Abstract

Micro-combined heat and power systems (Micro-CHP) are expected to play a major role in reducing carbon dioxide emission, increasing the primary energy and economic saving in the future. In this paper, the optimal planning of a residential Micro-CHP system for a single-family house situated in Iran is investigated. In order to achieve this target, a new mixed-integer linear programming model is developed. Mathematical modeling and optimization were carried out for the Micro-CHP system using natural gas, at the residential building level and for three different operating strategies, cost-driven, primary energy driven, and carbon emission driven. Three competing objective functions are simultaneously minimized using an augmented ε-constraint optimization algorithm. This work has multiple novelties, containing the consideration of some economic and technical constraints previously neglected, such as the energy, economic, and environmental effects of replacing conventional energy systems with a residential Micro-CHP system and the effects of integrating an electrical heating element for storing thermal energy (electrical heating element can act as a power sink when required). A detailed case study on a residential building situated in Tabriz city, Iran, was carried out by applying the developed model and the optimum strategies and optimal sizes for Micro-CHP, axillary boiler, and other equipment are obtained. Results have shown that the optimal values of CSR, PESR, and ERR, in the augmented ε-constraint method, were 12.46%, 1.19%, and 88.38%, respectively. In this case, the obtained result for a nominal capacity of Micro-CHP and boiler was 3.6 kW and 1.05 kW, respectively. Finally, the payback period was obtained for 2 years. Furthermore, to understand the influence of key parameters on the planning of the Micro-CHP system, the sensitivity analysis has been performed on energy prices. Sensitivity analysis of electricity price indicated that, by increasing the electricity price, the overall annual cost-saving value clearly increases, while increasing gas prices significantly reduces the profitability index.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

At the present time, many countries are developing sustainable energy policies to increase the overall energy conversion efficiencies and reduce emissions. So, technologies such as Micro-CHP, which has been promoted during the last years, become an absorbing alternative to conventional energy systems for providing energy demands in residential buildings. Cogeneration (also known as combined heat and power), CHP is the simultaneous production of electrical or mechanical energy (power) and useful thermal energy from a single energy stream such as oil, coal, natural or liquefied gas, biomass, or solar (ASHRAE handbook - heating, ventilating and air-conditioning systems and equipment (I-P edition) 2008). Cogenerations are not a new concept. Industrial plants go to the concept of cogeneration back in the 1880s when steam was the initial source of energy in industry, and electricity was just surfacing as a product for both power and lighting (ASHRAE handbook - heating, ventilating and air-conditioning systems and equipment (I-P edition) 2008). The use of cogeneration became usual practice as engineers replaced the steam-driven belt and pulley mechanisms with electric power and motors, moving from mechanical powered systems to electrically powered systems. In the early 1900s, as much as 58% of the total power produced in the USA by on-site industrial power plants was appraised to be cogenerated (ASHRAE handbook - heating, ventilating and air-conditioning systems and equipment (I-P edition) 2008).

Micro-CHPs have many functional, economic, and environmental advantages. A micro-CHP system can be integrated with various primary energy resources which consist of natural gas, wind, biomass, solar, geothermal energy, and other renewable energy resources (Zheng et al. 2018).

A wide variety of technologies could be used for Micro-CHP systems compared with the conventional energy systems, so it is considered the most promising technology which can achieve energy conversion efficiency up to 90% (Zheng et al. 2018).

Despite all the above advantages, the optimal design and operation of a Micro-CHP system will not a simple task (Karmellos and Mavrotas 2019). The determination of nominal capacity, the selection of technology combination, and the optimization of operation strategies to fulfill the energy demands needs a great amount of effort. Considering the complexity and difficulty of such process, there is too much interest in the performance evaluation and systematic analysis of Micro-CHP systems (Karmellos and Mavrotas 2019).

Literature Review

Many recent researches have been carried out to find the optimal operation of the Micro-CHP system, such as Barbieri et al. (Barbieri et al. 2012a) and Mongibello et al. (Mongibello et al. 2013), while others worked on the scheduling optimization of these systems (Mongibello et al. 2014). In (Merkel et al. 2015), an optimization model has been developed to determine the optimal capacity of residential Micro-CHP systems. The results have shown that optimal sizing and operation of a Micro-CHP system coupled with an auxiliary boiler and a storage tank can result in an annual cost saving of above 30%. Shaneb et al. (Shaneb et al. 2012) determined the optimal operation strategy of a Micro-CHP system. In this paper, an optimal online operation strategy is presented for the Micro-CHP system, which is more efficient than the aforementioned conventional pre-determined operation strategies. A generic optimal online linear programming (LP) optimizer has been developed for operating a Micro-CHP system. This optimizer is capable of minimizing the daily operation costs of this system. Three different simulation scenarios have been investigated: the new feed-in tariff (FIT) scheme; the trade of electricity; the introduction of a carbon tax. Results have shown that, in all three investigated scenarios, the optimizer significantly reduces operation costs compared to the conventional pre-determined operation strategies. Therefore, the optimizer has the potential to deliver significant energy savings in practice. Barbieri et al. (Barbieri et al. 2012b) have performed an energy and economic analysis with respect to the primary energy savings and payback period. Their analysis was applied to two single-family dwellings, to determine the optimal thermal size of the CHP plant. Conroy and Duffy (Conroy et al. 2014) evaluate the economic, energy, and carbon dioxide emissions performance of a Micro-CHP unit for use in a conventional house in Ireland. Results have revealed that using Micro-CHP can lead to 180€ annual cost-saving, 13.8 years payback period, and 16.1% reductions in carbon dioxide emissions compared to a conventional gas boiler. Caliano et al. (Caliano et al. 2016) analyzed the economic optimization of a Micro-CHP system for a residential building in Italy. The system followed two heat-led operational strategies comprised of limiting the Micro-CHP’s production to the heat loads and having heat dumping. The effect of heat dumping on the optimized operation schedule and feasibility of the economic optimization operation of the Micro-CHP system have been investigated for both operation strategies. Zheng et al. (Zheng et al. 2016) developed a simulation model for a Micro-CHP unit based on an internal combustion engine. Dynamic processes such as startup cool down and overheat protection controls are considered in the model. The results have shown that the primary energy saving ratio and CO2 emission reduction ratio increases with the increase of the start-stop interval. When the start-stop interval is shorter than a certain value, the energy consumption and CO2 emission of the micro-cogeneration unit would be larger than that of a conventional system. As a result, the start-stop interval for the unit in this paper is considered longer than 0.5 h (Zheng et al. 2016). Some previous researchers (Alahaivlaa et al. 2015; Houwing et al. 2011; Blarke 2012; Cao et al. 2013) have indicated that residential Micro-CHP systems can be more flexible if it utilized an electrical heating element to charge a thermal storage unit whenever the price of electricity was low.

Some other approaches were made for the design of a Micro-CHP systems, in most of them mixed-integer linear programming (MILP) models are used to minimize the total annual costs. Franco and Versace (Franco and Versace 2017) proposed some new composite technical and economic indicators to assess the performance of Micro-CHP units in district heating systems. Results have shown that using the defined composite indicators can increase the share of thermal energy produced with the Micro-CHP unit with respect to the conventional boilers. Mohamed et al. (Mohamed et al. 2014) developed a new model which calculated the weighting factors of the weighted matching index (WMI), for Micro-CHP under electrical and thermal tracking strategies, in the net-zero energy building (energy export priority and load-matching priority strategies). Pruitt et al. (Pruitt et al. 2013) proposed an integrated capacity and dispatch optimization model, based on mixed-integer non-linear programming, with regard to the technical characteristics of the CHP system and the thermal storage unit. They applied this model to a large hotel and compare the results with the results achieved from a linear optimization model which ignored mentioned performance characteristics. Results showed that the optimal capacity of the CHP system was 15% lower in the linear approach.

Ghadimi et al. (Ghadimi et al. 2014) investigated the optimal design of CHP systems with regard to their nominal capacity and operational strategy. Using a non-linear optimization model, the optimal size of the CHP system as well as optimal operation strategy is determined based on economic parameters including investment costs and energy prices. Buoro et al. (Buoro et al. 2014) perform an optimization model for an energy supply system including CHP, compression chiller, boiler, solar thermal plant, and a seasonal storage based on mixed-integer linear programming. Using the developed model, the size and existence of each component and energy flows, are determined. The model is implemented for an industrial area and results indicated that by the use of solar systems comprised of a solar field, thermal storage, and a district heat network the lowest costs are incurred.

Buoro et al. (Buoro et al. 2012) using a MILP model optimized the total costs of energy supply systems for two buildings. The same authors in (Buoro et al. 2013) presented a multi-objective optimization model for a distributed energy system. A MILP model was developed. Annual cost and carbon emissions are considered objective functions. The model is solved using the weighted sum method. Kopanos et al. (Kopanos et al. 2013) are developed a mathematical model for the operational strategy of a Micro-CHP system, by minimizing total costs. Omu et al. (Omu et al. 2013) developed a MILP model for optimal sizing and selection of technologies to satisfy heating and electricity loads. In this study, minimizing total annual costs is considered an objective function. Yang et al. (Yang et al. 2015) presented a MILP model to simultaneously optimize the configuration, structure, and locations of energy distribution networks with total annual cost as the objective function.

Falke et al. (Falke et al. 2016) developed a multi-objective optimization model for the operation management and investment planning of CHP systems. The minimizing of the annual total costs of energy and the carbon emissions are considered objective functions. Morvaj et al. (Morvaj et al. 2016) presented a multi-objective optimization MILP model for optimal design and operation of the distributed energy system. In this model, the minimizing of total costs and carbon emissions are considered objective functions and the ε-constraint method is used to solve it. The optimal sizes and configuration of technologies have been calculated for the district system. Sameti and Haghighat (Sameti and Haghighat 2017) proposed a two-level multi-objective optimization model for optimizing the total annual cost and carbon emissions of a tri-generation system. The cooling, heating, and hot water loads should be completely supplied. The results have shown a significant saving in costs and emissions.

Main Contribution and Proposed Improvements

Considering previous researches, the energy, economic, and environmental benefit derived from a residential Micro-CHP system which integrated with an electrical heating element, compared to a separated energy system has not been comprehensively studied. This study presents a methodology that using a techno-economic model optimizes the performance of a residential Micro-CHP system to obtain the optimum strategies and optimal sizes of Micro-CHP, axillary boiler, and other equipment. The Micro-CHP is composed of a gas-fired stirling engine-based prime mover, an auxiliary boiler and a thermal storage tank with an electrical heating element.

The main contributions and proposed improvements of this paper are:

-

a)

A multi-objective optimization model for the design of a Micro-CHP system with three objective functions; CSR (cost-saving ratio), PESR (primary energy saving ratio), and ERR (total annual CO2 emissions reduction ratio) are developed.

-

b)

The mixed-integer linear programming (MILP) model of residential Micro-CHP is solved using the augmented ε-constraint method and the performance of Micro-CHP integrated with an electrical heating element as a power sink is analyzed to obtain the optimum strategies and optimal sizes for Micro-CHP, axillary boiler, and other equipment.

-

c)

To understand the influence of key parameters on the planning and operation strategy of the Micro-CHP system, the sensitivity analysis has been performed on energy prices, and the changes of the cost-saving, primary energy saving, and carbon emission reduction ratio with respect to energy price changes have been analyzed.

This paper is organized as follows: In the “Description of Micro-CHP system” section, a description of Micro-CHP and conventional systems are described. In the “Mathematical modeling” section, the mathematical modeling of the systems is presented and the optimization algorithm is described. In the “Case study” section, the case study is described. In the “Results and discussions” section, the results of the optimization model (single and multi-objective) are presented and finally, the conclusion is described in the “Conclusions” section.

Description of Micro-CHP System

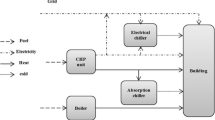

The simplified layout of the proposed residential Micro-CHP system is shown in Fig. 1. The Micro-CHP is composed of a power generation unit, a backup boiler, an electrical heating element as a power sink, and a thermal storage unit for storing the extra heat. The input fuel for a prime mover is natural gas. The Micro-CHP system can work in different operating strategy (thermal, electrical, and cost minimizing led). In order to select an operation mode, several factors are important such as electricity and heat demands of the building and operation cost. In thermal led, all thermal demands are provided at first and electricity is the second product, the extra electricity can send back to the grid and the lack of electricity is provide by the grid, vice versa. In electrical led, the Micro-CHP system is run to provide all electrical demands and heat is the secondary product, the extra heat is save in a thermal storage tank and the lack of heat is supplied by a backup boiler. In a cost-minimizing strategy, the aim is to find the overall minimum cost.

Mathematical Modeling

Micro-CHP Model

One of the most important factors in developing the residential Micro-CHP is economic. Economic assessments give significant information on resources, investment, cost, etc. In this study, a techno-economic model for a Micro-CHP system and conventional system (supply the electrical demands from the grid and thermal demands by a gas boiler) is developed to investigate the energy, economic, and environmental benefits of a residential Micro-CHP, compared to a conventional energy system. The total cost of the residential Micro-CHP system (υTCHP), which consists of the investment costs of Micro-CHP, boiler, and storage tank (υCHP, υBoiler, υTank), the operating costs (υOPCHP, υOPBoiler), annual maintenance cost (υMCHP), cost of buying electricity from the grid (υG), and the negative value of the benefit obtained from selling electricity to the grid (υS), is shown in Eq. (1).

The annual capital cost of Micro-CHP, boiler, and storage tank is shown in Eqs. (2)–(4). Since the investment cost is related to the whole lifetime of the system, and this model minimized the total cost in a sample year, the capital costs are distributed over the lifetime of each system, as shown in Eqs. (2)–(4).

The operation costs of Micro-CHP and boiler are shown in Eqs. (5) and (6), and the annual maintenance cost of Micro-CHP is shown in Eq. (7).

where \({GE}_{d,h}^{CHP}\) and \({T}_{d,h}^{Boiler}\) are the electricity and heat generated by Micro-CHP and boiler andξRCHP and ξRBoiler are maintenance cost coefficient of Micro-CHP and boiler, respectively.

The cost of buying electricity from the grid is:

The benefit of selling electricity to the grid is calculated by Eq. (9).

Imported and exported electricity is:

Constraints (10) and (11) limit the electricity purchased/sold from/to the grid, respectively. where \({G}_{d,h}^G\) and \({G}_{d,h}^S\) are total electrical energy purchased/sold from/to the grid, respectively, \({\kappa}_{d,h}^E\) is electrical load and \({GE}_{d,h}^{\operatorname{Re}s}\) is electrical energy consumed by the electrical heating element.

Main Constraints

In order to avoid infeasibilities in the model, the balance of supply and demand for both electric power and heat is considered as shown in Eqs. (12) and (13) respectively:

where ηt is the efficiency of building heating equipment and \({T}_{d,h}^{BCHP},{T}_{d,h}^{Boiler},{T}_{d,h}^{Out}\) are heat generated by Micro-CHP for using in building, boiler, and discharged heat of the storage tank, respectively. \({\kappa}_{d,h}^S\) and \({\kappa}_{d,h}^W\) are space heating and hot water loads, respectively.

The performance features of the Micro-CHP unit are constrained using Eqs. (14) to (17). Equation (14) indicated that the Micro-CHP plant cannot generate more than its nominal capacity. Equation (15) limits electricity sold to the grid. Equation (16) limits the generated heat of Micro-CHP by its nominal capacity. Equation (17) is implemented to show that the capacity of Micro-CHP should not be below the minimal size of it available in the market. Finally, Eq. (18) indicated that the generated heat of Micro-CHP is the sum of generated heat of Micro-CHP, stored in the storage tank (\({T}_{d,h}^{STCHP}\)) and the generated heat of Micro-CHP, used in the building (\({T}_{d,h}^{BCHP}\)).

The performance feature of the auxiliary boiler is constrained using Eq. (19).

Equation (20) is the thermal balance constraint of the storage tank. It indicates that the total amount of stored heat at the beginning of an hour is equal to the sum of non-wasted heat that has been stored at the beginning of the previous hour and recovered heat that has been delivered to the storage tank during that hour, minus thermal energy discharged from the storage tank. Equation (21) is similar to Eq. (20) but it is written for the first hour of a day. Equations (22) and (23) limit the charging and discharging of heat in the storage tank. The binary variables (\({b}_{d,h}^{In},{b}_{d,h}^{Out}\) ) in (22) and (23) avoid simultaneous charging and discharging of heat.

where \({T}_{d,h}^{Sto}\) is heat stored in the storage tank and \({T}_{d,h}^{In}\) and \({T}_{d,h}^{Out}\) are input/discharge heat to/of the storage tank, respectively.

Equation (24) states that the thermal storage tank cannot charge and discharge simultaneously. Equation (25) indicates that the stored heat should not be more than the nominal capacity of the storage tank.

The amount of heat input to the storage tank is:

As noted before, the electrical heating element is used to convert some of the electricity received from the grid to heat, when the electricity price is low. The heat generated by the electrical heating element (\({T}_{d,h}^{\operatorname{Re}s}\)) is:

The up and down constraint for electrical heating element is:

The volume of the storage tank is also calculated as follows:

where NRTank is the nominal capacity of the storage tank, C is the specific heat of water, ρ is the density of water, and \(\overline{T}\) and \(\underline{T}\) upper and lower bound of water storage temperature.

Separated Energy System Model

The simplified layout of the proposed conventional separated energy system is shown in Fig. 2.

In separate systems, the electrical loads are supplied by the national grid and thermal loads are provided by the boiler. The total costs of a separate system (υTCON) are calculated by Eq. (30).

where υCON is the investment cost of the boiler in a separate system and υMCON is the annual maintenance cost of a separate system. The same as the Micro-CHP the electricity and gas purchasing cost (υGC, υGasCON) are calculated as:

Objective Functions

To analyze the performance of the system, we have considered 3 objective functions which include economic, energy, and environmental functions. The aim of this optimization study is to obtain the optimum strategies and sizes of Micro-CHP, axillary boiler, heat storage tank, and other equipment. Furthermore, the energy economic and environmental benefits of Micro-CHP compared to a conventional energy system can be achieved.

Economic Terms

In economic assessments, an important index is a cost-saving ratio (CSR) that is the difference of the total cost of the separate system and the Micro-CHP system divided by the total cost of the separate system as shown in Eq. (34).

Annual energy cost saving is:

Finally, the payback period (year) is calculated from Eq. (36).

Energy Themes

Primary energy saving rate (PESR) is considered an energy function that can be shown as:

Environmental Issues

The excellent environmental performance of Micro-CHP is one of the motivations to promote these systems. To assess the environmental effects of the Micro-CHP system, the emissions reduction ratio (ERR) is used that can be defined as:

Annual carbon dioxide emission for separate systems is composed of carbon dioxide emission of natural gas and carbon dioxide emission of electricity produced in power stations and calculated from Eq. (41). Similarly, the annual carbon dioxide emission of Micro-CHP is calculated by Eq. (42).

Case Study

To evaluate the proposed model, a residential building in Tabriz city (Iran) has been selected as a case study. The mentioned building is a three-floor (6 units) residential building that we considered one unit of it. The total floor area of that is 150 m2. This building has three bedrooms, a lounge, a kitchen, a bathroom, and a toilet. The Design-Builder software (Design Builder 2019) is used to estimate the hourly energy demand for heating, hot water, cooling, and electricity in a sample year. Fig. 3a–d show the hourly loads of the mentioned building. Fig. 3a indicates the thermal demands of the mentioned building for 8760 h of the planning year. Fig. 3b shows hourly hot water supply-demand, Fig. 3c shows hourly cooling load demand, and finally, Fig. 3d shows the electric hourly load demand of the building during one year.

Energy Prices

The time of use (TOU) tariff for electricity price is shown in Table 1. It is divided in to on-peak, middle-peak and off-peak time and is different in various seasons as shown in Table 2. Some main assumed data for the techno economic model is summarized in Table 3.

Multi-objective Optimization Algorithms

So far, various methods have been used to solve multi-objective optimization problems, including weighted sum (WS) and goal programming (GP) methods (Chen 1998; Aouni et al. 2005); WS and GP are simple techniques for implementation. The main disadvantage of these two methods is that they generate only one solution for a set of weights. To overcome this limitation of WS and GP methods, some other more efficient approaches, such as the ε-constraint method, have been proposed (Mavrotas 2009). Although the ε-constraint method can generate a set of Pareto solutions and control their density in the objective space, there is no guarantee to generate non-dominated solutions. To treat this problem of the ε-constraint method, an augmented ε-constraint method using slack variables has been presented in the literature (Aghaei et al. 2011).

In this paper, we used augmented ε-constraint methods to solve the multi-objective optimization problem of the residential Micro-CHP system, and the performance of the system has been analyzed in different control strategy for a sample year. But, in order to better expose the results of optimization, 12 sample days were selected using the k-mean clustering algorithm (Jain 2010). The multi-objective solution methods have been implemented within the GAMS 24.1.2 software package using CPLEX solver on a PC with a 3.20 GHz processor and 4 GB RAM.

Results and Discussions

Single-Objective Optimization Results

To evaluate the performance of Micro-CHP in comparison with the conventional generation systems, three strategies exist: energy, cost, and carbon emission minimization. The various objectives will lead to various results. The people are worried about not only the energy minimizing performance, but also the cost-minimizing performance and the emissions. The ratio of greater cost minimizing means a better performance of cost-minimizing. In other words, higher energy minimizing means the better performance of energy minimizing. When the system reaches the highest energy minimizing ratio, cost minimizing and reducing carbon emission are not necessarily maximum and vice versa.

Table 4 shows the most important results of this modeling in 4 different cases (strategy of minimum cost, minimum rate of primary energy, strategy of carbon emission minimizing, and the strategy of minimum cost by omitting the impact of thermal electrical heating element).

Table 4 shows the optimized capacity of the Micro-CHP system in the different controlling strategies. The optimized capacity of Micro-CHP in the minimizing primary energy strategy with the amount of 7.8 kW has the highest value. Since the efficiency of thermal power plants is very low in Iran, and also a part of generated electricity is lost in the process of distribution and transmission. The system prefers to use the highest capacity of Micro-CHP for minimizing the amount of primary energy consumption. After that, the optimal capacity of the system in the carbon emission minimizing strategy has the value of 7.5 kW, being at the next rank. According to Table 3, the carbon dioxide emission rate of the grid is higher than the carbon dioxide emission rate of the natural gas so in order to minimize the carbon emission rate, the model will use the highest capacity of the Micro-CHP to supply electrical and thermal loads. In the state of minimizing the energy costs, the optimal capacity equals 2.4 kW, and by removing the impact of the electrical heating element, the optimal capacity does not change.

Being shown in the above table, the electrical heating element has no impact on the optimized capacity of Micro-CHP.

This procedure is totally different about the optimum capacity of the auxiliary boiler. The boiler has the highest capacity (4.4 kW) in the strategy of cost minimizing without considering the electrical heating element, although it has the lowest capacity (0.7 kW) in two cases of primary energy minimizing and carbon emission reduction strategy. In addition, the electrical heating element had a considerable impact on the optimized capacity of the boiler and increased its value from 3.8 kW in the base case to 4.4 kW in the case of not-using the electrical heating element. In fact, there exists a logical relationship between the optimal capacity of Micro-CHP and the auxiliary boiler. Where the Micro-CHP has the lowest capacity, the auxiliary boiler should have the highest capacity in order to provide the thermal loads required and vice versa.

As it was expected about the profitability percentage, it is the highest value (21.1%) in the strategy of cost-minimizing; the profitability percentage decreases a little by removing the electrical heating element and reaches to 20.4%. Meanwhile, the profitability percentage is negative and not justified economically in the control strategies of the primary energy minimizing and the carbon emission minimizing.

In the strategy of primary energy minimizing; the value of primary energy was the highest, i.e., 13.2%. In a similar vein, the amount of carbon emission reduction in the strategy of the lowest amount of disseminated carbon was the highest, 91.5%. Later on, it has been determined as 63.6%, 64.5., and 70.1% in the strategies of cost minimizing, cost minimizing without considering the electrical heating element, and the primary energy minimizing, respectively.

The payback period for the control strategies of cost-energy minimizing and cost-energy minimizing without considering the electrical heating element was 4.4 and 4.6 years, respectively. In addition, the payback period is very high in two control strategies of primary energy minimizing and the carbon emission minimizing due to insignificant savings in the energy costs.

Table 4 also shows the annual savings in energy costs, electricity and gas purchasing costs, benefit of selling electricity to the grid, consumed energy, and carbon emission. The highest profit relates to the result of selling electricity to the grid in the strategy of cost minimizing without considering the electrical heating element. The strategy of cost minimizing is in the next ranks. Meanwhile, no electricity has been sold to the grid in the two strategies of primary energy minimizing and carbon emission minimizing.

Diagrams 4a and 4b illustrate the total heat stored in the heat storage tank in different hours and under the different functional strategies.

According to Fig. 4a, the total stored heat in the storage tank had the highest value in the strategy of cost minimizing, the lowest value in the strategy of primary energy minimizing, and the average value in the strategy of carbon emission minimizing. In diagram 4b, it can be seen that the electrical heating element has not a significant effect on the stored heat in the storage tank.

Multi-objective Optimization Results

In this section, the results obtained from augmented ε-constraint methods for the multi-objective optimization problem of the residential Micro-CHP system are presented.

The Most Preferred Solution

The most preferred solution for the multi-objective optimization problem should be selected among the all Pareto optimal solutions generated, considering the importance of different objective functions. The important factor of the ith objective function in the range of [0,1] such that the sum of important factors is equal to one. The important factor should be determined by the designer. The more preferred solution to the multi-objective optimization problem will have a higher preference. Therefore, the Pareto optimal solution with the highest preference value is the most preferred solution, which will be selected as the final solution of the multi-objective optimization problem. The values of important factors for each of the objective functions in four different cases are shown in Table 5.

where IFCSRIFPESR and IFERR are related to the important factor of cost-saving ratio, primary energy saving ratio, and carbon emission reduction ratio respectively. According to Table 5, it can be shown that the important factor of the cost-saving ratio in all cases is higher than two other factors because in technical-economic analyses, saving energy costs often has a higher priority than other target functions.

The augmented ε-constraint can effectively search the Pareto frontier and generate all Pareto responses. The most advantage of the augmented ε-constraint method is that a uniform set of Pareto points are generated in the design space. The optimal values of the objective functions in 4 cases are shown in Table 6.

Sensitivity Analysis

Sensitivity Analysis of Electricity Price

In order to understand the influence of key parameters on the planning and operation strategy of the Micro-CHP system, sensitivity analysis has been performed on energy prices. The electricity, gas, and electricity buy-back prices change from 1 to 3% of the base price (Table 3). The changes of the cost-saving, primary energy saving, and carbon emission reduction ratio with respect to electricity price changes are shown in Fig. 5. Also, Fig. 6 indicates the changes in the optimal capacity of the heat boiler and Micro-CHP with respect to the electricity price changes.

As shown in Fig. 5, the changes in the CSR curve at low prices are higher than at high prices, i.e., when the electricity price is lower than 2.5 times the base price, the CSR curve shows a significant upward trend and then the changes are low. At the point of 0.6, the CSR has become positive. In fact, the profitability of the system will start from this point. At higher prices, rising electricity price do not have much effect on increasing the profitability index and there should be other policies such as increasing the electricity buy-back rate and creating subsidies to buy these products to motivate consumers. According to Fig. 5, curves PESR and ERR have no obvious change, i.e., only a small decrease when the price increase from 2.1 to 3 times the base price. As a result, when the electricity rate varies from 0.1 to 3 times the base price, the overall annual cost-saving rate clearly increases with the electricity price, while the primary energy savings and carbon emission reductions have a little change.

As indicated in Fig. 6, when the change in electricity price is in the range of 0.1 to 1.7, the optimum capacity of the boiler and Micro-CHP has not changed. After that, with a further increase in electricity rate, the optimum capacity of Micro-CHP was increased and the optimum capacity of the boiler was reduced. When the electricity rate rises, it would be wise to increase the nominal capacity of Micro-CHP, because the system prefers to generate large parts of the required power alone.

The changes of the cost-saving, primary energy saving and carbon emission reduction ratio with respect to gas price changes is shown in Fig. 7. Figure 8 shows the changes in the optimal capacity of the heat boiler and Micro-CHP with the gas price changes.

With respect to Figs. 7 and 8, it can be seen that the increase in gas prices significantly reduces the profitability index while the carbon emission reduction ratio remains constant. The primary energy saving rate has remained constant over the range of 0.1 to 0.8 and then increased. The optimum capacity of Micro-CHP and boilers in the range of 0.1 to 1.3 has been unchanged, and then with the increase in gas prices, the optimal capacity of the Micro- CHP is slightly reduced and the boiler’s optimum capacity is slightly increased. When the gas price rises, it would be wise to decrease the nominal capacity of the power generation unit.

As shown in Fig. 7, the sensitivity of the system’s profitability index to gas prices at low prices is much higher than at high prices. For instance, when the gas price is in the range of 0.1 to 1.5, the CSR changes from 37.07 to 8.78%, and then, there has been less change.

It is also seen in chart 8 that rising gas prices has led to a slight decrease in the capacity of Micro-CHP, and the boiler capacity slightly increases. When gas prices increase, the optimum capacity of Micro-CHP has been decreased to reduce energy costs and increase the profitability of the system. In contrast, in order to meet the thermal energy needs, the boiler capacity has been increased. According to the above diagrams, it can be concluded that electricity and gas prices have reverse effects on the optimization outcomes.

The changes of the cost-saving, primary energy saving, and carbon emission reduction ratio with respect to electricity buy-back price changes are shown in Fig. 9. Also, Fig. 10 indicates the changes in the optimal capacity of the heat boiler and Micro-CHP with the electricity buy-back price changes.

Considering Fig. 9, it can be deduced that the increase in electricity buy-back price led to a significant increase in CSR (from 2.37 to 57.19%). While the carbon emission reduction ratio remained constant. The ratio of primary energy savings has dropped as electricity prices rise up. With regard to Fig. 10, by increasing the electricity buy-back price, the optimal capacity of Micro-CHP has increased and the boiler capacity has reduced. When the electricity buy-back price increases, the electrical capacity of the Micro-CHP increased; therefore, more electricity and heat are generated, so the thermal capacity of the boiler has decreased.

In the following, the simultaneous effect of gas and electricity price changes on the key factors of the system will be investigated. Cost-saving ratio changes with electricity and gas price is shown in Fig. 11.

Regarding Fig. 11, it can be seen that the highest value of CSR was 57.50% which occur at the point of 0.6 for gas price and 3 for the electricity price, and the lowest value of it was − 16.02% at the point of 3 and 0.6 for gas and electricity price, respectively. In fact, when the gas price is the lowest and the electricity price is the highest, we will have the highest profitability. Because in this case, Micro-CHP operates with the highest capacity so it will generate the highest amount of heat and electricity, as a result, a large part of the surplus electricity is sold to the grid and the profitability index increases. Figure 12 shows the primary energy saving ratio changes with electricity and gas price changes.

As shown in Fig. 12, by changing the electricity and gas price, the primary energy savings ratio has been changed in the small range from 1.63 to − 1.85. The highest value of PESR was 1.63% which occur at the point of 0.6 for electricity price and 3 for the gas price, and the lowest value of it was −1.85% at the point of 3 and 0.6 for electricity and gas price, respectively. In fact, when the gas price is the highest and the electricity price is the lowest, we will have the highest value of PESR.

It is worth noting that primary energy consumption in conventional systems is not sensitive to changes in gas and electricity price, and only changes with load changes, but in Micro-CHP when the electricity price increases and the gas price decreases, the optimum capacity of Micro-CHP will rise. As a result, the primary energy consumption will increase and the percentage of energy savings will decrease.

According to the above explanations, it can be found that opposite goals lead to different results of optimization and multi-objective optimization is used to create a compromise between these objectives and to find the best point which optimized all goals simultaneously.

In the following, the carbon emission reduction ratio changes with electricity and gas price changes is shown in Fig. 13.

Figure 13 shows that gas and electricity price changes have a small effect on the carbon emissions reduction ratio and in most cases, the ERR remains constant at 85.27% value.

Finally, Fig. 14 shows the optimum capacity of Micro-CHP and boiler changes with electricity and gas price changes.

According to Fig. 14a and b, it is observed that the maximum capacity of Micro-CHP (3.38 kw) and the minimum capacity of the boiler (1.29 kw) occurred at the point of 3 for electric price and 0.6 gas base price. Also, the lowest capacity of Micro-CHP (2.98 kw) and the maximum capacity of the boiler (2.42 kw) were at the point of 0.6 electricity prices and 3 times the gas price.

Conclusions

This study presents a methodology that optimizes the performance of a residential Micro-CHP system integrated with an electrical heating element as a power sink to obtain the optimum strategies and optimal sizes for Micro-CHP, axillary boiler, and other equipment. Using a detailed techno-economic model, the energy, economic, and environmental benefits of a residential Micro-CHP system, compared to conventional energy systems, are conducted. Results have shown that the optimal values of CSR, PESR, and ERR, in the augmented ε-constraint method (with the important factor of 0.6, 0.2, and 0.2 for CSR, PESR, and ERR respectively), were 12.46%, 1.19%, and 88.38%, respectively. In this case, the obtained result for a nominal capacity of Micro-CHP and boiler was 3.6 kW and 1.05 kW, respectively. Finally, the payback period was obtained for 2 years.

In the following, some of the most important results of this modeling are presented:

-

1.

The optimized capacity of Micro-CHP in the minimizing primary energy strategy with the amount of 7.8 kW has the highest value. After that, the optimal capacity of the system in the carbon emission minimizing strategy has the value of 7.5 kW, being at the next rank. The electrical heating element has no impact on the optimized capacity of Micro-CHP.

-

2.

The boiler has the highest capacity (4.4 kW) in the strategy of cost minimizing without considering the electrical heating element, although it has the lowest capacity (0.7 kW) in two cases of primary energy minimizing and carbon emission reduction strategy. In addition, the electrical heating element had a considerable impact on the optimized capacity of the boiler and increased its value from 3.8 kW in the base case to 4.4 kW in the case of not-using the electrical heating element. In fact, there exists a logical relationship between the optimal capacity of Micro-CHP and the auxiliary boiler. Where the Micro-CHP has the lowest capacity, the auxiliary boiler should have the highest capacity in order to provide the thermal loads required and vice versa.

-

3.

Sensitivity analysis of electricity price indicates that, when the electricity rate varies from 0.1 to 3 times the base price, the overall annual cost-saving value clearly increases with the electricity price, while the primary energy savings and carbon emission reductions have a little change.

-

4.

Sensitivity analysis of gas price indicates that the increase in gas prices significantly reduces the profitability index while the carbon emission reduction ratio remains constant.

-

5.

Electricity and gas prices have reverse effects on the optimization outcomes.

-

6.

Increasing the electricity buy-back price led to a significant increase in CSR (from 2.37% to 57.19%). While the carbon emission reduction ratio remained constant. The ratio of primary energy savings has dropped as electricity prices rise up. By increasing the electricity buy-back price, the optimal capacity of Micro-CHP has increased and the boiler capacity has reduced.

According to the cases mentioned above, it can be realized that different functional strategies and also the real prices of electricity and gas influence the system’s functional parameters and the optimized capacity of the equipment. To gain an accurate and comprehensive analysis, an exhaustive investigation of the system, technical data equipment and other effective cases should be carried out.

Data Availability

The data that support the findings of this study are available on request from the corresponding author. The data are not publicly available due to their containing information that could compromise the privacy of research participants.

Abbreviations

- υ TCHP :

-

Total cost of residential Micro-CHP system ($)

- υ TCON :

-

Total energy costs of a separate system ($)

- υ CON :

-

Investment cost of the separate system ($)

- υ CHP :

-

Investment cost of Micro-CHP unit ($)

- υ Boiler :

-

Investment cost of the boiler ($)

- υ Tank :

-

Investment cost of the storage tank ($)

- υ OPCHP :

-

Operation cost of Micro-CHP ($)

- υ OPBoiler :

-

Operation cost of boiler ($)

- υ GasCON :

-

Cost of purchasing gas for separate system ($)

- υ G :

-

Cost of buying electricity from the grid ($)

- υ S :

-

Benefit of selling electricity to the grid ($)

- υ MCHP :

-

Maintenance cost of Micro-CHP ($)

- υ Save :

-

Annual energy cost saving ($)

- υ MCON :

-

Annual maintenance cost of a separate system ($)

- υ ECON :

-

Electricity purchasing cost for separate system ($)

- δ CHP :

-

Investment cost coefficient of Micro CHP ($/kw)

- δ Boiler :

-

Investment cost coefficient of boiler ($/kw)

- δ BCON :

-

Investment cost coefficient of boiler in a separate system ($/kw)

- δ Tank :

-

Investment cost coefficient of storage tank ($/kw)

- ξ RCHP :

-

Maintenance cost coefficient of Micro-CHP ($/kWh)

- ξ RBoiler :

-

Maintenance cost coefficient of boiler ($/kWh)

- N RCHP :

-

Nominal capacity of Micro-CHP (kW)

- N RBoiler :

-

Nominal capacity of auxiliary boiler (kW)

- N RTank :

-

Nominal capacity of the storage tank (kW)

- N RBoilerCON :

-

Nominal capacity of auxiliary boiler in a separate system (kW)

- \({GE}_{d,h}^{CHP}\) :

-

Electricity generated by Micro-CHP (kWh)

- \({GH}_{d,h}^{CHP}\) :

-

Heat produced by Micro-CHP (kWh)

- \({GE}_{d,h}^{\operatorname{Re}s}\) :

-

Electrical energy consumed by the electrical heating element (kWh)

- \({G}_{d,h}^G\) :

-

Total electrical energy purchased from the grid (kWh)

- \({G}_{d,h}^S\) :

-

Total electrical energy sold to the grid (kWh)

- \({T}_{d,h}^{Boiler}\) :

-

Generated heat of boiler (kWh)

- \({T}_{d,h}^{STCHP}\) :

-

Heat generated by Micro-CHP, stored in the storage tank (kWh)

- \({T}_{d,h}^{Sto}\) :

-

Heat stored in the storage tank (kWh (

- \({b}_{d,h}^{In}\) :

-

Binary variable for charging the storage tank

- \({b}_{d,h}^{Out}\) :

-

Binary variable for discharging the storage tank

- C :

-

Specific heat of water (kJ/kg °C)

- E TCHP :

-

Energy consumption of Micro-CHP (kWh)

- E CON :

-

Energy consumption of separate systems (kWh)

- CE CON :

-

Emission of a separate system (kg)

- CE CHP :

-

Emission of Micro-CHP (kg)

- υ GC :

-

Cost of buying electricity from the grid in the conventional system ($)

- \({T}_{d,h}^{Out}\) :

-

Heat discharged from the storage tank (kWh)

- \({T}_{d,h}^{In}\) :

-

Heat input to the storage tank (kWh)

- \({T}_{d,h}^{BCHP}\) :

-

Heat generated by Micro-CHP for using in building

- \({T}_{d,h}^{Boiler}\) :

-

Heat generated by boiler (kWh)

- \({T}_{d,h}^{\operatorname{Re}s}\) :

-

Heat produced by electrical heating element (kWh (

- \({\kappa}_{d,h}^E\) :

-

Electrical load (kWh)

- \({\kappa}_{d,h}^S\) :

-

Space heating load (kWh)

- \({\kappa}_{d,h}^W\) :

-

Hot water load (kWh)

- \({\varpi}_{d,h}^{ele}\) :

-

Power consumption tariff ($/kWh)

- \({\varpi}_{d,h}^{Gas}\) :

-

Gas price ($/m3)

- \({\varpi}_{d,h}^S\) :

-

Selling price of electricity to the grid ($/kWh)

- \({B}_m^{ele}\) :

-

Monthly base fee for electricity price ($)

- m :

-

Number of months (12)

- d :

-

Number of days (365)

- h :

-

Number hours (24)

- I :

-

Interest rate

- T :

-

lifetime of each system (year)

- HR :

-

Heating ratio (kWh/m3)

- V Tank :

-

Volume of storage tanks (m3)

- η b :

-

Efficiency of boiler (%)

- η t :

-

Efficiency of building heating equipment (%)

- η e :

-

Average efficiency of power plants (%)

- η grid :

-

Transmission and distribution efficiency (%)

- η eCHP :

-

Electrical efficiency of Micro-CHP (%)

- η tCHP :

-

Thermal efficiency of Micro-CHP (%)

- η Res :

-

Electricity to heat converting efficiency in electrical heating element (%)

- k :

-

Steps of consumption

- \(\overline{T}\) :

-

Upper bound of water storage temperature (°C)

- \(\underline{T}\) :

-

Lower bound of water storage temperature (°C)

- \({\overline{GE}}^{\operatorname{Re}s}\) :

-

Maximum electric power of electrical heating element (kW)

- σ :

-

Heat loss coefficient (h−1(

- N LimCHP :

-

Minimal commercial capacity of Micro-CHP (kW)

- M Hbig :

-

Big enough parameter

- γ gas :

-

Carbon intensity of the natural gas (kg/m3)

- γ ele :

-

Carbon intensity of the grid (kg/kwh)

- CSR :

-

Cost-saving ratio (%)

- PESR :

-

Primary energy saving ratio (%)

- ERR :

-

Emissions reduction ratio (%)

- Payback :

-

Payback period (year)

- ρ :

-

Density of water (kg/m3)

References

Aghaei J, Amjady N, Shayanfar HA (2011) Multi-objective electricity market clearing considering dynamic security by lexicographic optimization and augmented epsilon constraint method. Appl Soft Comput 11(4):3846–3858

Alahaivala A, Heb T, Cao S, Lehtonen M (2015) Analyzing the optimal coordination of a residential micro-CHP systemwith a power sink. Appl Energy 149:326–337

Alahaivlaa A, Heb T, Cao S, Lehtonen M (2015) Analyzing the optimal coordination of a residential micro-CHP system with a power sink. Appl Energy 149:326–337

Aouni B, Ben Abdelaziz F, Martel JM (2005) Decision-maker’s preferences modeling in the stochastic goal programming. Eur J Oper Res 162(3):610–618

ASHRAE handbook - heating, ventilating and air-conditioning systems and equipment (I-P edition) (2008) American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc

Barbieri ES, Melino F, Morini M (2012a) Influence of the thermal energy storage on the profitability of micro_CHP systems for residential building applications. Appl Energy 97:714–722

Barbieri ES, Spina PR, Venturini M (2012b) Analysis of innovative micro-CHP systems to meet household energy demands. Appl Energy 97:723–733

Blarke MB (2012) Towards an intermittency-friendly energy system: comparing electric boilers and heat pumps in distributed cogeneration. Appl Energy 91(1):349–365

Buoro D, Casisi M, Pinamonti P, Reini M (2012) Optimal synthesis and operation of advanced energy supply systems for standard and domestic home. Energy Convers Manag 60:96–105

Buoro D, Casisi M, De Nardi A, Pinamonti P, Reini M (2013) Multicriteria optimization of a distributed energy supply system for an industrial area. Energy 58:128–137

Buoro D, Pinamonti P, Reini M (2014) Optimization of a distributed cogeneration system with solar district heating. Appl Energy 124:298–308

Caballero F, Sauma E, Yanine F (2013) Business optimal design of a grid-connected hybrid PV (photovoltaic)- wind energy system without energy storage for an Easter Island’s block. Energy 61:248–261

Caliano M, Bianco N, Graditi G, Mongibello L (2016) Economic optimization of a residential micro-CHP system considering different operation strategies. Appl Therm Eng 101:592–600

Cao S, Hasan A, Siren K (2013) Analysis and solution for renewable energy load matching for a single-family house. Energy Build 65(0):398–411

Chen YL (1998) Weighted-norm approach for multi objective VAR planning. IEE Proceedings - Generation, Transmission and Distribution 145(4):369–374

CLICKSANAT (2017) Production Group of Click Sanat. Available at: http://www.clicksanat.com/

Conroy G, Duffy A, Ayompe LM (2014) Economic, energy and GHG emissions performance evaluation of a WhisperGen Mk IV stirling engine l-CHP unit in a domestic dwelling. Energy Convers Manag 81:465–474

Design Builder (2019) Simulation services, software sales & support. [Online]. Available: https://designbuilder.co.uk

Falke T, Krengel S, Meinerzhagen AK, Schnettler A (2016) Multi-objective optimization and simulation model for the design of distributed energy systems. Appl Energy 184:1508–1516

Franco A, Versace M (2017) Optimum sizing and operational strategy of CHP plant for district heating based on the use of composite indicators. Energy 124:258–271

Ghadimi P, Kara S, Kornfeld B (2014) The optimal selection of on-site CHP systems through integrated sizing and operational strategy. Appl Energy 116:38–46

Houwing M, Negenborn R, De Schutter B (2011) Demand response with micro-CHP systems. Proc IEEE 99(1):200–213

Jain AK (2010) Data clustering: 50 years beyond K-means. Pattern Recogn Lett 31(8):651–666

Karmellos M, Mavrotas G (2019) Multi-objective optimization and comparison framework for the design of distributed energy systems. Energy Convers Manag 180:473–495

Kopanos GM, Georgiadis MC, Pistikopoulos EN (2013) Energy production planning of a network of micro combined heat and power generators. Appl Energy 102:1522–1534

Li H, Kang S, Lu L, Liu L, Zhang X, Zhang G (2017) Optimal design and analysis of a new CHP-HP integrated system. Energy Convers Manag 146:217–227

Mavrotas G (2009) Effective implementation of the ɛ-constraint method in multi-objective mathematical programming problems. Appl Math Comput 213(2):455–465

Merkel E, McKenna R, Fichtner W (2015) Optimization of the capacity and the dispatch of decentralized micro-CHP systems: a case study for the UK. Appl Energy 140:120–134

Micro CHP products (2018) Micro combined heat and power. Available at: http://www.microchap.info/micro_chp_products.htm

Mohamed A, Cao S, Hasan A, Siren K (2014) Selection of micro-cogeneration for net zero energy buildings (NZEB) using weighted energy matching index. Energy Build 80:490–503

Mongibello L, Bianco N, Caliano M, Graditi G, Musto M (2013) Optimal operation of micro-CHP systems for a single-family house in Italy. Appl Mech Mater

Mongibello L, Graditi G, Bianco N, Musto M (2014) Optimal operation of residential micro-CHP systems with thermal storage losses modelling. International Symposium on Power Electronics, Electrical Drives, Automation and Motion, Italy

Morvaj B, Evins R, Carmeliet J (2016) Optimizing urban energy systems: simultaneous system sizing, operation and district heating network layout. Energy 116:619–636

Napoli R, Gandiglio M, Lanzini A, Santarelli M (2015) Techno-economic analysis of PEMFC and SOFC micro-CHP fuel cell systems for the residential sector. Energy Build 103:131–146

National Iranian Gas Company, NIGC (2017) Available at: http://www.iraniangas.ir

Omu A, Choudhary R, Boies A (2013) Distributed energy resource system optimization using mixed integer linear programming. Energy Policy 61:249–266

Pruitt KA, Braun RJ, Newman AM (2013) Evaluating shortfalls in mixed-integer programming approaches for the optimal design and dispatch of distributed generation systems. Appl Energy 102:386–398

Ren H, Gao W, Ruan Y (2008) Optimal sizing for residential CHP system. Appl Therm Eng 28:514–523

Rist JF, Dias MF, Palman M, Zelazo D, Cukurel B (2017) Economic dispatch of a single micro-gas turbine under CHP operation. Appl Energy 200:1–18

Sameti M, Haghighat F (2017) A two-level multi-objective optimization for simultaneous design and scheduling of a district energy system. Appl Energy 208:1053–1070

Shaneb OA, Taylor PC, Coates G (2012) Optimal online operation of residential CHP systems using linear programming. Energy Build 44:17–25

Tavanir company (2017) The Company of Management, production, transmission and distribution of electricity. Electric Power Industry Statistics. Available at: http://www.tavanir.org.ir

THE RENEWABLE ENERGY HUB (2018) Micro combined heat and power - micro CHP information. Available at: https://www.renewableenergyhub.co.uk/micro-combined-heat-and-power-micro-chp-information/types-of-chp-and-microchptechnologieshtml#jump_21927

Yang Y, Zhang S, Xiao Y (2015) A MILP (mixed integer linear programming) model for optimal design of district-scale distributed energy resource systems. Energy 90:1901–1915

Zeng R, Li H, Jiang R, Liu L, Zhang G (2016) A novel multi-objective optimization method for CCHP–GSHP coupling systems. Energy Build 112:149–158

Zheng CY, Wu JY, Zhai XQ, Yang G, Wang RZ (2016) Experimental and modeling investigation of an ICE (internal combustion engine) based micro-cogeneration device considering overheat protection controls. Energy 101:447–461

Zheng X, Wu G, Qiu Y, Zhan X, Shah N, Li N, Zhao Y (2018) A MINLP multi-objective optimization model for operational planning of a case study CCHP system in urban China. Appl Energy 210:1126–1140

Funding

Open Access funding provided by University of South-Eastern Norway

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Teymoori H., F., Safari, A. & Kamalinasab, M. Augmented ε-Constraint Algorithm Applied to Multi-objective Optimization Programs of Residential Micro-CHP Systems. Process Integr Optim Sustain 6, 1143–1161 (2022). https://doi.org/10.1007/s41660-022-00254-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41660-022-00254-2