Abstract

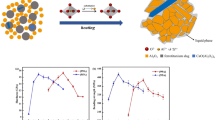

Hot isostatic pressing technique is one of the alternative fabrication processes that have been used to enhance the densification rate in ceramic processing. The aim of this paper is to observe the microstructure and determine the physical and mechanical characterization of alumina ceramic pellets sintered via conventional technique compared to hot isostatic pressing. The semidry alumina ceramic pellets obtained from uniaxially pressing were dried in an oven earlier before sintering via two different techniques. The microstructure of alumina ceramic pellets analyzed by scanning electron microscopy that showed the pellet with particle size (25 μm) and sintered via hot isostatic pressing had larger uniform grain shape and size (16.25 μm), lowest porosity (20.76%), highest bulk density (3.60 g cm−3), low top (2.87%) and bottom (2.68%) shrinkage, and highest hardness (871.56 Hv). The optimum particle size of alumina and sintering technique (HIP) improved the microstructure and physical characterization of ceramic pellets.

Similar content being viewed by others

References

Richardson, D.W.: Modern Ceramic Engineering: Properties, Processing, and Use in Design. (3rd edition), CRC Press, Taylor & Francis Group, Boca Raton, Florida, United States of America (2006)

Alias, S.S., Harun, Z., Latif, I.S.A.: Characterization and performance of porous photocatalytic ceramic membranes coated with TiO2 via different dip-coating routes. J Mater Sci. 53(16), 11534–11552 (2018)

Rahaman, M.N.: Ceramic Processing. CRC Press, Taylor & Francis Group, Boca Raton, Florida, United States of America (2007)

Figiel, P., Rozmus, M., Smuk, B.: Properties of alumina ceramics obtained by conventional and non-conventional methods for sintering ceramics. J Achiev Mater Manuf Eng. 48(1), 29–34 (2011)

Rangogajec, J., Djruric, M., Radeka, M., Jovanic, P.: Influence of particle size and atmosphere on the sintering of powder for tiles production. Ceramics-Silikáty. 44(2), 71–77 (2000)

Shiau, F.-S., Fang, T.-T., Leu, T.-H.: Effects of milling and particle size distribution on the sintering behavior and the evolution of the microstructure in sintering powder compacts. Mater Chem Phys. 57(1), 33–40 (1998)

Mikołajczak, A., Stodolny, M., Łaniecki, M.: Hydrothermal stability of mesoporous SBA-15 modified with alumina and titania. International Journal on Advanced Science, Engineering and Information Technology. 1(1), 60–64 (2011)

Miri, T., Barati, A.: A new method for preparation of cellular ceramics by gelcasting approach. Int J Adv Sci Eng Inf Techno. 2(3), 199–201 (2012)

Reed, J.S.: Introduction to The Principles of Ceramic Processing. Wiley, New York (1988)

Jinka, A.G.K.: A finite-element prediction of densification kinetics during the hot isostatic pressing of metal powder compacts. J Mater Process Technol. 57, 382–392 (1996)

Auerkari, P.: Mechanical and Physical Properties of Engineering Alumina Ceramics. VTT Manufacturing Technology, Technical Research Centre of Finland Espoo (1996)

Wonisch, A., Kraft, T., Moseler, M., Riedel, H.: Effect of different particle size distribution on solid state sintering: a microscopic simulation approach. J. Am. Ceram. Soc. 92(7), 1428–1434 (2009)

Yeh, T.S., Sacks, M.D.: Effect of particle size distribution on the sintering of alumina. J. Am. Ceram. Soc. 71(12), C-484–C-487 (1988)

Yan, M.F., Cannon, R.M., Bowen, H.K., Chowdry, U.: Effect of the grain size distribution. Mater Sci Eng. 60(7), 275–281 (1983)

Ishizaki, K., Takata, A., Okada, S.: Mechanically enhanced open porous materials by HIP process. J. Ceram. Soc. Jpn. 98, 533–540 (1990)

Biasini, V., Parasporo, M., Bellosi, A.: Fabrication and characterisation of Al2O3 porous bodies by isostatic pressing. Thin Solid Films. 297, 207–211 (1997)

Abdul Rahman, H., Rahmat, N., Shariff, M.: Microwave drying effects on properties of alumina zeolite foam. In: 2nd Annual International Conference on Green Technology and Engineering (ICGTE). (2009)

Abdul Rahman, H., Shariff, M., Rahmat, N.: A comparative study of green alumina foams prepared by microwave and conventional drying. In: 4th International Conference on Recent Advances in Materials, Minerals & Environment and 2nd Symposium on Materials & Processing (RAMM & ASMP), pp 1–7 (2009)

Harun, Z., Gethin, D.T.: Drying (consolidation) porous ceramic by considering the microscopic pore temperature gradient. In: Applied Mechanics and Materials. Trans Tech Publ, pp 210–214 (2012)

Ismail, N.F., Harun, Z., Badarulzaman, N.A.: A comparative study of double layers Al2O3/Al2O3 and Al2O3/SiO2 prepared by microwave and natural drying. International Journal of Integrated Engineering. 4(1), 16–21 (2012)

Ma, J., Lim, L.C.: Effect of particle size distribution on sintering of aggomerate-free submicron alumina powder compacts. J. Eur. Ceram. Soc. 22, 2197–2208 (2002)

Brosnan, D.A., Robinson, G.C.: Introduction to Drying of Ceramics: With Laboratory Exercises. Wiley, Hoboken (2003)

Meng, F., Liu, C., Zhang, F., Tian, Z., Huang, W.: Densification and mechanical properties of fine-grained Al2O3-ZrO2 composites consolidated by spark plasma sintering. J Alloys Compd. 512, 63–67 (2012)

Funding

This work was financially supported by the Manufacturing and Materials Centre (AMMC), Faculty of Mechanical and Manufacturing Engineering, Universiti Tun Hussein Onn Malaysia, under the Transdisciplinary Research Grant Scheme (TRGS Vot T001), Post Doc Grant (D005), and Ministry of Higher Education Malaysia (MOHE).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Alias, S.S., Harun, Z. & Ismail, N.F. Microstructure and physical characterization of alumina-sintered body via hot isostatic pressing. J Aust Ceram Soc 55, 969–975 (2019). https://doi.org/10.1007/s41779-019-00308-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41779-019-00308-8