Abstract

Eco-efficiency can be used as a useful indicator for decision-making. However, there are several production segments in which studies on eco-efficiency have not been conducted. One example is the thermal spraying production system. To evaluate eco-efficiency in the context of thermal spraying, one must integrate an approach that is able to assess the environmental impacts generated, as well as the costs involved for each step of the process. One technique that can meet this need is the data envelopment analysis (DEA). The overall objective of this work is to evaluate the eco-efficiency of thermal spray processes, through a combination of environmental and economic indicators using DEA. The environmental and economic variables (input and output) to be evaluated in the spraying process were verified. The framework to be employed for eco-efficiency evaluation was defined, and the evaluation was performed using DEA. A total of 33 decision-making units (DMU)s were evaluated, defined by 33 combinations of spraying processes, varying in three types (high-velocity oxy-fuel (HVOF), arc spray, and flame spray). Of the 33 DMUs, 14 presented scores equal to 1, that is, 14 eco-efficient processes present in the three types of TS analyzed. The type of application material used can influence these results, which can cause variation in the process parameters and in the final cost of the product. Companies in the industry can use these results as a basis to analyze their processes from an environmental standpoint concomitantly with the costs involved and increase their competitiveness in the market.

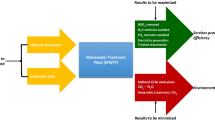

Source: Belém (2023)

Similar content being viewed by others

Data Availability

The authors confirm that the data supporting the results of this study are available in the article.

References

Arabi B, Munisamy S, Emrouznejad A, Toloo M, Ghazizadeh MS (2016) Eco-efficiency considering the issue of heterogeneity among power plants. Energy 111:722–735. https://doi.org/10.1016/j.energy.2016.05.004

Banker RD, Charnes A, Cooper WW (1984) Some models for estimating technical and scale inefficiencies in data envelopment analysis. Manage Sci 30(9):1078–1092. https://doi.org/10.1287/mnsc.30.9.1078

Belem MJX, Vieira Junior M, Mummolo G, Facchini F (2021) An ahp-based procedure for model selection for eco-efficiency assessment. Sustainability 13(21):12121. https://doi.org/10.3390/su132112121

Belém MJX (2023) Proposta de um modelo conceitual para avaliação da ecoeficiência em processos de aspersão térmica. Methodist University of Piracicaba, Thesis

Berg SA, Førsund FR, Jansen ES (1992) Malmquist indices of productivity growth during the deregulation of Norwegian banking, 1980–89. Scand J Econ 94:211–228. https://doi.org/10.2307/3440261

Berger LM (2015) Application of hardmetals as thermal spray coatings. Int J Refract Metal Hard Mater 49(1):350–364. https://doi.org/10.1016/j.ijrmhm.2014.09.029

Bidoki SM, Wittlinger R, Alamdar AA, Burger J (2006) Eco-efficiency analysis of textile coating materials. J Iran Chem Soc 3(4):351–359. https://doi.org/10.1007/BF03245958

Boulos MI, Fauchais PL, Heberlein JVR (2021) Thermal spray fundamentals: from powder to part. Springer Science & Business Media, New York

Brunelli M (2015) Introduction to the analytic hierarchy process. Springer, Espoo

Camanho AS, Silva MC, Piran FS, Lacerda DP (2023) A literature review of economic efficiency assessments using Data Envelopment Analysis. Eur J Oper Res. https://doi.org/10.1016/j.ejor.2023.07.027

Charnes A, Cooper WW, Rhodes E (1978) Measuring the efficiency of decision-making units. Eur J Oper Res 2(6):429–444. https://doi.org/10.1016/0377-2217(78)90138-8

Chung YH, Färe R, Grosskopf S (1997) Productivity and undesirable outputs: a directional distance function approach. J Environ Manage 51(3):229–240. https://doi.org/10.1006/jema.1997.0146

Cooper WW, Seiford LM, Tone K (2006) Introduction to data envelopment analysis and its uses: with DEA-solver software and references. Springer Science & Business Media, New York

Cooper WW, Seiford LM, Zhu J (2011) Handbook on data envelopment analysis. Springer, New York

Egilmez G, Kucukvar M, Tatari O (2013) Sustainability assessment of US manufacturing sectors: an economic input output-based frontier approach. J Clean Prod 53:91–102. https://doi.org/10.1016/j.jclepro.2013.03.037

Ehrenfeld JR (2005) Eco-efficiency: philosophy, theory, and tools. J Ind Ecol 9(4):6–8. https://doi.org/10.1162/108819805775248070

Emrouznejad A, Marra M, Yang GL, Michali M (2023) Eco-efficiency considering NetZero and data envelopment analysis: a critical literature review. IMA J Manag Math 34(4):599–632. https://doi.org/10.1093/imaman/dpad002

Emrouznejad A, Marra M (2017) The state of the art development of AHP (1979–2017): a literature review with a social network analysis. Int J Prod Res 55(22):6653–6675. https://doi.org/10.1080/00207543.2017.1334976

Espallargas N (2015) Future development of thermal spray coatings: types, designs, manufacture and applications. Woodhead Publishing, UK

Fauchais PL, Heberlein JVR, Boulos MI (2014) Thermal spray fundamentals: from powder to part. Springer Science & Business Media, New York

Fotovvati B, Namdari N, Dehghanghadikolaei A (2019) On coating techniques for surface protection: a review. J Manuf Mater Proc 3(1):1–22. https://doi.org/10.3390/jmmp3010028

Gandhi A, Shankar R (2014) Efficiency measurement of Indian retailers using data envelopment analysis. Int J Retail Distrib Manag 42(6):500–520. https://doi.org/10.1108/IJRDM-10-2012-0094

Golany B, Roll Y (1989) An application procedure for DEA. Omega 17(3):237–250. https://doi.org/10.1016/0305-0483(89)90029-7

Grand View Research GVR (2022) Thermal spray coatings market size, share & trends analysis report by product (metal, ceramics, abradable), by technology (plasma spray, HVOF), by application (aerospace, medical), and segment forecasts, 2022 – 2030. GVR. https://www.grandviewresearch.com/industry-analysis/thermal-spray-coatings-market. Accessed 28 April 2023

Grosse-Sommer AP, Grünenwald TH, Paczkowski NS, Van Gelder RN, Saling PR (2020) Applied sustainability in industry: the BASF eco-eEfficiency toolbox. J Clean Prod 258:120792. https://doi.org/10.1016/j.jclepro.2020.120792

Güngör B, Felekoğlu B, Taşan AS (2023) Eco-efficiency maturity model: a practical assessment tool for managers. Environ Dev Sustain 25(6):5087–5121. https://doi.org/10.1007/s10668-022-02257-y

Halkos G, Petrou KN (2019) Treating undesirable outputs in DEA: a critical review. Econ Anal Policy 62:97–104. https://doi.org/10.1016/j.eap.2019.01.005

Huppes G, Ishikawa M (2005) A framework for quantified eco-efficiency analysis. J Ind Ecol 9(4):25–41. https://doi.org/10.1162/108819805775247882

Ji Y, Lee C (2010) Data envelopment analysis. Stata J 10(2):267–280. https://doi.org/10.1177/1536867X1001000207

Koopmans TC (1951) Analysis of production as an efficient combination of activities. Anal Prod Allocation 158(1):33–97

Kortelainen M (2008) Dynamic environmental performance analysis: a Malmquist index approach. Ecol Econ 64(4):701–715. https://doi.org/10.1016/j.ecolecon.2007.08.001

Kuosmanen T, Kortelainen M (2005) Measuring eco-efficiency of production with data envelopment analysis. J Ind Ecol 9(4):59–72. https://doi.org/10.1162/108819805775247846

Lee H, Kim C (2014) Benchmarking of service quality with data envelopment analysis. Expert Syst Appl 41(8):3761–3768. https://doi.org/10.1016/j.eswa.2013.12.008

Leme RD Jr, Nunes AO, Silva DAL (2018) Creating value with less impact: lean, green and eco-efficiency in a metalworking industry towards a cleaner production. J Clean Prod 196(29):517–534. https://doi.org/10.1016/j.jclepro.2018.06.064

Lima CC, Trevisan R (2007) Aspersão térmica: fundamentos e aplicações. Artliber, São Paulo

Lovell CK, Pastor JT, Turner JA (1995) Measuring macroeconomic performance in the OECD: a comparison of European and non-European countries. Eur J Oper Res 87(3):507–518. https://doi.org/10.1016/0377-2217(95)00226-X

Lucato WC, Vieira M Jr, Santos JCS (2013) Measuring the ecoefficiency of a manufacturing process: a conceptual proposal. Manag Environ Qual: Int J 24(6):755–770. https://doi.org/10.1108/MEQ-10-2012-0063

Majid S, Zhang X, Khaskheli MB, Hong F, King PJH, Shamsi IH (2023) Eco-efficiency, environmental and sustainable innovation in recycling energy and their effect on business performance: evidence from European SMEs. Sustainability 15(12):9465. https://doi.org/10.3390/su15129465

Makhlouf ASH, Tiginyanu I (2011) Nanocoatings and ultra-thin films: technologies and applications. Woodhead Publishing Limited, Cambridge

Martins JC, Lacerda DP, Morandi MIWM, Goldmeyer D, Piran FS (2020) Systems dynamic modeling to analyze the systemic viability of the combined use of regenerative converters and energy storage in a UPS manufacturer. J Clean Prod 246:118950. https://doi.org/10.1016/j.jclepro.2019.118950

Mendoza JMF, D’aponte F, Gualtieri D, Azapagic A (2019) Disposable baby diapers: life cycle costs, eco-efficiency and circular economy. J Clean Prod 211:455–467. https://doi.org/10.1016/j.jclepro.2018.11.146

Mu E, Pereyra-Rojas M (2017) Practical decision making using super decisions v3: an introduction to the analytic hierarchy process. Springer, Pittsburgh

Pathak S, Saha GC (2017) Development of sustainable cold spray coatings and 3D additive manufacturing components for repair/manufacturing applications: a critical review. Coatings 7(8):122. https://doi.org/10.3390/coatings7080122

Piran FS, Lacerda DP, Camanho AS, Silva MC (2021) Internal benchmarking to assess the cost efficiency of a broiler production system combining data envelopment analysis and throughput accounting. Int J Prod Econ 238:108173. https://doi.org/10.1016/j.ijpe.2021.108173

Prasaja LE, Hadiyanto (2018) The application potential of eco-efficiency for greening company. In The 2nd International Conference on Energy, Environmental and Information System, vol 31, pp 1–4. https://doi.org/10.1051/e3sconf/20183107012

Ruberti M (2023) The chip manufacturing industry: environmental impacts and eco-efficiency analysis. Sci Total Environ 858:159873. https://doi.org/10.1016/j.scitotenv.2022.159873

Saaty TL (1980) The Analytic Hierarchy Process. McGraw-Hill, New York

Schaltegger S, Sturm A (1990) Ökologische rationalität: ansatzpunkte zur ausgestaltung von ökologieorientierten managementinstrumenten. Die Unternehmung 44(4):273–290. https://www.jstor.org/stable/24180467. Accessed 05 June 2023

Schmidheiny S, Timberlake L (1992) Changing course: a global business perspective on development and the environment. MIT Press, Cambridge

Serres N, Hlawka F, Costil S, Langlade C, Machi F (2010) Microstructures and environmental assessment of metallic NiCrBSi coatings manufactured via hybrid plasma spray process. Surf Coat Technol 205(4):1039–1046. https://doi.org/10.1016/j.surfcoat.2010.03.048

Tone K (2001) A slacks-based measure of efficiency in data envelopment analysis. Eur J Oper Res 130(3):498–509. https://doi.org/10.1016/S0377-2217(99)00407-5

Tschaffon P, Meza LA (2014) Assessing the efficiency of the electric energy distribution using Data Envelopment Analysis with undesirable outputs. IEEE Lat Am Trans 12(6):1027–1035. https://doi.org/10.1109/TLA.2014.6893996

Tyteca D (1997) Linear programming models for the measurement of environmental performance of firms—concepts and empirical results. J Prod Anal 8(2):183–197. https://doi.org/10.1023/A:1013296909029

Vardelle A, Moreau C, Akedo J et al (2016) The 2016 thermal spray roadmap. J Therm Spray Technol 25:1376–1440. https://doi.org/10.1007/s11666-016-0473-x

Viswanathan V, Katiyar NK, Goel G, Matthews A, Goel S (2021) Role of thermal spray in combating climate change. Emergent Mater 4:1515–1529. https://doi.org/10.1007/s42247-021-00307-1

Wigger H, Steinfeldt M, Bianchin A (2017) Environmental benefits of coatings based on nano-tungsten-carbide cobalt ceramics. J Clean Prod 148:212–222. https://doi.org/10.1016/j.jclepro.2017.01.179

World Business Council for Sustainable Development WBCSD (2000) Measuring eco-efficiency: a guide to reporting company performance. WBCSD. https://www.gdrc.org/sustbiz/measuring.pdf. Accessed 28 April 2023

World Business Council for Sustainable Development WBCSD (2006) Introduction to the learning module. WBCSD. https://docs.wbcsd.org/2006/08/EfficiencyLearningModule.pdf. Accessed 28 April 2023

Yin L, Liu J (2023) Impact of environmental economic transformation based on sustainable development on financial eco-efficiency. Sustainability 15(1):856. https://doi.org/10.3390/su15010856

Zheng J, Peng X (2019) Does an ecological industry chain improve the eco-efficiency of an industrial cluster? Based on empirical study of an energy-intensive industrial cluster in China. Sustainability 11(6):1651. https://doi.org/10.3390/su11061651

Zhu C, Zhu N (2023) Assessing the eco-efficiency of industrial investment in China: a DEA approach. IMA J Manag Math 34(1):143–163. https://doi.org/10.1093/imaman/dpab044

Acknowledgements

The researcher Maria Júlia Xavier Belém is grateful for the support of CAPES, Brazil—Funding Code 001. The researcher Fabio Antonio Sartori Piran is grateful for the support of FAPERGS, Rio Grande do Sul, Brazil.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Belém, M.J.X., Junior, M.V. & Piran, F.A.S. Eco-efficiency Evaluation of Thermal Spraying Processes using Data Envelopment Analysis. Process Integr Optim Sustain (2023). https://doi.org/10.1007/s41660-023-00377-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41660-023-00377-0