Abstract

In plasmas, a variety of radicals which are defined as electrically neutral radicals in this article are efficiently produced by collisions between electrons and gas molecules. These radicals can subsequently undergo gas phase reactions with solids, liquids and living organisms that result in non-equilibrium surface/interface physicochemical processes. The specific phenomena produced by these reactions remain largely unknown, even though these plasma-based processes could lead to disruptive technological innovations. As an example, in the case of semiconductor microfabrication processes, the density, energy and lifetime of individual radicals, as well as the reaction time constants of these species with various materials should be ascertained. This would allow the identification and control of the effective radical species during processes, such as the high-precision etching and deposition of functional thin films. In addition, the type of reactions occurring between radicals generated in plasmas with liquids or living organisms is still an unexplored area. Establishing a theoretical system for these radical reactions and controlling the associated mechanisms could lead to innovations in the fields of functional devices and materials as well as in the areas of environmental protection, medicine and agriculture/fisheries. Focusing on the non-equilibrium surface/interface physicochemical reactions between radicals and solids occurring in semiconductor plasma processing, this paper describes the formation of nanostructured thin films by top-down mechanisms based on controlled radical production and bottom-up processes involving radical-induced self-organization. As well, this review examines next-generation medical and agricultural applications, such as the selective killing of cancer cells and plant growth promotion and functionalization. These systems result from the interactions of radicals generated in atmospheric-pressure, low-temperature plasmas with liquids, or the interactions of gas or liquid phase radicals with biological species. Finally, the importance of academic research into radical-controlled plasma processes and potential future technologies based on this interdisciplinary field are examined.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Beginning in the 1970s, basic research regarding the use of plasma in semiconductor manufacturing emerged and, with the development of large-scale integrated circuits, the field of advanced semiconductor plasma processing has become important. Today, plasmas are used in 80% of semiconductor manufacturing processes and contribute to the manufacture of many items used in daily life. Approximately 55 years have passed, since Moore’s law was first proposed as both a summary of and a prediction for the growing semiconductor industry (Moore 1965). This law states that the number of transistors on an integrated circuit (IC) chip doubles every 18 months, and highlights the importance of miniaturization in the semiconductor industry. As a result of the ongoing miniaturization of ICs based on technological innovations aimed at increasing the number of components per chip, this law has continued to hold true. The increasing integration of semiconductor chips has been closely associated with the development of plasma processes such that, at present, plasma processing is the key technology driving semiconductor microfabrication. Currently, semiconductor devices are primarily fabricated using core plasma processes, including plasma etching, deposition and surface modification techniques. As these technologies are refined, revolutionary innovations are expected to occur that will create the society of the future.

Figure 1 depicts the innovations resulting from improvements in plasma science and technology, which has undergone a major evolution in association with the development of semiconductor plasma processing. This technology comprises plasma diagnostics, generation and control, along with modeling and simulation. Research into plasma technology incorporates disciplines within both science and engineering, including mathematics, informatics, chemistry, physics, agriculture, medicine, pharmacy and so on, making this a truly interdisciplinary endeavor. Plasma-based materials and processes have resulted in the appearance of new academic fields, such as plasma electronics and plasma chemistry, and have made significant contributions to industry. However, many of the non-equilibrium physical and chemical reactions resulting from the interactions among electrons, ions, radicals, radiation and solids in plasmas have not yet been fully elucidated. More recently, atmospheric-pressure non-equilibrium plasmas and in-liquid plasmas have been developed and have attracted significant attention based on their potential applications in industry as well as in medicine, agriculture and fisheries. In particular, new research concerning the interactions between plasmas and liquids has become a global trend. The microscopic structures of plasmas and their physicochemical reactions at the plasma-liquid interface is an unexplored scientific field. In addition, research and development of plasma processes, which is a cutting-edge core science and technology, has become extremely significant as a field that creates basic science while leading industry.

The non-equilibrium physical and chemical reaction fields caused by plasmas have also produced a variety of phenomena that have led to disruptive innovations. Plasmas have been incorporated into the microfabrication technology used to manufacture semiconductors because of the discovery of phenomena that cannot be realized by existing physical chemistry occurring in thermal equilibrium, opening up new fields of application. Thus, plasma science and technology is an interdisciplinary field that is expected to bring about various innovations in fields, such as nanotechnology, green technology, agriculture and fisheries, and medicine. This progress could enable the creation of future devices and materials while providing solutions to environmental problems, increased agricultural production and novel medical breakthroughs. Plasma-based technologies are also thought to have the potential to bring about social innovations such as the creation of devices and materials for digital transformation and to allow the mitigation of environmental problems, such as by ensuring carbon neutrality.

Despite the potential of plasma-based technology, 50 years of continuous research and development in this field has not kept pace with technological progress in general. One reason for this lack of progress is that available techniques for assessing the active species in plasmas have not been used sufficiently. Of course, plasma diagnostics and measurement techniques have been developed over the past five decades (Hori and Goto 2002; Bruggeman et al. 2016) and have revealed previously unknown phenomena and greatly advanced the development of plasma processes. In particular, methods to measure the densities and energies of electrons, ions, radicals, and radiation in plasmas have been devised and are relatively well established, with the exception of the measurement of some special active species. However, these techniques for the analysis of plasmas are not presently widely applied to plasma-based manufacturing and high-precision control processes to collect and systematize practical and reliable information.

It is evident that plasmas involve complex reaction systems and, as such, many researchers continue to use a trial-and-error research approach based on experience and intuition. Consequently, there is a need to develop more systematic processes that use scientific data. To this end, it is especially necessary to systematize the various phenomena produced by plasmas and to evaluate plasma processes and non-equilibrium plasmas. Figure 2 illustrates a potential approach to the systematic development of plasma science. As an example, in the case of the plasma processing of semiconductors, factors such as the deposition rate are related to the plasma power, pressure and gas flow rate. These external parameters are, in turn, strongly dependent on the type and geometry of plasma equipment, such that the deposition rate characteristics vary from equipment to equipment. As such, these etching characteristics are not purely scientific data. Because a plasma comprises electrons, ions, radicals and radiation, ascertaining the density and energy of these components and describing the deposition characteristics in terms of particle-based parameters (that is, internal parameters) provides equipment-independent scientific data. Monitoring the internal parameters of the plasma, especially the particle properties, can assist in describing various plasma-induced phenomena such that a reliable scientific understanding can be achieved.

During the plasma processing of semiconductors, particles in the plasma interact with solid surfaces and induce phenomena, such as etching and deposition. In particular, the interactions of charged ions and neutral radicals are thought to play a major role in non-equilibrium physicochemical reactions occurring on solid surfaces and/or subsurfaces. Thus, it is important to determine the types of ions and radicals on a solid surface, along with the absolute densities and energies of these species, and to evaluate the reaction rate constants and the loss probabilities of these particles. Such data can be correlated with quantitative etching and deposition characteristics so as to better understand non-equilibrium physicochemical reaction fields.

The reactions in plasmas are diverse and complex as a result of the many reactive species that can be present. The densities and energies of electrons, ions and radiation can be measured using relatively simple methods, while the absolute densities and energies of radicals are very difficult to ascertain, because these species are electrically neutral. As noted, developing a plasma processing science will require an understanding of the behavior of particles in plasmas and of correlations between particles and processing characteristics. The difficulty associated with measuring the densities of radicals is a major challenge in realizing this approach and so the system illustrated in Fig. 2 has not yet been achieved. Furthermore, because plasma treatments are carried out in various environments and there are numerous methods of generating plasmas, data regarding the in situ spatio-temporal distributions of particles, while reactions are taking place are required to understand these processes.

When evaluating the densities of ions and radicals in plasma processes, the densities of the latter will be more than an order of magnitude higher than those of the former. Consequently, radicals play an important role in these systems and should be systematically defined. The standard definition of a free radical is a species having an unpaired electron that is extremely reactive even at room temperature. However, in plasma processes, any electrically neutral reactive particle having a relatively short lifetime that participates in chemical reactions can be referred to as a radical. In a plasma, gas molecules are typically dissociated by collisions with electrons to generate reactive particles, after which these particles collide with other species in the gas phase and eventually reach the surface of the solid or liquid. These reaction processes are very complex. In particular, as the pressure increases, the frequency of collisions between particles in the gas phase increases and the radicals produced by electron impact are transformed into more diverse types by particle collisions. Therefore, it becomes necessary to measure the spatio-temporal distributions of radicals to fully understand the plasma process and to control the behavior of these species.

Recently, non-equilibrium atmospheric-pressure plasmas have been developed and so the behavior of radicals at ambient pressure has attracted much attention. The mean free path of particles at atmospheric pressure is on the micrometer level and the reactions due to particle collisions in the gas phase are very complex, with many radical species being generated as a result of such collisions. Furthermore, these radical species react with solid surfaces based on their surface loss probabilities. The loss probability for radicals at the surface (equal to the surface reaction probability) is, in turn, determined by the type of radical and its energy, and this probability varies greatly depending on the interactions of the radical with ions. In general, the reactivity of radicals can be increased by irradiation with high-energy ions. The reactions of such radicals with solid surfaces can lead to etching, deposition and surface modification, and some radicals can also form structures with unpaired electrons in solids. Recently, with the development of non-equilibrium atmospheric-pressure plasmas (that is, low-temperature atmospheric-pressure plasmas), the interactions of radicals with liquids have also become of interest as gas phase radicals will react with liquids to produce new radical species in the liquid.

The reactions of radicals in liquids are more complex than those on solid surfaces, and these species are typically transformed into chemically stable particles within a short time frame. Reactions between radicals in liquids and living organisms can also have bioactive effects, such as stimulating an organism to generate radicals and inactivating molecules in the organism by inducing various signal transductions (that is, forming in vivo radicals). The various bioactive substances that can be induced in living organisms in this manner can potentially result in the selective destruction of cancer cells as well as wound healing, gene transfer, regeneration of living tissues, promotion of plant growth, inactivation of viruses and killing of pathogens. The potential for chains of radical reactions from the gas phase to the interiors of living organisms has led to the emergence of new fields, namely, plasma medicine and plasma agriculture.

Figure 3 provides an overview of potential future innovations that could be brought about by the systematization and control of radical reactions in plasma processes. These processes have the potential to realize nano-information devices and environmental innovations that will create an advanced future society. To accomplish these goals, several developments are required. These include devising means of assessing the spatio-temporal distributions of radicals, quantification of the fundamental physical properties of radicals (such as surface reaction probabilities) and the effects of these properties, modeling and simulation of radical reactions, development of approaches to controlling radicals, and research into new technologies to control radicals. As shown in Fig. 3, innovations in silicon-based ultra-large scale integrated circuits (ULSIs), quantum devices, cell phones, artificial intelligence (AI) and nano-information devices may allow the realization of an advanced society. These innovations will require ultra-precise control of the behavior of radicals and ions in ultra-high density plasmas. In particular, the development of large-area, high-throughput, ultra-high density plasma devices and autonomous plasma generation systems capable of fine spatio-temporal control of particle fluctuations will be necessary (Hori et al. 2011). It will also be a requirement to incorporate self-organized reactions to allow the fabrication of ULSIs in conjunction with ultra-fine processing on the 1 or 2 nm scale. Currently, technologies to process materials in atomic layer units (atomic layer etching) (Kanarik et al. 2015; Oehrlein et al. 2015) and to deposit thin films in atomic layer units while processing solid surfaces (ALE: atomic layer deposition) are being developed (George 2010; Puurunen 2014; Johnson et al. 2014). Therefore, it is necessary to control the spatio-temporal fluctuations of the densities and energies of radicals in the plasma and to be able to observe and precisely control the solid surface reactions induced by radicals at the atomic level.

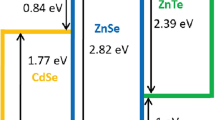

The plasma processes on which etching is based are able to produce three-dimensional (3D) heterogenous integrated microstructures by controlling the particles in the plasma, meaning that this is a so-called top-down process. As shown in Fig. 3, the use of self-organization phenomena induced by plasmas has attracted attention as a mean of realizing environmentally friendly innovations related to fuel cells, batteries, light-emitting diodes, solar cells, power devices, thermal electronic devices, carbon dioxide conversion and catalysis. The tuning of radical reactions could also allow the synthesis of nanomaterials with one-dimensional (1D), two-dimensional (2D) or 3D structures through self-assembly, equivalent to a bottom-up process. Thus, radical-controlled plasmas are expected to result in the creation of functional materials with ultrafine structures and new properties via the integration of top-down and bottom-up processes.

The last part of Fig. 3 shows the development of non-equilibrium atmospheric-pressure plasmas and non-equilibrium liquid plasmas, which has been actively pursued since approximately 2000. Studies have led to industrial applications, such as ultrafast material surface modification, bonding processes and the high-speed synthesis of nanoparticles. The development of room-temperature and room-pressure plasmas have also made it possible to irradiate pathogens, cells and biological tissues with plasmas. Starting with the use of plasmas for sterilization and disinfection, plasmas were later applied in the fields of medicine, pharmacy, agriculture and fisheries. As an example, it is now evident that plasma-based radicals can interact with various biological tissues to induce controlled and regulated cell suicide in vivo, meaning programmed cell death, such as apoptosis.

In this review, the principles of radical-controlled plasma processes are explained in Sect. 2, followed by examinations of techniques for assessing gas phase radicals during plasma processing in Sect. 3, approaches to radical-controlled plasma processes in Sect. 4, and radical-controlled plasma etching, thin-film deposition and growth processes in Sect. 5. Autonomously controlled radical processes are described in Sect. 6, radical control in atmospheric-pressure plasma processing in Sect. 7, the effects of direct irradiation with radicals on living organisms in Sect. 8, the development of plasma-activated media in Sect. 9, radical-induced material processing in liquids and/or interfaces in Sect. 10, and future prospects in Sect. 11. Section 12 provides a summary of radical-controlled plasma processes.

2 Principles of radical-controlled plasma processes

2.1 Generation of radicals

Figure 4 summarizes a plasma-based process. In such systems, active species such as ions, radicals and photons are generated on the basis of the ionization, attachment, dissociation and excitation of gaseous species by collisions with electrons. Reactive plasmas produce non-equilibrium physico-chemical reaction fields due to the inclusion of chemically active species, and these can be distinguished from the physical fields associated with noble gas plasmas. It is important to note that the formation of radicals in a plasma is completely different from the dissociation of molecules resulting from thermal excitation or other means. During the dissociation of a molecule in response to heat, the position and velocity of the molecule change and the distance between the nuclei along the dissociation potential curve varies. This causes the potential energy of the system to increase above the bond dissociation energy such that the molecule dissociates. In contrast, in the case of a plasma, collisions with electrons excite molecules without changing their position or velocity, leading to ionization and/or dissociation according to the Frank–Condon principle. Thus, when electrons having energies of several eV collide with gas phase molecules, high-energy active species (ions, radicals and photons) are produced. The generation of these products via thermal energy requires temperatures of several thousand degrees, whereas these can be obtained at relatively low temperatures in a plasma.

The frequency at which a given feedstock gas undergoes electron impacts can be expressed as kne, where k and ne denote the rate constant for the collision process and the electron density, respectively. Therefore, the rate of generation of active species by ionization, dissociation or excitation per second per unit volume can be written as

where ng is the feedstock gas density. The value of k can be calculated as

where E is the energy of electrons in the plasma, σ(E) is the cross-sectional area of the collision process between electrons and the source gas (that is, the probability that the molecules will be ionized or dissociated in a given collision), and v is the velocity of an electron during a collision, that is (2E/m)1/2 and f(E) are the electron energy distribution function (EEDF). The value of f(E) can be obtained based on Maxwell's energy distribution equation, written as

where Te and kB are the electron temperature and Boltzmann constant, respectively. The number of reactive particles produced is determined by the collision cross section for each process relative to the energy distribution of the electrons.

During the formation of radicals, the dissociation cross section for the gas is determined by the type of gas molecules that are present. Therefore, the EEDF in the plasma and the choice of feedstock gas are important aspects of reactive particle formation. In reactive plasma processes, a wide variety of active species are produced simultaneously. Some of these are important to the processing performance, while others are detrimental to the process. If the density of active species required for high processing performance can be increased (in particular that of radicals) and an optimal plasma composition can be obtained, then very high precision can be achieved. This is the essence of radical-controlled plasma processing, which is the primary subject of the present paper. As indicated by Eq. (2.1), it is important to select the optimum gaseous reactant so as to achieve the desired radical composition and density, and to control the ionization and dissociation of the raw material to provide the optimum EEDF and electron density for radical generation.

The residence time of gas molecules in the plasma, τ, can be expressed as

where p is the pressure, V is the volume of the plasma, and S is the flow rate of the gas. The density, n, of radicals produced by collisions between electrons and the reaction gas in the plasma is

Equation (2.5) demonstrates that, because the EEDF is a function of electron temperature, the radical generation process in the plasma can be tuned by controlling the reaction gas type, electron temperature, electron density and gas residence time.

Finally, the density of the radicals (based on the balance between radical generation and loss) can be expressed by Eq. (2.6). Here, ke and ke' are the rate constants for electron impact dissociation (in the case that the electron temperature varies spatially), while ne is the electron density, ng is the density of the feedstock gas, n is the density of the active species (that is, neutral radicals), N1 is the density of particles, k1 is the rate constant for reactions between particles and radicals, for example, N2 is the density of other particles, and k2 is the rate constant for reactions between these particles and radicals. The radical production rate resulting from electron impact is keneng, while that resulting from reactions is k1nN1. The losses stemming from electron impact, gas phase reactions, reactions at surfaces or walls and diffusion or pumping are ke'nen, k2nN2, n/τs and n/τ, respectively. Here, τs and τ are the lifetimes of the particles before they are depleted by surface reactions or by diffusion/pumping, respectively.

For these particles, the conservation rate in the steady state (meaning that production and loss are in equilibrium) can be expressed as

The diffusion lifetime, τs, can be calculated as (Chantry 1987)

where Λ0 and l0 are the geometric diffusion length and the volume-to-area ratio of the chamber, D is the diffusion coefficient and β is the loss probability for radicals.

2.2 Extinction terms for radicals

As shown in Fig. 4, the radicals produced in the plasma are injected into a material (either a solid or liquid) via collisions in the gas phase which depend on the mean free path. The velocities of the neutral particles (that is, the radicals) produced by the plasma have a Maxwellian distribution at thermodynamic equilibrium. Therefore, the average velocity, < v > , of these particles when incident on a surface will equal the sum of the velocities of all the molecules divided by the total number of molecules. Consequently, the velocity (or flux) of the particles at a given solid surface can be expressed as

where

Here, m and T are the mass and temperature of the radicals. Radicals that contact the surface of a solid or liquid will react with that surface to cause etching, deposition or surface modification, upon which the radical disappears.

Figure 5 presents a diagram of the surface reactions of such radicals and indicates that some of the incident radicals do not contribute to the surface reaction and are reflected directly, based on the reflection probability. Others diffuse across the surface, recombine to form other molecules and disappear, based on the recombination probability (γ). Those that remain will adhere to the surface and result in reactions, according to the sticking probability (s). Therefore, the total loss probability (β) is γ + s and the reflection probability is 1-β. It is important to understand this loss probability to control the radicals (Perrin et al. 1998). The relationships between processing characteristics (such as etching, deposition and surface modification) and the value of β or s can be summarized as

and

where nʹ is the density of radicals at the surface of the substrate. It should be noted that the spatial distribution of radicals is required to estimate their contribution to the reaction using Eq. (2.11). The radical loss probability can vary greatly depending on several factors. These factors include the chemical binding energy, the presence of dangling bonds and defects, the surface structure and the surface morphology, all of which can affect the chemical composition and energy states of the material with which the radicals react. Other important parameters are the temperature of the material, the surface charge, and the densities and energies of charged and neutral particles. It is known that these factors can greatly affect the etching and deposition rates, especially as the interactions between the incident ions and radicals with the substrate are modified. In the case that the incident ion energy is low, the ions can interact with radicals to promote thin-film formation (Shiratani et al. 1998) and surface modification on the substrate and/or reactor walls. In contrast, if the ion bombardment energy exceeds the material bond threshold, the substrate will be etched by reactive sputtering and the etching rate will increase along with the incident ion energy. Therefore, the loss term at the surface will vary greatly as the density and energy of the incident ions are changed.

On this basis, it is evident that tuning the radical surface loss probability is a very important aspect of radical-controlled plasma processing. This tuning requires that the correlations between processing characteristics (such as etching rate, deposition rate and surface modification), and the surface loss probability under various conditions, are known. In contrast, when atmospheric-pressure non-equilibrium plasmas interact with liquids, the surface loss probability for radicals entering from the gas phase is expected to be almost unity, although data to this effect have not yet been reported and so this represents a new research area in this field. A variety of radical species, such as reactive oxygen species (ROS) and reactive nitrogen species (RNS), are generated in liquids irradiated with plasma. Since the densities and lifetimes of these radicals are greatly affected not only by the type of liquid but also by temperature and pH, there is a need to establish technology to control radicals in liquids. Of particular interest are the various radical scavengers that have been developed to inactivate radicals in solution. The resulting concentration of radicals can be determined by the balance between the generation and annihilation rates as in Eq. (2.6) and adjusting these terms allows the density of radicals in the liquid to be tuned.

Figure 6 summarizes the possible radical generation and extinction processes that are available for radical control. Radical-controlled plasma processes can be realized by adjusting the factors in Eq. (2.6). In addition, Hiramatsu et al. (2004) have developed a new radical control method, which was named radical injection by Hori in which the desired radicals are pre-generated externally and injected into the plasma processing space, as described in Sect. 5.10.1. Using this method, it is possible to control radicals beyond the framework of the gas generation term based on electron impact and reaction factors.

3 Measuring gas phase radicals during plasma processing

A number of methods have been developed to ascertain the composition, density and dynamics of radicals in plasma processes and to understand the behavior of these radicals, which play important roles in the process. Figure 7 presents the typical techniques used to monitor radicals and trends in the various radical types with respect to the particle parameters that determine the radical generation term in Eq. (2.5). Further information regarding techniques for measuring radicals in plasmas is available in the literature (Hori et al. 2002; Bruggeman et al. 2016).

The typical techniques used to monitor radicals and trends in the various radical types with respect to the particle parameters that determine the radical generation term in Eq. (2.5)

A variety of gases are used in plasma processes and numerous radical species can appear in plasmas. As an example, when fluorocarbons, hydrocarbons or silicon hydride are introduced as the feedstock gas, radicals are generated according to Eq. (2.5). The density and energy distribution function for electrons in the plasma, which are important factors in the generation of these radicals, can be measured using a Langmuir probe, absorption probe, laser Thomson scattering spectroscopy or microwave interferometry. Radicals produced by electron impact dissociation of the feedstock gas molecules can be classified into higher order, lower order or atomic radicals. The higher order radicals can be monitored using electron or ion attachment mass spectrometry, while lower order radicals can be measured by mid-infrared time-resolved frequency comb, infrared diode laser absorption, ultraviolet absorption, ring-dye laser absorption, cavity ring-down, laser-induced fluorescence (LIF), laser resonance ionization or appearance mass spectroscopic techniques. Atomic radicals can be examined using vacuum ultraviolet absorption spectroscopy (VUVAS), multiphoton LIF, appearance mass spectrometry or electron spin resonance (ESR). Comb spectroscopy in particular has recently received much attention and dual comb techniques can generate a wide range of wavelengths in the mid-to-near-infrared region, allowing OH radicals to be monitored.

In radical-controlled plasma processing, it is also necessary to determine the spatio-temporal distribution of various radicals in the gas phase with respect to parameters, such as the absolute density and energy of the radicals (meaning the oscillation, rotation and translation temperatures). In the case of the pulsed plasmas described below, high-precision plasma processing can be obtained using pulses to control the dynamics of radical formation and annihilation based on the fundamental properties of radicals, such as their reaction and diffusion constants and extinction and attachment probabilities. In particular, the lifetimes of radicals during the off time between pulses is an important factor when designing the process.

4 Approaches to radical-controlled plasma processes

Abe et al. (2008) proposed an approach to developing a plasma-based etching process in which the reaction products are removed by an exhaust stream. For this method to be viable, it is necessary to determine the reaction products in the plasma while assuming that the products will eventually become volatile such that they can be removed using a pump. As an illustration of this process, the chemical binding energies and volatilities/vapor pressures and boiling points of the reaction products that may be produced by the interaction of radicals and ions in the plasma during ULSIs fabrication are summarized in Table 1. Based on these data, we can estimate the possible reactions that can occur in the plasma, the volatile reaction products and the required processing temperatures and energies. In particular, from the vapor pressure values, it is possible to define the gas pressure and plasma source needed to drive the desired etching reaction, shape (isotropic or anisotropic) and rate. The raw material gas that is required and the radicals that will be produced from that gas are determined based on Eq. (2.5). Here, the important parameter is the electron temperature, which is responsible for the majority of the gas-dependent plasma characteristics and in turn is affected by the gas pressure, gas flow rate, applied field strength and frequency, reactor structure and wall material, in addition to the processing conditions. The accumulation of the self-bias voltage (Vdc) that appears on the surface of a substrate on a radio frequency (RF) biased electrode is also an important process parameter that can control the energy of the incoming ions and their distribution. When selecting the feedstock gas, it is also important to carefully select the global warming potential of this gas to protect the environment.

When developing plasma processes, it is vital to understand the correlation between equipment parameters (that is, external parameters), such as pressure, power and gas flow rate, and internal parameters related to electron temperature, electron density and particle densities/energies, as shown in Fig. 2. Figure 8 summarizes the particle parameters based on the radicals in the plasma as well as approaches to controlling radicals during plasma processes. As a model process, we here discuss thin-film deposition using a SiH4 plasma as an example, in accordance with Fig. 8. Chittick et al. (1969) showed that hydrogenated amorphous silicon can be obtained by decomposing silane using a glow discharge, representing a breakthrough in plasma-based thin-film formation. Spear et al. (1975) succeeded in controlling the charge of amorphous silicon thin films deposited by glow discharge and discovered that these films could be applied to semiconductor devices. In 1980, the industrialization of amorphous silicon thin-film solar cells was initiated. Around the same time, Madan et al. (1979) and Matsuda (2004) discovered that microcrystalline silicon (μc-Si) could be formed at low temperatures by diluting a large volume of hydrogen gas in conjunction with plasma enhanced chemical vapor deposition (PECVD).

This discovery drew attention to the behavior of deposition precursors and hydrogen atoms during deposition in plasma processes using silane and hydrogen gas, and led to the construction of a model for the growth mechanism. This research, in turn, resulted in the production of thin-film silicon devices for solar cells. Subsequently, microcrystalline silicon thin films were also employed in thin-film transistors for liquid–crystal displays, leading to new breakthroughs in electronic devices. However, it remains necessary to improve the properties of amorphous silicon and microcrystalline silicon thin films, and new advances in plasma processes may make this possible. For this purpose, it is necessary to understand the gas-phase and surface reactions of active species in plasmas, especially process-critical radicals, and to construct thin-film deposition models to control critical radicals, as shown in Fig. 8.

Many researchers are working to establish these methods, and the properties of particles in H2 diluted SiH4 plasmas are becoming clearer. Based on correlations between thin-film properties and experimentally observed radical behavior, the radicals acting as precursors for thin-film deposition (e.g., SiH3) have been identified and their densities and surface adhesion coefficients determined. Other radicals, such as H, that are considered to be important during thin-film deposition by etching and the chemical termination of surfaces have also been identified. The densities and surface adhesion coefficients for such active species have also been clarified. Observations of various radicals in plasma processes and investigations of the surface attachment coefficients for these radicals have provided important insights into the most important species involved in such processes (Perrin 1998; Hori 2007). Recently, it has also become possible to predict process performance using simulations predicated on these basic parameters. Artificial Intelligence (AI)-based machine learning using large experimental data sets has been employed to derive important parameters for such processes. In fact, models of radical behavior constructed from assessments of the gas phase and surface reactions of these radicals have shown that SiH3 are the most important species serving as precursors for the fabrication of defect-free microcrystalline silicon thin films involved in the formation of high-quality amorphous silicon (a-Si) and μc-Si thin films. Such studies have examined the spatial distributions of densities of SiH3 using IRLAS (Infrared diode laser absorption spectroscopy) (Itabashi et al. 1988, 1990) and have also clarified the densities of H (Takashima et al. 2001), which play an important role in promoting the surface reactions of SiH3 in the process plasma. The reactions of these radicals have been found to be dependent on the surface temperature (Matsuda et al. 1990). A surface reaction model for radicals at relatively low pressures has been proposed by Perrin (1991), as shown in Fig. 9 and established, based on the accumulation of many measurements of radicals in silane plasmas (Matsuda 2004).

Plasma induced surface reactions during a-Si:H film growth (Perrin 1991)

Interestingly, Abe et al. (2013)) determined the density and extinction times for H in a SiH4/H2 plasma at room temperature using VUV absorption spectroscopy (VUVAS) with a micro hollow-discharge cathode lamp (MHCL) (Takashima et al. 1999) and found that the surface loss probability for H varied from 0.01 to 0.32 as the flow rate of SiH4 was adjusted. This probability was also greatly affected by the interaction between the surface and deposited species, such as SiH3, acting as thin-film precursors. Furthermore, it was found that the surface loss probability for H becomes 1 at a substrate temperature of 200 °C even after deposition. These results indicated that SiH3 and H were important active species that had a significant impact on thin-film formation.

Regarding behaviors of radicals at a low pressure in the high-density plasma, the densities of Si, SiH and SiH3 radicals in the electron cyclotron resonance (ECR) SiH4/H2 plasma, where SiH4 feed stock gas was much depleted were measured as a function of microwave power and total pressure, using IRLAS and ultraviolet absorption spectroscopy (UVAS). It was clarified that Si, SiH and SiH3 densities in the SiH4(50%)/H2 ECR plasma were 3.6 × 109, approximately 1 × 109 and 1.7 × 1010 cm−3, respectively, at the microwave power of 400 W and the total pressure of 1.3 Pa and SiH3 densities were decreased comparing with those of RF plasma (Yamamoto et al. 1994).

However, the mass production of a-Si and μc-Si thin films has been performed at relatively high pressures (approximately 1200 Pa) for obtaining higher deposition rates. Therefore, the information on the density of SiH3 and H in the high-pressure region was needed. Abe et al. (2017) quantitatively evaluated the contribution of these radicals to thin films in a PECVD system for the production of actual solar-cell devices. The absolute densities of H and SiH3 were measured under mass-production processing conditions while forming μc-Si thin films using a mixture of SiH4 and H2 gases at 1200 Pa in a 60 MHz very high frequency (VHF) parallel-plate plasma CVD system. These trials established the contributions of these species to thin-film formation. This work was highly valuable, since it represented the first investigation of the radicals active in the mass production of thin films for solar cells at high pressures.

In this study, the absolute density of H was measured by a two-photon resonance four-wave mixing technique in conjunction with VUV laser absorption spectroscopy (VUVLAS) and a Lyman-α light source emitting at 121.6 nm, employing the apparatus shown in Fig. 10 (Abe et al. 2012). The density of SiH3 radicals was ascertained by cavity ring down spectroscopy operating at wavelengths of 220 and 280 nm under the same conditions, using the apparatus shown in Fig. 11 (Abe 2013).

The measurement system for the absolute density of H by two-photon resonance four-wave mixing technique using VUVAS with Lyman-α light at 121.6 nm (Abe et al. 2012)

The measurement system for the absolute density of SiH3 by CRDS using wavelengths of 220 nm and 280 nm (Abe 2013)

Figure 12 plots the variations in the cavity losses at wavelengths of 220 and 280 nm in this system over time. At 220 nm, absorption due to SiH3 was observed along with losses due to scattering by nanoparticles, while at 280 nm only light scattering and absorption by nanoparticles was evident. At 2 ms after plasma ignition, a cavity loss at 220 nm was observed but not at 280 nm, while at 3 ms absorbance at 280 nm appeared and increased rapidly. After 8 ms, the values of both signals were almost the same. Interestingly, at a pressure of 1200 Pa, particles were produced within only 3 ms after plasma ignition. This result indicates that, following ignition, the number of fine particles generated in the plasma increased rapidly as a result of gas phase reactions between SiH4 and short-lived SiH2. Therefore, the difference between these two values of 220 nm and 280 nm could be used to estimate the density of SiH3 (Abe et al. 2017).

a Typical CRDS cavity decay profiles with and without plasma. b Time-evolution of cavity loss after plasma ignition at wavelengths of 220 and 280 nm. The lines are guides for the eye. Inset figure shows a logarithmic plot. The dashed line is a limit of detection (Abe et al. 2017)

Figure 13 summarizes the variations of SiH3 and H densities as the SiH4 flow rate is varied at a H2 gas flow rate of 470 sccm and at 1200 Pa, which are typical conditions for device production. Based on these radical measurements and the actual deposition rates, the quantitative contribution of SiH3 to thin-film formation was evaluated based on Eq. (2.10). Using a sticking probability (s) of 0.09 (Itabashi et al. 1990) and a radical temperature of 473 K, this contribution was found to be 45%. When evaluated using Eq. (2.11), the contribution was at most 59% when employing a total loss probability (β) of 0.5 (Matsuda 2004). These results demonstrate that the contribution of SiH3 to the formation of high-quality thin films is on the order of 50%, with the remainder of the process supported by short-lived radicals (such as Si, SiH and SiH2), higher order radicals and fine particles.

The relationships between the properties of the deposited thin film, the actual contributions of the precursors and the proportion of the H flux contributing to the surface reactions are shown in Fig. 14 (Abe et al. 2012). The φc, I(220)/(111) and Nd (1016 cm−3) values indicate the results obtained by evaluating the thin-film crystallinity using Raman spectroscopy, assessing the degree of crystalline orientation, (220)/(111), by Xray diffraction and examining the defect density by ESR, respectively. As noted earlier, the surface loss probability, s, for H in Eq. (2.10) is reported to be 1 when the substrate temperature is 200 °C (Abe et al. 2013). The contribution of all precursors can be estimated from the deposition rate using the equation:

Film properties interpreted in terms of the flux ratio ΓH/Γp (Abe et al. 2012)

where Rd is the deposition rate, ρ is the film density (2.18 g cm−3) and msi is the atomic mass of silicon (4.69 × 10–23 g). Therefore, the flux values represent the relationships between all deposition precursors and the H during the reactions associated with thin-film formation. These relationships in turn determine the thin-film properties, as shown in Fig. 2, and provide a key information regarding radical control during plasma processing, as shown in Fig. 8. In practice, the fabrication of high-quality thin films requires a crystallinity of approximately 50 to 60%, a preferential < 110 > orientation and a low defect density (< 1017 cm−3). In addition, the flux of precursors and H must be controlled to be within the range of 65–70, which is understood to be located in the transition region from a-Si to μc-Si. As a result, to obtain higher quality thin films with greater deposition rates, it is important to optimize the process using internal parameters to further increase the SiH3 contribution together with that of H so as to maintain a flux ratio of 65–70.

In summary, during plasma CVD of amorphous silicon thin films and microcrystalline silicon thin-film devices, SiH3 and H are important active species and are vital to the formation of high-quality thin films. It is, therefore, crucial to evaluate the densities and surface attachment coefficients (that is, the surface reaction constants) for both radicals under conditions conducive to mass production processes. The proportional contributions of these radicals to thin-film formation must also be estimated. On this basis, the properties of the resulting thin films can be predicted using an internal parameter known as the radical density ratio. Evaluating these radical-based internal parameters in a stepwise manner while clarifying their relationships with plasma processing characteristics will allow the control of radicals leading to various innovations. The systematic accumulation of large data sets concerning the behavior of radicals in the gas phase via real-time measurement and diagnostic techniques and subsequent data analysis using AI is also expected to identify important active species and improve the plasma processes by allowing control of these species.

5 Radical-controlled plasma etching, thin-film deposition and growth processes

5.1 Design of feedstock gases for SiO2 etching

When the material to be etched is known, the possible reaction products can be carefully investigated on the basis of their binding energies and volatilities/vapor pressures. Subsequently, the associated reaction processes, reactive gases and necessary processing temperature/energy values can be estimated. The first step in controlling the radicals in a plasma is the selection of the feedstock gas, as shown in Fig. 6. Table 1 provides the gases used in the etching of typical materials along with the properties of the radicals produced by these gases. Based on the pressure applied during processing, a gas with sufficient vapor pressure must be introduced, and so the boiling point of the gas is important. The chemical binding energies of the elements in the gas are also included in this table and the types of radicals that are expected to be produced are indicated.

As an example, fluorocarbons are generally used in the selective etching of SiO2 films and CF2 is known to be an important radical in the etching process (Takahashi et al. 1996a). During etching, these radicals are transported to the bottoms of high-aspect-ratio holes because of their relatively low attachment coefficients and rapidly etch SiO2 in conjunction with ion impact processes according to the reactions:

and

Although CF2 instantaneously generates SiF2 on Si with a high vapor pressure by ion impact, C remains on the surface to prevent etching of the Si, such that film formation occurs and etching stops, as discussed in Sect. (5.2). Evidently, CF2 is important for the selective etching of SiO2 on Si. Figure 6 demonstrates that the initial step of designing an etching process is to select the feedstock gas. As an example, in selective etching of SiO2 films against Si and Si3N4 films, fluorocarbon gases are used. In early work, CF4 gas was employed but a greater variety of such compounds is now used. These include fluorocarbons having linear structures (such as C2F6, C3F8 and C3F6), cyclic structures (such as C4F8 and C5F8) and containing different atoms (such as CHF3 and C3F6O). In plasmas using these gases, the electron density, electron temperature, and the type and density of active species will differ depending on the type of gas. Therefore, it is necessary to systematically measure the plasma parameters and clarify their physicochemical properties before constructing a radical-controlled process.

In Fig. 6, we consider a plasma process going from the bottom of the figure to the top to obtain the desired processing characteristics shown at the base of the diagram. To obtain the desired processing characteristics, the various particle parameters for the gas phase must be selected so that the radicals that are most effective cause the desired reactions on the solid surface in synergy with the ions. The ionization and dissociation reactions of the feedstock gas should selectively generate radicals and ions that are effective during the process. To achieve the desired process, it is necessary to select an appropriate feedstock gas and to control the particles in the plasma reaction vessel. Figure 15 shows the results of systematic measurements of the absolute densities of fluorocarbon gases and radicals in C4F8, CF2F6 and CHF3 plasmas using infrared diode laser absorption spectroscopy (IRLAS) (Miyata et al. 1996). It is evident that a high density of CF2 radicals can be obtained using C4F8 to generate the plasma, indicating that the desired radical species and density can be controlled by selecting the gas type and input power. In fact, C4F8 gas is now often used, because it efficiently produces CF2 radicals that perform well during SiO2 etching.

CFX (1–3) densities in ECR plasmas employing a C4F8, b C2F6, c CF4 and d CHF3 gases as a function of microwave power. The pressure and the flow rate are fixed at 0.40 Pa and 3.0 sccm, respectively (Miyata et al. 1996)

Shibano et al. (2008) showed that CF3 ions provide the highest SiO2 etching rates (Fig. 16). Hayashi et al. (1999) investigated the radical composition produced by the ionization of C4F8 gas and demonstrated that light fluorocarbon ions CF+ and CF2+ and heavy fluorocarbon ions such as C3F5+ and C4F7+ were generated (Fig. 17). In addition, CF2 radicals were found to be primarily obtained from the dissociation of C4F8, while F was the main product generated by the dissociation of CF2 following electron impact and was found to be removed by pumping. This prior work estimated that the C2F4 density was roughly comparable to the densities of CF and CF3 and that the surface loss probability for C2F4 increased with increasing electron density. These results suggest that C2F4 might play an important role in the etching because of its polymerization characteristics. Therefore, gases that efficiently generate CF2 and/or C2F4 and CF3+ ions in the plasma would be expected to provide the optimum performance during the high-aspect-ratio etching of SiO2.

Etching yields of SiO2 as a function of CFx+ and F.+ ion energy. Angle of incidence was 15°. Negative values mean increases of film thickness caused by deposition of some film on the SiO2 surface. The error bars show the uncertainty of the actual energy of incident ions, which is caused by charging of the SiO2, surface (Shibano et al. 2008)

Mass spectrum for positive ions extracted from the plasma at electron densities of a 1.9 × 109, b 1.1 × 1010, and c 1.9 × 1010 cm.−3. The ions with the energy corresponding to the time-averaged plasma potential were measured (Hayashi et al. 1999)

While researching the optimal radicals for etching, Nagai et al. (2006) developed an environmentally benign gas with low global warming potential: C5F10O (CF3CF2CF2OCFCF2). This compound efficiently produces radicals and CF3+ ions in response to electron impact and so could be used to replace the fluorocarbons having high global warming potential that are conventionally used for SiO2 etching. The dissociative ionization cross section for CF3+ ions obtained from gaseous C5F10O is much higher than that for other ionic species (more than ten times that for C4F8), as shown in Fig. 18. This is important, because CF3+ is the most effective ion in terms of improving the etching rate of SiO2. This compound was found to generate several radicals in relative quantities of CF3 > CF2 > CF. Diluting this gas with N2 or Ar was shown to decrease the densities of CF3 and CF in the plasma but had no effect on the density of CF2. Consequently, the relative proportion of CF2, which provides advantageous etching properties, could be increased. In this manner, by controlling the densities of ionic and radical species via careful selection of the feedstock gas, improved etching characteristics could be achieved. As an example, the etching rate of a SiOCH film using an Ar/C5F10O/N2 plasma was approximately 1000 nm/min, which was much higher than the rate obtained using an Ar/C4F8/N2 plasma. This pioneering study confirmed that the generation of specific desirable radicals and ions is possible based on tuning the feedstock gas.

Left diagram: mass spectra of a C4F8 and b C5F10O at electron energy of 70 eV. Right diagram: CF, CF2, and CF3 radical densities as functions of N2 flow rate in Ar/C4F8/N2 or Ar/C5F10O/N2 plasma under conditions of pressure of 10 Pa, gas flow rate of Ar/C4F8/N2 = 1000–x /10/x or Ar/C5F10O/N2 = 1000-x/10/x sccm, and 60 MHz power of 1200 W (Nagai et al. 2006)

5.2 Dilution by noble gases

5.2.1 Silane plasmas

During plasma processing, the pressure affects various key parameters, such as the gas density, electron temperature, vapor pressure, mean free path and gas residence time. Thus, there is typically an optimal pressure, and dilution of the feedstock gas represents an effective means of controlling the radical density. Equation (2.5) indicate that the radical density is directly related to the density of the feedstock gas. Consequently, the radical density can be adjusted by diluting the feedstock with a noble gas that does not contribute directly to any chemical reactions. He, Ne, Ar, Kr and Xe are the most commonly used diluent gases and the ionization energies of these elements are 24.58, 21.55, 15.75, 13.96 and 12.12 eV, respectively. The electron temperature and electron density of the plasma are affected by the ionization energy as well as the ionization cross section of the noble gas. As an example, diluting the feedstock gas with Xe, which has a low ionization energy and a large ionization cross section, increases the electron density and decreases the electron temperature. As discussed in Sect. 4, once the radical species that are involved in thin-film formation are identified, it is vital to control these species. Experiments concerning the fabrication of thin-film solar cells using a SiH4/H2 gas plasma have shown that SiH3 are important precursors.

Nomura et al. (1994) determined the absolute density of SiH3 using IRLAS and investigated the effect of dilution with noble gases on these radicals. The SiH3 density in the plasma was ascertained using a 13.56 MHz RF parallel-plate system at a low pressure of 4.0 Pa in conjunction with H2/SiH4, He/SiH4, Ar/SiH4 or Xe/SiH4 gas mixtures. The density was found to decrease with increasing dilution rate for all gas mixtures, as shown in Fig. 19, although the number of SiH3 generated per SiH4 molecule increased significantly when Xe was used as the diluent. The SiH3 density increased when a low electron temperature was achieved by diluting the feedstock with Xe, because SiH3 were selectively produced in conjunction with a relatively large dissociative cross section at low electron energies. In addition, the diffusional annihilation of radicals was reduced by Xe dilution, as shown in Fig. 20.

SiH3 radical density vs the SiH4 fraction in rf plasma using H2/SiH4, He/SiH4, Ar/SiH4, and Xe/SiH4 gas mixtures. The total gas pressure was 4.0 Pa and the input rf power was 200 W (Nomura et al. 1994)

SiH3 loss rate as a function of SiH4 fraction in the afterglow of H2/SiH4, He/SiH4, Ar/SiH4, and Xe/SiH4 gas mixture plasmas. The total gas pressure was 4.0 Pa and the input rf power was 200 W (Nomura et al. 1994)

In the case that SiH2 or SiH and Si are incident on the surface of an a-SiH thin film, these species generate a columnar surface morphology with a porous, rough texture as they are inserted into SiH bonds with an attachment coefficient (equal to the total loss probability) of approximately 1. Kawasaki et al. (1997) also established that SiH2 are responsible for the nucleation of particles based on reactions with SinH2n+2 (n = 1, 2, 3, …) to form polymerized species. This contribution to particle nucleation may affect the film deposition rate when the particle radius increases above approximately 10 nm, and so it is important to clarify the behavior of such radicals in the gas phase. Kono et al. (1995) investigated SiH2 in a plasma based on SiH4 gas diluted with various noble gases and with H2, using LIF, with the results presented in Fig. 21. It is apparent that SiH2 was produced in these systems primarily by the reaction:

Comparison of the SiH2 densities in 40 W, 40 mTorr plasmas using SiH4/Xe, SiH4/Ar, SiH4/He and SiH4/H2 gas mixtures (Kono et al. 1995)

In contrast, in the case of dilution with Xe or Ar, the formation of SiH2 was found to be promoted by the reaction of SiH4 with metastable Xe* or Ar* species according to the reaction:

Figure 22 shows the data obtained from analyses of SiHx (x = 0–3) species in a parallel-plate electrode RF SiH4/Ar plasma (Hori et al. 2006; Goto 2001; Kono et al. 1993; Sakakibara et al. 1991; Nomura et al. 1994). The densities of Si, SiH and SiH2 were found to increase following dilution with Ar, while that of SiH3 decreased. The lifetimes of SiH3, which act as precursors for the fabrication of high-quality a-Si and μc-Si thin films, were found to be as long as several ms, whereas those of Si, SiH and SiH2 were less than 100 μs. These short lifetimes are attributed to reactions with the SiH4 feedstock to produce larger molecules (Si2H6 and Si2H5) responsible for the appearance of defects. The gas-phase reactions of these short-lived radicals with heavier molecules also produced fine particles that were a factor in the formation of defects in the thin films. Therefore, it is necessary to remove these molecules before they reach the surface of the film (that is, to control the gas residence time). SiH, Si and SiH2 all have large surface attachment coefficients ranging from 0.7 to 1.0. Naturally, short-lived radicals generate defects during the surface reaction process that make it challenging to fabricate high-quality thin films. Therefore, it is very important to control not only SiH3 but also these short-lived radicals.

As noted above, to obtain high-quality a-Si and μc-Si thin films, the density of SiH3 must be as high as possible relative to those of Si, SiH and SiH2 and larger molecules. The density of SiH3 can be increased in an undiluted SiH4 plasma but the removal of heavier molecules by an exhaust pump or other means is necessary. In the case that the plasma is diluted with Ar gas, the SiH4 density decreases such that the formation of larger molecules is suppressed, while the densities of Si, SiH and SiH2 increase. The latter effect is disadvantageous with regard to the formation of high-quality thin films. As shown in Fig. 6, dilution with noble gases may be an important aspect of controlling the formation and disappearance of radicals to realize radical-controlled plasma processes.

The electron temperature can also be controlled by noble gas dilution, and so is a very important factor with respect to adjusting the generation of radicals. Ishijima et al. (2008) reported changes in the electron temperature in a plasma based on 10% C4F8 mixed with different noble gases (He, Ne, Ar, Kr and Xe) as a result of measurements using an absorption probe. The addition of noble gases having different ionization potentials into the reaction gas allowed the electron temperature to be tuned, the F, CF, CF2 and CF3 densities to be systematically controlled, and the final radical composition to be modified. From these studies, it is apparent that the dissociation of the source gas can be adjusted by dilution with a noble gas having a low ionization potential to give a lower electron temperature. Thus, careful selection of the noble gas diluent allows the radicals generated in the plasma to be controlled.

5.2.2 O2 plasmas

SiO2 is a very important insulating film in ULSIs but must be fabricated at relatively low temperatures (below 550 °C). For this reason, low-temperature oxidation of silicon using plasmas has attracted much attention. Itoh et al. (1999) reported that radical oxidation is a very promising approach to controlling SiO2 uniformity and reliability, because O is able to oxidize Si to produce atomically flat SiO2/Si interfaces. It is also evident that the O oxidation mechanism is different from the conventional dry oxidation mechanism. The addition of Kr as a diluent in this plasma-based low-temperature oxidation process has been reported to result in the formation of a high-quality silicon oxide film with a low leakage current (Ueno et al. 2000; Sekine et al. 2001; Tanaka et al. 2003; Goto et al. 2003). The incorporation of Kr at a dilution ratio of 97% or higher is believed to promote collisions between metastable Kr atoms and oxygen molecules to generate excited state O (1D2) in addition to ground-state oxygen atoms. These O (1D2) contributes to the formation of high-quality oxide films. Takeda et al. (2007) reported the first-ever assessment of the absolute densities of O (3Pj=0, 1, 2) and O (1D2) as well as O2+ in a surface-wave excited plasma in which oxygen was highly diluted with Kr. The O (3Pj) density was measured using VUVAS in conjunction with MHCL. Figure 23 demonstrates that the density of O (3Pj=0, 1, 2) decreased with increasing Kr gas dilution ratio. The O (1D2) density was ascertained using VUVAS based on the 3 s 1Do − 2p 1D2 transition at 115.22 nm and was determined to be almost constant over the Kr dilution range of 0 to 30%. However, above 30%, the density increased drastically with further increases in the extent of dilution (Fig. 24). The density of this species was also two orders of magnitude lower than that of the O (3Pj=0, 1, 2) as a consequence of the reactions:

Absolute densities of O (3Pj) radical as a function of the Kr gas dilution ratio in O2/Kr surface wave excited plasma (Takeda et al. 2007)

Absolute densities of O (1D2) radical as a function of the Kr gas dilution ratio in O2/Kr surface wave excited plasma (Takeda et al. 2007)

and

The generation of O (3Pj) as a result of electron impact dissociation [Eqs. (5.5) and (5.6)] appears to have been dominant over the collisional dissociation of oxygen molecular with metastable Kr atoms (Eq. 5.8). The formation of O (1D2) due to electron impact dissociation and excitation [Eqs. (5.6) and (5.7), respectively] was also more pronounced than that stemming from the collisional dissociation of oxygen molecules with metastable Kr atoms. It is noteworthy that O2+ ions have been shown to be the primary species even at high Kr dilutions employing quadrupole mass spectrometry (QMS) as shown in Fig. 25. These results indicate effective charge transfer under these conditions according to the reaction equation:

QMS as a function of the Kr gas dilution ratio in O2/Kr surface wave excited plasma (Takeda et al. 2007)

Significantly diluting the O2 with gaseous Kr can evidently produce high quality Si oxide films at rapid rates. The associated reaction mechanism is determined both by the presence of O and by the density of O2+. Increased dilution of the O2 with noble gases, especially with Kr gas, results in surface activation of the Si as a consequence of collisions with low-energy O2+ that promote the oxidation action of highly reactive O (1D2).

The effects of Kr and Ar dilution on O2 gas plasmas have been compared (Takeda et al. 2008) and the data show that O (1D2) are primarily generated by electron impact and that Ar produces a greater radical density by raising the electron temperature. Based on VUVAS data, the translational temperature of oxygen atoms was estimated to be approximately 2000 K at a pressure of 90 Pa. In the pressure region between 116 and 133.3 Pa, the translational temperature of O (1D2) during Kr dilution trials was found to be higher than that obtained with Ar dilution (Fig. 26). The radical density and translational temperature data allowed estimation of the radical flux at the substrate surface using Eq. (2.9). These estimates indicated that the incident flux of O (1D2) was larger in the case of Ar dilution (Fig. 27), meaning that Ar dilution promoted the oxidation of silicon to a greater extent. This finding that the radical flux contributing to oxidation can be controlled by adjusting the temperature of radicals via significant dilution with noble gas is of significant interest.

Absolute densities and translational temperatures of O (1D2) in Kr/O2 and Ar/O2 (Takeda et al. 2008)

Fluxes of O (1D2) in Kr/O2 and Ar/O2 surface wave excited plasma (Takeda et al. 2008)

Taylor and Tynan (2005) systematically examined the electron density, electron temperature and atomic oxygen density in an O2 gas plasma diluted with He, Ar or Xe. The oxygen radical density was determined by both actinometry and mass spectrometry, while the plasma density and electron temperature were ascertained using Langmuir probes. The oxygen radical density was highest for the O2/Xe mixture and lowest for the O2/He mixture (see Fig. 28a). Somewhat surprisingly, increasing the electron temperature at a fixed plasma density (ne < 1.33 × 1011 cm−3) decreased the O density (Fig. 28b). This effect was analyzed in terms of the dissociation, ionization and diffusion of oxygen radicals and was attributed to variations in the transport of radicals, and not to the actual effect of electron temperature. It is apparent that the control of radicals requires a comprehensive analysis of the behavioral dynamics of such radicals in the reaction equipment and tuning of radical reactions and transport processes. The use of oxygen mixtures expanded the ranges of O and ion densities, while at the same time allowing independent control of these densities.

a O density measured by actinometry vs the ratio of O2 /(He + O2), O2 /(Ar + O2), and O2 /(Xe + O2), (b) O density variation with electron temperature (Taylor and Tynan 2005)

5.3 High-precision etching with radical control

The composition of radicals in the gas phase is greatly affected by the gas residence time. The flow rate for the gas has a significant effect on the residence time and, as the dissociation of the raw gas proceeds, atomic radicals are increasingly formed, as demonstrated by Fig. 7. Equation (2.5) also show that suppressing excessive dissociation of the feedstock gas and obtaining the desired radical composition requires shortening the residence time of the gas. Because radicals are also generated when electrons collide with the byproducts generated during etching, a shorter residence time will increase this effect. Therefore, the radical density in the process can be controlled by applying a high level of dilution with a noble gas to control the degree of dissociation of the feedstock gas, and by rapidly removing byproducts without changing the chemical composition of the raw gas. A high-precision etching process requires a plasma chemistry that can selectively generate the radical species serving as precursors for etching by comprehensively controlling internal parameters (Hayashi et al. 1999). This necessitates control of the electron density and gas residence time, as indicated by Fig. 6.

Tatsumi et al. (1997) studied F/CF, F/CF2 and F/CF3 controlled by suppressing the excessive dissociation of gaseous C4F8 by applying a short gas residence time and high electron density in a mass production equipment for parallel plate plasma etching. The formation of radicals was tuned by changing the Ar flow rate, pressure and power according to the τne term, as shown in Fig. 29. In addition, introducing O2 gas at an optimum flow rate into the C4F8 stream did not change the F density but reduced the high densities of CF and CF2 that were otherwise deposited on the bottom and sidewalls of the fine pattern and degraded the etching shape. In this manner, the deposition of a fluorocarbon thin film on the surface of the fine pattern was suppressed. The disappearance of F was controlled by placing a Si plate on the top electrode of the parallel plate. As a result, deep contact hole with a high aspect ratio (pore diameter: 0.09 μm, aspect ratio: 11) were successfully fabricated in the SiO2 film by skillfully controlling the generation and loss processes of radical species important for etching while employing a C4F8/Ar/O2 gas mixture (Fig. 30). This work demonstrated that superior etching performance can be obtained by identifying the radical species important for etching and controlling these radicals based on Eq. (2.6).

Comparison of radicals as a function of the number of collisions (Tatsumi et al. 1997)

Optimized etched profile. A 0.09μmΦ contact hole with aspect ratio of 11 was obtained (Tatsumi et al. 1997)

5.4 Design and control of feedstock gases for SiNx etching

During the etching of Si3N4, H promote the removal of N in the Si3N4 by producing volatiles, such as NHx and HCN, and so function as an etchant. Consequently, hydrofluorocarbons such as gaseous CH2F2 have been used to achieve the highly selective etching of Si3N4 on Si. The dissociation of C–H and C–F bonds in hydrofluorocarbons is important in terms of controlling the density of reactive species, such as ions and radicals. Generally speaking, the F produced by the dissociation of C–F bonds are the main Si etching agent, while the H resulting from the rupture of C–H bonds promote the deposition of fluorocarbon polymers on Si3N4 and the etching of Si3N4 and polymers. The dissociation of C–F and C–H bonds also produces CHxFy that contribute to the deposition process.

The highly selective etching of SiO2 and SiN in the presence of polymeric Si (poly-Si) has been demonstrated in trials employing fluorocarbon gases containing H, such as CH2F2 (Kondo et al. 2015a, b) and CH2FCHF2 (Hsiao 2021). Figure 31 shows the SiO2, SiN and poly-Si etching rates as functions of the flow rate of CH2F2 diluted with Ar (Kondo et al. 2015a). It is noteworthy that the etching rate for SiN films became higher than that for SiO2 films upon increasing the proportion of CH2F2. In addition, a polymeric film was deposited on the poly-Si film and no etching was observed. During etching of SiN with a CH2F2 plasma, CHxFy radicals and ions exhibited unique reaction kinetics, as indicated in Fig. 32 (Kondo et al. 2015b). These data confirm the dependence of the proportional densities of CH2F and CHF2 on the Ar/(Ar + Kr) value in the CH2F2 plasma. During these trials, the various radicals were monitored using QMS and CH2F were found to be dominant. This result is attributed to CH2F2 → CH2F + F dissociation occurring preferentially rather than CH2F2 → CHF2 + H dissociation. As the Ar/(Ar + Kr) ratio was varied, the densities of CHF2 decreased and CH2F conversely increased, indicating that dilution with a noble gas was able to selectively control the radicals. This phenomenon was not ascribed to the variation in electron bombardment associated with the electron temperature change induced by modifying the Ar/Kr ratio, as discussed in Sect. 5.2. Rather, it was suggested that metastable Ar and Kr atoms contributed to the dissociation of the source gas. Using appearance mass spectrometry, the CHF2+ obtained from the dissociation of hydrogen were assessed at a threshold energy of 13.8 eV, while those from the dissociation of fluorine (CH2F+) were monitored at a threshold energy of 15.8 eV. These assessments showed that radical formation comprised [1] dissociative ionization, [2] radical ionization, and [3] Penning [metastable] ionization stages. Using the data cross section and assuming electron temperatures of 3 eV for Ar and 2.6 eV for Kr, the radical production fractions were fit to the experimental results, as shown in Fig. 33. In this manner, the CH2F/CHF2 radical density ratios during these three stages were estimated to be 0.3: 0.1: 0.6. Thus, almost half of the density was the result of Penning ionization, suggesting that CH2F2 diluted with Kr may produce CHF2+, CHF2 and H, whereas Ar dilution tends to generate CH2F+, CHF2 and F.

Dependence of etching rates of SiO2, SiN, and poly-Si films in Ar-diluted CH2F2 plasma on flow rate of CH2F2 for Ar (300sccm), electron density of 1011 cm.−3, 2 Pa, and Vpp of − 1000 V) (Kondo et al. 2015a)

Dependence of CH2F and CHF2 radical fraction on total CHxFy radical density over Ar fraction (Ar/(Ar + Kr) flow rates) in CH2F2 plasma (Kondo et al. 2015b)

Dependence of CH2F and CHF2 radical fraction on total CHxFy radical density over Ar fraction (Ar/(Ar + Kr) flow rates in CH2F2 plasma (Kondo et al. 2015b)

Figure 34 demonstrates that CHF2+ and CH2F+ were very close to the ionization threshold energies for Ar and Kr (16.0 and 14.0 eV, respectively) (Kondo et al. 2015b). Therefore, it is likely that the ionization of CH2F2 is modified in plasmas diluted with noble gases. In the case that a CH2F2 plasma is diluted with Ar or Kr, either CHF2+ or CH2F+ ions may be selectively produced, along with H and F. These ions are preferentially generated based on the dissociative ionization pathways associated with charge exchange collisions, via the reactions:

Dependence of a Ar+ and Kr+ ion densities, b total CHxFy ion density, and c individual CH2F+ or CHF2.+ ion fraction on total CHxFy density over Ar fraction (Ar/(Ar + Kr) flow rates in CH2F2 plasma (Kondo et al. 2015b)

and

Significant dilution with a noble gas increases the density of noble gas ions due to the large ionization cross sections of these elements. In addition, at higher pressures, the density of active species ions increases due to charge exchange caused by collisions between the noble gas ions and the feedstock gas or other active species. This charge exchange process is also seen in Kr+–O2 gas mixtures [Eq. (5.9)].

Recently, an interesting approach to the etching of SiN films by CF4/D2 gas mixtures has been proposed. The etching rates using this plasma were found to be superior to those obtained from a CF4/H2 plasma. A model incorporating hydrogen abstraction by deuterium indicated a greater probability of reactions between the etchants (F, C or D) and Si or N dangling bonds, as shown in Fig. 35 (Hsiao et al. 2021). The different masses of D and H will promote reactivity by modifying the vibrations of chemical bonds. Thus, the use of isotopes may have a role in radical-controlled plasma processes.

Schematic illustration of the proposed etching mechanism of the SiN film etched by the a CF4/D2 plasma and b CF4/H2 plasma (Hsiao et al. 2021)

5.5 Short pulse modulation etching

The physicochemical properties of various plasmas, such as electron density, electron temperature, plasma potential and active species densities, can be altered by applying time modulation to the plasma power. Of particular interest is the ability to change the electron temperature by applying a short pulse modulation. Chinzei et al. (1996) reported the CF, CF2 and CF3 densities in a helicon wave plasma generated using a C4F8/H2 gas mixture when a 10 μs pulse modulation was applied at a duty ratio of 50%. By systematically measuring the densities of CF, CF2 and CF3 with an appearance mass spectrometry and monitoring changes in the density of F via emission spectroscopy, it was shown that the radicals could be controlled by pulse modulation. Figure 36 confirms that the electron temperature was lowered and gas dissociation was suppressed by pulse modulation. In addition, the proportion of CF (the precursor radical for deposition) to F (the precursor radical for etching) was increased. During etching, CF was deposited on Si to prevent the etching of SiO2/Si, thereby improving the etching selectivity.

Comparisons of the deposition rate and radical densities for pulse and CW discharges. The source Power of 1 kW is the instantaneous value in the pulse (Chinzei et al. 1996)