Abstract

Driven by digital technologies, manufacturers aim to tap into data-driven business models, in which value is generated from data as a complement to physical products. However, this transformation can be complex, as different archetypes of data-driven business models require substantially different business and technical capabilities. While there are manifold contributions to research on technical capability development, an integrated and aligned perspective on both business and technology capabilities for distinct data-driven business model archetypes is needed. This perspective promises to enhance research’s understanding of this transformation and offers guidance for practitioners. As maturity models have proven to be valuable tools in capability development, we follow a design science approach to develop a maturity model for the transformation toward archetypal data-driven business models. To provide an integrated perspective on business and technology capabilities, the maturity model leverages a layered enterprise architecture model. By applying and evaluating in use at two manufacturers, we find two different transformation approaches, namely ‘data first’ and ‘business first’. The resulting insights highlight the model’s integrative perspective’s value for research to improve the understanding of this transformation. For practitioners, the maturity model allows a status quo assessment and derives fields of action to develop the capabilities required for the aspired data-driven business model.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In today’s digitally connected world, data has become a valuable asset and has been dubbed ‘the new oil’ (Bhageshpur 2019). Digital technologies continuously produce increasing amounts of structured and unstructured data driving the trend toward big data. Data can be collected, processed, and analyzed to derive valuable information, insights, and recommendations (LaValle, et al. 2011; Herden 2020). Especially for manufacturers, whose complex physical machines continuously generate valuable data while operated, this bears great economic potential (Müller and Buliga 2019). For those companies, data-driven business models (DDBMs) are an emerging strategic option that can tackle dwindling margins in pure product sales, strengthen customer loyalty, help garner competitive advantages, or even tap new markets (Voigt et al. 2021; Kowalkowski et al. 2017). In DDBMs, data-driven services make a significant contribution to value creation, delivery, and capture (Kühne and Böhmann 2020; Hunke et al. 2019). However, there are very different options for configuring data-driven services and physical products in a DDBM to deliver enhanced customer value (Hunke, et al. 2021). Research has therefore examined systematization approaches for this field, such as taxonomies or archetypes (Davenport and Bean 2018; Hartmann et al. 2016). Especially in practice, archetypal DDBMs offer a concrete strategic orientation for the transformation towards DDBMs as they systematically characterize configurations of business models (Müller and Buliga 2019). In this context, archetypes depict an aligned set of business model components that help decision-makers to develop a clearer understanding of how an aspired DDBM creates, delivers, and captures value (Pieroni et al. 2020; Bergman et al. 2022).

For instance, some manufacturers strive to become a ‘data provider’ by making data (e.g., production data to track performance) accessible and useful to their customers. While the manufacturer solely provides the data via defined interfaces, customers can then leverage this data to create benchmarks or dashboards. In contrast, others seek to position themselves as a ‘recommendation provider’. In this DDBM archetype, manufacturers perform sophisticated data processing and analytics to derive actionable recommendations (Zonta et al. 2020; Hunke et al. 2021).

Hence, DDBMs can vary greatly regarding their technical requirements and value proposition for customers. This poses a challenge to manufacturers, as they must develop capabilities appropriately and aligned to the DDBM archetype to address both business and technical demands (Hunke et al. 2019; Azkan et al. 2021; Rashed and Drews 2021). For instance, manufacturers must develop business capabilities for the successful monetization and marketing of their data-driven offering (Baltuttis et al. 2022; Häckel et al. 2021). New, complementary technological capabilities are also needed for data processing and delivery based on proper tooling and infrastructure (Frank et al. 2019; Weber et al. 2017). Consequently, especially for incumbent and product-centric manufacturers, this implies a tremendous shift in the organizational rationale and requires the structured development of new capabilities that are both of a business and technological nature (Comuzzi and Patel 2016).

To guide transformative endeavors and structure capability development, maturity models (MMs) are valuable artifacts offering guidance for research and practice (Mettler 2011; Becker et al. 2009). From a research perspective, MMs represent theories of how organizational capabilities develop progressively along an expected, desired, or logical maturation path (Pöppelbuß and Röglinger 2011). As such, MMs strive to disentangle required capabilities and offer descriptive knowledge (Gregor and Hevner 2013). In practice, MMs are useful for assessing an organization’s status quo, determining a desired target state, and identifying fields of action (Pöppelbuß and Röglinger 2011). Indeed, existing MMs offer valuable contributions to leverage data in the manufacturing sector. Literature reviews of existing MMs in the manufacturing context indicate that existing research has extensively investigated technological capabilities (Hein-Pensel et al. 2023). Hence, many existing works focus on technological topics, such as big data analytics (Comuzzi and Patel 2016) or data science (Gökalp et al. 2021). Thus, these models provide tangible capabilities needed to leverage data for value creation, for example, by extracting equipment condition information (Comuzzi and Patel 2016). In contrast, another research stream focuses more on how to capture value from DDBM and therefore sheds light on business capabilities (Parvinen et al. 2020; Woroch and Strobel 2021). For instance, Woroch and Strobel (2021) point out that DDBMs require dedicated capabilities to formulate new value propositions and enable customer co-creation.

However, research indicates that an integrated, organization-spanning perspective on business and technology is needed for successful mastery of DDBM transformation, just as demonstrated by Hausladen and Schosser (2020) for the aviation sector. Hence, for the manufacturing industry, the understanding of the technical and business capabilities for DDBMs is limited (Favoretto et al. 2022; Hein-Pensel et al. 2023). While archetypal DDBMs, such as those of Hunke et al. (2021), represent desirable digital transformation outcomes for manufacturers and give strategic orientation, it remains unclear what technology and business capabilities are needed to master them. This shortcoming leaves practitioners without tangible guidance on what technical and business capabilities archetypal DDBMs require (Hunke et al. 2021). Against this background, this paper seeks to address this research need by answering the following research question (RQ):

RQ

What capabilities do manufacturers require to transform toward distinct archetypal data-driven business models?

Having proven their worth as artifacts for capability development in the context of manufacturing (e.g., Chen et al. (2022), Gökalp et al. (2021) and Sjödin et al. (2018)), this paper develops an integrated DDBM MM (DDBM3). We use the procedure model by Becker et al. (2009) to develop a MM closely aligned with three practice-grounded key requirements based on the Design Science Research (DSR) paradigm (Hevner et al. 2004; Peffers et al. 2007). To evaluate our model, we use the criteria developed by Sonnenberg and vom Brocke (2012). We assess the model’s real-world applicability and usefulness by applying the DDBM3 to two incumbent manufacturers. We involve focus groups comprised of industry experts to assess the manufacturers’ status quo and the target state of their DDBM. We also conduct semi-structured interviews to identify actions that led to the assessed status quo and investigate the approaches taken by the two manufacturers.

This paper’s contributions to the discourse on DDBM in the manufacturing sector are twofold. Firstly, this work’s central artifact, the developed and evaluated DDBM3, provides descriptive knowledge on capabilities required to offer specific archetypal DDBMs (Gregor and Hevner 2013). This artifact builds on established DDBM archetypes and enterprise architecture models to provide a hitherto untaken integrated and aligned perspective on DDBM capabilities. In practice, the DDBM3 offers guidance when transforming toward a defined DDBM and serves as a diagnostic tool. Secondly, as evident in our application of the DDBM3 for evaluation purposes, the DDBM3 provides an integrated lens for examining the DDBM transformation. In our evaluation, we find that the two manufacturers transform toward DDBM differently—by either being more mature in business (‘business first’) or in technology capabilities (‘data first’). These initial findings may stimulate further research to leverage the DDBM3 as an investigative lens to examine patterns of DDBM transformations and shed light on how manufactures transform toward DDBM.

2 Theoretical Background

2.1 Data-Driven Business Models and Archetypes in Manufacturing

In the manufacturing sector, cyber-physical systems and the industrial internet of things have led more and more companies to get involved in data collection, analysis, and utilization (Häckel et al. 2019; Cui et al. 2020). Manufacturers use data internally to improve decision-making and enhance efficiency (Hess et al. 2016; LaValle et al. 2011; Sjödin et al. 2018). Furthermore, manufacturers can leverage data analytics to create new, data-driven service offerings for their customers by including data as the key resource (Azkan et al. 2021; Hunke et al. 2021). For instance, data-based alert systems and predictive maintenance services provide the customer with maintenance cost reduction, optimized machine operation, or increased machine availability (Hartmann et al. 2016; Bertolini et al. 2021). As a result of these new technical opportunities, DDBMs are gaining importance for manufacturers as a strategic option for differentiation (Voigt et al. 2021). Nevertheless, the concept of the ‘business model’ is not uniformly defined, and literature provides a wide range of definitions (e.g., Chesbrough (2002), Johnson et al. (2008), Osterwalder and Pigneur (2013)). Osterwalder and Pigneur (2013) highlight the business model canvas (BMC), which they cite as a popular approach in practice thanks to its conciseness (Müller and Pfleger 2014). They conceptualize business models using nine building blocks (i.e., customer segments and relationships, key partners, resources and activities, value propositions and channels, revenue streams and cost structure) that are assigned to four overarching categories (i.e., clients, organization, sales, and financials) (Kotarba 2018). This conceptualization mainly addresses the outward-facing elements of a business model and describes external mechanisms such as customer offerings and interactions (Jonker and Faber 2021). When evaluated through the lens of Porter’s (1985) value chain, it becomes clear that internally-directed capabilities are only superficially addressed in the BMC (Joyce and Paquin 2016). An organization’s inward-facing value creation activities are multi-layered and can be subdivided into primary, strategically relevant, and supporting activities (Porter 2014). Hence, we follow Teece’s definition of business models as the “design or architecture of the value creation, delivery, and capture mechanisms of a firm” as it covers both internal and external views (Teece 2010, p. 172). Consequently, DDBMs can be defined as business models in which data-driven services contribute significantly to value creation, delivery, and capture (Kühne and Böhmann 2020; Hunke et al. 2019).

For the manufacturing industry, the development of DDBMs builds on the exploitation of data to deliver additional customer value and enhance the utility of the physical product (Lehrer et al. 2018; Burström et al. 2021). However, as there are multiple options to enfold business models with data-driven services, Hunke et al. (2021) conceptualize four archetypal DDBMs, characterized by their data-driven service (i.e., data provider, insight provider, recommendation provider, and digital solution provider). These archetypes enable the identification of strategies for realizing DDBMs with distinct value offerings for the customer (Hunke et al. 2021). In the first archetype, manufacturers provide customers with (product) data beyond the physical product (data provider). The data is only moderately processed, provided in a standardized form, and subject to descriptive analytics (Hartmann et al. 2016). Offerings include, for example, aggregated reports or dashboards on machine utilization. The second DDBM archetype is based on delivering data-based insights, which are supportive and actionable for the customer (Hunke et al. 2021). In these cases, the provider processes the data to meet specific objectives associated with a customer’s needs (Hunke et al. 2019). This is achieved by applying diagnostic analytics—i.e., highlighting whether or not something has happened and delivering insights into why this is the case (Hunke et al. 2021). Examples of use-cases include digital alarms triggered when machines or processes malfunction. As a third option, manufacturers can offer data-based recommendations. This business model aims to provide tailored decision support for customers. Here, the interaction between supplier and customer increases significantly, and integration into the customer’s value creation is facilitated. Predictive maintenance services are an example of this type of offering. Finally, manufacturers can act as digital solution providers, opening up novel ways of doing business, e.g., by turning into a smart data platform provider (Beverungen et al. 2019, 2021). In this context, value is created through unique digital information, and the physical product recedes into the background (Beverungen et al. 2021). Manufacturers, in order not to end up in an unreflective, technology-driven ‘catch-all’ approach, must identify and develop capabilities required to master their aspired DDBM (Bertolini et al. 2021; Hunke et al. 2021).

2.2 Structuring the Data-Driven Business Model Transformation

Many manufacturers are incumbents whose organizational logic is tightly bound to the physical product. Consequently, striving toward a specific DDBM archetype requires manufacturers to embark on a transformation to develop business and technology capabilities to create, deliver, and capture value based on data (Foss and Saebi 2017; Kotarba 2018). For instance, in the case of a DDBM providing data-based insights, manufacturers need capabilities to plan, roll out, and maintain connected machinery that collects data and creates a proper use profile (value creation). Next, the manufacturer must be capable of storing and processing the obtained data to derive descriptive, diagnostic, or prescriptive insights about the machinery’s operation. These insights must be tailored to the customer’s requirements (value offer) (Sarker 2021). Finally, the manufacturers need capabilities to make the insights available to the customer, for instance, via digital channels, and define a suitable monetization strategy to enable a viable business, e.g., pay-per-use (value capture) (Häckel et al. 2021).

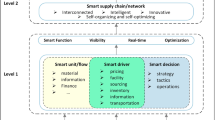

Consequently, both the outward-facing and primarily business-related capabilities of the business model (e.g., customer connections or value proposition) and the technology-associated inward-facing capabilities and structures of an organization (e.g., processes or infrastructure) are required to enable DDBMs (Hausladen and Schosser 2020). Thus, to master any type of DDBM, manufacturers need to transform toward an aligned organizational structure that provides the necessary capabilities (Rashed and Drews 2021). In this context, enterprise architecture (EA) models are a valuable tool for obtaining an integrated view of an organization and for outlining reference architectures (Gampfer et al. 2018; Gong and Janssen 2021). The commonly-used frameworks for EA—e.g., TOGAF (The Open Group 2018) or RAMI4.0 (Hernández et al. 2020)—all involve a hierarchical, multilevel layered structure to comprehensively cover the organization’s elements (Winter and Fischer 2006). Within this layered structure, the outward-facing ‘business model’ represents the top layer, with ‘(technical) infrastructure’ providing the basis of these models. The existing models include various intermediary layers connecting these two edges (Gampfer et al. 2018)—for example, ‘business processes’ (Šaša and Krisper 2011), ‘people and application systems’ (Pereira and Sousa 2005; Urbach and Röglinger 2019), and ‘data and information’ (Gong and Janssen 2021). Their ability to provide a socio-technical perspective on organizations (Appelbaum 1997; Baxter and Sommerville 2011) means that EA models are suited to outlining referential, aligned architectures that enable DDBMs at different organizational levels (Rashed and Drews 2020). In this work, we use the EA model according to Urbach and Röglinger (2019) (Fig. 1 Layered Enterprise Architecture Model (Urbach and Röglinger 2019; Urbach et al. 2021)), as it combines both technology and business layers. The socio-technical orientation of this model is particularly suitable for transformative processes associated with digitalization (Cleven et al. 2014).

Within this five-layered EA model, the top ‘business model’ layer includes outward-facing aspects of DDBMs—for instance, value offer and customer interaction (Vanauer et al. 2015; Rashed and Drews 2021). The subsequent intermediate layer ‘business processes’ relates to processual activities to operationalize the business model (Pathak et al. 2021). For example, a DDBM requires the restructuring of existing business and IT processes to ensure better internal and external data assimilation. The EA layer of ‘people and applications’ depicts human resources, associated competencies, and application systems that employees work with (e.g., data scientists, data engineers, or product owners) (Pathak et al. 2021). The ‘data and information’ layer refers to information and data from the organization that is being collected, processed, and stored, and refers to how this data is managed (e.g., data quality management) (Rashed and Drews 2021). The bottom layer, ‘infrastructure’, consists of IT systems, sensory-equipped machinery, and other hardware resources based on cyber-physical systems and the industrial internet of things (Pathak et al. 2021). EA models have proven to be particularly valuable in the implementation of DDBMs as the models can be used as reference architectures to highlight organizational configurations aligned with certain DDBMs (Rashed and Drews 2020). Yet, while EA models provide an integrated perspective on a target state, they are limited in their ability to provide insight as to how organizations might move toward such a state and what capabilities need to be developed.

2.3 Capability Development and Maturity Models

MMs have become established managerial tools used to structure the development of organizational capabilities (Mettler 2011). MMs map maturity paths by logically grading maturity (maturity levels) and describing the distinctive capabilities or attributes (e.g., in capability dimensions) of each level (Pöppelbuß and Röglinger 2011). MMs can be used for descriptive (determination of the status quo), prescriptive (identification of target states), or comparative (e.g., by comparing several companies based on a model) purposes (Becker et al. 2009). In practice, MMs are instrumental in identifying deficiencies that may hinder the achievement of a mature, desired state (Olszak and Mach-Krol 2018). The number of MMs indicates a promising approach for structuring capability development, including the DDBM domain. Among the many extant MMs are technical frameworks and process models for developing data analytics systems. The target groups for these MMs are organizational units close to technology, such as IT, that focus on capability development in technical domains—i.e., the lower EA layers (e.g., Olszak and Mach-Krol (2018), Sjödin, et al. (2018)). For example, the Industrial Analytics Maturity Model (IAMM) by O’Donovan et al. (2016) provides a clear focus on analytics and technology capabilities in manufacturing. Other, more comprehensive MMs exist, combining technological, organizational, and, to some extent, business perspectives. These models are managerial tools for organization-wide transformations. For instance, the big data maturity model (BDMM) by Comuzzi and Patel (2016) broadens perspectives on organizational issues such as ‘culture’, ‘strategic alignment’, or ‘processes’. This approach has also been taken up by Gökalp et al. (2021), for example, and expanded to include capability dimensions such as ‘vision and strategy’ and ‘knowledge management’. Nevertheless, existing research finds that the development of business-related capabilities, such as interaction with the customer or monetization, are a particular challenge for established manufacturers (Baltuttis et al. 2022; Schroderus et al. 2022; Kotarba 2018). However, providing an integrated perspective on which business and technology capabilities are required to offer DDBMs in manufacturing remains a gap in existing research (Hunke et al. 2021). Examples from other domains indicate that integrated business and technology models can be effective tools to structure the transformation toward DDBMs, as Hausladen and Schosser (2020) demonstrate for the air transport sector. Therefore, this paper seeks to develop an integrated MM that guides manufacturers in developing the required capabilities to offer an archetypal DDBM.

3 Research Methodology

This paper follows the methodological DSR paradigm (Hevner et al. 2004; Gregor and Hevner 2013), which aims to design solutions using various artifact forms (e.g., constructs, models, or methods) to solve problems grounded in practice (vom Brocke et al. 2020). Following Peffers et al. (2007), DSR is implemented as an iterative, six-step process that starts with problem definition, defines goals, develops and refines a solution, demonstrates or applies this solution, and evaluates whether the requirements have been met and the problem solved. Finally, the insights gained are communicated.

While this procedure is designed to be applicable in developing various artifact types, MMs represent a particular artifact type for which dedicated procedure models of the DSR paradigm exist (Mettler 2011). In particular, the procedure model of Becker et al. (2009) represents an established methodological approach that proposes specified DSR activities for the iterative development of MMs (Pöppelbuß and Röglinger 2011; Stelzl et al. 2020). For instance, the procedure model includes a comparison with existing models and the formulation of a development strategy before the development of the artifact. In addition, the demonstration phase is enriched with a transfer phase, wherein the developed model is prepared for the appropriate application in business (e.g., by translating the MM into a software tool). While Peffers et al. (2007) and Becker et al. (2009) focus on activities involved in the DSR process, other works provide valuable insights into the evaluation of artifacts (vom Brocke et al. 2020). Sonnenberg and vom Brocke (2012), for example, provide four patterns and associated criteria for evaluating DSR activities (i.e., Eval 1–4) and distinguish between ex-ante and ex-post evaluation. Ex-ante evaluation patterns aim to justify the problem statement (e.g., the extent of the research need) and the validity of design decisions (e.g., the internal consistency of design objectives). By contrast, ex-post evaluation challenges the artifact in artificial (e.g., challenging the model’s robustness) and naturalistic settings (e.g., the model’s usefulness in a real-world demonstration) (Sonnenberg and vom Brocke 2012; vom Brocke et al. 2020). In structuring our research, we follow the procedure model by Becker, et al. (2009) and use the evaluation patterns developed by Sonnenberg and vom Brocke (2012) to ensure the rigorous development of our MM. This paper comprises four main phases, each comprising activities and a subsequent evaluation (Fig. 2).

The first phase in our approach is problem justification and the definition of requirements. The second phase is comparing existing MMs and selecting a suitable development strategy. The third phase comprises iterative model development and artificial evaluation. The fourth phase is the application of the model and the accompanying naturalistic evaluation. In the four phases of our research approach, we used various research techniques to ground data and, finally, to complete the evaluation of the phase (Hausladen and Schosser 2020) (Fig. 3).

3.1 Phase 1: Problem Justification and Requirement Definition

In the first phase, we used the existing literature to substantiate the research needs and justify the problem statement. Based on the research needs, we developed requirements tailored to the needs of practitioners from manufacturing companies. We conducted semi-structured interviews (Myers and Newman 2007) with eight experts from two manufacturers to verify practical relevance from an ex-ante perspective. Table 1 presents an overview of the manufacturers and industry experts interviewed. The two manufacturers were chosen as a stratified sample (Robinson 2014). Both are in the middle of the transformation to a DDBM, with the sales of physical machinery being enhanced with data-driven services. Thus, the two companies are comparable in this respect and correspond to the defined user group of DDBMs. Importantly, however, these two companies used different strategies to approach their DDBM, and thus enabled us to familiarize ourselves with different ways of transforming from a traditional manufacturer business model to a DDBM. In selecting the interviewees, we aimed to capture independent expert opinions from business and technical areas, as well as the intersection of the two, to ensure broad understandability and real-world relevance. The interviewees have significant knowledge of their respective manufacturing companies and play a key role in the transition to a DDBM. All interviews in our research approach lasted between 44 to 93 min and were conducted digitally and transcribed. For our research phase 1, we then examined the transcripts in accordance with the criteria established by Sonnenberg and vom Brocke (2012) to clarify the problem to be addressed by this paper and to determine three reasonable requirements for the development of our artifact (see Sect. 4).

3.2 Phase 2: Comparison of Existing Maturity Models

The second phase involved identifying existing MMs and examining whether these already fulfilled the requirements. To this end, we identified existing works via a structured literature review (Webster and Watson 2002; vom Brocke et al. 2015) using the Web of Science, known for its high-quality citation data and for covering a broad range of disciplines (Zupic and Čater 2015). We used a two-part search string for related research publications (Huang et al. 2015). The first part of the string addressed the issue of data-related business (“data analytics” OR “data driven*” OR “data-driven*” OR “machine learning” OR “big data” OR “artificial intelligence”). The second part sought articles providing insights on relevant capabilities of success factors (“maturity model” OR “capability framework” OR “actionable practice*” OR “success factor*”). The initial search yielded 166 papers, which we subsequently screened for title, abstract, and full text. We excluded papers that made no substantive reference to success factors or capabilities of DDBMs and focused on domains or research areas other than business or management (e.g., medicine or educational sciences). Thus, we excluded 101 papers based on title screening, 11 based on abstract screening, and 13 after our analysis of the full paper. The search resulted in 41 papers that addressed issues directly relating to our research (e.g., papers identifying success factors or key challenges for DDBMs). These papers included ten related maturity models. Using forward and backward searches, another five models were identified, leading to a final set of 15 related models. We used a comparison table to decide whether these works fulfilled the requirements derived from Phase 1 (Cuylen et al. 2016). The resulting ten models included in this table fulfill at least one of our requirements. Based on this comparison, a development strategy for the MM was selected. This could involve the complete redesign of a model, the extension of an existing model, the combination of several models to form a new model, or the transfer of structures or content from existing models to new areas of application (Becker et al. 2009; Gregor and Hevner 2013). To create an integrated model that would cover business and technology aspects not addressed in existing models, we decided to develop a new model drawing on valuable structures from existing models and existing research, such as EA models and DDBM archetypes.

3.3 Phase 3: Model Development and Artificial Evaluation

In the third phase, the model was iteratively developed. In keeping with Becker et al. (2009), we started designing the model’s architecture (i.e., maturity levels and capability dimensions) before working on the matrix content. Following the requirements identified in Phase 1, the maturity levels were designed following archetypes of business models to cover the rising sophistication of data-driven services and data analytics with increasing maturity. For this purpose, we designed five maturity levels corresponding with the analytics-based services archetypes of Hunke et al. (2021). Subsequently, we developed the capability dimensions of the DDBM. To provide an integrated perspective, including business and technology capabilities for DDBMs, we drew guidance from the EA model of Urbach and Röglinger (2019) outlined in Sect. 2. To identify the capability dimensions of the DDBM3, we deconstructed existing models and assigned their capability dimensions to the levels of the EA model. Based on this structure, it became clear that existing models comprehensively covered the technological levels of the EA (i.e., ‘data and information’ and ‘infrastructure’).

Hence, we investigated other works which provided a business perspective on DDBM. From these models, we extracted further capability dimensions (e.g., ‘value proposition’ from Payne et al. (2017) and ‘sales and channel management’ from Leiting et al. (2020)). We then developed the matrix content (i.e., the capabilities per maturity level). Herein, we used descriptions from existing works or developed new descriptions based on guidance from the literature. Overall, the development of our model took place over three iterations. In the first iteration, we developed the basic structure, which we then compared with existing models. In the second iteration, we specified the initial matrix content. In the third iteration, we aligned the capabilities horizontally (i.e., to the capability dimensions) and vertically (i.e., to the maturity levels). We completed this third phase of our research approach by hosting an academic focus group involving eleven researchers in the field of digital transformation. The workshop led us to make final changes—for example, we adjusted descriptions to meet evaluation criteria such as completeness and internal consistency (Sonnenberg and vom Brocke 2012).

3.4 Phase 4: Naturalistic Evaluation by Demonstration

A subsequent fourth phase involved a naturalistic evaluation by applying the model to two real-world organizations (Sonnenberg and vom Brocke 2012). We applied the model in two focus groups consisting of experts from the two selected manufacturers (see Table 1) to assess the status quo and target state. As a qualitative research method, focus groups are particularly suitable for this purpose as they allow mutual inspiration and facilitate discussion among the participants (Tremblay et al. 2010; Stewart and Shamdasani 2014). A digital whiteboard was employed as a user-friendly transfer medium to facilitate an assessment of the company’s status within the focus group (Becker et al. 2009). The MM was displayed on the whiteboard and the focus group participants could give their assessment independently of one another in successive rounds (i.e., per capability dimension). To enable sensitivity and specificity in their assessments, the participants were allowed to assess the status as ‘in-between’ two capabilities. After each capability dimension, the individual assessments were revealed to all participants. Based on the current state assessment in all capability dimensions, particularly weak dimensions were identified, and options for improvements were discussed. Finally, the participants reflected on the application of the model to verify whether the model met the practical requirements. This evaluation indicated high applicability and utility, as the integrated perspective of business and technology supported the identification of shortcomings. The practitioners thus concluded that the model was highly useful and effective for capturing DDBM transformation.

Based on this, we use our model as an analytical lens to better understand what actions (e.g., digitalization projects) the companies had implemented to reach the current status quo. We performed semi-structured interviews (Miles and Huberman 2009) to outline actions taken within the last ten to fifteen years to achieve the current status quo of DDBMs in each focus area of the MM. Firstly, we asked the interview partners to explain their company’s overall DDBM approach. Secondly, we asked them to describe initiatives and actions across all organizational layers. Thirdly, we pinpointed challenges associated with DDBM development. All interviews were digitally recorded and transcribed. In our analysis, we coded the interviews along the structure of our MM. This enabled us to identify in each case a company’s approach, the actions taken, and the challenges encountered.

4 Results

In this section, we present the results of our research, following the guidelines developed by Becker et al. (2009). Firstly, we describe the requirements we identified as necessary to enable a possible solution. We then present the result of our comparison between the requirements identified and existing MMs. Next, we present the DDBM3 and its artificial evaluation. Finally, we offer insights on the naturalistic evaluation of our model and on the transformation of manufacturers toward DDBM.

4.1 Phase 1: Design Requirements

As outlined in Sect. 3, we identified requirements for our model using eight interviews with manufacturing practitioners. Below, we present three key requirements (R) for a MM supporting capability development among manufacturers in the transition to DDBMs.

4.1.1 [R-1] Representation of Business Model Archetypes

Firstly, as interview partner B1 stated, “[…] a major challenge is to identify a clear business model within our transformation activities.” The guidance offered by the solution should refer to practice-oriented, clearly defined archetypes of DDBMs. This will enable practitioners to identify a target state clearly. As A1 attested, “[…] for us, having a clear business model vision is essential.” Moreover, the practitioners demanded a continuum from providers of traditional products to providers of digital solutions. This range was chosen to fully cover the manufacturing transformation of the focus groups’ organizations: While both organizations are currently undergoing their DDBM transformation, all began as providers of physical products, i.e., machinery. The representation of DDBM archetypes was, thus, identified as strategically important in that it may help to provide a long-term perspective on how the business model could be further developed if competitive pressure continues to increase at the product level.

4.1.2 [R-2] Completeness of EA Coverage

Secondly, the model should outline capabilities relevant to DDBM, including a business and technology perspective. As outlined by interviewee B3, “[…] to structure this [DDBM] transformation, it is essential to have a comprehensive perspective on the organization that includes business and technology.” Thus, the model should provide a comprehensive view of the organization, including the business (e.g., value proposition, monetization strategies) and technical (e.g., infrastructure) capabilities. This urgency was underpinned by A2 stating that “[…] in previous projects, we often looked at either technology or business principles. However, it is becoming clear that these perspectives need to be considered jointly so that the entire organization remains focused on one objective.”

4.1.3 [R-3] Completeness of Capability Descriptions

Thirdly, the MM should clearly describe the capabilities of specific business model archetypes. Interview partner A2 stated that “[…] for us it is essential to have a description of the capabilities rather than just some keywords.” Clear descriptions enable both the classification of one’s own organization (descriptive) and the identification of future steps for building more mature capabilities in the transition to the target state (prescriptive).

4.2 Phase 2: Feature Comparison

In keeping with our DSR approach, both our problem statement and design requirements are grounded in practice. Based on the requirements, existing models can be identified. Thus, we could determine whether existing research met our requirements and, if not, we could derive a development strategy for a MM (Becker et al. 2009).

Our structured literature review, presented in Sect. 3, initially identified 15 related works. We evaluated existing models against the three requirements. For this purpose, comparison tables provide a useful means to conduct a feature comparison and evaluate whether the requirements have been sufficiently fulfilled by existing works (Cuylen et al. 2016; Stelzl et al. 2020). During the screening process, ten models were identified that at least partially fulfilled the requirements (Table 2). We excluded five models during the screening process as these either could not be classified as MMs (i.e., Grossman (2018), Chen et al. (2017), Frank et al. (2019)), did not describe any capabilities related to DDBMs (e.g., Farah (2017)), or focused solely on technology rather than providing an integrated perspective on the company (e.g., the MLOps MM of John et al. (2021)).

We found that the remaining ten MMs provided descriptions of their model’s capabilities (R-3). Only Ge et al. (2020) and Weber et al. (2017) offered notably limited insights on the outlined capabilities (e.g., in the form of a capability index). Except for the model of Hausladen and Schosser (2020), the MMs only partially fulfilled the requirement for comprehensiveness, i.e., R‑2. We examined whether the models covered the entire EA (i.e., technical, organizational, and business aspects). We found that coverage of business aspects was broadly lacking in the models studied. Many papers examined the technical and organizational capabilities for value creation rather than value delivery and capture. Therefore, the need for business model archetypes specified in R‑1 was not fully addressed by any model. The model by Hausladen and Schosser (2020) offers business model references for airlines, yet the potential for generalization is limited, especially for manufacturers.

Existing models provide valuable descriptions of DDBM capabilities, particularly in the technical and organizational domains. However, the business domain remains mainly unaddressed and poses a considerable challenge for manufacturers. Against this background, it seems reasonable to draw on and combine insights from existing models and related models (e.g., EA models and business model archetypes) to form a new model, which can be supplemented by elements from business models (Becker et al. 2009).

4.3 Phase 3: Description of the Data-Driven Business Model Maturity Model

In developing our DDBM3, we followed a top-down approach, initially defining maturity levels and capability dimensions (Becker et al. 2009). The model was developed as a continuous MM, implying that it spans a matrix between capability dimensions and increasing maturity levels, the content of which is fully specified (Stelzl et al. 2020; van Steenbergen et al. 2010). The matrix content of the DDBM3 thus describes the minimal archetypical capabilities required by a manufacturer if they are to offer a specific DDBM archetype. In the following, the basic structure of the DDBM3 is presented (Fig. 4), the maturity levels are defined (Table 3), and the capability dimensions are described (Table 4).

To fulfill R‑2, the DDBM3 does not draw on abstract maturity levels. Instead, it builds on the DDBM archetypes by Hunke et al. (2021). These archetypes are empirically grounded and provide discrete characteristics that increase with maturity levels (Table 3). Firstly, the relevance of data-driven services to the overall business model increases with maturity. Secondly, the depth of data processing and analytics increases with maturity levels. Thirdly, customization of the digital component of the value proposition increases. Moreover, we extended the archetypes with an initial maturity level—‘product provider’—based on requirement R‑2. The DDBM3 thus comprises five maturity levels that cover the continuum from ‘product provider’ to ‘digital solution provider’.

Next, we defined the capability dimensions of the DDBM3. To provide an integrated perspective, including business and technology capabilities, we drew on the EA model by Urbach and Röglinger (2019) as focus areas. Capability dimensions extracted from existing literature were clustered and assigned to these focus areas. Overall, the DDBM3 consists of 22 capability dimensions (Table 4).

In the DDBM3, the focus area ‘business model’ includes capabilities that refer to the organization’s market interface. Hence, this focus area includes those components of the business model that are outward-facing and concern the company’s interaction with customers. A key element is the ‘value proposition’, i.e., the capability to provide a consistent offering, comprising digital and physical components, that generates value for the customer (Payne et al. 2017). The value proposition is closely related to the DDBM archetypes according to Hunke et al. (2021)—e.g., value generation through customer-specific insights. The ‘customer relations’ refers to the degree of (digital) interaction between supplier and customer in the value creation process. This capability enables the supplier to tailor the data-driven services to the customer’s needs and, hence, enables co-creation (Hunke et al. 2021; Zhang et al. 2019). ‘Monetization and pricing’ capabilities enable manufacturers to price and successfully monetize the value of data-driven services, e.g., via pay-per-use models (Baltuttis et al. 2022; Schüritz et al. 2017). ‘Sales and channel management’ is an essential capability for the effective distribution of the company’s digital offerings. It includes the digitalization and adoption of new distribution channels, such as digital platforms, that are highly suited for offering DDBMs (Leiting et al. 2020).

The focus area of ‘business processes’ covers specific processual capabilities that enable the creation, delivery, and capture of data-driven services and break down the business model into internal activities (Porter 2014). Business processes also direct the flow of information and enable alignment between business and IT (Harmon 2015; Comuzzi and Patel 2016). The capability to provide ‘strategy and vision for data-based business’ refers to management providing a clear strategic vision for the transformation toward DDBM. It thus provides strategic alignment and includes the management’s provision of dedicated resources (financial, human, etc.) for DDBM (Gökalp et al. 2021; Hausladen and Schosser 2020). ‘Data-centric process management’ is an organization’s capability to manage processes in such a way that they contribute to the DDBM strategy, are measured and traced based on data, and are enhanced through data-driven improvements (Comuzzi and Patel 2016; Malta and Sousa 2016). Moreover, to enable DDBMs, it is essential to share and actively manage domain and IT knowledge within the organization to promote inter-organizational exchange (‘knowledge sharing and management’) (Gökalp et al. 2021). This capability is relevant, as data-driven services require that knowledge from the domain is bundled with digital capabilities to provide, for example, data-driven recommendations that increase the utility of the physical product (Hausladen and Schosser 2020). In addition, manufacturers need to transform their ‘product life cycle management’. This capability refers to the planning and management of the product’s life cycle, including collecting, storing, and processing data for data-driven services (Schroderus et al. 2022).

The focus area ‘people and applications’ comprises cultural aspects, soft and hard skills, responsibilities, and analytics tooling for data-driven business models at the employee level. This focus area ensures that the organization’s employees are empowered to implement DDBMs. ‘Recognition & mindset’ is an essential capability referring to a collective understanding among all organizational members of the potential and value of data (Hausladen and Schosser 2020; Davenport and Bean 2018). This corporate culture ensures that the organizational members embrace DDBMs as the desired objective and align their actions accordingly (Comuzzi and Patel 2016). In this context, ‘methods’ also have a vital function. This capability encompasses leveraging customer-centric, experimental, iterative approaches to reduce uncertainty and enable learning in order to develop data-driven solutions (Tsoy and Staples 2021). It also involves rapid prototyping to evaluate the applicability and feasibility of a data-driven service (Gökalp et al. 2021). Manufacturers must create new ‘roles and responsibilities’ for DDBMs. Intra- and inter-organizational professional roles and responsibilities enable the company’s data-driven value creation, delivery, and capture (Förster et al. 2022). In addition, it must be ensured that the organization is capable of externally acquiring and internally developing ‘data analytics competencies’ to enable data-driven services (Comuzzi and Patel 2016; LaValle et al. 2011). Consequently, employees need to be equipped with the ‘data analytics tooling’ applications. This describes an organization’s capability to effectively provide data analytics tooling (i.e., visualization, processing, and mining tools) (Hausladen and Schosser 2020; Comuzzi and Patel 2016).

The focus area ‘data and information’ covers data management, the integration of data sources (horizontal and vertical), the establishment of governance and quality mechanisms, and the analytics applied to data. One capability dimension is the ‘applied forms of analytics’, which deals with methods and models such as descriptive, diagnostic, or prescriptive analytics, depending on the associated DDBM archetype (Gökalp et al. 2021; Schroderus et al. 2022). ‘Data management’ addresses the capability to manage the data analytics life-cycle (i.e., collecting, storing, transforming, and analyzing data for information extraction). This capability also covers levels of access to data at different stages of this life cycle, across the organization (Comuzzi and Patel 2016; Hausladen and Schosser 2020). Another vital capability in this focus area is the assurance of ‘data governance & quality’. This capability includes rights and access management, metadata management, and data cartography (Gökalp et al. 2021). For mature DDBMs, a high level of quality among the available data is essential. ‘Horizontal and vertical data integration’, referring to the identification and integration of internal and external data types and sources, is also an important capability dimension (Comuzzi and Patel 2016). Vertical integration refers to the integration of internal data from business units, while horizontal integration involves external data sources and domains (e.g., customer data) (Weber et al. 2017).

The focus area ‘infrastructure’ comprises mostly technological enablers that organizations need to provide DDBMs. The associated capabilities include the secure and scalable operation of software and hardware. The ‘data analytics software management & operations’ capability refers to an organization’s capability to adopt and integrate data analytics software tools to provide data-driven services. It covers the installation, operation, and monitoring of software and associated infrastructure. The aim is to optimize software availability, speed, and reliability (Gökalp et al. 2021; John et al. 2021). Another relevant capability is ‘data-driven service integration & deployment’. This relates to the software-based configuration, deployment, and maintenance of data-driven services, and their integration into existing infrastructure (Gökalp et al. 2021; John et al. 2021). Manufacturers must also be able to adapt their data architecture design to handle the volume, velocity, and actuality of existing and new data sources (‘data architecture & scaling’) (Hausladen and Schosser 2020; Muller and Hart 2016). This includes, for instance, storage capacity, computational capacity, as well as sufficient interconnectivity to enable the transfer of data from cyber-physical systems to local servers or the cloud. It also includes the capacity to feed insights drawn from the cloud/server to machines and onward, to customers (Chen et al. 2022). Another relevant capability in the infrastructure area is ‘cybersecurity & privacy’. This involves applying technical and managerial measures to ensure confidentiality, integrity, and availability when processing large volumes of data (Ullah and Ali Babar 2019; Chen et al. 2022; Guggenmos et al. 2022). Finally, ’cyber-physical systems & connectivity’ is an infrastructure-related capability that covers capturing and collecting data via cyber-physical systems. For manufacturers, this involves establishing an accessible machine base—e.g., equipping the physical product with sensors, actuators, and connectivity. This capability lays the ground for data collection and processing and enables cyber-physical interaction with equipment (Weber et al. 2017).

Based on the structure of the DDBM3, the individual capability manifestations were fully defined for each maturity level (see Appendix 1).

4.4 Phase 4: Insights On Manufacturers’ Transformations to DDBMs

A particular focus in the DDBM development process is evaluating a model’s practical value. For this purpose, the DDBM3 was applied with two manufacturers (Table 1). For each of these manufacturers, an interdisciplinary focus group of practitioners used the model to analyze their company’s status quo and define a target state for DDBM development (Fig. 5). The focus group was initially consulted on the target state of the current DDBM transformation. The DDBM archetypes presented by Hunke et al. (2021) were used for this purpose. Both organizations unanimously classified the target state as a ‘recommendation provider’ within the next five years.

The application of the DDBM3 revealed that both manufacturers’ capabilities are among ‘data provider’ and ‘insight provider’ (average values 2.7 and 2.4). In addition, we could identify that Alpha held mature capabilities, particularly in the upper levels of the model, which are closer to the target state (i.e., strategy, process management, knowledge sharing, mindset, and methods). However, the application also revealed that some of this manufacturer’s other capabilities—mainly technical and data-related—were significantly less developed. These included capabilities associated with data quality, analytics tooling, and software management.

In contrast, Beta’s assessment was less scattered and indicated that most of this manufacturer’s capabilities were at the maturity level of an ‘insight provider’. However, we observed that Beta did possess some more mature capabilities, mostly among those on the lower EAs, (e.g., in the area of infrastructure). Consequently, the potential for transformation in the manufacturer’s business capabilities was identified, including the potential to formulate a suitable value proposition, manage digital channels, and share knowledge across the organization. Overall, users in the focus groups considered the model to be particularly helpful due to its comprehensiveness, enabling the practitioners to identify relevant fields of action within their DDBM transformation. It was also confirmed that the DDBM3 meets the identified relevant requirements.

4.5 Findings On Approaches for DDBM Transformation

In addition to the focus groups on the application of DDBM3, interviews were conducted with practitioners to gain insight into the transformation to DDBMs and develop an understanding of the reasons for the companies’ status quo. Although both companies held roughly similar capability averages across the model, Alpha held more substantial business capabilities, whereas Beta held more mature technology capabilities. Both Alpha and Beta started their transformation to DDBMs around ten years ago and had been implementing various actions in terms of projects and initiatives. To better understand how both companies had reached their status quo, they were asked about their overall approach and goals, their actions, and the challenges they faced.

4.6 Alpha—A ‘Business First’ Approach

In line with observations drawn from the application of the DDBM3, a ‘business first’ approach was identified at Alpha. Here, it was mainly the business side, i.e., customers, who initiated the transformation actions, as they demanded data delivery. These actions were followed by some measures that developed the maturity of the upper levels of the EA (e.g., strategic initiatives and new roles). However, weaknesses remained in the lower EA—e.g., in the data analysis capability or the scaling of networked machines.

Insights On Action Taken for DDBM Transformation

“[…] actually, our [business] customers triggered us to provide data-driven services. They clearly demanded access to machinery data. This triggered the process of thinking about all relevant requirements to realize this business opportunity and to create more services […]” (A1). Starting from the ‘business model’ area, Alpha’s DDBM transformation began with increasing customer demand for access to machine data. The service department initiated the provision of data that had, until that point, only been used internally. Next, Alpha’s management established a customer-oriented strategic initiative to explore DDBM, starting with a clear business perspective and employing associated tools and methods (e.g., business model canvas, value proposition design, etc.). Alpha then launched new external applications (e.g., digital service portals, end-user apps) which were developed to create digital channels for data-driven service provision.

Alpha subsequently defined new ‘processes’ for developing and operating data-driven services and associated roles on the ‘people and applications’ layer. These included digital product managers as bridgeheads between technology development and business management (A2). However, the acquisition of data analytics competencies to match these roles and the provision of appropriate tooling remain a key challenge for Alpha, resulting in lower maturity of these capability areas. On the ‘data and information’ layer, the company did not purposefully gather data to be exploited for DDBMs. Yet, the company worked, primarily, with established ‘infrastructure’ not targeted at extensive data practices (e.g., ERP systems) (A5). Thus, the company recently started implementing a data lake to provide a single source of truth for the different kinds of data and data sources (A1, A2). One primary data source is the latest machines equipped with many sensors. In this case, data collection is mainly driven by reporting, diagnosis, and maintenance. Even though the company now provides every new machine with connectivity, only about 15% are fully accessible via connectivity services (A1).

In sum, the driving force for Alpha was the customer and business model perspective: “[…] the development of digital end customer solutions, in particular, was driven by the promising business model […]” (A2). In turn, Alpha follows a ‘business first’ approach, with case-by-case project budgeting and clear financial targets (e.g., cost reduction, margin enhancement, and return on investment). Technological advances and investments have thus always been aligned with clear business-oriented goals.

Challenges

Alpha’s approach was associated with some challenges. The company gathered data more as a by-product rather than with a clear intention in data management. Existing data sources (e.g., ERP systems) remain untapped due to missing analytics tools and a lack of internal data domain knowledge (A5). Another critical issue remains the rollout of connected machinery and long lifecycles. With an average seven-year period of use, Alpha’s machinery is remarkably reliable and durable (A1, A2). However, this results in a slow turnover of the installed base and massively hinders the rollout of digital solutions over many sites, hence, limiting access to data. Another challenge is that the development of data-driven services is mainly undertaken by external partners. This is due to limited internal capabilities and resources to implement and deploy the DDBM. The overarching challenge of the ‘business first’ approach is that, while solutions can be purposefully designed and offered on the business side, a lack of technology-related capabilities slows down the transformation.

4.7 Beta—A ‘Data First’ Approach

From the assessment of Beta in the DDBM3, we observed that Beta possessed more mature capabilities in the technological and data areas of the model. However, weaknesses were apparent in the upper EA regarding, for instance, monetization and pricing capabilities and knowledge sharing within the organization.

Insights On Action Taken for DDBM Transformation

Starting mainly on the ‘infrastructure’ layer, Beta was early in enabling machine connectivity through wired or wireless communication (MQTT)—one of the first technical initiatives to enable DDBMs around the core product. This approach enables machines up to around ten years old to be connected digitally, resulting in a potential installed base of around 80%, if connected by the customer (B1, B4). Moreover, the company initiated the build-up of the first data warehouse in 2004 and has since been continuously enhancing its technical capabilities in the ‘data and information’ layer. Additionally, Beta profits from the fact that many of its product’s electric components enable the measuring of various parameters without additional sensory equipment (B2). Regarding the ‘people and applications’ layer, Beta developed a service platform and leveraged the know-how of the service partner to identify use cases providing efficiency gains. Furthermore, an integrated cloud-based solution has recently been introduced to enable the continuous integration and deployment of data-driven services. Building on mature technology capabilities, Beta realized use cases to enable digital status and health reports for a service partner maintaining their machines (B3). The development of capabilities at the ‘process’ layer was use-case-driven and not strategically pushed early on, as was the case with Alpha. After establishing a solution for their service partner, the data-driven services expanded toward an end customer base. “[…] we started with low-hanging digital services to enhance the productivity of our customers and partners. We see such potential in the service domain, in particular, and have the required data at hand […]” (B1). Regarding the ‘business’ layer, Beta’s customers were less actively demanding data-driven services than Alpha’s customers, and Beta mainly used trials to evaluate digital services—e.g., with key accounts. Thanks to market conditions and the fact that they held fewer capabilities to actively place DDBMs, only about 5% of customers use data-driven services (B1).

Beta’s transformation toward DDBMs has been driven mainly by technical affordances and a dominant market position, rather than active pressure from the demand side or a business-driven initiative.

Challenges

Along the data-driven service development process, Beta’s main challenge in data management lies in increasing the market penetration of the connected products. While the technical preconditions are mainly mature and the internal systems are available, customers need to be persuaded to connect their machines with the standard interfaces and use the necessary data-driven services (B4). Dedicated value propositions for different customer groups and associated channels and monetization strategies must be established at the business level (B1). In summary, the overarching challenge of the data-first approach is that the market-side realization of DDBMs is fraught with uncertainty. While the technological requirements and necessary investments for the realization of DDBM have been made, there is much uncertainty about the monetization potential of DDBMs. Hence, the key issue here is this strategy has not yet been widely validated in business contexts, and technological development may occur without the necessary, simultaneous development of the business model.

5 Discussion

5.1 Theoretical Contribution and Implications

Many manufacturers strive to leverage the opportunities of digitalization to offer data-driven services and transform toward DDBM (Müller and Buliga 2019; Voigt et al. 2021). However, this transformation, especially for incumbents, often implies the development of new capabilities across the organization (Gong and Janssen 2021; Comuzzi and Patel 2016). Existing research has already examined this transformation, systematizing DDBM, for example, and developing archetypes that differ in their logic of value creation and value delivery (Weking et al. 2020). At the same time, existing research shows that both technology and business capabilities are needed to enable DDBM (Rashed and Drews 2021; Favoretto et al. 2022). However, the inquiry as to which capabilities manufacturers need across the organization to offer distinct DDBM archetypes remains unanswered (Hunke et al. 2021).

To fill this research gap and provide practical help for manufacturers, this paper follows a DSR approach to develop and evaluate the DDBM3 as a central artifact that identifies 22 business and technology capability dimensions in five focus areas (i.e., business model, business processes, people and applications, data and information, and infrastructure) for archetypal DDBMs. By developing the DDBM3 as a continuous MM (van Steenbergen et al. 2010), the relevant business and technology capabilities within each capability dimension are identified for each archetypal DDBM of Hunke et al. (2021) (i.e., data provider, insight provider, recommendation provider, and digital solution provider). As such, the MM is embedded in both practice (i.e., the problem context, requirements, and evaluation context) and research (i.e., the knowledge base and the contributions of this study) (Hevner et al. 2004; vom Brocke et al. 2020). To design a solution, we build on three strands of research. First, we build on the developed DDBM archetypes of Hunke et al. (2021) as focal points of our model that allow determining aligned target states of the DDBM transformation. Second, we use layered EA models to offer an integrated, organization-spanning perspective from business to technology capabilities (i.e., business model, business processes, people & applications, data & information, and infrastructure) (Rashed and Drews 2021). Using the layered EA model of Urbach and Röglinger (2019) to structure these capabilities along different enterprise levels, we identify the 22 literature-based capability dimensions that are relevant for transforming to archetypal DDBM. Third, we identify and analyze existing MMs in the field to develop the 110 capabilities of the DDBM3 (Comuzzi and Patel 2016; Gökalp et al. 2021; Hausladen and Schosser 2020). On the one hand, the model was challenged for completeness and internal consistency in artificial evaluation settings. On the other hand, through an application at two manufacturers, the model was naturalistically evaluated regarding its applicability and effectiveness to understand better the DDBM transformation (Sonnenberg and vom Brocke 2012).

As the DDBM3 strives to enhance the understanding of the required capabilities to offer distinct DDBM archetypes, it can be classified as an ‘improvement’ artifact (Gregor and Hevner 2013). While existing models focus on either business or technology capabilities, the DDBM3 offers an integrated and aligned perspective on the capabilities of different organizational layers, allowing the model to be more suited to address the complex real-world phenomenon of DDBM transformations (Baskerville et al. 2018). The model’s continuous design creates a high level of descriptive knowledge, as qualitatively described capabilities can be related to the DDBM archetypes and EA levels. By this design, the DDBM3 moves beyond the conception that follows a ‘more mature capabilities are better’-logic (Hunke et al. 2021) that was adopted in some MMs (for instance Gökalp et al. (2021)). Rather, by providing distinct DDBM archetypes as focal points of the transformation, the model creates an awareness that the alignment and matching of these capabilities is essential.

The model and its application offer several implications for research. As demonstrated in the model’s application at two manufacturers, the model can serve as an ‘analytical lens’ that allows an investigation of the progress of the DDBM transformation across different organizational layers (Pöppelbuß and Röglinger 2011). With this tool, research can identify maturation paths and patterns that emerge from its application. This may unravel success factors or impediments associated with distinct paths of maturation, as demonstrated in the study of Mugge et al. (2020) for digital transformation endeavors. This potential becomes initially evident from the two case study demonstrations of this paper: We find that the two manufacturers followed different approaches to tackle DDBMs: While Alpha took a ‘business first’ approach—i.e., in which business capabilities are more mature than technological ones—we observed a ‘data first’ approach at Beta, revealing a greater maturity in technological and data-related capabilities. Our findings give rise to existing theories that transformations toward DDBM are not accomplished in a uniform and aligned manner, which results in different challenges. For instance, Vanauer et al. (2015) theorized about how big data projects are initiated. They assume that these projects can, on the one hand, be driven from a business perspective (‘business first’), based on a business vision and requirements. On the other hand, these projects can be initiated by a resource or affordance perspective that builds on existing data and assets (‘data first’). Our results suggest that both approaches can occur when a manufacturing company transforms toward DDBM. However, from our initial investigation, these approaches were indebted to the prevailing context and history of a company rather than a strategic choice.

5.2 Practical Contribution and Implications

Aside from its merits for research, the developed DDBM3 also offers value for practice. To ensure the model’s practical relevance, a crucial demand of DSR research, it was developed in close alignment with practical requirements (Hevner et al. 2004). Moreover, with a naturalistic evaluation at two manufacturers, the model’s impact, effectiveness, and efficiency were evaluated (Sonnenberg and vom Brocke 2012). In the course of our evaluation, we outline the model’s ‘diagnostic’ purposes that may assist the management of manufacturers to better understand and structure their transformation toward DDBM. On the one hand, the DDBM3 may capture the current ‘status quo’ of DDBM transformation and thus gain insights into an organization’s strengths and weaknesses from a capability perspective. This allows management to understand how mature the company’s capabilities are across the 22 capability dimensions. On the other hand, a ‘target state’ can be defined based on the model’s alignment with DDBM archetypes. In contrast to models using generic maturity levels (e.g., Gökalp et al. (2021) use five generic levels from 1= ‘initiated’ to 5=‘innovating’), the model allows us to characterize target states qualitatively. This may stimulate a reflection on which DDBM archetype is to be aimed for and to derive which capabilities are typically required for this purpose.

Moreover, applying the model at two manufacturers allowed us to gain insights into the transformation at these two companies and brought along some practical implications. As discussed in the research implications section, both companies took very different transformation approaches that brought along challenges. The challenges of the two companies arose particularly from a misalignment of capabilities so that the full potential of DDBM could not be realized at either. We draw the implication from this that management should attempt to keep capability divergence to a minimum, as small building blocks of missing capabilities can slow down the transformation. An implication of this could be that manufacturers should try to adopt both approaches. On the one hand, management may leverage ‘business first’ perspective to identify valuable, customer-oriented use cases (e.g., predictive maintenance or automated supply) (Müller and Buliga 2019; Hunke et al. 2021). In this context, it is necessary to consider possible monetization models and channels for DDBMs at an early stage (Baltuttis et al. 2022). Leadership is called upon to develop a clear vision of DDBMs to mobilize the organization and create a DDBM culture (Davenport and Bean 2018). Hence, management must establish data-driven ‘processes’ early on, yet must still ensure flexibility (Malta and Sousa 2016). Furthermore, our results indicate that the roles of ‘people and application’ need to be defined (Förster et al. 2022). However, the challenge of bringing these roles to life involves the time-consuming development or acquisition of related competencies and the provision of associated tooling.

On the other hand, management may use the ‘data first’ perspective associated with technological affordances (Lehrer et al. 2018; Zammuto et al. 2007)—for instance, by addressing the layer of ‘data and information’ with dedicated investments in hardware (e.g., sensors and connectivity) and software (e.g., data warehouse) (Pathak et al. 2021). A dedicated strategy and roadmap help identify levers that optimize data quality and availability in the long term (Kehrer et al. 2016). Manufacturers can also leverage success factors at the ‘infrastructure’ level by proactively equipping their machines with connectivity and sensors and considering scalable systems (Gökalp et al. 2021). This perspective is particularly in line with existing work that advises companies not to build up technical debt (Tom et al. 2013).

5.3 Limitations and Further Research

Our research has limitations regarding the DDBM3 itself and its evaluation and associated findings. We present these limitations in line with Becker et al. (2009) procedure model for MM development.

First, the DDBM3’s generalizability is limited due to its dedicated focus on manufacturers in the mechanical engineering and machinery sector. We follow the argumentation that such machines especially provide promising potentials for DDBM due to their technical sophistication and the possibility to continuously deliver data while they are being operated (Voigt and M. Müller 2021; Beverungen et al. 2021). However, the DDBM archetypes of Hunke et al. (2021) that we build on in this paper are of a general nature that may apply to other industries (e.g., the food industry). In these contexts, the DDBM archetypes may differ in their configuration and associated capabilities, as the technical possibilities of data collection and processing and the customer requirements differ. For instance, the focus for data deliveries in the food sector may lay on production and supply chain data to enhance transparency regarding environmental impact (Astill et al. 2019). This indicates that the generalizability of the DDBM3 is limited and is particularly tailored to the use cases of manufacturers for equipment and machinery.

Second, a limitation concerning the structure of the DDBM3 is inherent to the design decisions and especially to the three key requirements made during the MM development. By aligning the DDBM3 with existing data-driven business model archetypes and an EA model, the DDBM3 was developed to focus on internal consistency and comprehensiveness. Therefore, the development logic of the model follows a predominantly deductive perspective, such as established focus areas due to the EA model. In contrast, such models can also be developed from an inductive perspective, e.g., when ‘actionable practices’ are extracted from empirical data (Stelzl et al. 2020). This could encourage future works to provide tools that are less of a ‘diagnostic’ character and instead assist in operationalizing the transformation, e.g., by offering ‘lessons learned’.

Third, this paper faces a limitation regarding the generalizability of the implications drawn from the naturalistic evaluation of the DDBM3. This demonstration aims to exemplify the application of the model to examine the transformation of two manufacturers and therefore evaluate the model’s design. In this context, the artifact proved to be a helpful tool for the two cases studied to better understand and diagnose their transformation status. However, this work is limited regarding the generalizability of the two identified transformation paths, i.e., ‘business first’ and ‘data first’, which have already been outlined conceptually in other work (Vanauer et al. 2015). While this reflects the exploratory nature of our work, the evaluation decision potentially limits the ability to generally underlying the two transformation approaches or even identify new approaches. As a result, the theoretical implications regarding the two transformation approaches outline the model’s usefulness as an investigative lens but fall short of providing generalizable theories on transformation paths. While this limits our work’s merits to the core artifact of DDBM3, it is intended to stimulate further research. Further, larger-scale studies can leverage the model as an investigative tool to identify patterns in transformation. In this way, the identified transformation approaches and theory, i.e., ‘business first’ and ‘data first, and the associated actions and challenges could be further empirically substantiated and generalized.

Finally, our work and its limitations lead us to make a call for action. As business, environmental, and technical conditions are subject to change (Becker et al. 2009) the content of the DDBM3 should be regularly evaluated to ensure its real-world fidelity and actuality. To identify such adjustments, new interviews with additional manufacturers should be conducted and upcoming publications should be considered to keep the DDBM3 up to date. For instance, if future research changes the understanding of archetypal business models, the DDBM3’s architectural logic and capability descriptions should be scrutinized. Furthermore, due to the alignment with existing frameworks, i.e., the EA model, the DDBM3 could be expanded to include additional focus areas and capabilities, such as more social-focused capabilities.

6 Conclusion

In line with their ongoing digital transformation, many manufacturers strive to offer DDBM, where data-driven services are essential to the value offering. These business models are geared toward creating high customer value and thus represent a promising option for creating competitive advantages in hitherto hardware-centric business areas. However, especially for incumbent firms, this implies a tremendous shift in their organizational logic and the development of new capabilities. Based on a DSR approach, this study strives to guide in this transformative endeavor through a MM that structures the required capabilities for archetypal DDBM. The model was built based on existing literature and provides an integrated perspective. The model links business and technical capabilities along five organizational levels and presents them in 22 capability dimensions. The real-world application of the MM with two manufacturers shows its practical value in allowing companies to grasp their current capabilities on the different organizational layers and define their DDBM target state. Thus, practitioners better understand their company’s individual transformation path and recognize missing capabilities on the way to their archetypal DDBM target.

While the artifact thus developed provides clear practical added value, it also contributes to the scientific discourse. This study answers the research gap of an integrated perspective on necessary capabilities at different organizational layers for the DDBM transformation of manufacturing companies. The potential of leveraging the resulting model as an integrated lens on the transformation path of manufacturing companies becomes exemplified in the initial application at two manufacturers. Thus, the resulting artifact may stimulate future research to better and more comprehensively understand the transformation of manufacturers toward DDBM.

References