Abstract

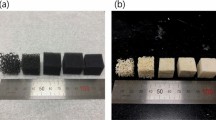

Mullite reticulated porous ceramics (RPCs) were fabricated with fly ash, alumina, and andalusite by polymer sponge replica technique, followed by the process of vacuum infiltration with recoating slurry included. And the effect of different recoating slurry with different particle size fly ash on the properties of mullite RPCs was studied. The matrix slurry and recoating slurry were investigated and optimized. And then, the microstructure, composition of phases, and mechanical properties of mullite RPCs were examined by SEM (scanning electron micrograph), XRD (X-ray diffraction), and hydraulic universal testing machine. Moreover, the influence of particle size of fly ash on the thermal shock stability was analyzed by calculating residual stress model and grey relational model. The result indicated that the specimens that were recoated by the slurry with the smaller particle size of fly ash might have more excellent properties.

Similar content being viewed by others

References

Taslicukur, Z., Balaban, C., Kuskonmaz, N.: Production of ceramic foam filters for molten metal filtration using expanded polystyrene. J. Eur. Ceram. Soc. 27, 637–640 (2007)

Damoah, L.N.W., Zhang, L.: AlF3, reactive Al2O3, foam filter for the removal of dissolved impurities from molten aluminum: preliminary results. Acta Mater. 59, 896–913 (2011)

Nishikawa, T., Ono, T., Yano, M.: Estimation of pore size distribution in different structural cylindrical porous ceramic filters from gas permeability. J. Ceram. Soc. Jpn. 102, 430–435 (2010)

Soldati, A., Campolo, M., Sbrizzai, F.: Modeling nano-particle deposition in diesel engine filters. Chem. Eng. Sci. 65, 6443–6451 (2010)

Faure, R., Rossignol, F., Chartier, T.: Alumina foam catalyst supports for industrial steam reforming processes. J. Eur. Ceram. Soc. 31, 303–312 (2011)

Faure, R., Basile, F., Bersani, I.: Foam-supported catalysts tailored for industrial steam reforming processes. Stud Surf Sci. 175, 241–244 (2010)

Zhang, R., Feng, J., Cheng, X., Gong, L., Li, Y., Zhang, H.: Porous thermal insulation materials derived from fly ash using a foaming and slip casting method. Energ.Buildings. 81, 262–267 (2014)

Han, L., Li, F., Deng, X., Wang, J., Zhang, H., Zhang, S.: Foam-gelcasting preparation, microstructure and thermal insulation performance of porous diatomite ceramics with hierarchical pore structures. J. Eur. Ceram. Soc. 37(7), (2017)

Zhu, X., Jiang, D., Tan, S.: Reaction bonding of open cell Sic-Al2O3 composites. Mater. Res. Bull. 36(11), 2003–2015 (2001)

Ahmaruzzaman, M.: A review on the utilization of fly ash. Prog Energ Combust. 36(3), 327–363 (2010)

Guo, R.Q., Rohatgi, P.K., Nath, D.: Preparation of aluminium-fly ash particulate composite by powder metallurgy technique. J. Mater. Sci. 32(15), 3971–3974 (1997)

Yao, X., Yang, Y., Liu, X., Huang, Z.: Effect of recoating slurry compositions on the microstructure and properties of sic reticulated porous ceramics. J. Eur. Ceram. Soc. 33(15–16), 2909–2914 (2013)

Hashin, Z.: Thermal expansion coefficients of cracked laminates. Compos. Sci. Technol. 31(4), 247–260 (1988)

Blanks, K.S., Kristoffersson, A., Carlström, E., Clegg, W.J.: Crack deflection in ceramic laminates using porous interlayers. J. Eur. Ceram. Soc. 18(13), 1945–1951 (1998)

Liang, X., Li, Y., Liu, J., Sang, S., Chen, Y., Li, B.: Improvement of the mechanical properties of sic reticulated porous ceramics with optimized three-layered struts for porous media combustion. Ceram. Int. 43, 3741–3747 (2017)

Toledano, A., Murakami, H.: Shear-deformable two-layer plate theory with interlayer slip. J. Eng. Mech. 114, 604–623 (1988)

X., L. U., Liu, D: Interlayer shear slip theory for cross-ply laminates with nonrigid interfaces. AIAA J. 30(30), 1063–1073 (2015)

Liang, X., Li, Y., Liu, J., Sang, S., Chen, Y., Li, B.: Fabrication of sic reticulated porous ceramics with multi-layered struts for porous media combustion. Ceram. Int. 42(11), 13091–13097 (2016)

Zhu, X., Jiang, D., Tan, S.: Reaction bonding of open cell SiC-Al2O3 composites. Mater. Res. Bull. 36(11), 2003–2015 (2001)

Mei, S., Yang, J., Ferreira, J.M.F.: Effect of dispersant concentration on slip casting of cordierite-based glass ceramics. J. Colloid Interface Sci. 241(2), 417–421 (2001)

Mewis, J., Wagner, N.J., Thixotropy, A.: Colloid Interfac. 147, 214–227 (2009)

Dolz, M., Hernández, M.J., Pellicer, J., Delegido, J.: Shear stress synergism index and relative thixotropic area. J. Pharm. Sci. 84(6), 728–732 (1995)

Parkinson, C., Matsumoto, S., Sherman, P.: The influence of particle-size distribution on the apparent viscosity of non-newtonian dispersed systems. J. Colloid Interface Sci. 33(1), 150–160 (1970)

Sultana, P., Das, S., Bagchi, B., Bhattacharya, A., Basu, R., Nandy, P.: Effect of size of fly ash particle on enhancement of mullite content and glass formation. B Mater Sci. 34(7), 1663–1670 (2011)

Chen, R., Li, Y., Xiang, R., Li, S.: Effect of particle size of fly ash on the properties of lightweight insulation materials. Constr. Build. Mater. 123, 120–126 (2016)

Creig, J.W.: Formation of mullite from cryanite, andalusite, and silimanite. J. Am. Ceram. Soc. 8(8), 465–484 (2010)

Schneider, H., Schreuer, J., Hildmann, B.: Structure and properties of mullite—a review. J. Eur. Ceram. Soc. 28(2), 329–344 (2008)

Fahrenholtz, W.G., Smith, D.M., Iii, J.C.: Effect of precursor particle size on the densification and crystallization behavior of Mullite. J. Am. Ceram. Soc. 76(2), 433–437 (1993)

Ivankovic, H., Tkalcec, E., Nass, R.: Correlation of the precursor type with densification behavior and microstructure of sintered mullite ceramics. J. Eur. Ceram. Soc. 23(2), 283–292 (2003)

Nakahara, M., Kondo, Y., Hamano, K.: Effect of particle size of powders ground by ball milling on densification of cordierite ceramics. J. Ceram. Soc. Jpn. 107(1244), 308–312 (2010)

Kara, F., Şener, O.: Improvement of sintering and microstructural homogeneity of a diphasic mullite. J. Eur. Ceram. Soc. 21(7), 901–905 (2001)

Fu, L., Gu, H., Ao, H., et al.: Correlations among processing parameters and porosity of a lightweight alumina. Ceram. Int. 44(12), 14076–14081 (2018)

Huang, K., Li, Y., Li, S.: Effects of microsilica addition on the microstructure and properties of alumina foams. Ceram. Int. 42(14), 16401–16404 (2016)

Zhu, Q.Y., Peng, W., Deng, C.J.: The preparation of porous Andalusite refractory by foaming method. Adv. Mater. Res. 881-883, 1026–1030 (2014)

Yao, X., Tan, S., Huang, Z.: Effect of recoating slurry viscosity on the properties of reticulated porous silicon carbide ceramics. Ceram. Int. 32(2), 137–142 (2006)

Xu, X., Li, J., Wu, J.: Preparation and thermal shock resistance of corundum-mullite composite ceramics from andalusite. Ceram. Int. 43(2), (2016)

Zhou, Z.: A thermal-shock-resistance model for laminated ceramics and its validation. J. Eur. Ceram. Soc. 30(6), 1543–1547 (2010)

Yu, H., Wan, J., Liang, K., Da, N., Liu, F.: Toughening and transformation of 14mol% Ce-TZP and Al2O3/Ce-TZP layered micro-composites. J. Mater. Sci. Lett. 18, 1965–1967 (1999)

Bao, Y., Su, S., Huang, J.L.: An uneven strain model for analysis of residual stress and interface stress in laminate composites. J. Compos. Mater. 36(14), 1769–1778 (2002)

Aksel, C.: The effect of mullite on the mechanical properties and thermal shock behaviour of alumina–mullite refractory materials. Ceram. Int. 29(2), 183–188 (2003)

Lai, W., Chang, T., Wang, J.: An evaluation of Mahalanobis distance and grey relational analysis for crack pattern in concrete structures. Comput. Mater. Sci. 65, 115–121 (2012)

Chiang, K., Chang, F.: Optimization of the WEDM process of particle-reinforced material with multiple performance characteristics using grey relational analysis. J. Mater. Process. Technol. 180, 96–101 (2006)

Funding

This work was supported by the National Key Scientific Instrument and Equipment Development Projects (Grant No. 2013YQ040861) and Nanjing University of Aeronautics and Astronautics Graduate Innovation Base (Lab) Open Fund (No. KFJJ20180607).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, Y., Hei, D., Jia, W. et al. Effect of recoating slurry with different particle size on the properties of reticulated porous mullite ceramics. J Aust Ceram Soc 56, 619–629 (2020). https://doi.org/10.1007/s41779-019-00377-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41779-019-00377-9