube coatings on platelet adhesion and activation. Mater. Sci. Eng. C 82, 91–101 (2017)

Cochran, D., Schenk, R., Lussi, A., Higginbottom, F., Buser, D.: Bone response to unloaded and loaded titanium implants with a sandblasted and acid-etched surface: a histometric study in the canine mandible. J. Biomed. Mater. Res. 40, 1–11 (1998)

Wennerberg, A., Hallgren, C., Johansson, C., Danelli, S.: A histomorphometric evaluation of screw-shaped implants each prepared with two surface roughnesses. Clin. Oral Implants Res. 9, 11–19 (1998)

Duraccio, D., Mussano, F., Faga. M.: Biomaterials for dental implants: current and future trends. J. Mater. Sci. 50, 4779–4812 (2015)

Kokubo, T., Kushitani, H., Sakka, S., Kitsugi, T., Yamamuro, T.: Solutions able to reproduce in vivo surface-structure changes in bioactive glass-ceramic A-W. J. Biom. Mate. Rese. 24, 721–734 (1990)

Li, P., Ducheyne, P.: Quasi-biological apatite film induced by titanium in a simulated body fluid. J. Biom. Mate. Rese. 41, 341–348 (1998)

Yallappa, S., Manjanna, J., Dhananjaya, B.L., Vishwanatha, U.: Phytochemically functionalized Cu and Ag nanoparticles embedded in MWCNTs for Enhanced Antimicrobial and Anticancer Properties. Nano-Micro Lett. 8, 120–130 (2016)

Rupp, F., Scheideler, L., Olshanska, N., Wild, M.: Enhancing surface free energy and hydrophilicity through chemical modification of microstructured titanium implant surfaces. J. Biomed. Mater. Res. Part A 76, 323–334 (2006)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mutter, M.M., Jabbar, R.H. & Khudiar, A.I. Synthesis and characterization of TiO2: Al thin films for bacteria resistance in the implanted dental. J Aust Ceram Soc 58, 145–149 (2022). https://doi.org/10.1007/s41779-021-00637-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41779-021-00637-7