Abstract

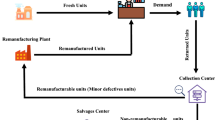

This paper develops an integrated inventory model for a closed-loop supply chain (CLSC) system consisting of a manufacturer and a retailer. The demand and the returns of used products are assumed to be stochastic in nature. A carbon tax policy is implemented to cut down the emissions from transportation, production, and storage. To lessen the emissions from the operations, the manufacturer invests in green technologies. In addition, the take-back investment is also done by the manufacturer to increase the number of returned products collected from the market. A mathematical model is proposed to minimize the joint total cost incurred by the supply chain. An iterative procedure is employed to find the optimal values of the number of shipments, amount of investments, safety factor, shipment quantity, and the collection rate. A numerical example and a sensitivity analysis are presented to show the application of the model and to investigate the influence of key parameters on the performance of the model. The results show that by adjusting the production rate flexibly and setting the appropriate level of collection rate, the supply chain can maintain the emissions and cost. Furthermore, the green investment and take-back investment can be used as mechanism to cut down the emissions and to manage the requirement of used product in the production process.

Similar content being viewed by others

Data availability

My manuscript has no associated data, or the data will not be deposited.

References

As’ad R, Hariga M, Alkhatib O (2019) Two stage closed loop supply chain models under consignment stock agreement and different procurement strategies. Appl Math Model 65:164–186

Bai Q, Xua J, Chauhan SC (2020) Effects of sustainability investment and risk aversion on a two-stage supply chain coordination under a carbon tax policy. Comput Ind Eng 142:106324

Bazan E, Jaber MY, El-Saadany AMA (2015) Carbon emissions and energy effects on manufacturing–remanufacturing inventory models. Comput Ind Eng 88:307–316

Bazan E, Jaber MY, Zanoni S (2017) Carbon emissions and energy effects on a two-level manufacturer-retailer closed-loop supply chain model with remanufacturing subject to different coordination mechanisms. Int J Production Economics 183(part B):394–408

Ben-Daya M, Hariga M (2004) Integrated single vendor single buyer model with stochastic demand and variable lead time. Int J Prod Econ 92(1):75–80

Bhattacharya R, Kaur A (2014) Single stage closed loop manufacturing-remanufacturing system profitability with different combinations of internal and external return flows: an analytical study. Int J Logist Syst Manag 17(4):416–446

Bogaschewsky R (1995) Natürliche Umwelt und Produktion. Gabler-Verlag, Wiesbaden

De M, Giri BC (2020) Modelling a closed-loop supply chain with a heterogeneous fleet under carbon emission reduction policy. Trans Res E: Logist Transp Rev 133:1–24

Dobos I, Richter K (2004) An extended production/recycling model with stationary demand and return rates. Int J Prod Econ 90(3):311–323

Dwicahyani AR, Jauhari WA, Rosyidi CN, Laksono PW (2017) Inventory decisions in a two-echelon system with remanufacturing, carbon emission, and energy effects. Cogent Eng 4:1–17

Dwicahyani AR, Kholisoh E, Rosyidi CN, Laksono PW, Jauhari WA (2020) Inventory model optimisation for a closed-loop retailer-manufacturer-supplier system with imperfect production, reworks and quality dependent return rate. Int J Serv Oper Manag 35(4):528–556

El Saadany AMA, Jaber MY (2008) The EOQ repair and waste disposal model with switching. Comput Ind Eng 55(1):219–233

El Saadany AMA, Jaber MY (2011) A production/remanufacture model with returns’ subassemblies managed differently. Int J Prod Econ 133(1):119–126

Ghosh A, Jha JK, Sarmah SP (2017) Optimal lot-sizing under strict carbon cap policy considering stochastic demand. Appl Math Model 44:688–704

Giri BC, Glock CH (2017) A closed-loop supply chain with stochastic product returns and worker experience under learning and forgetting. Int J Prod Res 55(22):6760–6778

Hadley G, Within TM (1963) Analysis of Inventory Systems. Prentice-hall, Englewood Cliffs

Hasanov P, Jaber MY, Zolfaghari S (2012) Production, remanufacturing and waste disposal models for the cases of pure and partial backordering. Appl Math Model 36(11):5249–5261

Hasanov P, Jaber MY, Tahirov N (2019) Four-level closed loop supply chain with remanufacturing. Appl Math Model 66:141–155

H&M Group (2018) H&M Sustainability Report. https://hmgroup.com/content/dam/hmgroup/groupsite/documents/masterlanguage/CSR/reports/2018_Sustainability_report/HM_Group_SustainabilityReport_2018_%20FullReport.Pdf

Jauhari WA, Hendaryani O, Kurdhi NA (2018) Inventory decisions in a closed-loop supply chain system with learning and rework. Int J Procure Manag 11(5):551–585

Jauhari WA, Septian RD, Laksono PW, Dwicahyani AR (2020) A Closed-loop Supply Chain Inventory Model Considering Limited Number of Remanufacturing Generation and Environmental Investigation. IOP Conf Ser: Mater Sci Eng 943(1):012054

Jauhari WA, Adam NAFP, Rosyidi CN, Pujawan IN, Shah NH (2020) A closed-loop supply chain model with rework, waste disposal, and carbon emissions. Oper Res Persp 7:100155

Khouja M, Mehrez A (1994) Economic production lot size model with variable production rate and imperfect quality. J Oper Res Soc 45(12):1405–1417

Konstantaras I, Skouri K, Benkherouf L (2021) Optimizing inventory decisions for a closed–loop supply chain model under a carbon tax regulatory mechanism. Int J Prod Econ 239:108185

Liao H, Li L (2021) Environmental sustainability EOQ model for closed-loop supply chain under market uncertainty: a case study of printer remanufacturing. Comput Ind Eng 151:106525

Lou GX, Xia HY, Zhang JQ, Fan TJ (2015) Investment strategy of emission-reduction technology in a supply chain. Sustainability 7:10684–10708

Mawandiya BK, Jha JK, Thakkar JJ (2020) Optimal production-inventory policy for closed-loop supply chain with remanufacturing under random demand and return. Oper Res: Int J 20:1623–1664

Mishra M, Hota SK, Ghosh SK, Sarkar B (2020) Controlling waste and carbon emission for a sustainable closed-loop supply chain management under a cap-and-trade strategy. Mathematics 8(4):466. https://doi.org/10.3390/math8040466

Mitra S (2009) Analysis of a two-echelon inventory system with returns. Omega 37(1):106–115

Modak NM, Kelle P (2021) Using social work donation as a tool of corporate social responsibility in a closed-loop supply chain considering carbon emissions tax and demand uncertainty. J Oper Res Soc 72(1):61–77

Nahmias N, Rivera H (1979) A deterministic model for repairable item inventory system with a finite repair rate. Int J Prod Res 17(3):215–221

Panja S, Mondal SK (2019) Analyzing a four-layer green supply chain imperfect production inventory model for green products under type-2 fuzzy credit period. Comput Ind Eng 129:435–453

Richter K (1996a) The EOQ and waste disposal model with variable setup number. Eur J Oper Res 95(2):313–324

Richter K (1996b) ‘The extended EOQ repair and waste disposal model. Int J Prod Econ 45(1–3):443–447

Saga RS, Jauhari WA, Laksono PW, Dwicahyani AR (2019) Investigating carbon emissions in a production-inventory model under imperfect production, inspection errors and service-level constraint. Int J Logistic Syst Manag 34:29–55

Samuel CN, Venkatadri U, Diallo C, Khatab A (2020) Robust closed-loop supply chain design with presorting, return quality and carbon emission considerations, Journal of Cleaner Production, https://doi.org/10.1016/j.jclepro.2019.119086

Sarkar B, Tayyab M, Kim N, Habib MS (2019) Optimal production delivery policies for supplier and manufacturer in a constrained closed-loop supply chain for returnable transport packaging through metaheuristic approach. Comput Ind Eng 135:987–1003

Schaefer B, Konur D (2015) Economic and environmental considerations in a continuous review inventory control system with integrated transportation decisions. Transp Res Part E 80:142–165

Schrady DA (1967) ‘A deterministic model for reparable items. Nav Res Logist Q 14(3):391–398

Son Y, Kim T, Omar M (2015) The beneficial effect of information sharing in a two-stage reverse supply chain. Int J Procure Manag 8(6):688–709

Taleizadeh AA, Haghighi F, Niaki STA (2019) Modeling and solving a sustainable closed loop supply chain problem with pricing decisions and discounts on returned products. J Clean Prod 207:163–181

Taleizadeh AA, Moshtagh MS (2019) A consignment stock scheme for closed loop supply chain with imperfect manufacturing processes, lost sales, and quality dependent return: multi levels structure. Int J Prod Econ 217:298–316

Taleizadeh AA, Alizadeh-Basban N, Niaki STA (2019b) A closed-loop supply chain considering carbon reduction, quality improvement effort, and return policy under two remanufacturing scenarios. J Clean Prod 232:1230–1250

Teunter RH (2001) Economic order quantities for recoverable item inventory system. Nav Res Logist 48(6):484–495

Wahab MIM, Mamun SMH, Ongkunaruk P (2011) EOQ models for a coordinated two-level international supply chain considering imperfect items and environmental impact. Int J Prod Econ 134:151–158

Wang Z, Wu Q (2021) Carbon emission reduction and product collection decisions in the closed-loop supply chain with cap-and-trade regulation. Int J Prod Res 59(14):4359–4383 (in press)

Wangsa ID (2017) Greenhouse gas penalty and incentive policies for a joint economic lot size model with industrial and transport emissions. Int J Ind Eng Comput 8:453–480

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jauhari, W.A., Wangsa, I.D. A Manufacturer-Retailer Inventory Model with Remanufacturing, Stochastic Demand, and Green Investments. Process Integr Optim Sustain 6, 253–273 (2022). https://doi.org/10.1007/s41660-021-00208-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41660-021-00208-0