Abstract

This comprehensive review critically examines the application of natural fibers (NFs) in structural concrete. Natural fibers, derived from plant resources, are integrated into concrete to enhance its mechanical properties and overall functionality. The utilization of these fibers in concrete reinforcement represents a sustainable alternative to traditional steel or synthetic fibers, contributing to environmentally conscious construction practices. India leads in plant fiber research, with significant attention on coconut fiber. Notably, fiber chemical compositions, which depend on factors like environment and geography, have profound implications for concrete characteristics. Various fibers exhibit unique relationships with concrete compressive and flexural strength, highlighting the importance of determining optimal fiber concentrations. The integration of fibers influences concrete’s tensile strength, density, and elasticity, with effects varying based on fiber type and concentration. Treatment protocols, particularly with sodium hydroxide and hydrogen peroxide, enhance tensile strength. However, introducing NFs typically compromises workability, necessitating adjustments in water or additives. Additionally, plant-derived fibers offer enhanced thermal insulation, fire resistance, and sound absorption in concrete. Continued research is vital for optimizing the benefits and addressing challenges of fiber-reinforced concrete.

Similar content being viewed by others

Abbreviations

- AMs:

-

Adobe mixtures

- BSF:

-

Banana stem fiber

- CF:

-

Coir fibers

- CCFC:

-

Coconut coir fiber in concrete

- CFRC:

-

Coir fiber-reinforced concrete

- CSA:

-

Cotton stalk ash

- EBCM:

-

Earth-based construction materials

- EIA:

-

Environmental impact assessment

- ER:

-

Electrical resistivity

- FA:

-

Fly ash

- JF:

-

Jute fibers

- KF:

-

Kenaf fibers

- KFLFC:

-

Kenaf fiber-reinforced lightweight foamed concrete

- LCA:

-

Life cycle assessment

- LFC:

-

Lightweight foamed concrete

- LWSCC:

-

Lightweight self-compacting concrete

- MDPSF:

-

Male date palm surfaces fibers

- NF:

-

Natural fibers

- NFRC:

-

Natural fiber-reinforced concrete

- OPBF:

-

Oil palm broom fibers

- OPEFB:

-

Oil palm empty fruit bunch fibers

- PNFRC:

-

Pine needle fiber-reinforced concrete

- RSA:

-

Rice straw ash

- RT:

-

Room temperature

- UHPC:

-

Ultra-high-performance concrete

- UPV:

-

Ultrasonic pulse velocity

- SCC:

-

Self-consolidating concrete

- SCUHPC:

-

Self-compacting ultra-high-performance concrete

- SEM:

-

Scanning electron microscope

- WG:

-

Waste glass

References

Netinger Grubeša I, Marković B, Gojević A, Brdarić J (2018) Effect of hemp fibers on fire resistance of concrete. Constr Build Mater 184:473–484. https://doi.org/10.1016/j.conbuildmat.2018.07.014

Kumar P, Gautam P, Kaur S et al (2021) Bamboo as reinforcement in structural concrete. Mater Today: Proc 46:6793–6799. https://doi.org/10.1016/j.matpr.2021.04.342

Razmi A, Mirsayar MM (2017) On the mixed mode I/II fracture properties of jute fiber-reinforced concrete. Constr Build Mater 148:512–520. https://doi.org/10.1016/j.conbuildmat.2017.05.034

Sen T, Jagannatha Reddy HN (2013) Strengthening of RC beams in flexure using natural jute fibre textile reinforced composite system and its comparative study with CFRP and GFRP strengthening systems. Int J Sustain Built Environ 2:41–55. https://doi.org/10.1016/j.ijsbe.2013.11.001

Shahinur S, Hasan M (2020) Jute/coir/banana fiber reinforced bio-composites: critical review of design, fabrication, properties and applications. Encycl Renew Sustain Mater 5:751–756. https://doi.org/10.1016/b978-0-12-803581-8.10987-7

Sanjay MR, Arpitha GR, Yogesha B (2015) Study on mechanical properties of natural - glass fibre reinforced polymer hybrid composites: a review. Mater Today: Proc 2:2959–2967. https://doi.org/10.1016/j.matpr.2015.07.264

Sharma K, Devnani GL (2022) Recent advancement in sisal fiber reinforced polymer composites. Mater Today: Proc 65:3893–3901. https://doi.org/10.1016/j.matpr.2022.07.185

Islam MS, Ahmed SJ (2018) Influence of jute fiber on concrete properties. Constr Build Mater 189:768–776. https://doi.org/10.1016/j.conbuildmat.2018.09.048

Ali B, Azab M, Ahmed H et al (2022) Investigation of physical, strength, and ductility characteristics of concrete reinforced with banana (Musaceae) stem fiber. J Build Eng 61:105024. https://doi.org/10.1016/j.jobe.2022.105024

Asim M, Uddin GM, Jamshaid H et al (2020) Comparative experimental investigation of natural fibers reinforced light weight concrete as thermally efficient building materials. J Build Eng 31:101411. https://doi.org/10.1016/j.jobe.2020.101411

Niyasom S, Tangboriboon N (2021) Development of biomaterial fillers using eggshells, water hyacinth fibers, and banana fibers for green concrete construction. Constr Build Mater 283:122627. https://doi.org/10.1016/j.conbuildmat.2021.122627

Avubothu M, Ponaganti S, Sunkari R, Ganta M (2021) Effect of high temperature on coconut fiber Reinforced concrete. Mater Today: Proc. https://doi.org/10.1016/j.matpr.2021.11.036

Araya-Letelier G, Antico FC, Burbano-Garcia C et al (2021) Experimental evaluation of adobe mixtures reinforced with jute fibers. Constr Build Mater 276:122127–122127. https://doi.org/10.1016/j.conbuildmat.2020.122127

Ghalieh L, Awwad E, Saad G et al (2017) Concrete columns wrapped with hemp fiber reinforced polymer – an experimental study. Proc Eng 200:440–447. https://doi.org/10.1016/j.proeng.2017.07.062

Ankit RM, Chauhan P et al (2021) A review on mechanical properties of natural fiber reinforced polymer (NFRP) composites. Mater Today: Proc. https://doi.org/10.1016/j.matpr.2021.07.275

Abdalla JA, Thomas BS, Hawileh RA (2022) Use of hemp, kenaf and bamboo natural fiber in cement-based concrete. Mater Today: Proc 65:2070–2072. https://doi.org/10.1016/j.matpr.2022.06.428

Awwad E, Mabsout M, Hamad B et al (2012) Studies on fiber-reinforced concrete using industrial hemp fibers. Constr Build Mater 35:710–717. https://doi.org/10.1016/j.conbuildmat.2012.04.119

Tezara C, Siregar JP, Hamdan MHM et al (2021) Influence of layering sequences on tensile properties of hybrid woven Jute/Ramie fibre reinforced polyester composites. Mater Today: Proc. https://doi.org/10.1016/j.matpr.2021.09.151

Prakash R, Raman SN, Divyah N et al (2021) Fresh and mechanical characteristics of roselle fibre reinforced self-compacting concrete incorporating fly ash and metakaolin. Constr Build Mater 290:123209–123209. https://doi.org/10.1016/j.conbuildmat.2021.123209

Karimah A, Ridho MR, Munawar SS et al (2021) A review on natural fibers for development of eco-friendly bio-composite: characteristics, and utilizations. J Market Res 13:2442–2458. https://doi.org/10.1016/j.jmrt.2021.06.014

Merta I, Tschegg EK (2013) Fracture energy of natural fibre reinforced concrete. Constr Build Mater 40:991–997. https://doi.org/10.1016/j.conbuildmat.2012.11.060

Gencel O, Yavuz Bayraktar O, Kaplan G et al (2021) Characteristics of hemp fibre reinforced foam concretes with fly ash and Taguchi optimization. Constr Build Mater 294:123607. https://doi.org/10.1016/j.conbuildmat.2021.123607

Ramesh M (2018) Hemp, jute, banana, kenaf, ramie, sisal fibers. Handbook of Properties of Textile and Technical Fibres 23:301–325. https://doi.org/10.1016/b978-0-08-101272-7.00009-2

Dhakal HN, Zhang Z (2015) The use of hemp fibres as reinforcements in composites. Biofiber Reinforce Compos Mater: Use Hemp Fibres Reinforce Compos 24:86–101. https://doi.org/10.1533/9781782421276.1.86

Sultana N, Hossain SMZ, Alam MS et al (2020) An experimental investigation and modeling approach of response surface methodology coupled with crow search algorithm for optimizing the properties of jute fiber reinforced concrete. Constr Build Mater 243:118216. https://doi.org/10.1016/j.conbuildmat.2020.118216

Hasan R, Sobuz MdHR, Akid ASM et al (2023) Eco-friendly self-consolidating concrete production with reinforcing jute fiber. J Build Eng 63:105519. https://doi.org/10.1016/j.jobe.2022.105519

Sabarish KV, Paul P, Bhuvaneshwari JJ (2020) An experimental investigation on properties of sisal fiber used in the concrete. Mater Today: Proc 22:439–443. https://doi.org/10.1016/j.matpr.2019.07.686

Rahimi M, Hisseine OA, Tagnit-Hamou A (2022) Effectiveness of treated flax fibers in improving the early age behavior of high-performance concrete. J build Eng 45:103448–103448. https://doi.org/10.1016/j.jobe.2021.103448

Elbehiry A, Elnawawy O, Kassem M et al (2021) FEM evaluation of reinforced concrete beams by hybrid and banana fiber bars (BFB). Case Stud Constr Mater 14:e00479. https://doi.org/10.1016/j.cscm.2020.e00479

Page J, Khadraoui F, Boutouil M, Gomina M (2017) Multi-physical properties of a structural concrete incorporating short flax fibers. Constr Build Mater 140:344–353. https://doi.org/10.1016/j.conbuildmat.2017.02.124

Adeniyi AG, Onifade DV, Ighalo JO, Adeoye AS (2019) A review of coir fiber reinforced polymer composites. Compos B Eng 176:107305. https://doi.org/10.1016/j.compositesb.2019.107305

Ali M, Li X, Chouw N (2013) Experimental investigations on bond strength between coconut fibre and concrete. Mater Des 44:596–605. https://doi.org/10.1016/j.matdes.2012.08.038

Banerjee PK (2020) Environmental textiles from jute and coir. Elsevier eBooks 33:621–651. https://doi.org/10.1016/b978-0-12-818782-1.00019-5

Sathia R, Vijayalakshmi R (2021) Fresh and mechanical property of caryota-urens fiber reinforced flowable concrete. J Market Res 15:3647–3662. https://doi.org/10.1016/j.jmrt.2021.09.126

Tioua T, Kriker A, Barluenga G, Palomar I (2017) Influence of date palm fiber and shrinkage reducing admixture on self-compacting concrete performance at early age in hot-dry environment. Constr Build Mater 154:721–733. https://doi.org/10.1016/j.conbuildmat.2017.07.229

Feng B, Liu J, Lu Z et al (2023) Study on properties and durability of alkali activated rice straw fibers cement composites. J Build Eng 63:105515. https://doi.org/10.1016/j.jobe.2022.105515

Liu J, Xie X, Li L (2022) Experimental study on mechanical properties and durability of grafted nano-SiO2 modified rice straw fiber reinforced concrete. Constr Build Mater 347:128575. https://doi.org/10.1016/j.conbuildmat.2022.128575

Pachla EC, Silva DB, Stein KJ et al (2021) Sustainable application of rice husk and rice straw in cellular concrete composites. Constr Build Mater 283:122770. https://doi.org/10.1016/j.conbuildmat.2021.122770

Ali M, Liu A, Sou H, Chouw N (2012) Mechanical and dynamic properties of coconut fibre reinforced concrete. Constr Build Mater 30:814–825. https://doi.org/10.1016/j.conbuildmat.2011.12.068

Khan M, Rehman A, Ali M (2020) Efficiency of silica-fume content in plain and natural fiber reinforced concrete for concrete road. Constr Build Mater 244:118382. https://doi.org/10.1016/j.conbuildmat.2020.118382

Wang W, Chouw N (2017) The behaviour of coconut fibre reinforced concrete (CFRC) under impact loading. Constr Build Mater 134:452–461. https://doi.org/10.1016/j.conbuildmat.2016.12.092

Gupta M, Kumar M (2019) Effect of nano silica and coir fiber on compressive strength and abrasion resistance of Concrete. Constr Build Mater 226:44–50. https://doi.org/10.1016/j.conbuildmat.2019.07.232

Ramaswamy HS, Ahuja BM, Krishnamoorthy S (1983) Behaviour of concrete reinforced with jute, coir and bamboo fibres. Int J Cem Compos Lightweight Concrete 5:3–13. https://doi.org/10.1016/0262-5075(83)90044-1

Aziz MA, Paramasivam P, Lee SL (1981) Prospects for natural fibre reinforced concretes in construction. Int J Cem Compos Lightweight Concrete 3:123–132. https://doi.org/10.1016/0262-5075(81)90006-3

Khan M, Ali M (2019) Improvement in concrete behavior with fly ash, silica-fume and coconut fibres. Constr Build Mater 203:174–187. https://doi.org/10.1016/j.conbuildmat.2019.01.103

Sudarshan Dattatraya Kore (2021) Sustainable production of concrete using coir fibres. IOP Conf series 795:012006–012006. https://doi.org/10.1088/1755-1315/795/1/012006

Krishna NK, Prasanth M, Gowtham R, Karthic S, Mini KM (2018) Enhancement of properties of concrete using natural fibers. Mater Today: Proc 5(11):23816–23823. https://doi.org/10.1016/j.matpr.2018.10.173

Pickering KL, Efendy MGA, Le TM (2016) A review of recent developments in natural fibre composites and their mechanical performance. Compos A Appl Sci Manuf 83:98–112. https://doi.org/10.1016/j.compositesa.2015.08.038

Ali M (2014) Seismic performance of coconut-fibre-reinforced-concrete columns with different reinforcement configurations of coconut-fibre ropes. Constr Build Mater 70:226–230. https://doi.org/10.1016/j.conbuildmat.2014.07.086

Ruben JS, Baskar G (2014) experimental study of coir fiber as concrete reinforcement material incement based composites. Int J Eng Res Appl 4(1):128–131

Affan M, Ali M (2022) Experimental investigation on mechanical properties of jute fiber reinforced concrete under freeze-thaw conditions for pavement applications. Constr Build Mater 14(323):126599. https://doi.org/10.1016/j.conbuildmat.2022.126599

Zhang D, Tan KH, Dasari A, Weng Y (2020) Effect of natural fibers on thermal spalling resistance of ultra-high performance concrete. Cement Concr Compos 109:103512. https://doi.org/10.1016/j.cemconcomp.2020.103512

Pruthviraj KN, Jagalur Mahalingasharma S, Patil S (2022) Experimental study on strength behaviour of concrete reinforced with natural fibers. Mater Today: Proc. https://doi.org/10.1016/j.matpr.2022.11.065

Thomas BC, Jose YS (2021) A study on characteristics of sisal fiber and its performance in fiber reinforced concrete. Mater Today: Proc. https://doi.org/10.1016/j.matpr.2021.07.312

Prakash Chandar S, Sangeeth Kumar SK (2022) Mechanical properties of fiber reinforced concrete – natural fibers: a review. Mater Today: Proc. https://doi.org/10.1016/j.matpr.2022.08.362

Kumar P, Roy R (2018) Study and experimental investigation of flow and flexural properties of natural fiber reinforced self compacting concrete. Proc Comput Sci 125:598–608. https://doi.org/10.1016/j.procs.2017.12.077

Poongodi K, Murthi P, Gobinath R (2021) Evaluation of ductility index enhancement level of banana fibre reinforced lightweight self-compacting concrete beam. Mater Today: Proc 39:131–136. https://doi.org/10.1016/j.matpr.2020.06.397

Poongodi K, Murthi P (2020) Impact strength enhancement of banana fibre reinforced lightweight self-compacting concrete. Mater Today: Proc 27:1203–1209. https://doi.org/10.1016/j.matpr.2020.02.108

Kriker A, Debicki G, Bali A et al (2005) Mechanical properties of date palm fibres and concrete reinforced with date palm fibres in hot-dry climate. Cement Concr Compos 27:554–564. https://doi.org/10.1016/j.cemconcomp.2004.09.015

Momoh EO, Osofero AI (2019) Behaviour of oil palm broom fibres (OPBF) reinforced concrete. Constr Build Mater 221:745–761. https://doi.org/10.1016/j.conbuildmat.2019.06.118

Nathalie K, Jacqueline S, Nadia S (2020) Fracture behavior of flax fibers reinforced earth concrete. Eng Fracture Mech. https://doi.org/10.1016/j.engfracmech.2020.107378

Mahpour AR, Ventura H, Raso MA et al (2023) The effect of fibres and carbonation conditions on the mechanical properties and microstructure of lime/flax composites. Cement Concr Compos 138:104981–104981. https://doi.org/10.1016/j.cemconcomp.2023.104981

Kouta N, Saliba J, Saiyouri N (2020) Effect of flax fibers on early age shrinkage and cracking of earth concrete. Constr Build Mater 254:119315. https://doi.org/10.1016/j.conbuildmat.2020.119315

Koichi MINAMI, Masakazu TERAI Basic Study on Mechanical Properties of Bamboo Fiber Reinforced Concrete.

Abirami R, Vijayan DS (2020) Experimental study on concrete properties using pineapple leaf fiber. Int J Adv Res Eng Technol (IJARET) 11:913–920. https://doi.org/10.34218/IJARET.11.6.2020.082

Wang Y, Long W (2021) Complete stress–strain curves for pine needle fibre reinforced concrete under compression. Constr Build Mater 302:124134. https://doi.org/10.1016/j.conbuildmat.2021.124134

Long W, Wang Y (2021) Effect of pine needle fibre reinforcement on the mechanical properties of concrete. Constr Build Mater 278:122333. https://doi.org/10.1016/j.conbuildmat.2021.122333

Tolga Cogurcu M (2022) Investigation of mechanical properties of red pine needle fiber reinforced self-compacting ultra high performance concrete. Case Stud Constr Mater 16:e00970. https://doi.org/10.1016/j.cscm.2022.e00970

Dávila-Pompermayer R, Lopez-Yepez LG, Valdez-Tamez P et al (2020) Lechugilla natural fiber as internal curing agent in self compacting concrete (SCC): mechanical properties, shrinkage and durability. Cement Concr Compos 112:103686. https://doi.org/10.1016/j.cemconcomp.2020.103686

Sepe R, Bollino F, Boccarusso L, Caputo F (2018) Influence of chemical treatments on mechanical properties of hemp fiber reinforced composites. Compos B Eng 133:210–217. https://doi.org/10.1016/j.compositesb.2017.09.030

Guo A, Sun Z, Satyavolu J (2020) Impact of modified kenaf fibers on shrinkage and cracking of cement pastes. Constr Build Mater 264:120230. https://doi.org/10.1016/j.conbuildmat.2020.120230

Abbas A-G, Nora F, Abdan K et al (2023) Experimental evaluation and statistical modeling of kenaf fiber-reinforced geopolymer concrete. Constr Build Mater 367:130228–130228. https://doi.org/10.1016/j.conbuildmat.2022.130228

Elsaid A, Dawood M, Seracino R, Bobko C (2011) Mechanical properties of kenaf fiber reinforced concrete. Constr Build Mater 25:1991–2001. https://doi.org/10.1016/j.conbuildmat.2010.11.052

Nithambigai G, Rameshwaran PM (2021) Effect of binders and hemp fibre in concrete. Mater Today: Proc 1(46):3791–3794. https://doi.org/10.1016/j.matpr.2021.02.029

Tampi R, Parung H, Djamaluddin R, Amiruddin A (2020) Elasticity modulus concrete of abaca fiber. IOP Conf Series: Earth Environ Sci 473:012146. https://doi.org/10.1088/1755-1315/473/1/012146

Tiwari S, Sahu AK, Pathak RP (2020) Mechanical properties and durability study of jute fiber reinforced concrete. IOP Conf Series: Mater Sci Eng 961:012009. https://doi.org/10.1088/1757-899x/961/1/012009

Chen M, Ye L, Li H et al (2020) Flexural strength and ductility of moso bamboo. Constr Build Mater 246:118418. https://doi.org/10.1016/j.conbuildmat.2020.118418

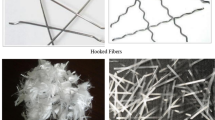

Al-Masoodi AHH, Kawan A, Kasmuri M et al (2016) Static and dynamic properties of concrete with different types and shapes of fibrous reinforcement. Constr Build Mater 104:247–262. https://doi.org/10.1016/j.conbuildmat.2015.12.037

MstS M, Hock LJ, Hossain MdS, Kang LS (2018) The influence of addition of treated kenaf fibre in the production and properties of fibre reinforced foamed composite. Constr Build Mater 178:518–528. https://doi.org/10.1016/j.conbuildmat.2018.05.169

Sasikumar P, Nandhakumar P, Manju R (2022) An experimental work on high strength concrete with addition of sisal fibre. Nucl Atmosph Aerosols. https://doi.org/10.1063/50108053

Li Z, Wang X, Wang L (2006) Properties of hemp fibre reinforced concrete composites. Compos A Appl Sci Manuf 37:497–505. https://doi.org/10.1016/j.compositesa.2005.01.032

Zhou X, Ghaffar SH, Dong W et al (2013) Fracture and impact properties of short discrete jute fibre-reinforced cementitious composites. Mater Des 49:35–47. https://doi.org/10.1016/j.matdes.2013.01.029

Mansur MA, Aziz MA (1982) A study of jute fibre reinforced cement composites. Int J Cem Compos Lightweight Concrete 4(2):75–82. https://doi.org/10.1016/0262-5075(82)90011-2

Anthony R, Awasthi SY, Singh P, Prasath Kumar VR (2020) An experimental and characteristic study of abaca fiber concrete. IOP Conf Series: Mater Sci Eng 912:032077. https://doi.org/10.1088/1757-899x/912/3/032077

Kumar S, Gupta D, Sharma V et al (2023) Recent development in natural fiber composites, testing and fabrication methods: a review. Mater Today: Proc. https://doi.org/10.1016/j.matpr.2023.02.073

Rama Rao P, Ramakrishna G (2022) Oil palm empty fruit bunch fiber: surface morphology, treatment, and suitability as reinforcement in cement composites- a state of the art review. Cleaner Mater 6:100144. https://doi.org/10.1016/j.clema.2022.100144

Grégoire M, Bar M, De Luycker E et al (2021) Comparing flax and hemp fibres yield and mechanical properties after scutching/hackling processing. Ind Crops Prod 172:114045. https://doi.org/10.1016/j.indcrop.2021.114045

Pickering KL, Beckermann GW, Alam SN, Foreman NJ (2007) Optimising industrial hemp fibre for composites. Compos A Appl Sci Manuf 38:461–468. https://doi.org/10.1016/j.compositesa.2006.02.020

Le Troëdec M, Rachini A, Peyratout C et al (2011) Influence of chemical treatments on adhesion properties of hemp fibres. J Colloid Interface Sci 356:303–310. https://doi.org/10.1016/j.jcis.2010.12.066

Wei J, Meyer C (2014) Improving degradation resistance of sisal fiber in concrete through fiber surface treatment. Appl Surf Sci 289:511–523. https://doi.org/10.1016/j.apsusc.2013.11.024

Alatshan F, Altlomate AM, Mashiri F, Alamin W (2017) Effect of date palm fibers on the mechanical properties of concrete. Int J Sustain Build Technol Urban Dev. https://doi.org/10.12972/susb.20170007

Lim SK, Tiong HY, Woon KS (2018) Compressive strength and dimensional stability of palm oil empty fruit bunch fibre reinforced foamed concrete. E3S Web of Conf 65:02001. https://doi.org/10.1051/e3sconf/20186502001

Al-Oraimi SK, Seibi AC (1995) Mechanical characterisation and impact behaviour of concrete reinforced with natural fibres. Compos Struct 32:165–171. https://doi.org/10.1016/0263-8223(95)00043-7

Althoey F, Hakeem IY, Hosen MdA et al (2022) Behavior of concrete reinforced with date palm fibers. Materials 15:7923. https://doi.org/10.3390/ma15227923

Aljalawi NMF (2019) Effect of sustainable palm fiber on high strength concrete properties. IOP Conf Series: Mater Sci Eng 518:022004. https://doi.org/10.1088/1757-899x/518/2/022004

Lee SW, Oh CL, Zain MRM, Yahya NA (2018) In: 14th International Conference on Concrete Engineering and Technology. IOP Conference Series: Materials Science and Engineering 431:012001. https://doi.org/10.1088/1757-899x/431/1/012001.

Prakash Chandar S, Murugan D (2022) Experimental investigation on banana stem fibre in the production of M40 grade concrete: a review. Mater Today: Proc. https://doi.org/10.1016/j.matpr.2022.09.354

El-Nadoury WW (2020) Applicability of using natural fibers for reinforcing concrete. IOP Conf Series: Mater Sci Eng 809:012018. https://doi.org/10.1088/1757-899x/809/1/012018

Nurwidayati R, Fardheny Asyifha AF (2021) Investigation on mechanical properties of fiber reinforced concrete. IOP Conf Series 758:012016–012016. https://doi.org/10.1088/1755-1315/758/1/012016

Vidya Bharathi S, Vinodhkumar S, Saravanan MM (2021) Strength characteristics of banana and sisal fiber reinforced composites. IOP Conf Series: Mater Sci Eng 1055:012024. https://doi.org/10.1088/1757-899x/1055/1/012024

Ren G, Yao B, Huang H, Gao X (2021) Influence of sisal fibers on the mechanical performance of ultra-high performance concretes. Constr Build Mater 286:122958. https://doi.org/10.1016/j.conbuildmat.2021.122958

Solai Mathi S, Karthikeyan S, Johnpaul V et al (2021) WITHDRAWN: Experimental investigation on self compacting concrete with sisal fibre. Mater Today: Proc. https://doi.org/10.1016/j.matpr.2020.10.1011

Liu Y, Wang Z, Fan Z, Gu J (2020) Study on properties of sisal fiber modified foamed concrete. IOP Conf Series: Mater Sci Eng 744:012042. https://doi.org/10.1088/1757-899x/744/1/012042

Syed H, Nerella R, Madduru SRC (2020) Role of coconut coir fiber in concrete. Mater Today: Proc 27:1104–1110. https://doi.org/10.1016/j.matpr.2020.01.477

Naamandadin NA, Rosdi MS, Mustafa WA et al (2020) Mechanical behaviour on concrete of coconut coir fiber as additive. IOP Conf Series: Mater Sci Eng 932:012098. https://doi.org/10.1088/1757-899x/932/1/012098

Walter Otunyo A, Dan Nyechieo N (2017) Mechanical properties and fracture behaviour of coconut fibre reinforced concrete (CFRC). Am J Civil Eng Arch 5:208–216. https://doi.org/10.12691/ajcea-5-5-5

Nadgouda, K. (2014). Coconut fibre reinforced concrete. In: Thirteenth IRF International Conference, 14th September.

Mydin MO, Rozlan NA, Ganesan S (2015) Experimental study on the mechanical properties of coconut fibre reinforced lightweight foamed concrete. J Mater Environ Sci 6(2):407–411

Nambiar RA, Haridharan MK (2021) Mechanical and durability study of high performance concrete with addition of natural fiber (jute). Mater Today: Proc 46:4941–4947. https://doi.org/10.1016/j.matpr.2020.10.339

Olaoye Oluremi RA et al (2014) The use of fibre waste as complement in concrete for a sustainable environment. Innov Syst Des Eng 4(9):2222–2871

Huang J, Qiu S, Rodrigue D (2022) Parameters estimation and fatigue life prediction of sisal fibre reinforced foam concrete. J Market Res 20:381–396. https://doi.org/10.1016/j.jmrt.2022.07.096

Ruano G, Bellomo F, López G et al (2020) Mechanical behaviour of cementitious composites reinforced with bagasse and hemp fibers. Constr Build Mater 240:117856. https://doi.org/10.1016/j.conbuildmat.2019.117856

Mohammed WH, Shambina SL, Ammash HK (2023) Reducing Effects of initial imperfection by investment in the orthotropic characteristics of laminated composite plate. Civil Eng J 9:1579–1596. https://doi.org/10.28991/cej-2023-09-07-03

Asasutjarit C, Charoenvai S, Hirunlabh J, Khedari J (2009) Materials and mechanical properties of pretreated coir-based green composites. Compos B Eng 40:633–637. https://doi.org/10.1016/j.compositesb.2009.04.009

Guo A, Sun Z, Satyavolu J (2019) Impact of chemical treatment on the physiochemical and mechanical properties of kenaf fibers. Ind Crops Prod 141:111726. https://doi.org/10.1016/j.indcrop.2019.111726

Narendar R, Priya Dasan K (2014) Chemical treatments of coir pith: Morphology, chemical composition, thermal and water retention behavior. Compos B Eng 56:770–779. https://doi.org/10.1016/j.compositesb.2013.09.028

Nam TH, Ogihara S, Tung NH, Kobayashi S (2011) Effect of alkali treatment on interfacial and mechanical properties of coir fiber reinforced poly(butylene succinate) biodegradable composites. Compos B Eng 42:1648–1656. https://doi.org/10.1016/j.compositesb.2011.04.001

Park J-M, Kim P-G, Jang JE et al (2008) Interfacial evaluation and durability of modified Jute fibers/polypropylene (PP) composites using micromechanical test and acoustic emission. Composites Part B-Eng 39:1042–1061. https://doi.org/10.1016/j.compositesb.2007.11.004

Ramadan R, Saad G, Awwad E et al (2017) Short-term durability of hemp fibers. Proc Eng 200:120–127. https://doi.org/10.1016/j.proeng.2017.07.018

Rajesh G, Prasad AVR (2014) Tensile properties of successive alkali treated short jute fiber reinforced PLA composites. Proc Mater Sci 5:2188–2196. https://doi.org/10.1016/j.mspro.2014.07.425

Nayak SY, Shenoy Heckadka S, Seth A et al (2021) Effect of chemical treatment on the physical and mechanical properties of flax fibers: a comparative assessment. Mater Today: Proc 38:2406–2410. https://doi.org/10.1016/j.matpr.2020.07.380

Perremans D, Hendrickx K, Verpoest I, Van Vuure AW (2018) Effect of chemical treatments on the mechanical properties of technical flax fibres with emphasis on stiffness improvement. Compos Sci Technol 160:216–223. https://doi.org/10.1016/j.compscitech.2018.03.030

Boonterm M, Sunyadeth S, Dedpakdee S et al (2016) Characterization and comparison of cellulose fiber extraction from rice straw by chemical treatment and thermal steam explosion. J Clean Prod 134:592–599. https://doi.org/10.1016/j.jclepro.2015.09.084

Agwa IS, Omar OM, Tayeh BA, Abdelsalam BA (2020) Effects of using rice straw and cotton stalk ashes on the properties of lightweight self-compacting concrete. Constr Build Mater 235:117541. https://doi.org/10.1016/j.conbuildmat.2019.117541

Aslam F, Zaid O, Althoey F et al (2022) Evaluating the influence of fly ash and waste glass on the characteristics of coconut fibers reinforced concrete. Struct Concr. https://doi.org/10.1002/suco.202200183

de Bruijn PB, Jeppsson K-H, Sandin K, Nilsson C (2009) Mechanical properties of lime–hemp concrete containing shives and fibres. Biosys Eng 103:474–479. https://doi.org/10.1016/j.biosystemseng.2009.02.005

Tronet P, Lecompte T, Picandet V, Baley C (2016) Study of lime hemp concrete (LHC) – Mix design, casting process and mechanical behaviour. Cement Concr Compos 67:60–72. https://doi.org/10.1016/j.cemconcomp.2015.12.004

Nistratov AV, Klimenko NN, Pustynnikov IV, Vu LK (2022) thermal regeneration and reuse of carbon and glass fibers from waste composites. Emer Sci J 6:967–984. https://doi.org/10.28991/esj-2022-06-05-04

Othuman Mydin MA, Zamzani NM, Ghani ANA (2019) Experimental data on compressive and flexural strengths of coir fibre reinforced foamed concrete at elevated temperatures. Data Brief 25:104320. https://doi.org/10.1016/j.dib.2019.104320

Ramadan R, Jahami A, Khatib J et al (2023) Improving structural performance of reinforced concrete beams with phragmites australis fiber and waste glass additives. Appl Sci 13:4206–4206. https://doi.org/10.3390/app13074206

Olukunle BG, Uche NB, Efomo AO et al (2018) Data on acoustic behaviour of coconut fibre-reinforced concrete. Data Brief 21:1004–1007. https://doi.org/10.1016/j.dib.2018.10.133

Barbhuiya S, Bhusan Das B (2022) A comprehensive review on the use of hemp in concrete. Constr Build Mater 341:127857. https://doi.org/10.1016/j.conbuildmat.2022.127857

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflicts of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed consent

For this type of study, formal consent is not required.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jahami, A., Zeaiter, N. & Cheaib, M. Reviewing the potential: a comprehensive review of natural fibers (NFs) in structural concrete and their multifaceted influences. Innov. Infrastruct. Solut. 9, 102 (2024). https://doi.org/10.1007/s41062-024-01384-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-024-01384-x